Technical Contents

Engineering Guide: Aluminum Casting Molds For Sale

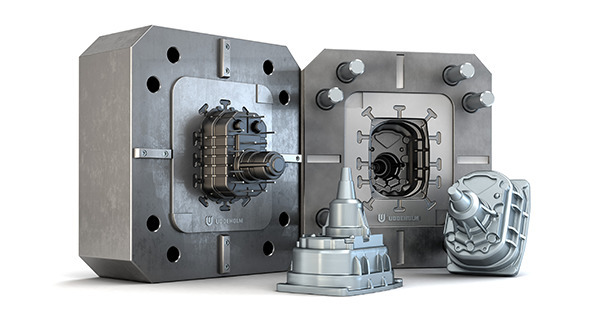

Engineering Insight Precision as the Non-Negotiable Core of Aluminum Casting Molds

Achieving flawless aluminum cast components demands mold precision that transcends standard manufacturing tolerances. In high-integrity applications spanning aerospace, defense, and premium automotive sectors, the mold is not merely a tool; it is the foundational determinant of part performance, structural integrity, and production economics. Minute deviations in cavity geometry, cooling channel placement, or surface finish directly propagate into casting defects—micro-shrinkage, porosity, warpage, or inconsistent wall thickness. These flaws compromise mechanical properties, necessitate costly secondary operations, and risk catastrophic in-service failure. Precision engineering mitigates these risks by ensuring exact thermal gradient control during solidification, uniform pressure distribution, and perfect replication of intricate geometries. This level of accuracy requires integrated expertise in metallurgy, thermodynamics, and advanced CNC machining, where micron-level deviations are systematically eliminated through iterative design validation and process refinement.

At Wuxi Lead Precision Machinery, we treat precision as an uncompromising standard, not an aspiration. Our engineering protocols are forged in the crucible of mission-critical projects where failure is not an option. We engineered molds for components deployed in Olympic-standard sporting equipment requiring absolute fatigue resistance under extreme stress. More significantly, our molds meet stringent military specifications for defense systems, where dimensional stability across extreme temperature cycles and vibration environments is mandatory. This heritage instills rigorous discipline: every mold undergoes multi-axis CMM verification against 3D CAD models, thermal simulation validation, and material certification traceable to aerospace-grade standards. We understand that a tolerance stack-up of mere 0.05mm can invalidate an entire production run for high-pressure die casting, leading to scrap rates exceeding 30%. Our process eliminates such vulnerabilities through predictive analytics and closed-loop machining control.

The tangible output of this precision philosophy is reflected in mold performance metrics directly impacting your bottom line. Our molds deliver extended service life, reduced cycle times, and near-net-shape accuracy that minimizes post-cast machining. Below are key specifications achievable through our engineered approach:

| Critical Parameter | Standard Industry Range | Wuxi Lead Precision Capability | Impact on Casting Quality |

|---|---|---|---|

| Dimensional Tolerance (mm) | ±0.10 to ±0.20 | ±0.02 to ±0.05 | Eliminates fit/assembly issues |

| Surface Roughness (Ra μm) | 0.8 – 1.6 | 0.2 – 0.4 | Reduces porosity; enhances finish |

| Thermal Conductivity (W/mK) | Varies by steel grade | Optimized H13/H11 alloys | Ensures uniform solidification |

| Cooling Channel Accuracy (mm) | ±0.15 | ±0.03 | Prevents hot spots; extends mold life |

| Hardness Uniformity (HRC) | ±3 | ±1 | Maximizes wear resistance |

Partnering with Wuxi Lead means leveraging engineering rigor proven where consequences matter most. We transform casting challenges into competitive advantages through precision that is measured, validated, and guaranteed. Contact our engineering team for a consultation on optimizing your aluminum casting process with molds built for uncompromised performance.

Precision Specs & Tolerances

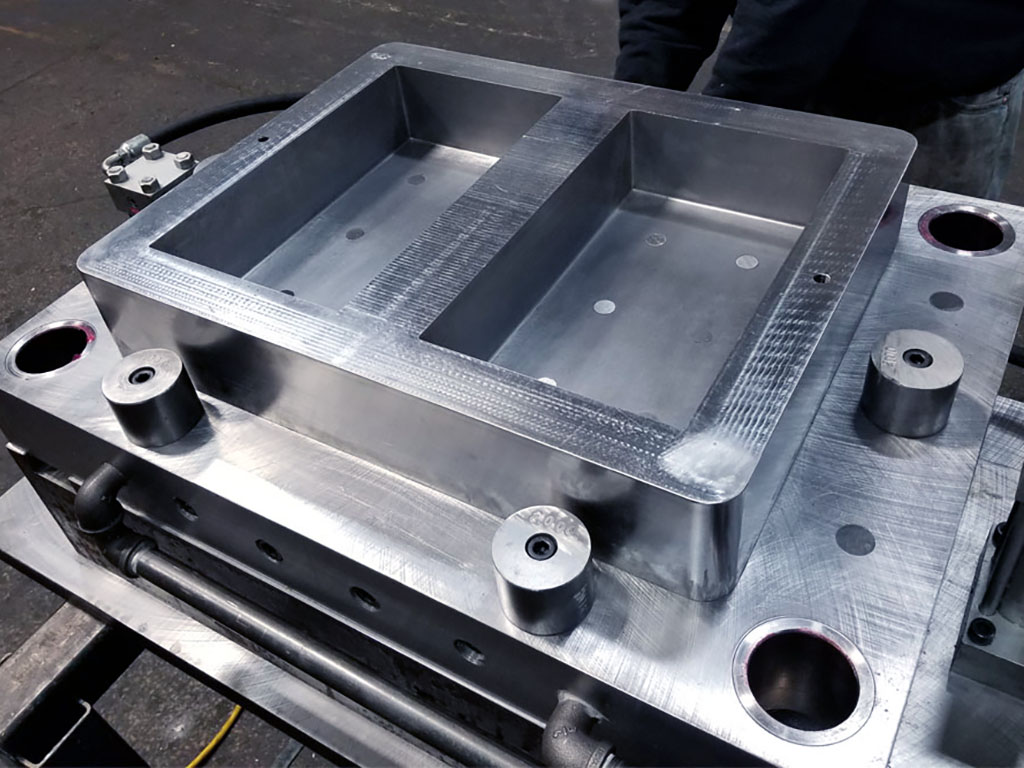

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the production of aluminum casting molds, engineered to meet the rigorous demands of high-performance industrial applications. Our facility integrates state-of-the-art 5-axis CNC machining centers, enabling us to execute complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, ensuring precise tool engagement and minimizing setup changes. This results in superior part consistency, reduced lead times, and the ability to manufacture intricate mold cavities and cores that are typical in die casting and gravity casting processes.

Each aluminum casting mold is developed using high-grade tool steels and aluminum alloys, selected based on thermal stability, wear resistance, and cycle life requirements. Our engineering team leverages CAD/CAM software to simulate toolpaths and optimize machining strategies, ensuring efficient material removal and long-term mold durability. The integration of high-speed machining techniques further enhances productivity while maintaining micron-level precision across critical mold features.

Quality control is embedded at every stage of production. All molds undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), which verifies dimensional accuracy against the original 3D model. This metrology-grade verification ensures conformity to tight tolerances and provides full traceability for each component. Our CMM system is calibrated to international standards and operated by certified technicians, guaranteeing repeatable and reliable measurement data across all production batches.

In addition to dimensional inspection, we perform surface roughness testing, hardness verification, and, where required, first-article inspection reports (FAIR) and material certifications. This systematic approach to quality assurance supports compliance with ISO 9001 standards and meets the expectations of industries such as automotive, aerospace, and industrial equipment manufacturing.

The following table outlines the standard technical specifications and tolerances achievable with our 5-axis CNC machining and inspection processes:

| Specification | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Surface Roughness (Ra) | 0.4 – 1.6 µm |

| Maximum Work Envelope (X×Y×Z) | 2000 × 1000 × 800 mm |

| Angular Tolerance | ±0.001° |

| Repeatability | ±0.003 mm |

| CMM Measurement Accuracy | ±0.0025 mm |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for manufacturers seeking high-integrity aluminum casting molds that combine precision, durability, and performance. Our technical expertise ensures that every mold is built to exacting standards, supporting efficient casting cycles and long-term operational reliability.

Material & Finish Options

Material Selection for Aluminum Casting Molds: Precision Engineering for Performance

Selecting the optimal material for aluminum casting molds is a critical engineering decision directly impacting mold longevity, production efficiency, part quality, and total cost of ownership. At Wuxi Lead Precision Machinery, we understand that the intense thermal cycling, mechanical stress, and chemical exposure inherent in aluminum die casting demand materials engineered for resilience. While aluminum alloys are the primary casting material, the mold itself must withstand significantly harsher conditions. We rigorously evaluate Aluminum, Steel, and Titanium based on specific application requirements, balancing thermal management, wear resistance, and economic factors.

Aluminum mold bases, typically utilizing high-grade alloys like 7075-T6 or H13 tool steel clad variants, offer superior thermal conductivity. This enables faster cooling cycles, boosting production rates for lower-volume or prototype runs where rapid heat dissipation is paramount. However, their lower hardness limits wear resistance against abrasive aluminum alloys, making them less suitable for extended high-volume production. Tool steels, particularly H13 (AISI H13), remain the dominant choice for high-pressure die casting (HPDC) molds. H13 provides an exceptional balance of high-temperature strength, excellent toughness, good thermal fatigue resistance, and machinability. Its ability to maintain hardness at elevated operating temperatures (500-600°C) ensures dimensional stability and extended mold life for demanding, high-cavitation applications. Titanium alloys, while offering the highest strength-to-weight ratio and exceptional corrosion resistance, present significant challenges. Their high cost, complex machining requirements, and lower thermal conductivity compared to steel generally restrict their use to highly specialized, low-volume aerospace applications where weight savings justify the investment, not mainstream aluminum casting.

The following table summarizes key comparative properties for mold material selection:

| Property | Aluminum Alloys (e.g., 7075-T6) | Tool Steel (e.g., H13) | Titanium Alloys (e.g., Ti-6Al-4V) |

|---|---|---|---|

| Hardness (HRC) | 40-50 | 46-52 (after treatment) | 35-40 |

| Thermal Conductivity | Very High (130-180 W/m·K) | Moderate (25-35 W/m·K) | Low (6-7 W/m·K) |

| Thermal Fatigue Res. | Low | Very High | Moderate |

| Wear Resistance | Low | High | Moderate |

| Relative Cost | Low | Medium | Very High |

| Typical Application | Prototypes, Low Volume | High Volume HPDC | Specialized Aerospace |

Surface finishing, particularly anodizing, is essential for enhancing aluminum-based mold performance. Standard anodizing provides basic corrosion resistance, but for molds, Type III Hardcoat Anodizing is imperative. This process creates a thick (50-100+ µm), dense, hard aluminum oxide layer significantly improving surface hardness (up to 600-800 HV), wear resistance against aluminum adhesion (soldering), and thermal barrier properties. At Wuxi Lead, we implement stringent hardcoat anodizing protocols with precise control over electrolyte composition, temperature, and current density to ensure uniform, pore-free coatings that maximize mold release and extend service life in aluminum casting environments.

Material selection is never one-size-fits-all. Wuxi Lead Precision Machinery leverages decades of foundry experience and advanced metallurgical analysis to recommend the precise material and surface treatment combination for your specific aluminum casting process, volume, and part complexity. Our engineering team evaluates thermal loads, cycle times, and alloy chemistry to deliver molds engineered for peak performance and maximum return on investment. Partner with us to transform your material selection from a cost factor into a strategic production advantage.

Manufacturing Process & QC

The production of high-performance aluminum casting molds at Wuxi Lead Precision Machinery follows a rigorously controlled, end-to-end process designed to ensure precision, durability, and zero defects. Every stage—from initial design to mass production—is executed with advanced engineering standards, ensuring molds meet the exact requirements of die casting applications in automotive, aerospace, and industrial equipment sectors.

Design begins with a comprehensive analysis of the client’s technical specifications, including part geometry, material flow, thermal dynamics, and cycle time requirements. Our engineering team utilizes 3D CAD software and simulation tools such as SolidWorks, AutoCAD, and MAGMAsoft to model the mold and predict casting behavior. This virtual prototyping phase identifies potential defects such as porosity, shrinkage, or misruns before physical production begins. Finite element analysis (FEA) is applied to assess structural integrity under high-pressure and high-temperature conditions, ensuring long service life and dimensional stability.

Following design validation, the prototyping phase commences. A single mold unit is fabricated using high-grade tool steels such as H13 or SKD61, selected for their thermal fatigue resistance and hardness. Precision CNC machining, wire EDM, and surface grinding are employed to achieve tight tolerances down to ±0.005 mm. The prototype undergoes full functional testing in a controlled die casting environment using A380 or ADC12 aluminum alloys. Real-time data on fill patterns, cooling rates, and ejection performance are collected and analyzed. Any deviations are corrected through iterative adjustments, ensuring optimal performance prior to scaling.

Once the prototype is approved, the process transitions to mass production. Our automated manufacturing cells replicate the validated design with absolute consistency. Each mold is machined, heat-treated, and polished under ISO 9001-certified quality protocols. In-process inspections are conducted at critical stages using coordinate measuring machines (CMM) and optical comparators. Surface finish, dimensional accuracy, and alignment are verified to ensure uniformity across all units. Final assembly includes integration of cooling channels, ejector systems, and sensors for smart monitoring, if requested.

Wuxi Lead Precision Machinery’s zero-defect philosophy is enforced through a closed-loop quality management system. Every mold is traceable via a unique serial number, with full documentation of materials, process parameters, and inspection results. This enables full accountability and continuous improvement.

Below are key technical specifications of our aluminum casting molds:

| Parameter | Specification |

|---|---|

| Material | H13, SKD61, or client-specified tool steel |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 0.8 µm (polished as required) |

| Hardness | 48–52 HRC after heat treatment |

| Mold Life | 100,000 – 150,000 cycles (typical) |

| Compatible Alloys | A380, A360, ADC12, ZL101 |

| Cooling Channel Design | Optimized via thermal simulation |

| Production Lead Time | 4–8 weeks (prototype), scalable for volume |

This disciplined approach ensures that every aluminum casting mold delivered by Wuxi Lead Precision Machinery meets the highest standards of performance, reliability, and repeatability in industrial manufacturing environments.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Aluminum Casting Mold Excellence

In the demanding landscape of high-integrity aluminum casting, your mold supplier is not a vendor but a strategic production partner. Wuxi Lead Precision Machinery elevates this partnership beyond transactional supply. We engineer aluminum casting molds as critical production assets—designed for maximum cavity life, thermal stability, and dimensional repeatability under sustained industrial pressure. Our ISO 9001-certified processes integrate German-engineered standards with advanced CNC milling and EDM capabilities, ensuring molds meet aerospace, automotive, and energy sector tolerances where failure is not an option. We eliminate the guesswork in mold performance through rigorous material validation and FEA-driven thermal analysis, directly translating to reduced scrap rates and optimized cycle times for your foundry.

Our technical mastery is quantifiable. The table below outlines core specifications achievable across our mold portfolio, reflecting our commitment to precision that aligns with global manufacturing benchmarks. These parameters are not theoretical ideals but consistently delivered outcomes under real-world production conditions.

| Specification Category | Standard Capability | Premium Option | Validation Method |

|---|---|---|---|

| Mold Material Grade | H13 (AISI) Pre-hardened | H13 ESR / MAR-M 247 | Spectrochemical Analysis & Hardness Testing |

| Dimensional Tolerance | ±0.02 mm | ±0.005 mm | CMM Scanning (Zeiss CONTURA) |

| Surface Finish (Cavity) | Ra 0.4 µm | Ra 0.05 µm | Profilometer Measurement |

| Lead Time (Complex Mold) | 8-10 Weeks | 6-8 Weeks | Integrated Project Management Dashboard |

Choosing Lead Precision means inheriting decades of specialized metallurgical insight and proactive engineering collaboration. We do not merely deliver molds; we co-develop solutions addressing your specific alloy flow dynamics, ejection challenges, and cooling efficiency requirements. Our team engages during the design phase to prevent costly iterations, leveraging simulation tools to predict solidification behavior and minimize porosity risks inherent in aluminum casting. This upstream partnership approach reduces time-to-market by up to 30% while extending mold service life by 25% compared to industry averages.

The cost of mold failure extends far beyond replacement—it disrupts production schedules, compromises part integrity, and erodes customer trust. Partner with an organization built on technical accountability and transparent engineering. Contact our application engineering team today to discuss your next aluminum casting project. Provide your casting requirements, material specifications, and volume targets. We will deliver a detailed capability assessment and feasibility study within 24 business hours.

Secure your production advantage. Email [email protected] with subject line “Aluminum Casting Mold Partnership Inquiry” to initiate a precision-focused dialogue. Let Lead Precision become the silent force behind your casting success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.