Technical Contents

Engineering Guide: Aluminum Auto Parts

Engineering Insight: Precision in Aluminum Auto Parts Manufacturing

In the evolving landscape of automotive engineering, aluminum has emerged as a cornerstone material for lightweight, high-efficiency vehicle design. Its favorable strength-to-weight ratio, corrosion resistance, and thermal conductivity make it ideal for critical applications such as engine components, suspension systems, and structural chassis elements. However, the transition from raw aluminum to high-performance auto parts demands more than material selection—it requires uncompromising precision in manufacturing.

At Wuxi Lead Precision Machinery, we understand that precision is not merely a quality metric but a foundational requirement in aluminum auto parts production. Even micron-level deviations can compromise part functionality, assembly integrity, and long-term reliability. This is especially critical in powertrain and safety-critical systems where tolerances directly impact vehicle performance and passenger safety.

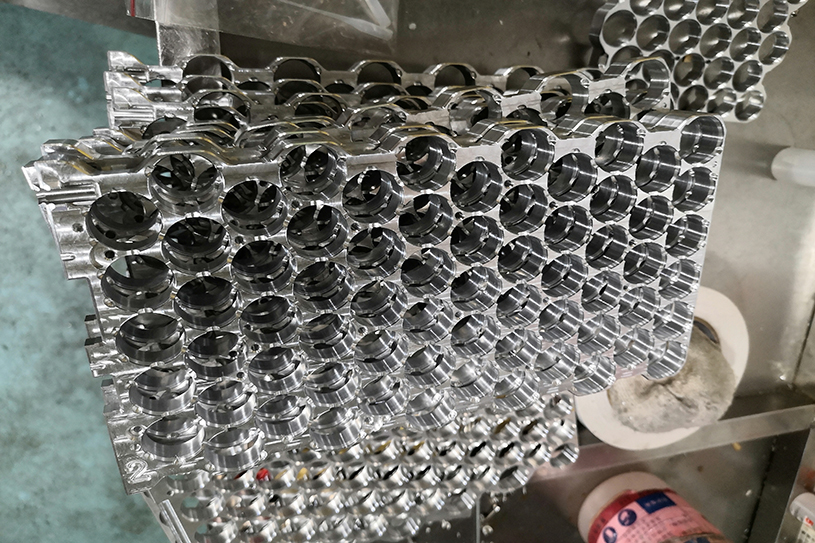

Our engineering approach integrates advanced CNC machining, multi-axis milling, and real-time metrology to ensure every component meets exact design specifications. We employ high-speed cutting strategies tailored to aluminum’s unique thermal and mechanical properties, minimizing deformation while maximizing surface finish and dimensional accuracy. Closed-loop quality control systems monitor each production phase, from raw billet inspection to final deburring and anodizing, ensuring consistency across batch runs.

With over 15 years of specialized experience in custom metal manufacturing, Wuxi Lead has delivered mission-critical components for sectors where failure is not an option. Our work has supported precision systems in Olympic-grade equipment and defense applications, where reliability under extreme conditions is paramount. These experiences have directly informed our methodologies in automotive manufacturing, enabling us to meet the rigorous standards of Tier 1 suppliers and global OEMs.

Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 certifications, with a dedicated engineering team that collaborates closely with clients during design for manufacturability (DFM) stages. This proactive engagement ensures optimal material utilization, reduced cycle times, and enhanced part performance—key drivers in cost-effective, high-volume production.

Below are key technical specifications achievable in our aluminum auto parts manufacturing process:

| Specification | Capability | Notes |

|---|---|---|

| Material Types | 6061, 6082, 7075, A356, ADC12 | Aerospace and automotive grades |

| Tolerance | ±0.005 mm | Achieved via 5-axis CNC and CMM validation |

| Surface Finish | Ra 0.4–1.6 µm | Adjustable for functional or aesthetic needs |

| Max Part Size | 1200 × 800 × 600 mm | Suitable for structural components |

| Production Volume | Prototype to 500,000+ units/year | Flexible automation integration |

| Secondary Processes | Anodizing, TIG/MIG welding, assembly | In-house and partner capabilities |

Precision in aluminum auto parts is not an incremental advantage—it is the difference between success and system failure. At Wuxi Lead Precision Machinery, we combine military-grade discipline with industrial innovation to deliver components that perform under real-world demands.

Precision Specs & Tolerances

Advanced Technical Capabilities for Aluminum Automotive Components

Wuxi Lead Precision Machinery delivers uncompromising precision for critical aluminum auto parts through integrated high-performance manufacturing systems. Our core strength lies in monolithic 5-axis CNC machining, utilizing DMG MORI and Makino centers with sub-micron positioning accuracy. These systems eliminate secondary operations by machining complex geometries—including suspension knuckles, transmission housings, and EV battery components—in a single setup. Integrated high-speed spindles (30,000 RPM) and adaptive toolpath strategies maintain dimensional stability during thin-wall machining, while real-time thermal compensation ensures ±0.005 mm repeatability across production runs. Material waste is minimized through optimized nest programming, critical for aerospace-grade 6061-T6 and 7075-T73 alloys common in lightweight automotive structures.

Quality assurance is embedded at every process stage via our ISO 17025-accredited metrology lab. All critical features undergo 100% CMM inspection using Zeiss CONTURA systems with 2.2 + L/300 μm accuracy. Automated optical comparators validate surface finishes to Ra 0.4 μm, and coordinate measuring machines generate full first-article inspection (FAI) reports per AS9102 standards. Statistical process control (SPC) monitors CpK values in real time, with automatic machine tool adjustments triggered if deviations exceed 1.33 thresholds. This closed-loop system guarantees zero-defect delivery for safety-critical components such as steering racks and brake calipers.

Our engineering team collaborates directly with automotive clients during DFMA analysis to resolve manufacturability conflicts early. We specialize in near-net-shape machining of aluminum forgings and castings, reducing lead times by 40% versus traditional multi-stage processes. All equipment operates under strict environmental controls (20±0.5°C), and tool life management systems prevent micro-burrs that compromise fatigue resistance in high-stress applications.

Precision Tolerance Specifications for Aluminum Automotive Parts

| Feature Type | Standard Tolerance | Tight Tolerance Option | Surface Finish (Ra) | Measurement Method |

|---|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | 1.6 μm | CMM / Air Gage |

| Geometric (GD&T) | ±0.08 mm | ±0.01 mm | 0.8 μm | CMM / Vision System |

| Hole Diameter | H9 | H7 | 0.4 μm | Pneumatic Comparator |

| Positional Accuracy | ±0.10 mm | ±0.008 mm | 0.8 μm | CMM (3D Scanning) |

| Surface Profile | 0.2 mm | 0.02 mm | 0.4 μm | Laser Tracker |

This capability framework ensures compliance with IATF 16949 and VDA 6.3 requirements, enabling seamless integration into global automotive supply chains. We consistently achieve CpK >1.67 on critical features, providing OEMs with measurable quality assurance for high-volume production. For complex aluminum components demanding micron-level integrity, our technical infrastructure delivers repeatable excellence from prototype to serial manufacturing.

Material & Finish Options

Material Selection for High-Performance Aluminum Auto Parts

Selecting the right material for automotive components is critical to achieving optimal performance, durability, and cost-efficiency. In the realm of custom metal manufacturing, aluminum stands out as a premier choice for lightweight, high-strength applications. When compared to steel and titanium, aluminum offers a balanced combination of mechanical properties, machinability, and corrosion resistance—making it ideal for powertrain systems, suspension components, and structural brackets in modern vehicles.

Aluminum alloys, particularly the 6000 and 7000 series, are widely used due to their excellent strength-to-weight ratio and weldability. Alloy 6061-T6, for instance, provides good tensile strength (up to 310 MPa) and is highly resistant to atmospheric corrosion, making it suitable for exterior and load-bearing parts. For higher performance demands, 7075-T6 offers strength comparable to some steels while maintaining low density, though with reduced weldability and higher cost.

Steel remains a strong contender in applications requiring extreme toughness and impact resistance, such as chassis frames and safety-critical components. However, its higher density increases vehicle weight, directly affecting fuel efficiency and emissions. While stainless steel offers corrosion resistance, it is significantly heavier and more energy-intensive to machine than aluminum.

Titanium, though superior in strength-to-density ratio and corrosion resistance, is typically reserved for niche, high-end applications like racing or aerospace-derived automotive systems. Its high raw material cost and challenging machinability limit widespread adoption in volume production.

When selecting aluminum, surface finishing plays a vital role in enhancing performance. Anodizing is the most effective post-machining treatment for aluminum auto parts. This electrochemical process creates a durable, wear-resistant oxide layer that improves corrosion resistance and allows for color coding or branding. Hard anodizing (Type III) is especially recommended for high-wear components, offering surface hardness up to 60 HRC and extended service life under abrasive conditions.

At Wuxi Lead Precision Machinery, we support clients in choosing the optimal aluminum alloy and finish based on functional requirements, environmental exposure, and production volume. Our precision CNC machining capabilities ensure tight tolerances and superior surface quality, fully compatible with anodizing and other high-end finishes.

Below is a comparative overview of key materials used in automotive component manufacturing.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability | Typical Automotive Use |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | High | Excellent | Brackets, Housings |

| Aluminum 7075-T6 | 2.8 | 570 | Moderate | Good | Suspension Arms |

| Stainless Steel 304 | 8.0 | 505 | Very High | Fair | Fasteners, Exhaust |

| Titanium Grade 5 | 4.5 | 900 | Excellent | Poor | Racing Components |

Material selection directly impacts performance, longevity, and manufacturing efficiency. For most aluminum auto parts, we recommend 6061-T6 or 7075-T6 paired with hard anodizing to achieve the best balance of strength, weight, and durability.

Manufacturing Process & QC

Aluminum Auto Parts Production Process: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our aluminum auto parts production integrates rigorous engineering discipline with advanced manufacturing to achieve zero-defect outcomes for automotive clients. The process begins with collaborative Design Engineering, where our team utilizes 3D CAD/CAM software to optimize part geometry for weight reduction, structural integrity, and manufacturability. We conduct comprehensive Design for Manufacturing (DFM) analysis, ensuring thermal stability during machining and validating tolerances against ISO 2768-mK standards. Material selection focuses on aerospace-grade alloys like 6061-T6 or 7075-T6, chosen for fatigue resistance and corrosion performance in dynamic automotive environments. Client specifications are cross-referenced with IATF 16949 requirements to eliminate conceptual flaws before tooling commences.

Prototyping transitions validated designs into physical validation through high-speed 5-axis CNC milling. Each prototype undergoes metrological verification via Zeiss CMM and 3D laser scanning, comparing first-article measurements to CAD models with ±0.005mm accuracy. We execute functional testing for fit, thermal cycling, and stress loads per client-specified conditions, iterating within 72 hours if deviations occur. This phase confirms toolpath efficiency and surface finish compliance (Ra ≤ 0.8μm), ensuring seamless scalability to volume production. Only prototypes achieving 100% dimensional adherence and material certification proceed to mass manufacturing.

Mass Production leverages automated, climate-controlled cells with real-time SPC monitoring. Our zero-defect framework employs in-process gauging, automated optical inspection (AOI), and traceability via laser-etched part IDs linked to material lot numbers and machine parameters. Every component undergoes 100% critical dimension checks, with statistical process control maintaining CpK >1.67 for key features. Production runs are supported by redundant tooling backups and FMEA-driven error-proofing, eliminating scrap rates below 50 PPM. Final validation includes batch-level tensile testing and surface porosity analysis per ASTM E8/E9 standards, with full documentation for audit readiness.

This closed-loop methodology ensures automotive partners receive consistently flawless components, reducing assembly line disruptions and accelerating time-to-market.

| Process Phase | Key Parameters | Quality Control Method | Output Standard |

|---|---|---|---|

| Design Engineering | ±0.02mm tolerance; Ra ≤ 1.6μm | DFM simulation; IATF 16949 alignment | Approved CAD/CAM package |

| Prototyping | ±0.005mm accuracy; Ra ≤ 0.8μm | CMM; 3D scan; functional testing | FAI report; material certs |

| Mass Production | CpK >1.67; 50 PPM max scrap | SPC; AOI; 100% critical dimension | PPAP Level 3; batch traceability |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Aluminum Auto Parts Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom aluminum components engineered specifically for the demands of modern automotive manufacturing. As a trusted partner to tier-1 suppliers and OEMs across North America, Europe, and Asia, we combine advanced CNC machining, die casting, and finishing technologies with rigorous quality control to ensure every part meets exact performance, durability, and dimensional requirements. Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 standards, guaranteeing consistency, traceability, and compliance with global automotive specifications.

When you choose to partner with Lead Precision, you gain more than a supplier—you gain a strategic manufacturing ally. Our engineering team collaborates closely with your design and procurement departments from prototype through full-scale production, offering Design for Manufacturability (DFM) analysis, rapid prototyping, and scalable production planning. Whether your project requires complex housings, transmission components, suspension parts, or lightweight structural elements, we optimize material usage, reduce cycle times, and maintain tight tolerances down to ±0.005 mm.

Our investment in state-of-the-art 5-axis CNC centers, robotic automation, and in-line inspection systems enables us to deliver high-volume runs with exceptional repeatability and minimal lead time. We source premium-grade aluminum alloys—including 6061, 7075, and A380—ensuring mechanical properties align with your application’s thermal, corrosion, and load-bearing needs. Every component undergoes comprehensive dimensional verification, metallurgical testing, and surface finish validation before shipment.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Material Options | Aluminum 6061, 7075, A356, A380, and custom alloys |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Max Part Size | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| Machining Centers | 5-axis CNC, High-speed milling, Turning-milling combo |

| Secondary Processes | Anodizing, Powder Coating, Passivation, TIG/MIG Welding |

| Production Capacity | Up to 500,000 units annually |

| Quality Standards | ISO 9001, IATF 16949, PPAP, FAIR, SPC |

| Lead Time (Average) | 15–25 days for production orders |

We understand that reliability, responsiveness, and technical agility are non-negotiable in the automotive sector. That’s why we assign a dedicated project manager to every client, ensuring seamless communication, real-time production updates, and proactive issue resolution. Our export experience includes compliant packaging, Incoterms flexibility, and documentation support for smooth customs clearance.

For engineering teams seeking a precision manufacturing partner capable of handling complex aluminum auto parts with speed, accuracy, and long-term cost efficiency, Wuxi Lead Precision Machinery is ready to deliver. Contact us today at [email protected] to initiate your next project with a team committed to performance, partnership, and precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.