Technical Contents

Engineering Guide: Aluminum Alloys Used In Aerospace Industry

Engineering Insight Precision Imperatives in Aerospace Aluminum Alloys

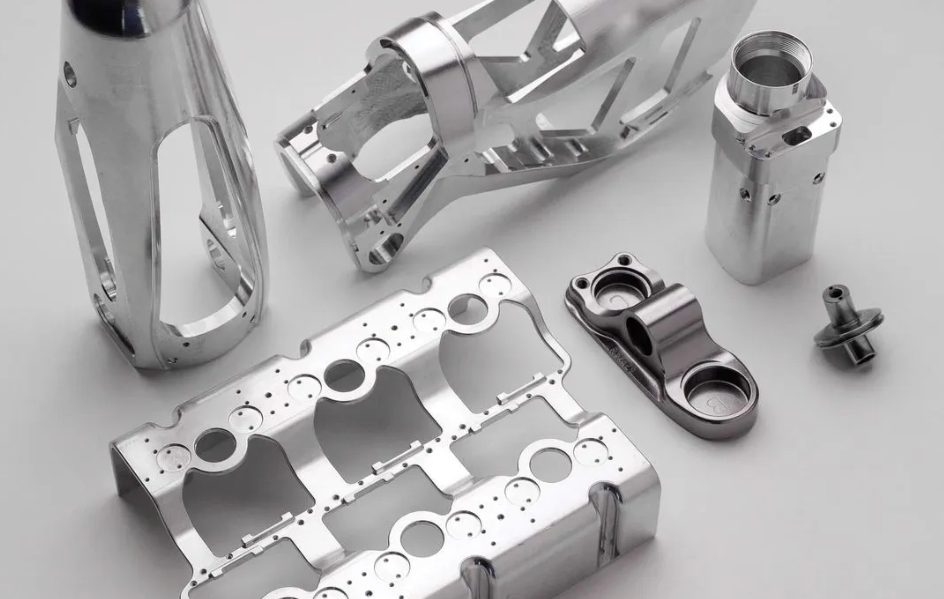

Aerospace engineering demands materials that defy conventional limits, where every micron of dimensional accuracy directly impacts safety, performance, and longevity. Aluminum alloys remain indispensable in this sector, balancing exceptional strength-to-weight ratios with fatigue resistance critical for airframes, landing gear, and engine components. However, the intrinsic properties of alloys like 7075-T6 or 2024-T3 are only fully realized through manufacturing precision that operates at the very edge of technological capability. Tolerances measured in thousandths of an inch are not merely specifications; they are non-negotiable requirements governing structural integrity under extreme cyclic stress, temperature fluctuations, and aerodynamic loads. Deviations imperceptible to the naked eye can propagate catastrophic fatigue cracks or induce aerodynamic inefficiencies at scale. This necessitates machining processes governed by rigorous thermal compensation protocols, real-time in-process metrology, and environmental controls far exceeding standard industrial practices.

At Wuxi Lead Precision Machinery, we engineer to these uncompromising standards daily. Our CNC machining centers operate within ISO Class 7 cleanrooms, utilizing sub-micron probing systems and adaptive control loops to counteract thermal drift during extended high-precision operations. This capability is proven in mission-critical applications where failure is not an option. We manufactured titanium and aluminum structural components for the Beijing Winter Olympics bobsled/luge track, where aerodynamic surface tolerances directly influenced athlete safety and speed. Similarly, our facility holds certifications for producing precision-machined parts for defense aerospace platforms, adhering to ITAR controls and MIL-STD-883 testing protocols that mandate zero-defect outcomes. Our engineers understand that aerospace aluminum isn’t just cut; it’s sculpted with predictive toolpath strategies that manage residual stress and microstructure integrity, preventing distortion in thin-walled structures common in fuel systems and avionics housings.

The selection of alloy must align precisely with the component’s functional demands and manufacturability constraints. Below are key aerospace aluminum alloys and their precision machining considerations:

| Alloy & Temper | Key Aerospace Applications | Critical Machining Parameters | Fatigue Strength (MPa) | Lead Precision Experience |

|---|---|---|---|---|

| 7075-T6 | Wing spars, fuselage frames, missile parts | Aggressive chip evacuation to prevent built-up edge; strict coolant control to avoid stress corrosion | 150-180 | Military aircraft structural components |

| 2024-T3 | Skin panels, riveted structures, truck wheels | Low radial depth of cut to minimize work hardening; vibration damping for thin walls | 130-160 | Commercial airframe sub-assemblies |

| 6061-T6 | Non-structural brackets, hydraulic manifolds | High-speed finishing for surface integrity; thermal management in complex geometries | 90-110 | Satellite mounting hardware |

| 2014-T6 | High-strength forgings, truck wheels | Precision boring for concentricity; controlled feed rates to avoid chatter marks | 140-170 | Landing gear fittings |

Precision in aerospace aluminum manufacturing transcends dimensional accuracy. It encompasses material science awareness, process stability, and absolute traceability from billet to finished part. Wuxi Lead Precision Machinery delivers this through integrated metrology, AS9100-certified workflows, and engineering expertise forged in applications where human lives depend on the absence of error. We transform aerospace-grade aluminum alloys into components that perform flawlessly at the edge of engineering possibility.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the stringent demands of the aerospace industry. Our expertise in machining high-performance aluminum alloys ensures components meet the highest standards for strength, weight efficiency, and reliability under extreme operational conditions. We specialize in processing aerospace-grade alloys such as 2024-T3, 6061-T6, 7050-T7451, and 7075-T6, which are widely used in airframes, engine mounts, landing gear systems, and structural components due to their excellent strength-to-density ratios and corrosion resistance.

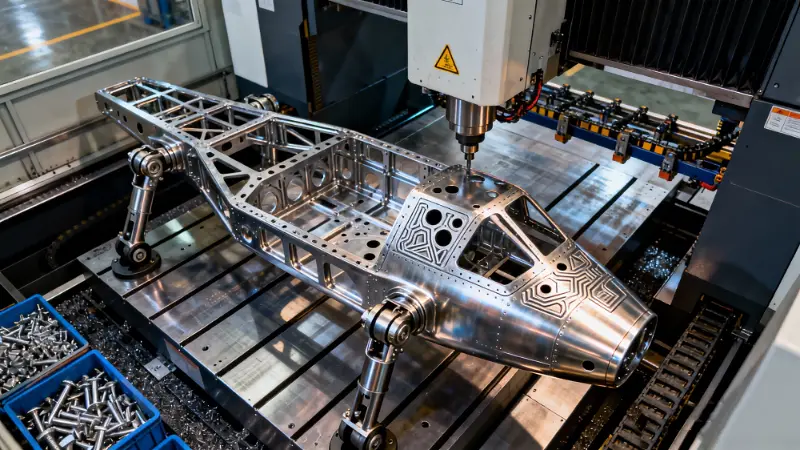

At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform. This advanced system allows for complex geometries to be machined in a single setup, minimizing cumulative tolerances and enhancing dimensional accuracy. The simultaneous movement across five axes enables us to produce intricate contours, deep pockets, and asymmetric features commonly found in aerospace components. Our CNC centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent material removal rates and surface finishes down to 0.8 μm Ra.

Precision is non-negotiable in aerospace manufacturing, which is why every component undergoes comprehensive quality control using a Coordinate Measuring Machine (CMM). Our Zeiss and Mitutoyo CMM systems provide micron-level verification of critical dimensions, geometric tolerances, and positional accuracy in full compliance with AS9100 and ISO 9001 standards. Data from CMM inspections is documented in detailed First Article Inspection (FAI) reports, available to clients for full traceability and audit readiness.

Our production environment is climate-controlled to minimize thermal distortion during machining and inspection, ensuring long-term repeatability. In addition to 5-axis milling, we offer precision turning, drilling, tapping, and surface treatments such as anodizing and alodine coating—services that support complete component readiness from raw stock to final delivery.

The table below outlines the standard tolerances we consistently achieve on aluminum aerospace components:

| Feature | Standard Tolerance | Capability Range | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | Up to 1,200 mm | Per ISO 2768-m |

| Geometric Tolerances (Flatness, Perpendicularity) | ±0.02 mm / 100 mm | Full surface coverage | Verified via CMM |

| Hole Position | ±0.015 mm | True position GD&T | Critical for fastening |

| Thread Accuracy | 6H / 6g | Metric and Unified | CNC tapping & threading |

| Surface Finish | 0.8 – 3.2 μm Ra | As machined or specified | Adjustable per requirement |

| Angular Accuracy | ±0.05° | 5-axis simultaneous | Complex interface surfaces |

Wuxi Lead Precision Machinery combines cutting-edge technology with rigorous process controls to deliver mission-critical aluminum components trusted by aerospace innovators worldwide. Our technical team collaborates closely with engineering partners to optimize designs for manufacturability, reduce lead times, and ensure compliance with industry-specific certifications.

Material & Finish Options

Aerospace Material Selection: Aluminum Alloys, Steel, Titanium & Critical Finishes

Aluminum alloys remain the dominant structural material in aerospace, constituting over 80% of modern airframe weight due to their exceptional strength-to-weight ratio, fatigue resistance, and manufacturability. At Wuxi Lead Precision Machinery, we prioritize aerospace-grade alloys like 2024-T3, 7075-T6, and 6061-T6 for critical components where weight savings directly impact fuel efficiency and payload capacity. While aluminum excels in primary structures, steel alloys such as 4340 and 17-4PH stainless serve indispensable roles in landing gear and high-stress fittings requiring extreme toughness. Titanium alloys, notably Ti-6Al-4V, are irreplaceable for high-temperature applications like engine mounts, balancing corrosion resistance with strength at elevated temperatures where aluminum falters. Material selection must align with operational stress profiles, environmental exposure, and lifecycle cost—not merely initial procurement price.

The following table compares key mechanical properties for common aerospace materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Primary Aerospace Applications |

|---|---|---|---|---|---|

| 7075-T6 Aluminum | 2.81 | 572 | 503 | Moderate | Wing spars, fuselage frames |

| 2024-T3 Aluminum | 2.78 | 470 | 325 | Low-Moderate | Aircraft skins, structural panels |

| 4340 Steel | 7.85 | 1100 | 860 | Low (requires coating) | Landing gear, engine shafts |

| 17-4PH Stainless | 7.75 | 1310 | 1170 | High | Fasteners, hydraulic systems |

| Ti-6Al-4V | 4.43 | 900 | 830 | Excellent | Engine components, critical fittings |

Aluminum 7075-T6 delivers the highest strength among common aluminum alloys, making it ideal for highly stressed airframe sections, though its lower corrosion resistance necessitates protective finishes. Conversely, 2024-T3 offers superior fatigue performance for dynamically loaded areas like wing skins. Steel selections must address weight penalties; 17-4PH stainless provides corrosion resistance without the density of carbon steels, while 4340 requires meticulous surface treatment. Titanium’s premium cost is justified only where its unique high-temperature stability and corrosion immunity are non-negotiable.

Surface finishing is equally critical to material integrity. Anodizing—specifically Type II (sulfuric acid) for general corrosion protection and Type III (hardcoat) for wear resistance—significantly enhances aluminum’s durability in harsh aerospace environments. Type III anodizing, achieving thicknesses of 50–100 µm, is mandatory for landing gear components and engine mounts subjected to abrasive contact. For titanium, anodizing provides decorative and mild corrosion resistance, but alodine or passivation treatments are often preferred for functional surfaces. Our CNC machining processes integrate seamlessly with post-fabrication finishing protocols, ensuring dimensional stability and adhesion integrity for all specified coatings.

Material and finish decisions directly impact aircraft safety, maintenance intervals, and total lifecycle value. Wuxi Lead Precision Machinery combines metallurgical expertise with precision manufacturing to optimize these selections for your specific aerospace application—ensuring compliance with AMS, ASTM, and OEM specifications while minimizing total cost of ownership. Consult our engineering team to validate your material strategy against operational demands.

Manufacturing Process & QC

The production process for aluminum alloys in aerospace applications demands an uncompromising standard of precision, consistency, and traceability. At Wuxi Lead Precision Machinery, we execute a rigorously controlled workflow that spans from initial design through prototyping to full-scale mass production, all governed by a zero-defect philosophy. This methodology ensures every component meets the stringent performance and safety requirements of the aerospace industry.

Design begins with a detailed analysis of the component’s functional requirements, environmental exposure, and integration within larger assemblies. Our engineering team collaborates closely with clients to select the optimal aluminum alloy—typically 2024, 7075, or 6061—based on strength-to-weight ratio, fatigue resistance, and machinability. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are employed to validate structural integrity and thermal performance under operational loads. All design data is managed within a secure Product Lifecycle Management (PLM) system to ensure version control and full auditability.

Prototyping follows the design phase, serving as a critical validation step before mass production. Using 5-axis CNC machining centers with sub-micron accuracy, we produce functional prototypes from aerospace-grade aluminum stock. These prototypes undergo comprehensive testing, including dimensional inspection via coordinate measuring machines (CMM), non-destructive testing (NDT) such as X-ray and ultrasonic inspection, and mechanical property verification. Feedback from this stage is systematically incorporated to refine toolpaths, fixturing, and process parameters, ensuring readiness for high-volume output.

Mass production is executed on fully integrated, automated manufacturing lines equipped with real-time monitoring and statistical process control (SPC). Each machining center is calibrated daily, and tool wear is continuously tracked using sensor-based feedback systems. Every component is traceable through a digital twin system, linking material certificates, process logs, inspection data, and final test results. Our clean-room machining environment minimizes particulate contamination, while automated coolant filtration maintains consistent cutting performance.

The following table outlines key specifications and process controls applied during manufacturing:

| Parameter | Specification | Standard / Tolerance |

|---|---|---|

| Material Grades | 2024-T3, 7075-T6, 6061-T6 | AMS 4027, AMS 4025, AMS 4026 |

| Dimensional Accuracy | ±0.005 mm | ISO 2768-m |

| Surface Roughness | Ra ≤ 0.8 µm | ISO 1302 |

| Positional Tolerance | ±0.01 mm | GD&T ASME Y14.5 |

| Inspection Method | CMM, NDT, Optical Profiling | ASTM E303, ASTM E542 |

| Process Control | SPC, Real-Time Tool Monitoring | ISO 13383-1 |

Zero defects are achieved through preventive quality engineering, not post-production inspection. Our AS9100D-certified quality management system enforces error-proofing at every stage, from raw material incoming checks to final packaging. This disciplined approach ensures that every aluminum component we manufacture performs reliably in the most demanding aerospace environments.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Aerospace Aluminum Manufacturing

Selecting the right manufacturing partner for aerospace aluminum components is not merely a procurement decision—it is a direct investment in flight safety, regulatory compliance, and operational longevity. At Wuxi Lead Precision Machinery, we engineer solutions where material science meets uncompromising precision. Our facility operates under AS9100D and ISO 9001:2015 certifications, with dedicated cleanrooms and traceability protocols exceeding FAA and EASA requirements. We specialize in transforming high-performance aluminum alloys into structural airframe components, engine mounts, and landing gear systems where failure is not an option.

Our technical mastery spans the full spectrum of aerospace-grade aluminum alloys, from high-strength 7000-series to corrosion-resistant 5000-series variants. Every component undergoes rigorous in-process inspection via CMM, optical comparators, and non-destructive testing to ensure dimensional stability under extreme thermal cycling and fatigue loads. Our 5-axis CNC machining centers achieve tolerances of ±0.005mm while maintaining surface finishes critical for fatigue resistance. Below are key alloys we routinely certify and machine to aerospace specifications:

| Alloy | Temper | Tensile Strength (MPa) | Key Properties | Typical Aerospace Applications |

|---|---|---|---|---|

| 2024 | T3 | 470 | High strength, good fatigue res. | Wing skins, fuselage frames |

| 7075 | T6 | 570 | Exceptional strength-to-weight | Landing gear, bulkheads |

| 6061 | T6 | 310 | Weldability, corrosion resistance | Brackets, hydraulic systems |

| 7050 | T7451 | 540 | Thick-section strength retention | Stringers, wing ribs |

| 5052 | H32 | 225 | Marine-grade corrosion resistance | Fuel tanks, external panels |

We integrate material certification with real-time process validation. Each batch undergoes chemical composition verification per AMS 4027 and AMS 4041 standards, while our thermal stress-relief ovens eliminate residual stresses that could compromise dimensional integrity during service. Our engineering team collaborates from design-for-manufacturability (DFM) through first-article inspection (FAI), providing PPAP documentation aligned with SAE AS13100. This end-to-end control ensures your components meet the exacting demands of Tier 1 aerospace integrators without costly rework or delays.

When milliseconds and millimeters define mission success, trust a partner who operates at the intersection of metallurgical expertise and precision execution. Wuxi Lead Precision Machinery delivers certified quality with the agility to support rapid prototyping and high-volume production under demanding schedules. Initiate your precision manufacturing partnership by contacting our aerospace engineering team directly. Submit your RFQ with material specifications and performance requirements to [email protected]. Our engineers will respond within 24 business hours with a detailed capability assessment and timeline proposal. Elevate your supply chain with a manufacturer engineered for aerospace excellence—where every micron meets the sky.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.