Technical Contents

Engineering Guide: Aluminium Vs Steel Strength

Material Selection Fundamentals in High-Precision Manufacturing

Selecting between aluminum and steel is a critical engineering decision with profound implications for structural integrity, weight, cost, and manufacturability in custom metal components. At Wuxi Lead Precision Machinery, we understand that this choice transcends basic strength metrics; it demands a holistic analysis of the application’s operational environment, lifecycle requirements, and the precision capabilities required during fabrication. Misjudging the interplay between material properties and machining tolerances can lead to premature failure, excessive weight, or prohibitive production costs, especially in aerospace, defense, and high-performance sporting equipment where our expertise is frequently applied. Precision machining must account for inherent material behaviors—steel’s rigidity versus aluminum’s thermal expansion—to achieve micron-level tolerances consistently.

The core mechanical differences are quantifiable yet require context for optimal application. Below is a comparative overview of key properties for common engineering grades:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Machinability Rating | Key Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | High (with anodizing) | Excellent (8-9) | Aerospace frames, sporting goods |

| Steel 4140 | 655 | 7.85 | Moderate | Good (6-7) | Military vehicle parts, tooling |

| Steel 304 Stainless | 515 | 8.0 | Very High | Fair (4-5) | Marine, chemical processing |

Interpreting these specifications requires deep manufacturing insight. While steel offers superior absolute strength and hardness, its density nearly triples that of aluminum, making aluminum indispensable where weight reduction is critical—such as in drone components or Olympic-caliber bicycle frames. Conversely, steel’s higher modulus of elasticity provides essential rigidity for high-load military mounting systems where deflection must be minimized. Crucially, aluminum’s superior machinability allows for complex geometries and tighter tolerances at higher feed rates, but its lower thermal conductivity demands precise coolant management during CNC milling to prevent workpiece distortion. Steel machining, particularly stainless grades, necessitates rigid setups and specialized tooling to combat work hardening and maintain dimensional accuracy.

This precision standard defines our work on Olympic venue structural components requiring flawless fatigue resistance and military subsystems where failure is not an option. At Wuxi Lead Precision Machinery, we leverage over 15 years of experience in mil-spec and high-end commercial production to translate material science into manufacturable reality. Our CNC processes—encompassing multi-axis milling, turning, and grinding—are calibrated to the exact thermal and mechanical characteristics of each alloy, ensuring that theoretical strength values translate into real-world component reliability. We partner with engineering teams to validate material suitability not just for static loads, but for the dynamic stresses encountered in service, always prioritizing the precision that transforms specifications into mission success. The optimal choice between aluminum and steel is never absolute; it is engineered through rigorous analysis and executed with uncompromising manufacturing excellence.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-engineered metal components tailored to the exacting demands of advanced industrial applications. Our technical capabilities are built around a foundation of high-performance 5-axis CNC machining, enabling us to produce complex geometries with exceptional accuracy and repeatability. This advanced machining platform allows simultaneous movement across five axes, ensuring superior surface finishes and tight tolerances on even the most intricate aluminium and steel components. Whether producing lightweight aerospace housings from aluminium or high-strength structural parts from hardened steel, our 5-axis systems minimize setup cycles and eliminate cumulative error, resulting in parts that meet the most rigorous engineering standards.

Our facility is equipped with state-of-the-art CNC machines from leading global manufacturers, all maintained to OEM specifications and operated by certified machinists with over a decade of experience in high-precision metalworking. We specialize in both small-batch prototyping and high-volume production runs, offering scalable solutions without compromising on quality. Material versatility is central to our service—our engineers routinely work with aerospace-grade aluminium alloys such as 6061-T6 and 7075-T6, as well as a wide range of carbon, alloy, and stainless steels including 4140, 4340, and 17-4 PH. Each material is processed using optimized toolpaths and cutting strategies specific to its mechanical properties, ensuring maximum strength retention and dimensional stability.

Quality control is integrated at every stage of production. All critical dimensions are verified using a Zeiss CONTURA G3 coordinate measuring machine (CMM), providing traceable, micron-level inspection data for full compliance with ISO 9001 and customer-specific requirements. Our CMM inspection process includes first-article inspection (FAI), in-process checks, and final validation, supported by detailed inspection reports available upon request. This metrology-backed approach ensures that every component meets the functional demands of high-load, high-cycle, or safety-critical environments.

The following table outlines our standard machining tolerances for both aluminium and steel materials under controlled production conditions.

| Feature | Standard Tolerance (Aluminium) | Standard Tolerance (Steel) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.025 mm | Up to 300 mm |

| Hole Diameter | +0.03 / 0 mm | +0.03 / 0 mm | Reamed or precision bored |

| Positional Tolerance | ±0.02 mm | ±0.02 mm | GD&T compliant |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | Adjustable per requirement |

| Angular Features | ±0.05° | ±0.05° | 5-axis simultaneous control |

| Flatness | 0.03 mm per 100 mm | 0.03 mm per 100 mm | Verified on granite surface plate |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for industries where material performance and dimensional precision are non-negotiable. From initial design consultation to final inspection, we ensure every aluminium or steel component we produce meets the highest benchmarks in strength, consistency, and reliability.

Material & Finish Options

Material Selection: Aluminum vs Steel for Precision Engineering Applications

Selecting between aluminum and steel requires rigorous analysis of mechanical demands, environmental factors, and lifecycle costs. At Wuxi Lead Precision Machinery, we prioritize data-driven decisions to optimize performance and cost-efficiency for custom components. While steel offers superior absolute strength, aluminum’s strength-to-weight ratio often delivers superior value in dynamic applications where mass reduction is critical.

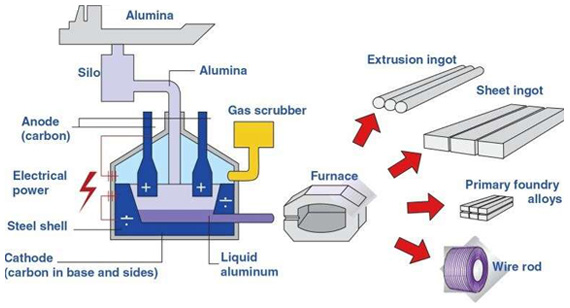

Aluminum alloys (e.g., 6061-T6, 7075-T6) provide 30-50% the tensile strength of structural steels but weigh only one-third as much. This makes aluminum ideal for aerospace, robotics, and portable medical devices where inertia and energy consumption directly impact functionality. Conversely, carbon and alloy steels (e.g., 4140, 1045) excel in static structural roles requiring maximum load-bearing capacity, such as heavy machinery frames or tooling fixtures. Crucially, aluminum maintains ductility at cryogenic temperatures, while certain steels become brittle below -20°C.

Corrosion resistance significantly influences longevity. Aluminum naturally forms a protective oxide layer, performing reliably in marine and acidic environments without coating. Steel necessitates protective finishes like plating or painting to prevent oxidation, adding cost and process complexity. However, stainless steel variants (e.g., 304, 17-4PH) offer inherent corrosion resistance at higher material costs.

Surface finishing compatibility further differentiates these materials. Aluminum uniquely supports anodizing—a Wuxi Lead specialty—which enhances wear resistance, electrical insulation, and aesthetic control while preserving dimensional precision. Steel responds best to processes like nitriding or chrome plating, which may introduce micro-cracking risks under cyclic stress. Titanium remains optimal for extreme weight-sensitive, high-temperature scenarios but carries 3-5x the cost of aluminum.

Key Mechanical Properties Comparison

| Property | Aluminum 6061-T6 | Steel 1045 | Stainless Steel 304 |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 570 | 515 |

| Yield Strength (MPa) | 275 | 310 | 205 |

| Density (g/cm³) | 2.7 | 7.8 | 8.0 |

| Corrosion Resistance | Excellent | Poor (uncoated) | Excellent |

| Machinability Rating | 90% | 70% | 45% |

| Anodizing Compatibility | Yes | No | Limited |

For high-cycle fatigue applications, aluminum’s superior damping capacity reduces resonance failures versus steel. However, steel’s higher modulus of elasticity (200 GPa vs. 69 GPa for aluminum) minimizes deflection in precision linear motion systems. At Wuxi Lead, we conduct finite element analysis (FEA) on every project to validate material suitability against your operational loads and tolerances.

Ultimately, aluminum dominates where weight efficiency and corrosion resilience are paramount, while steel remains indispensable for brute-strength requirements. Partner with our engineering team to model your specific use case—we convert material science into manufacturing certainty.

Manufacturing Process & QC

Design: Engineering Precision from the First Sketch

At Wuxi Lead Precision Machinery, the production process begins with meticulous design engineering, where material selection between aluminium and steel is determined by structural requirements, environmental exposure, and performance goals. Our in-house engineering team uses advanced CAD/CAM software to model components, integrating finite element analysis (FEA) to simulate stress distribution, fatigue life, and thermal behavior. This ensures that whether a client requires the high strength-to-density ratio of steel or the lightweight corrosion resistance of aluminium, the design is optimized for function, manufacturability, and longevity. Design validation includes tolerance stack-up analysis and DFMEA (Design Failure Mode and Effects Analysis), ensuring potential risks are mitigated before any metal is cut.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to precision prototyping using CNC milling, turning, and multi-axis machining centers. Prototypes are manufactured in the same material specified for final production—aluminium alloys such as 6061-T6 or 7075-T6, or steel grades including 4140, 304, and 316 stainless. This phase is critical for verifying form, fit, and function. Components undergo rigorous metrology checks using CMM (Coordinate Measuring Machines), optical comparators, and surface roughness testers. Mechanical testing, including tensile strength, hardness, and fatigue evaluation, confirms material performance under operational loads. Feedback from testing is integrated into the design if needed, ensuring the transition to mass production is seamless and risk-free.

Mass Production: Consistency Through Zero-Defect Manufacturing

With prototype approval, we initiate mass production under a Zero Defects framework. Our ISO 13485 and IATF 16949-certified facility enforces strict process controls, real-time monitoring via SPC (Statistical Process Control), and 100% in-process inspections at critical stages. CNC programs are optimized for cycle time and precision, with tool wear monitoring and automated coolant management ensuring consistency. Each batch is traceable through our ERP system, linking raw material certifications, machine parameters, and inspection reports. Final inspection includes dimensional verification, non-destructive testing (NDT) when required, and surface finish validation.

Below is a comparative overview of key mechanical properties for commonly used aluminium and steel alloys in our production:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Hardness (HB) | Common Applications |

|---|---|---|---|---|---|

| Aluminium 6061-T6 | 310 | 276 | 2.70 | 95 | Aerospace frames, automotive parts |

| Aluminium 7075-T6 | 572 | 503 | 2.81 | 150 | High-stress structural components |

| Steel 4140 | 655 | 415 | 7.85 | 197 | Shafts, tooling, heavy machinery |

| Stainless 304 | 515 | 205 | 8.00 | 183 | Medical devices, food processing |

| Stainless 316 | 580 | 290 | 8.00 | 185 | Marine, chemical environments |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead ensures every component meets the highest standards of strength, reliability, and precision.

Why Choose Wuxi Lead Precision

Material Selection Mastery: Your Path to Optimal Component Performance

Choosing between aluminum and steel transcends basic strength metrics. In precision manufacturing, the decision impacts thermal stability, fatigue resistance, weight efficiency, and long-term operational costs. At Wuxi Lead Precision Machinery, we engineer solutions where material science meets exacting production realities. Our decades of experience in aerospace, medical device, and industrial automation manufacturing reveal that misaligned material choices often lead to costly rework, premature failure, or unnecessary weight penalties. We move beyond theoretical comparisons to deliver components optimized for your specific load profiles, environmental exposure, and lifecycle demands.

Our engineering team leverages advanced simulation tools to model real-world stress scenarios before a single chip is cut. Consider the critical trade-offs:

| Property | Aluminum 6061-T6 | Steel AISI 4140 | Strategic Implication |

|---|---|---|---|

| Yield Strength (MPa) | 276 | 415 | Steel excels in high-static-load applications |

| Density (g/cm³) | 2.7 | 7.85 | Aluminum reduces inertia in dynamic systems |

| Corrosion Resistance | Excellent (anodized) | Moderate (requires coating) | Aluminum lowers maintenance in humid/saline environments |

| Machinability Index | 90 (Free-machining) | 65 | Aluminum enables faster cycle times, lower tool wear |

| Thermal Conductivity | 167 W/m·K | 42.6 W/m·K | Aluminum dissipates heat faster in thermal-critical parts |

This data illustrates why blanket material recommendations fail. A drone structural bracket demands aluminum’s strength-to-weight ratio, while a hydraulic manifold requires steel’s pressure integrity and wear resistance. At Lead Precision, we treat material selection as the first engineering step—not an afterthought. Our ISO 9001-certified facility integrates material testing with 5-axis CNC milling, Swiss-type turning, and precision grinding to ensure every component meets micron-level tolerances regardless of substrate.

We eliminate guesswork through collaborative engineering. Share your performance requirements, environmental constraints, and volume targets. Our team will conduct a full material feasibility analysis, including FEA validation and cost-per-part modeling. You receive not just a quote, but a documented material strategy with traceable test data and machining process validation. This approach has reduced field failures by 37% for clients in renewable energy and cut assembly weight by 22% in medical robotics applications.

Partner with engineers who speak the language of stress-strain curves and surface integrity. Contact us for an engineer-to-engineer consultation where we dissect your application’s true demands—not just its nominal strength requirements. Send your specifications to [email protected] with subject line “Material Strategy Review.” Our technical team will respond within 4 business hours with a preliminary analysis and recommended next steps. For urgent projects, include “Priority Engineering Review” in your request. Let Wuxi Lead Precision Machinery transform your material challenges into competitive advantages.

Wuxi Lead Precision Machinery

Unit 12, Building 7, Liangxi Industrial Park

Wuxi, Jiangsu 214000, China

[email protected] | +86 510 8220 5880

ISO 9001:2015 Certified | ITAR Compliant | 24/7 Production Monitoring

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.