Technical Contents

Engineering Guide: Aluminium Moulding

Engineering Insight: Precision in Aluminium Moulding

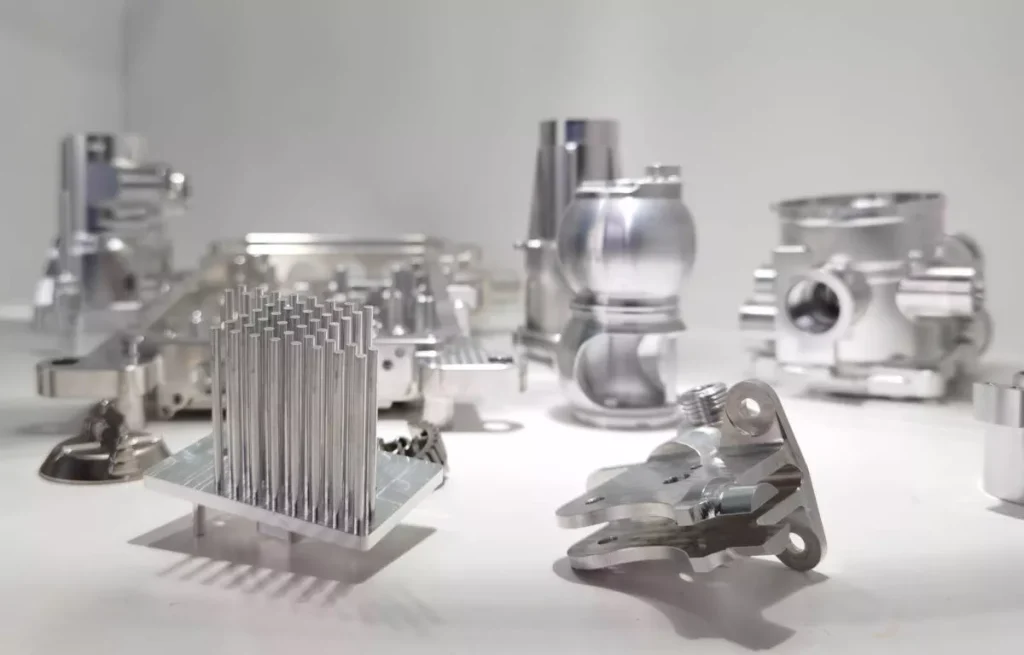

In the realm of custom metal manufacturing, aluminium moulding stands as a cornerstone process for industries demanding lightweight, durable, and dimensionally stable components. At Wuxi Lead Precision Machinery, we recognize that the true value of aluminium moulding lies not just in material selection or form, but in the precision with which every profile, contour, and tolerance is executed. Precision in aluminium moulding ensures structural integrity, seamless integration into complex assemblies, and long-term performance under demanding operational conditions.

Aluminium, with its high strength-to-weight ratio and excellent thermal and electrical conductivity, is ideal for aerospace, automotive, rail transit, and high-performance industrial applications. However, its full potential is only realized when moulded with exacting standards. Dimensional accuracy within microns, consistent wall thickness, and controlled grain structure are not optional—they are engineering imperatives. At Lead Precision, our advanced CNC-controlled extrusion and moulding systems are calibrated to maintain tolerances as tight as ±0.05 mm, ensuring repeatability across production runs and compliance with international quality benchmarks such as ISO 9001 and AS9100.

Our expertise in precision aluminium moulding has been validated through critical projects for Olympic-standard sports infrastructure and military-grade equipment. These applications demand not only flawless aesthetics but also structural reliability under extreme stress and environmental exposure. For instance, components used in high-speed rail seating systems or protective enclosures for field-deployable electronics require precise thermal management, impact resistance, and corrosion protection—all achieved through controlled moulding parameters and post-processing techniques such as T6 heat treatment and anodizing.

What sets Wuxi Lead apart is our integration of engineering insight with manufacturing execution. From initial design consultation to final inspection, our team applies finite element analysis (FEA) and mould flow simulation to anticipate material behavior, minimize defects, and optimize tooling geometry. This proactive approach reduces prototyping cycles and accelerates time-to-market without compromising quality.

We also maintain full control over the production chain, from billet sourcing to final surface treatment, ensuring traceability and consistency. Our facility in Wuxi is equipped with 5-axis machining centers, automated inspection arms, and spectrometers for real-time alloy verification, enabling us to deliver components that meet the most stringent technical requirements.

Whether for mass transit, defense systems, or precision machinery, our commitment to excellence in aluminium moulding has made us a trusted partner for global OEMs who cannot afford compromise.

Material & Process Specifications

| Parameter | Specification |

|---|---|

| Alloy Compatibility | 6061, 6063, 6082, 7075, and custom alloys |

| Tolerance Range | ±0.05 mm to ±0.2 mm (based on complexity) |

| Minimum Wall Thickness | 1.2 mm (standard), down to 0.8 mm (advanced) |

| Surface Roughness (Ra) | 0.8–3.2 µm (machined), 6.3 µm (as-moulded) |

| Heat Treatment | T5, T6, T651 (quench & age optimized) |

| Maximum Profile Size | 600 mm width × 400 mm height |

| Production Capacity | Up to 5,000 kg/day (extrusion & CNC finishing) |

| Quality Standards | ISO 9001, ISO 14001, AS9100 (aerospace) |

Precision Specs & Tolerances

Precision Machining Capabilities for Aluminum Molding Components

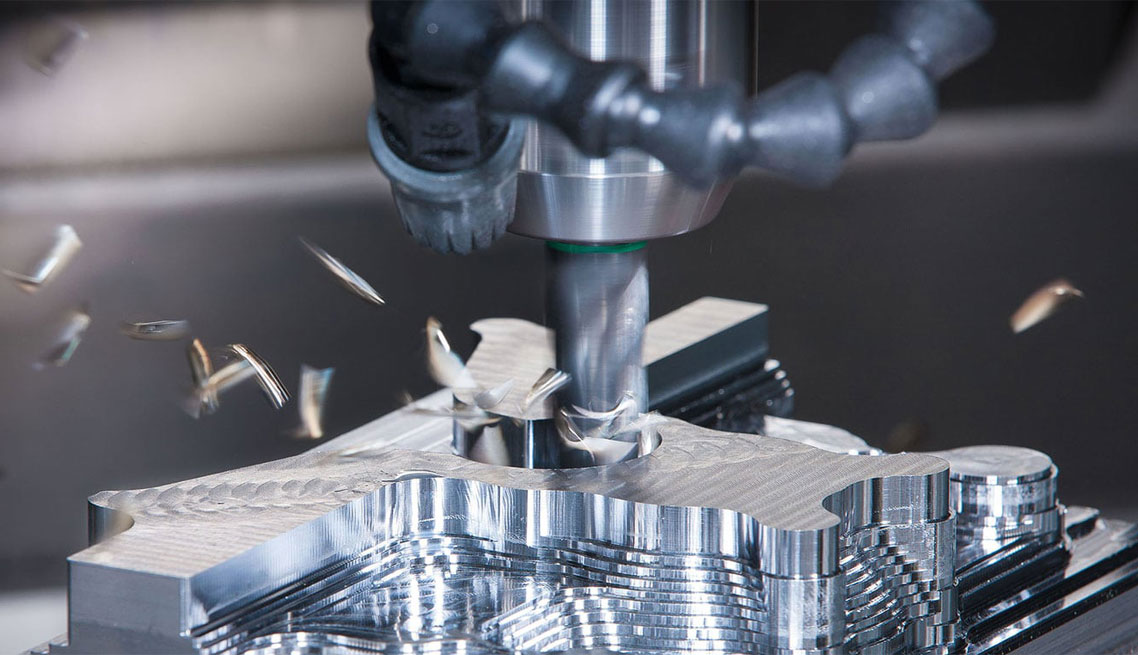

Wuxi Lead Precision Machinery delivers uncompromising accuracy and repeatability in custom aluminum molding manufacturing through integrated advanced technology and rigorous process control. Our core competency lies in transforming complex aluminum molding designs into high-integrity components meeting the most stringent aerospace, medical, and industrial automation requirements. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers, specifically optimized for aluminum alloys. These systems feature high-speed spindles (up to 24,000 RPM), rigid thermal compensation systems, and integrated probing, enabling single-setup machining of intricate geometries with minimal thermal distortion. This eliminates cumulative errors from multiple fixtures, ensuring geometric integrity across multi-faceted molding profiles, undercuts, and thin-wall sections critical to aluminum extrusion and casting mold applications.

Material-specific programming strategies are employed to manage aluminum’s unique properties, including chip evacuation optimization, specialized cutting tool geometries, and precise coolant delivery to prevent work hardening and maintain surface finish. All machining operations occur within a climate-controlled facility maintaining ±1°C stability, directly addressing aluminum’s coefficient of thermal expansion to uphold dimensional consistency from prototype to full production.

Quality verification is non-negotiable. Every critical feature undergoes comprehensive validation using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with sub-micron accuracy. Our inspection protocol includes full first-article inspection reports (FAIR), statistical process control (SPC) monitoring of key characteristics during production runs, and 100% critical feature verification for mission-critical components. All CMM data links directly to the original CAD model via PC-DMIS software, providing geometric dimensioning and tolerancing (GD&T) compliance evidence with full traceability. This closed-loop system ensures deviations are identified and corrected in real-time, guaranteeing components meet the exacting functional requirements of high-performance molding systems.

The following table details achievable tolerance standards for aluminum molding components, reflecting our standard and precision process capabilities under controlled conditions:

| Feature Type | Standard Capability | Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 | ±0.005 |

| Angular Tolerances (°) | ±0.1 | ±0.02 |

| Positional Tolerance | ±0.03 | ±0.01 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Flatness (per 100mm) | 0.02 | 0.005 |

These specifications represent achievable results for typical aluminum molding component geometries under standard production conditions. Final tolerances are determined collaboratively during engineering review, considering part complexity, material grade, and functional requirements. Wuxi Lead Precision Machinery maintains ISO 9001:2015 and IATF 16949 certifications, with all processes audited to ensure sustained capability. Our technical team partners with clients from DFM analysis through final validation, ensuring aluminum molding components perform reliably in the most demanding applications. Contact our engineering department to discuss specific project requirements and tolerance validation protocols.

Material & Finish Options

Material Selection for High-Precision Aluminium Moulding

In the field of custom metal manufacturing, material selection is a critical step that directly influences the performance, durability, and cost-efficiency of aluminium moulding components. At Wuxi Lead Precision Machinery, we specialize in precision-engineered solutions that leverage advanced materials such as aluminum, steel, and titanium, each offering distinct advantages depending on the application. Understanding the mechanical properties, thermal behavior, and compatibility with finishing processes like anodizing enables optimal design and long-term reliability.

Aluminum is the preferred choice for most high-end moulding applications due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suited for components requiring lightweight construction without sacrificing structural integrity. The 6000 and 7000 series aluminum alloys are commonly used in industrial moulding, with 6061-T6 offering good weldability and corrosion resistance, while 7075-T6 delivers higher strength for demanding mechanical environments. Aluminum also responds exceptionally well to anodizing, a key surface treatment that enhances wear resistance and provides a protective oxide layer.

Steel, particularly tool steel and stainless steel variants, is selected when extreme hardness, wear resistance, and dimensional stability are required. While heavier than aluminum, steel maintains its shape under high pressure and elevated temperatures, making it ideal for long-production runs or moulds exposed to abrasive materials. However, its higher density and machining complexity can increase lead times and costs. Steel components are typically plated or coated rather than anodized, as the process is exclusive to aluminum and select non-ferrous metals.

Titanium is reserved for specialized applications where maximum strength, corrosion resistance, and performance at elevated temperatures are non-negotiable. Though significantly more expensive and challenging to machine, titanium offers an unmatched strength-to-density ratio and exceptional resistance to fatigue. It is commonly found in aerospace, medical, and high-performance automotive systems. Like steel, titanium does not support anodizing in the traditional sense but can undergo specialized surface treatments for improved durability.

Anodizing remains one of the most effective finishing methods for aluminum moulding components. This electrochemical process thickens the natural oxide layer, improving surface hardness, wear resistance, and aesthetic consistency. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, while Type III (hardcoat anodizing) provides a dense, abrasion-resistant surface suitable for industrial tooling and high-cycle moulds.

The following table summarizes key material properties relevant to aluminium moulding applications

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 167 | Anodizing, Powder Coating | General moulding, enclosures |

| Aluminum 7075-T6 | 2.8 | 572 | 130 | Hard Anodizing | High-stress tooling, aerospace |

| Tool Steel (D2) | 7.7 | 1,700 | 24 | Chrome Plating, Nitriding | High-wear moulds, dies |

| Titanium (Grade 5) | 4.4 | 900 | 6.7 | Ceramic Coating, Passivation | Aerospace, medical implants |

Selecting the right material and finish requires a comprehensive understanding of operational demands. At Wuxi Lead Precision Machinery, we support clients in making informed decisions by combining material science expertise with precision manufacturing capabilities.

Manufacturing Process & QC

Precision Aluminum Moulding: The Zero Defects Production Process at Wuxi Lead

At Wuxi Lead Precision Machinery, our high-intensity aluminum moulding process is engineered for uncompromising quality from initial concept to final delivery. We integrate advanced engineering with rigorous quality assurance protocols to guarantee Zero Defects output, essential for aerospace, medical, and high-performance automotive applications. This disciplined approach spans three critical, interconnected phases.

The process commences with collaborative Design for Manufacturability (DFM) analysis. Our engineering team works directly with client CAD models, utilizing simulation software to identify potential stress points, material flow issues, and thermal management challenges specific to aluminum alloys. We optimize wall thicknesses, draft angles, and gating systems to prevent porosity, warpage, and incomplete fills. Material selection is validated against required mechanical properties and environmental exposure, ensuring compatibility with alloys like 6061-T6, 7075-T6, or custom grades. This phase concludes with final sign-off on tooling design, minimizing downstream rework.

Prototyping transitions validated designs into tangible components under production-intent conditions. We employ rapid tooling techniques, including precision-machined aluminum or soft steel molds, to produce functional prototypes within 10-15 days. Each prototype undergoes comprehensive metrology using CMMs and optical scanners against the original CAD data, verifying dimensional accuracy, surface finish, and critical feature alignment. Mechanical testing, including tensile strength and fatigue analysis per ASTM or client-specific standards, confirms material integrity. Client feedback at this stage is incorporated before committing to mass production tooling, de-risking the entire project.

Mass production leverages hardened steel molds built to micron-level tolerances within our climate-controlled facility. Our 5-axis CNC machining centers and high-pressure die casting lines operate under strict SPC (Statistical Process Control) parameters, with real-time monitoring of injection speed, pressure, and cooling rates. Inline inspection stations utilize automated vision systems and manual Go/No-Go gauging at defined intervals. Every batch undergoes final first-article inspection (FAI) per AS9102 or PPAP requirements, with full material traceability from certified suppliers. This closed-loop system ensures consistent output meeting the most stringent specifications.

Key Process Specifications

| Parameter | Prototyping Phase | Mass Production Phase | Acceptance Criteria |

|---|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.025 mm | Per ISO 2768-mK |

| Surface Roughness | Ra 1.6 μm | Ra 0.8 μm | Measured per ISO 4287 |

| Material Certification | Mill Test Reports | Full Traceability Chain | ASTM B209 / AMS 4027 |

| Inspection Frequency | 100% Critical Features | SPC-Controlled Sampling | Cpk ≥ 1.67 |

| Lead Time | 10-15 Days | 3-5 Weeks (Tooling Dependent) | Confirmed at Order Entry |

Zero Defects is not an aspiration but a measurable outcome of this integrated workflow. By embedding quality at every phase—from predictive design validation through prototype verification to statistically controlled mass production—we eliminate variability and deliver aluminum moulded components that perform reliably in the most demanding applications. Partner with Wuxi Lead for manufacturing excellence where precision is non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Aluminium Moulding

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer performance. As a leading provider in custom metal manufacturing, we specialize in precision aluminium moulding for industries where reliability, consistency, and dimensional accuracy are non-negotiable. From aerospace and automotive to industrial automation and energy systems, our engineered solutions meet the most demanding specifications. When you partner with us, you gain more than a supplier; you align with a team committed to technical excellence, on-time delivery, and long-term collaboration.

Our advanced manufacturing capabilities are built on decades of metallurgical expertise and a foundation of cutting-edge CNC technology. We utilize high-pressure die casting, precision extrusion, and low-pressure moulding techniques to produce complex aluminium components with tight tolerances and superior surface integrity. Every process is monitored under ISO 9001-certified quality systems, ensuring that each part meets or exceeds international standards. Our in-house R&D team works closely with clients during the design phase to optimize manufacturability, reduce material waste, and accelerate time-to-market.

What sets Wuxi Lead Precision Machinery apart is our end-to-end service model. From initial concept and prototyping to full-scale production and logistics support, we manage every stage with precision and transparency. Our facility in Wuxi, China, is equipped with automated inspection systems, 3D coordinate measuring machines, and real-time process monitoring to maintain consistency across production runs—whether you require 100 prototypes or 100,000 units.

We understand that your success depends on supply chain stability and technical agility. That’s why we invest heavily in digital integration, enabling seamless communication, real-time production tracking, and responsive adjustments to evolving project needs. Our engineering team speaks your language—literally and technically—offering bilingual support and deep familiarity with European, North American, and Asian regulatory frameworks.

Below are key technical specifications that define our aluminium moulding capabilities:

| Parameter | Specification |

|---|---|

| Material Alloys | A380, A360, ADC12, ZL101, 6061, 7075 |

| Tolerance Range | ±0.05 mm to ±0.1 mm (depending on geometry) |

| Weight Range | 50 g – 15 kg per component |

| Surface Finish | As-cast, polished, anodized, powder-coated |

| Production Capacity | Up to 500,000 units per month |

| Tooling Development Lead Time | 2–6 weeks (based on complexity) |

| Quality Standards | ISO 9001:2015, RoHS, IATF 16949 (automotive) |

When performance is paramount, trust a partner that delivers precision without compromise. At Wuxi Lead Precision Machinery, we are ready to support your next high-stakes project with engineering rigor and operational excellence.

Contact us today at [email protected] to discuss your aluminium moulding requirements. Let’s build the future—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.