Technical Contents

Engineering Guide: Aluminium Machining And Iso 14001

Engineering Insight Precision Aluminum Machining and ISO 14001 Integration

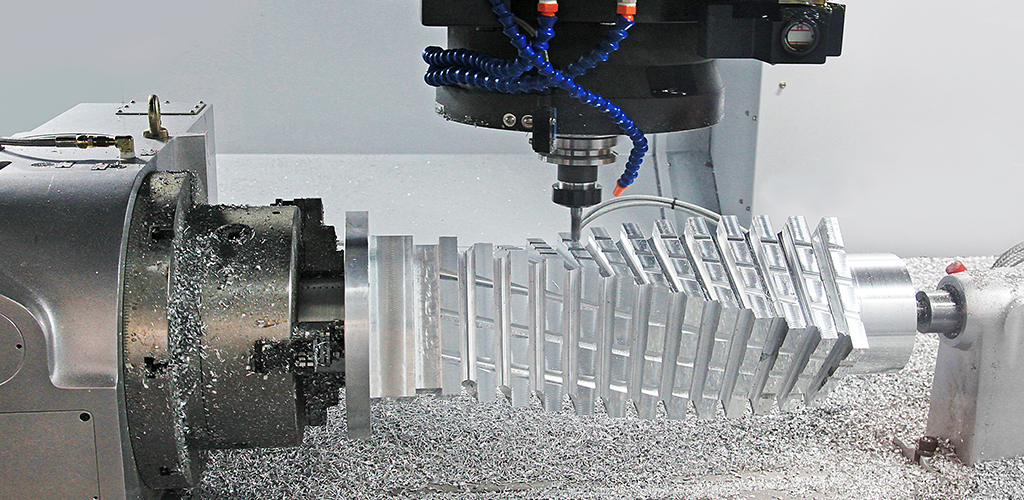

Aluminum machining demands exceptional precision due to the material’s inherent properties. Its low density and high thermal conductivity are advantageous for weight-critical applications like aerospace and automotive components, yet these same characteristics present significant manufacturing challenges. Thermal expansion during high-speed CNC operations can easily compromise dimensional stability if not meticulously controlled. Achieving tight tolerances, often within ±0.005mm for critical aerospace or medical parts, requires advanced machine calibration, optimized cutting strategies, and rigorous environmental management. At Wuxi Lead Precision Machinery, we treat precision not as an endpoint but as a continuous engineering discipline. Our decades of experience machining complex aluminum alloys—from 6061-T6 structural frames to 7075-T73 high-strength aerospace fittings—demonstrate that consistent accuracy hinges on integrating material science, process control, and sustainable operational practices.

This is where ISO 14001 certification becomes a strategic engineering asset, not merely a compliance checkbox. Our certified Environmental Management System directly enhances machining precision. Strict protocols for coolant management minimize thermal fluctuations in the machining environment, preventing part distortion. Controlled waste heat recovery systems stabilize workshop temperatures, a critical factor for maintaining micron-level tolerances in aluminum. Furthermore, systematic resource efficiency drives down particulate contamination, ensuring surface finishes meet exacting requirements like Ra 0.4µm for optical or fluidic components. ISO 14001 compels us to audit every variable affecting part integrity—from lubricant viscosity stability to compressed air purity—creating a foundation for repeatability that raw machine capability alone cannot achieve.

Wuxi Lead’s commitment to this integrated approach is validated by mission-critical applications. We supplied precision-machined aluminum structural components for the Beijing Winter Olympics venue systems, where thermal cycling resistance and dimensional permanence were non-negotiable under extreme conditions. Similarly, our ISO 14001-aligned processes support classified military programs requiring zero-defect aluminum housings for guidance systems, where environmental compliance directly correlates with ballistic performance reliability. These projects underscore that environmental stewardship and extreme precision are interdependent in high-stakes manufacturing.

Our core aluminum machining capabilities reflect this philosophy, combining technical rigor with sustainable execution as shown in the table below.

| Parameter | Capability Range | Relevance to Precision & ISO 14001 Integration |

|---|---|---|

| Dimensional Tolerance | ±0.005mm standard | Achieved via climate-controlled machining cells (ISO 14001 thermal management) |

| Surface Roughness (Ra) | 0.2µm to 3.2µm | Optimized coolant filtration reduces micro-scratches |

| Max Work Envelope | 2000 x 1200 x 1000mm | Energy-efficient spindle control minimizes thermal drift |

| Coolant Management | Closed-loop recycling >95% | ISO 14001 waste reduction; stable viscosity for accuracy |

| Material Utilization | >85% through nesting AI | Resource efficiency standard; lowers cost per precision part |

For global OEMs, partnering with a manufacturer where ISO 14001 is engineered into the precision workflow eliminates hidden risks. Wuxi Lead delivers not just aluminum components, but certified process integrity—proven in the world’s most demanding applications. Contact our engineering team to discuss how our integrated system ensures your specifications are met with environmental accountability.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced aluminum machining solutions tailored for industries demanding precision, repeatability, and compliance with international standards. As a certified ISO 14001 manufacturer, we integrate environmental responsibility into every stage of production while maintaining the highest levels of technical performance. Our expertise in custom metal manufacturing is anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and part handling, which enhances consistency—especially critical when machining aluminum components for aerospace, medical, and high-performance industrial applications.

Aluminum, with its favorable strength-to-weight ratio and excellent machinability, is a preferred material across precision engineering sectors. At Wuxi Lead, we specialize in machining a wide range of aluminum alloys, including 6061, 7075, and 2024, optimizing cutting parameters, tooling strategies, and coolant application to prevent deformation and ensure dimensional stability. Our 5-axis CNC platforms are equipped with high-speed spindles and automated tool changers, supporting uninterrupted operation and tight tolerance control. Each machining program is verified using advanced CAM simulation software to eliminate collisions and ensure first-time-right production.

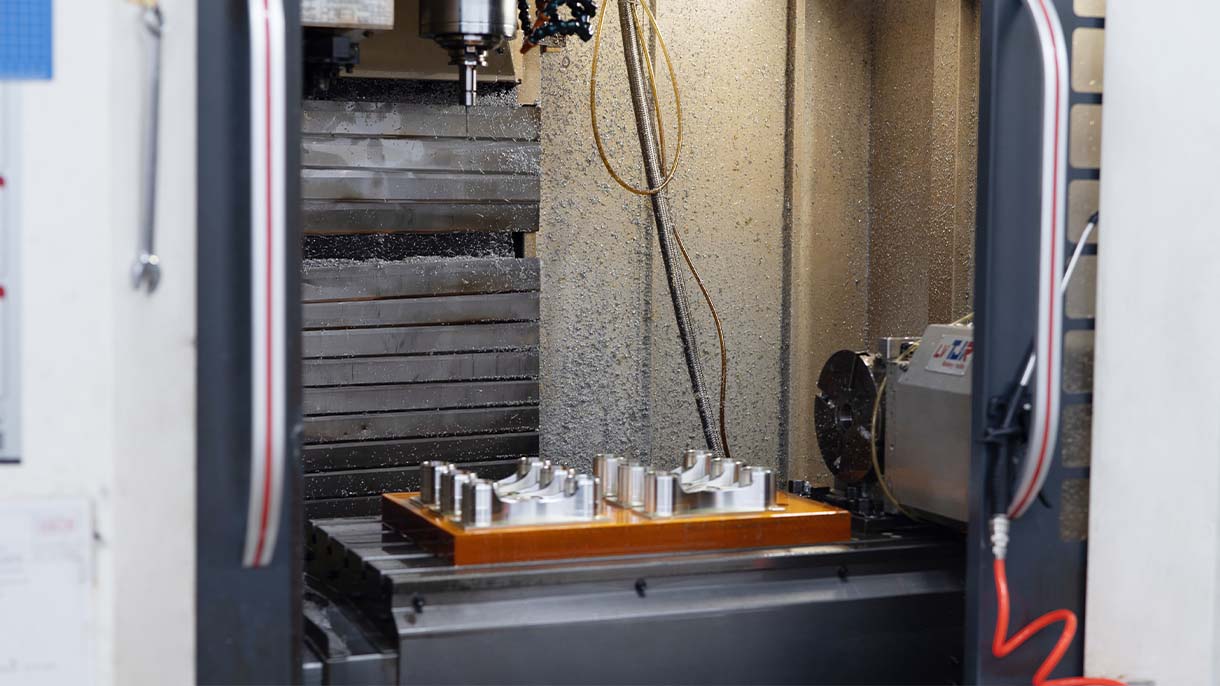

Quality assurance is central to our operational philosophy. Every aluminum component undergoes rigorous inspection using a coordinate measuring machine (CMM) to validate geometric accuracy and compliance with engineering specifications. Our CMM system is calibrated to international standards and operated by certified metrology technicians, ensuring traceable, repeatable measurement results. In addition to post-machining inspection, we implement in-process gauging and statistical process control (SPC) to monitor trends and maintain process capability over production runs.

Our ISO 14001 certification reflects our commitment to sustainable manufacturing practices. We manage coolant recycling, aluminum chip segregation, and energy-efficient machine operation to minimize environmental impact without compromising precision or throughput.

The following table outlines the typical machining tolerances achievable on our 5-axis CNC systems when working with aluminum alloys:

| Feature | Standard Tolerance | Precision Tolerance (Optional) |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm |

| Positional Tolerance | ±0.05 mm | ±0.02 mm |

| Flatness | 0.05 mm per 100 mm | 0.02 mm per 100 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

All tolerances are achievable across part sizes ranging from 10 mm to 800 mm in length, depending on geometry and material condition. Wuxi Lead Precision Machinery combines technical excellence with environmental accountability, providing clients with reliable, high-precision aluminum components suitable for the most demanding applications.

Material & Finish Options

Strategic Material Selection for Precision Machined Components

Precision outcomes in custom metal manufacturing fundamentally hinge on intelligent material science. At Wuxi Lead Precision Machinery, we guide clients through selecting optimal alloys considering functional requirements, manufacturability, environmental impact, and compliance with standards like ISO 14001. Aluminum alloys, particularly 6061 and 7075, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and superior machinability. These alloys allow for high-speed CNC processing, minimizing tool wear and energy consumption – a direct alignment with ISO 14001’s focus on resource efficiency. While inherently corrosion-resistant, aluminum often benefits from anodizing, a critical finish we specialize in. Our controlled anodizing processes strictly adhere to environmental regulations, utilizing closed-loop systems to manage effluents and eliminate heavy metals, ensuring the finish enhances durability without compromising ecological responsibility.

Steel remains indispensable for applications demanding extreme strength, wear resistance, and structural integrity, such as heavy machinery components. Grades like 4140 and 17-4 PH stainless offer robust performance but present higher machining challenges, requiring more power and generating greater heat and swarf. Titanium alloys, exemplified by Ti-6Al-4V, are the pinnacle choice for extreme environments like medical implants or jet engines, offering unparalleled strength-to-weight and corrosion resistance. However, their low thermal conductivity and chemical reactivity necessitate specialized tooling, slower speeds, and meticulous process control, significantly increasing production complexity and energy use. Understanding these trade-offs is essential for sustainable manufacturing.

The comparative properties below highlight key decision factors for precision machining under ISO 14001 frameworks.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Corrosion Resistance | ISO 14001 Relevance |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Excellent (Machinability Index 90) | Good (Requires Anodizing for harsh env.) | High (Low energy machining, recyclable) |

| Steel 4140 | 7.85 | 655 | Moderate (Machinability Index 65) | Fair (Requires plating/coating) | Medium (Higher energy use, recyclable) |

| Titanium Ti-6Al-4V | 4.43 | 900 | Poor (Machinability Index 20) | Excellent | Low-Medium (High energy, complex waste) |

Anodizing, particularly Type II (Sulfuric) and Type III (Hardcoat), is the definitive surface treatment for aluminum components requiring enhanced wear resistance, electrical insulation, or aesthetic consistency. Wuxi Lead implements anodizing baths with rigorous chemical management per ISO 14001 protocols, ensuring minimal wastewater generation and maximum resource recovery. This commitment transforms a standard finish into a demonstrable environmental asset for your supply chain. Selecting the right base material and finish is not merely a technical choice; it is a strategic decision impacting product lifecycle, regulatory compliance, and your environmental stewardship. Partner with Wuxi Lead to ensure your material specification delivers peak performance while meeting the highest standards of sustainable manufacturing.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our aluminium machining process is engineered for precision, repeatability, and compliance with ISO 14001 environmental standards. We specialize in custom metal manufacturing for high-performance industries such as aerospace, automotive, and medical devices. Our production workflow is structured into three core phases: Design, Prototyping, and Mass Production—each rigorously controlled to achieve zero defects.

The process begins with collaborative design engineering. Our team works closely with clients to analyze technical drawings, material specifications, and functional requirements. Using advanced CAD/CAM software, we simulate machining paths and perform tolerance analysis to ensure optimal geometry and fit. Design for Manufacturability (DFM) principles are applied early to eliminate potential production risks, reduce waste, and enhance efficiency—aligning with our ISO 14001 commitment to sustainable manufacturing.

Once the design is finalized, we proceed to prototyping. This phase is critical for validating form, fit, and function. We produce low-volume prototypes using the same CNC machining centers intended for mass production, ensuring consistency in material behavior and dimensional accuracy. Each prototype undergoes full metrological inspection using coordinate measuring machines (CMM) and optical comparators. Any deviations are addressed through iterative adjustments, with full traceability maintained throughout. This stage not only confirms design integrity but also verifies tooling, fixturing, and programming parameters under real machining conditions.

Following successful prototype approval, we transition seamlessly into mass production. Our facility in Wuxi operates a fleet of high-speed CNC milling and turning centers, all maintained to strict calibration schedules. Aluminium components are machined from certified raw materials, with batch tracking from receipt to shipment. In-process inspections occur at defined intervals, supported by statistical process control (SPC) methodologies to detect trends before they impact quality. Our zero-defect strategy is enforced through automated defect detection systems, real-time monitoring of cutting parameters, and 100% final inspection of critical dimensions.

Environmental responsibility is embedded in every phase. As an ISO 14001-certified manufacturer, we minimize coolant consumption through closed-loop filtration systems, recycle aluminium swarf, and optimize energy usage across all operations. This ensures not only compliance but also long-term sustainability in high-volume production.

The table below outlines key specifications for our aluminium machining capabilities:

| Parameter | Specification |

|---|---|

| Materials | 6061, 6082, 7075, 2024, 5052, and custom alloys |

| Tolerance | ±0.005 mm (standard), down to ±0.001 mm (tight) |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (custom finishes available) |

| Max Workpiece Size | 800 mm × 600 mm × 500 mm |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| Quality Standards | ISO 9001, ISO 14001, RoHS, full traceability |

| Production Capacity | 50,000+ units per month |

Every component we deliver reflects our dedication to engineering excellence, environmental stewardship, and zero-defect performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Where Aluminum Excellence Meets Environmental Integrity

When your aluminum components demand micron-level precision, flawless surface integrity, and unwavering compliance, the choice of manufacturing partner transcends cost. It becomes a strategic decision impacting product performance, supply chain resilience, and your own environmental, social, and governance (ESG) commitments. At Wuxi Lead Precision Machinery, we engineer solutions where advanced CNC aluminum machining converges with certified environmental management under ISO 14001:2015. This integration is not incidental; it is fundamental to delivering the consistent, high-reliability parts your critical applications require while safeguarding your brand’s sustainability narrative.

Aluminum’s unique properties – strength-to-weight ratio, thermal conductivity, and corrosion resistance – make it indispensable across aerospace, medical device, and premium automotive sectors. However, unlocking its full potential demands more than capable machines. It requires deep metallurgical understanding, process control to prevent microstructural damage, and an operational culture committed to minimizing waste at every stage. Our ISO 14001 certification is the tangible framework ensuring this commitment. It means rigorous resource consumption tracking, proactive hazardous material management for coolants and lubricants, continuous waste stream optimization, and systematic review of environmental impacts within your specific machining processes. This certified system directly translates to reduced scrap rates, stable process parameters for superior dimensional repeatability, and audit-ready documentation that simplifies your own compliance reporting.

We understand the high stakes involved in your supply chain. A single non-conformance or environmental audit finding can disrupt production and damage hard-earned reputations. Partnering with Lead Precision mitigates these risks. Our environmental management system is seamlessly embedded within our quality management system (ISO 9001:2015), creating a unified operational excellence platform. This ensures the aluminum components you receive meet exacting technical specifications while being produced within a demonstrably responsible framework, enhancing your supply chain transparency and resilience.

Lead Precision Aluminum Machining Capabilities & Environmental Integration

| Specification Category | Capability Detail | ISO 14001 Integration Point |

|---|---|---|

| Material Expertise | Aerospace (2024, 7075), Medical (6061, 6082), High-Silicon Alloys | Material-specific coolant recycling protocols |

| Dimensional Accuracy | ±0.005 mm (5 microns) typical | Stable process control via energy/resource monitoring |

| Max Work Envelope (mm) | 1200 x 800 x 650 | Optimized machine scheduling to reduce idle energy |

| Surface Finish (Ra) | As low as 0.4 µm (16 µin) | Closed-loop coolant management minimizing waste |

| Key Processes | 5-Axis Milling, Precision Turning, Deburring, CMM | Certified waste disposal documentation for all streams |

| Certification Validity | ISO 9001:2015, ISO 14001:2015 (Current Cycle) | Annual internal/external audits, continuous improvement |

Initiate your audit trail towards a more resilient and responsible supply chain. Contact our engineering team directly at Contact [email protected] to discuss your specific aluminum machining requirements and ISO 14001 integration needs. Provide your target tolerances, material grade, volume, and environmental compliance objectives. We will schedule a confidential capability review, sharing detailed process plans and our environmental management protocols relevant to your project. Discover how precision manufacturing, executed within a certified environmental framework, delivers not just parts, but peace of mind and a competitive advantage. Let Lead Precision become your trusted partner in sustainable high-performance manufacturing. Reach out today to engineer excellence, responsibly.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.