Technical Contents

Engineering Guide: Aluminium Machining And Automotive & Mobility

Engineering Insight: Precision Aluminum Machining for Automotive & Mobility Innovation

Aluminum machining is the cornerstone of modern automotive and mobility advancement, directly enabling weight reduction, thermal efficiency, and structural performance critical for electric vehicles, autonomous systems, and high-performance platforms. Its high strength-to-weight ratio and excellent thermal conductivity are essential, yet these very properties introduce significant engineering challenges. Achieving the required dimensional stability during high-speed machining demands exceptional control over thermal expansion, vibration, and material removal rates. Thin-walled components common in battery housings, motor mounts, and suspension systems are particularly susceptible to deflection and chatter, where micron-level deviations compromise assembly integrity, sealing performance, and ultimately, vehicle safety and longevity. Precision is not merely a specification; it is the non-negotiable foundation for reliability, efficiency, and meeting stringent automotive safety standards like ISO 26262.

At Wuxi Lead Precision Machinery, we engineer solutions for these exact complexities. Our deep expertise in high-tolerance aluminum machining stems from decades of delivering mission-critical components where failure is not an option. This includes precision-machined structural elements for Olympic-grade athletic equipment demanding absolute consistency under extreme stress, and specialized components for defense applications requiring unwavering performance in harsh environments. This heritage instills a rigorous quality culture focused on process stability, advanced metrology, and material science understanding specific to aluminum alloys like 6061-T6, 7075-T6, and custom aerospace grades. We leverage multi-axis CNC machining centers with real-time thermal compensation, specialized high-speed tooling strategies, and stringent in-process inspection protocols to maintain tolerances consistently, even on the most intricate geometries.

Our commitment translates into tangible performance for automotive and mobility partners. The table below outlines key capabilities directly addressing industry demands:

| Critical Parameter | Lead Precision Standard | Industry Relevance for Automotive/Mobility |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Ensures perfect fit for drivetrain components, eliminating vibration and noise issues in EV powertrains. |

| Surface Roughness (Ra) | 0.4 µm – 1.6 µm | Critical for sealing surfaces in battery enclosures and hydraulic systems, preventing leaks and ensuring safety. |

| Material Utilization | >92% | Reduces waste and cost for high-value aluminum alloys, supporting sustainable manufacturing goals. |

| Process Capability (Cpk) | ≥1.67 | Guarantees consistent part quality batch after batch, minimizing scrap and assembly line disruptions. |

| Alloy Expertise | 6061, 7075, 2024, Custom | Optimized machining parameters for diverse applications from structural brackets to high-conductivity heat sinks. |

Partnering with a manufacturer possessing proven precision engineering rigor is paramount in today’s competitive mobility landscape. Wuxi Lead Precision Machinery applies its Olympic and military-grade discipline to every automotive project, transforming complex aluminum designs into high-integrity components that accelerate innovation and ensure roadworthiness. Contact our engineering team to discuss how our precision machining capabilities can solve your specific mobility challenges.

Precision Specs & Tolerances

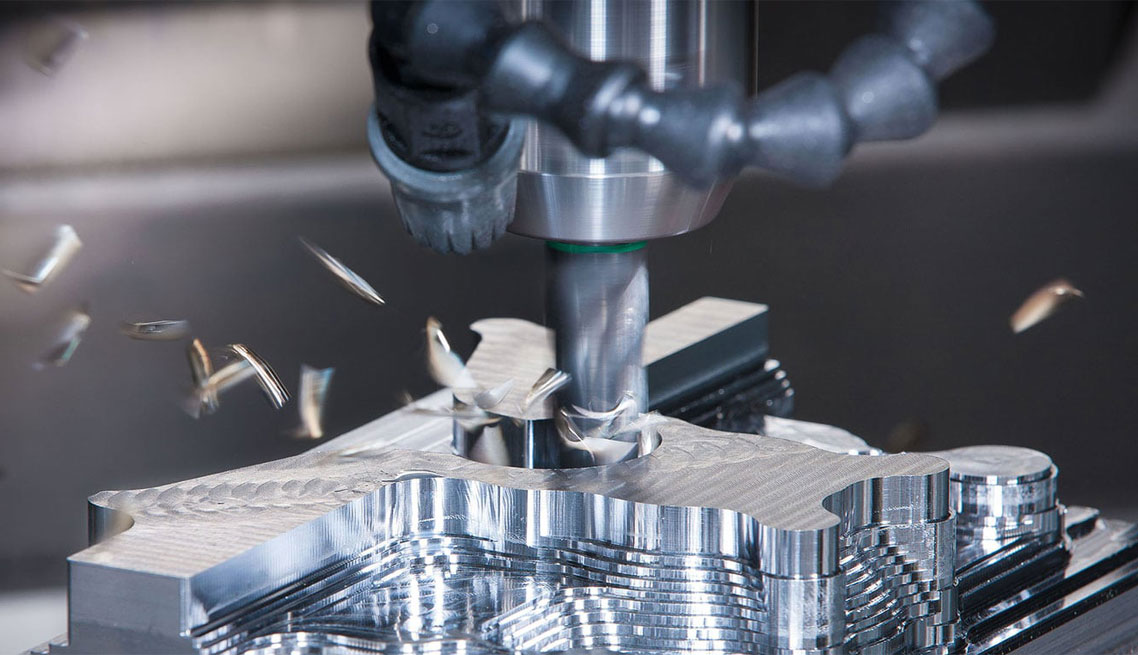

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision aluminium machining for the automotive and mobility sectors. Our expertise lies in transforming complex engineering designs into mission-critical components with exceptional repeatability, surface integrity, and dimensional accuracy. At the core of our production workflow is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute multi-faceted operations on intricate geometries in a single setup. This reduces cumulative tolerance stack-up, improves part consistency, and significantly shortens lead times—critical advantages in fast-paced automotive development and high-volume production environments.

Our 5-axis CNC systems are equipped with high-speed spindles, automated tool changers, and real-time monitoring software, ensuring optimal cutting performance across a wide range of aluminium alloys, including 6061, 7075, and cast variants used in lightweight structural and powertrain applications. The simultaneous movement across five axes allows for superior tool access, enabling undercuts, deep cavities, and organic contours to be machined with precision—features commonly required in electric vehicle battery housings, suspension components, and aerodynamic chassis systems. All machining programs are developed using advanced CAM software, with rigorous simulation to prevent collisions and ensure process reliability before material engagement.

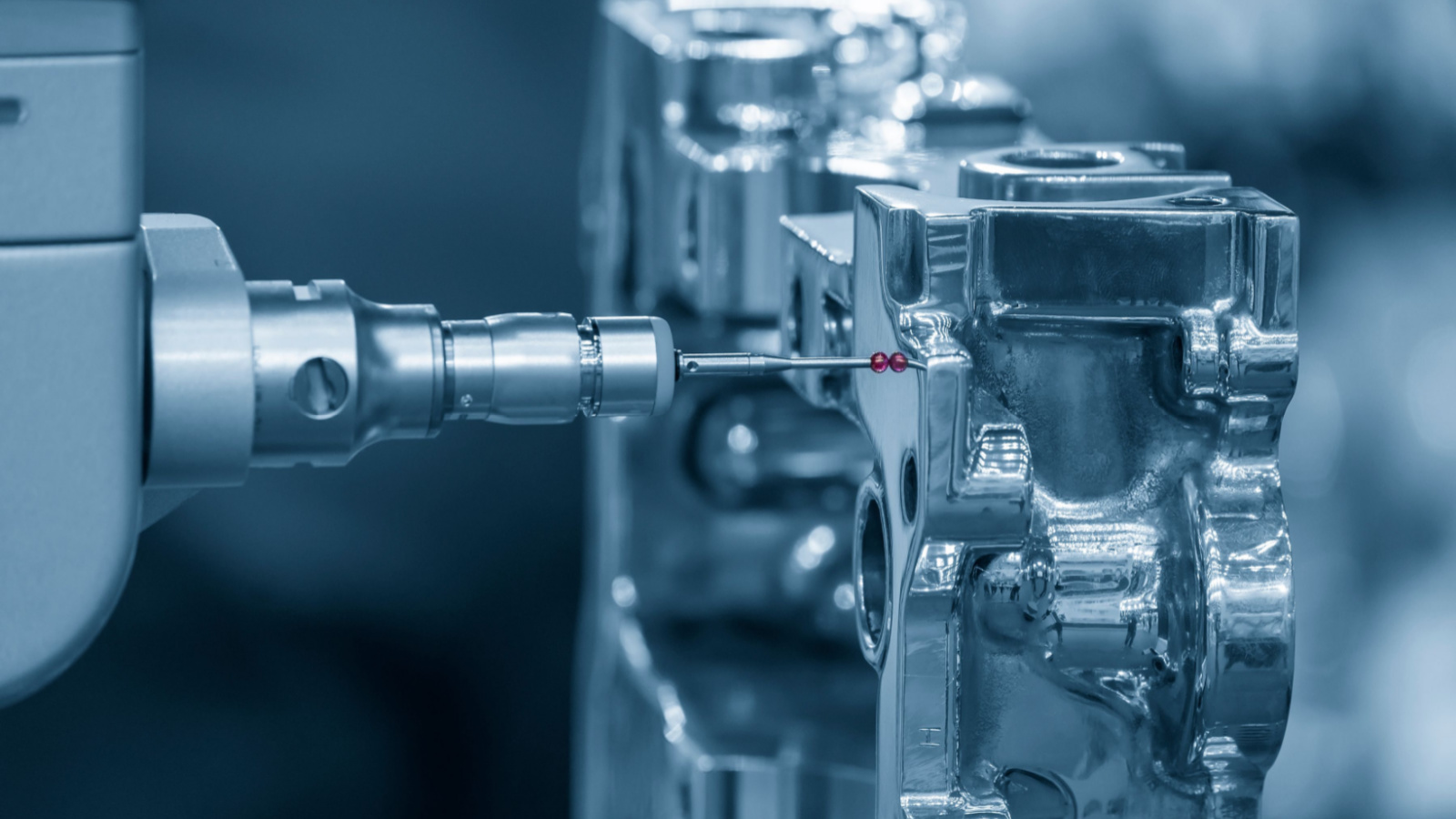

To maintain the highest quality standards, every production run is supported by a comprehensive quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D metrology validation, capturing thousands of data points to verify geometric dimensions, positional tolerances, and surface profiles against CAD models. This closed-loop inspection process ensures full traceability and compliance with automotive industry standards such as ISO 26262 and IATF 16949. In addition to CMM, we employ optical comparators, surface roughness testers, and in-process probing to monitor quality at every stage of production.

The following table outlines the standard machining tolerances we consistently achieve on aluminium components:

| Feature Type | Typical Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.01 mm | Up to 300 mm; ±0.02 mm beyond |

| Positional Tolerance | ±0.015 mm | Relative to datum |

| Flatness | 0.01 mm per 100 mm | Verified via CMM |

| Circular Runout | 0.01 mm | Full surface measurement |

| Surface Roughness (Ra) | 0.8 – 3.2 µm | Adjustable per requirement |

| Angular Features | ±0.05° | 5-axis precision alignment |

These capabilities are backed by a team of experienced CNC engineers and quality technicians who collaborate closely with clients during prototyping and production ramp-up. Wuxi Lead Precision Machinery is committed to delivering not just parts, but engineered solutions that meet the evolving demands of modern automotive and mobility innovation.

Material & Finish Options

Material Selection Strategy for High-Performance Automotive & Mobility Components

Selecting the optimal material is a critical engineering decision directly impacting performance, weight, durability, and cost in automotive and mobility applications. At Wuxi Lead Precision Machinery, we prioritize material science expertise to ensure your components meet stringent industry demands. Aluminum alloys remain the dominant choice for weight-sensitive applications like EV chassis, suspension arms, and thermal management systems, offering an exceptional strength-to-weight ratio. Steel variants, particularly high-strength low-alloy (HSLA) and stainless grades, are essential for structural safety components requiring maximum impact resistance. Titanium, while higher cost, is increasingly vital for high-temperature exhaust systems and critical fasteners where ultimate strength and corrosion resistance in extreme environments are non-negotiable. The choice fundamentally hinges on balancing specific application loads, environmental exposure, lifecycle requirements, and production economics.

Aluminum alloys 6061-T6 and 7075-T6 represent the core of our high-volume automotive machining. 6061-T6 provides an excellent balance of moderate strength, superior weldability, and good corrosion resistance, making it ideal for brackets, housings, and frames. 7075-T6 delivers significantly higher strength, crucial for suspension links and high-stress structural nodes, though with reduced corrosion resistance and weldability compared to 6061. Understanding these nuances is paramount. Below is a comparative overview of key properties:

| Material Grade | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Typical Automotive Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | Excellent | Very Good | Brackets, Housings, Frames, Heat Sinks |

| Aluminum 7075-T6 | 2.81 | 572 | Moderate | Good | Suspension Links, High-Stress Nodes, Fittings |

| Steel 4140 | 7.85 | 655 | Moderate (Requires Coating) | Good | Axles, Gears, Drive Components |

| Titanium Gr 5 (6Al-4V) | 4.43 | 900 | Excellent | Fair | Exhaust Components, Critical Fasteners, High-Temp Brackets |

Surface finishing, particularly anodizing, is not merely aesthetic for aluminum parts in mobility. It is an engineered process critical for enhancing wear resistance, electrical insulation, and long-term corrosion protection against road salts and environmental exposure. Type II (Sulfuric Acid) anodizing provides a robust, decorative, and protective layer suitable for most interior and exterior non-critical wear parts. For components facing severe abrasion or requiring stringent electrical isolation – such as sensor mounts or high-wear bushings – hardcoat Type III anodizing delivers a significantly thicker, harder ceramic layer. Precise process control during anodizing is essential; variations in voltage, temperature, or electrolyte concentration directly impact coating integrity, adhesion, and dimensional stability, especially on tight-tolerance features. Our integrated finishing capabilities ensure consistent, specification-compliant results meeting ISO and OEM standards.

Material selection transcends basic properties; it requires deep application understanding. Wuxi Lead Precision Machinery combines advanced CNC manufacturing with materials engineering consultation. We analyze your specific load cases, environmental factors, and lifecycle goals to recommend the precise alloy and finish combination, optimizing performance while controlling cost and ensuring manufacturability. Partner with us to transform material potential into reliable, high-value mobility solutions.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process begins with meticulous design engineering, where performance, durability, and manufacturability converge. Our engineering team collaborates closely with clients in the automotive and mobility sectors to translate conceptual requirements into detailed 3D CAD models and technical drawings. Utilizing advanced simulation software, we conduct structural, thermal, and tolerance analyses to ensure each aluminium component meets exact functional and safety standards. Design for Manufacturing and Assembly (DFM/A) principles are rigorously applied to optimize part geometry, reduce material waste, and streamline downstream processes. This phase establishes the foundation for zero-defect production by identifying and resolving potential issues before any material is cut.

Prototyping: Validating Performance and Fit

Once the design is finalized, we proceed to precision prototyping using state-of-the-art CNC machining centers. Prototypes are manufactured from high-grade aluminium alloys such as 6061-T6 and 7075-T6, selected for their strength-to-weight ratio and corrosion resistance—critical attributes in automotive applications. These functional prototypes undergo comprehensive validation, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and real-world fitment testing in client assemblies. Feedback from this stage is integrated into final design refinements, ensuring full compliance with performance and regulatory standards. Our rapid prototyping capability accelerates time-to-market while maintaining the highest fidelity to production intent.

Mass Production: Scalable Precision with Zero Defects

With design and prototype approval, we transition seamlessly into high-volume manufacturing. Our automated CNC machining lines operate under strict ISO 9001-certified quality management systems, enabling consistent output across batches of any scale. Each aluminium component is machined with micron-level accuracy, supported by in-process gauging and real-time tool wear monitoring. To uphold our zero-defect commitment, every part undergoes 100% visual inspection and statistical sampling with full traceability. We employ advanced coolant and chip management systems to maintain surface integrity and prolong tool life, essential for sustained precision in long production runs.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material Grades | 6061-T6, 7075-T6, 2024-T3, Custom Alloys |

| Tolerance Range | ±0.005 mm to ±0.025 mm (per feature) |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (customizable) |

| Max Workpiece Size | 1200 mm × 800 mm × 600 mm |

| Production Capacity | Up to 50,000 units/month (per part) |

| Quality Standards | ISO 9001:2015, IATF 16949 (Automotive) |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester |

This end-to-end process—spanning intelligent design, verified prototyping, and defect-free mass production—ensures that every aluminium component we deliver meets the exacting demands of modern automotive and mobility engineering.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Aluminum Solutions in Automotive & Mobility

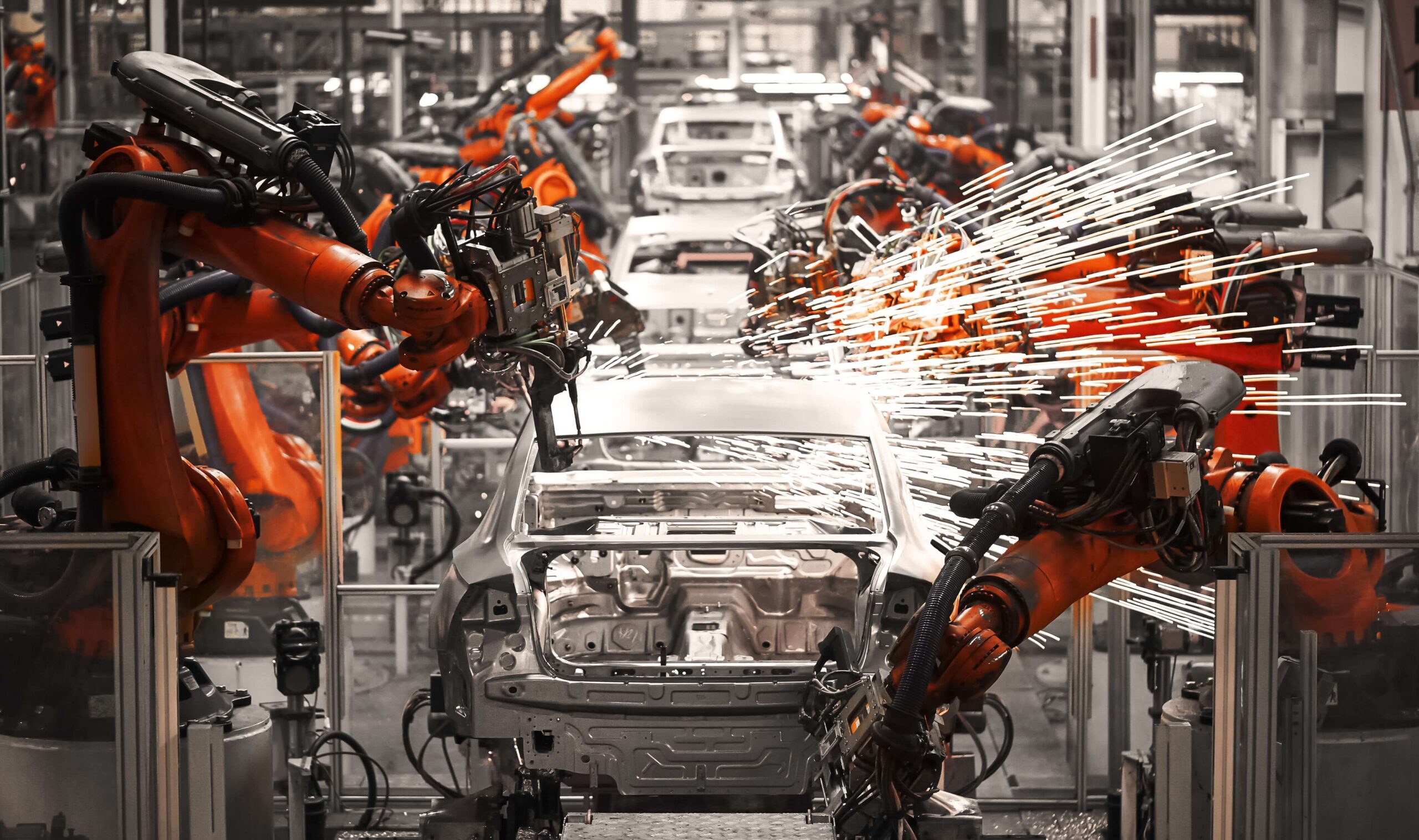

Precision aluminum components define modern mobility, from lightweight EV structural frames to intricate thermal management systems and high-integrity safety components. In this demanding landscape, your choice of manufacturing partner directly impacts vehicle performance, safety compliance, and time-to-market. Wuxi Lead Precision Machinery is engineered to be your strategic manufacturing partner, not merely a supplier. We bridge the gap between ambitious automotive design and flawless, scalable production through deep material science expertise and uncompromising process control.

Our specialization in complex aluminum machining for Tier 1 suppliers and OEMs ensures your critical components meet the exacting standards of the global automotive sector. We understand the non-negotiable requirements: zero-defect delivery, rigorous traceability, adherence to IATF 16949 protocols, and the ability to rapidly scale from prototyping to high-volume production. Our advanced CNC infrastructure, coupled with in-house secondary operations including precision anodizing and laser marking, provides a single-source solution that eliminates supply chain complexity and quality risks inherent in multi-vendor approaches. When your project demands micron-level tolerances on challenging alloys like 6061-T6, 7075-T73, or custom castings, our engineering team collaborates from the design phase to optimize manufacturability, reduce waste, and accelerate your development cycle.

The table below summarizes our core capabilities relevant to automotive aluminum applications:

| Capability Category | Specific Parameters | Automotive Relevance |

|---|---|---|

| Material Expertise | 6061, 7075, 2024, 5052, A356 Castings, Custom Alloys | Lightweighting, structural integrity, thermal management |

| Machining Precision | Tolerances: ±0.005mm (0.0002″), Surface Finish: Ra 0.4µm (16 µin) achievable | Critical sealing surfaces, bearing fits, sensor mounts |

| Equipment Scale | 5-Axis Milling (up to Ø1200mm x 1000mm H), High-Speed Milling, Precision Turning | Complex brackets, housings, suspension components |

| Quality Assurance | IATF 16949 Certified, CMM (Zeiss), Optical Comparators, In-Process Gauging, Full Traceability | PPAP compliance, zero-defect programs, recall prevention |

| Production Scalability | Prototype to 50,000+ units/year, 2-4 week standard lead time for complex parts | Agile response to program launches and volume ramps |

Moving beyond component supply, we integrate seamlessly into your engineering workflow. Our dedicated project managers and applications engineers provide proactive technical support, real-time production data, and collaborative problem-solving for design for manufacturing (DFM) challenges. This partnership approach minimizes risk, ensures consistent quality across batches, and delivers tangible cost savings through optimized processes. The automotive and mobility sector demands more than machining; it requires a partner invested in your innovation and success.

Elevate your aluminum component supply chain with a manufacturer built for the future of mobility. Contact our engineering team today to discuss how Lead Precision’s capabilities can solve your most complex machining challenges and accelerate your next-generation vehicle programs. Reach out directly at [email protected] for a confidential consultation and technical capability review. Let us prove why leading automotive innovators trust Lead Precision as their strategic manufacturing partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.