Technical Contents

Engineering Guide: Aluminium Cnc Machining China

Engineering Insight: Precision in Aluminium CNC Machining in China

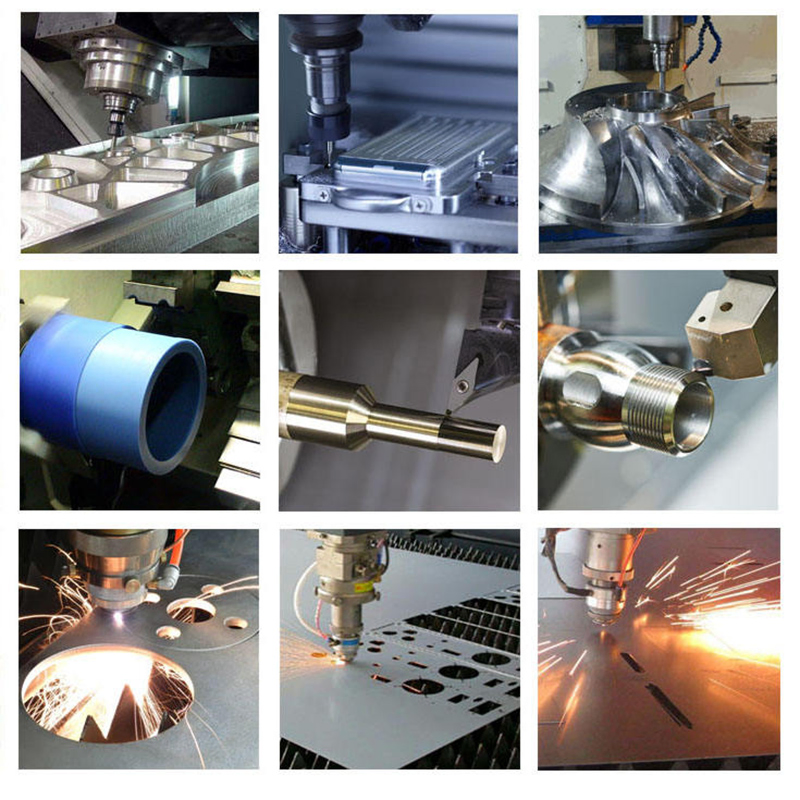

In the realm of high-performance manufacturing, aluminium CNC machining stands as a cornerstone for industries demanding lightweight strength, thermal efficiency, and exceptional machinability. In China, the evolution of precision engineering has positioned domestic manufacturers as competitive global partners—especially in sectors where tolerances are measured in microns and reliability is non-negotiable. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a specification; it is a philosophy embedded in every stage of the machining process.

Aluminium, with its favourable strength-to-weight ratio and excellent thermal conductivity, is widely used in aerospace, automotive, medical, and high-end industrial applications. However, its softness and thermal expansion characteristics require meticulous control during CNC machining. Even minor deviations in tool path, spindle speed, or coolant application can compromise part integrity. This is where advanced CNC capabilities, combined with deep material expertise, become critical. At Lead Precision, our machining centres operate under strict environmental controls, ensuring dimensional stability and repeatability across production runs.

Our commitment to precision is underscored by our involvement in projects of the highest national and international standards. We have delivered mission-critical aluminium components for military-grade equipment and infrastructure supporting Olympic-level athletic facilities. These applications demanded not only adherence to ISO and AS9100 standards but also the ability to innovate within tight tolerances and complex geometries. Our engineers employ multi-axis CNC milling and turning centres, equipped with high-speed spindles and real-time tool monitoring systems, to achieve surface finishes down to Ra 0.8 µm and tolerances within ±0.005 mm.

Material selection is equally vital. We work with a range of aluminium alloys—including 6061, 7075, and 2024—tailoring machining strategies to each alloy’s unique properties. For instance, 7075 aluminium, favoured in aerospace for its high strength, requires optimized cutting parameters to prevent work hardening and tool wear. Our in-house metallurgical analysis ensures compatibility between material, design, and application environment.

Beyond machinery and materials, precision is sustained through rigorous quality assurance. Every component undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and 3D scanning technologies. This end-to-end traceability ensures that every part meets or exceeds client specifications.

The following table outlines key capabilities of our aluminium CNC machining services:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Tolerance Range | ±0.005 mm typical |

| Surface Finish | Ra 0.8 – 3.2 µm (adjustable) |

| Common Alloys | 6061, 7075, 2024, 5052, 6082 |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centres |

| Quality Standards | ISO 9001, AS9100 (aerospace) |

At Wuxi Lead Precision Machinery, we blend technical mastery with proven experience in high-stakes industries to deliver aluminium CNC machining solutions that meet the most exacting global demands. Precision isn’t just our standard—it’s our promise.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum CNC Machining at Wuxi Lead

Wuxi Lead Precision Machinery delivers advanced aluminum CNC machining solutions engineered for the most demanding aerospace, medical, and industrial applications. Our core strength lies in sophisticated 5-axis simultaneous machining, enabling the production of complex geometries with exceptional accuracy and reduced setup times. This capability eliminates the need for multiple fixtures, minimizing cumulative error and ensuring superior part integrity critical for high-performance aluminum components. We operate a modern fleet of Haas and DMG MORI 5-axis CNC machining centers, specifically optimized for aluminum alloys. These machines feature high-speed spindles, rigid construction, and advanced thermal stability protocols essential for maintaining tight tolerances during extended production runs. Our programming leverages Mastercam and Siemens NX CAM to generate highly efficient, collision-free toolpaths that maximize material removal rates while preserving surface finish quality and dimensional control inherent to aluminum processing.

Precision aluminum machining demands specialized process knowledge beyond standard CNC operation. Our engineering team implements rigorous protocols addressing aluminum’s unique characteristics, including optimized coolant strategies for chip evacuation and heat management, specialized tooling geometries to prevent built-up edge, and vibration damping techniques for thin-wall features. Every stage of production adheres to strict in-process inspection routines. Final verification is non-negotiable, performed exclusively using Zeiss CONTURA G2 and Wenzel LH877 coordinate measuring machines (CMMs). These systems operate within a certified ISO 17025 calibration laboratory, providing traceable, NIST-aligned measurement data for every critical feature. Comprehensive first-article inspection reports (FAIRs) and production batch certifications are standard deliverables, ensuring full dimensional conformance and material verification per client specifications.

Our commitment to precision is quantifiable through consistently achieved tolerances across diverse aluminum components. The table below outlines our standard and premium capability ranges for common feature types. Achieving these specifications requires the integrated application of our advanced equipment, meticulous process control, and expert operator oversight. We partner with clients during the design phase to optimize manufacturability, ensuring tolerance requirements are both achievable and cost-effective within the context of high-integrity aluminum part production. This disciplined approach, combined with our integrated supply chain within China, delivers unparalleled value without compromising on the stringent quality expectations of global high-tech industries.

| Feature Type | Standard Capability | Premium Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.005 mm |

| Angular Tolerances | ±0.1° | ±0.02° |

| Positional Tolerance | ±0.03 mm | ±0.01 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Profile Tolerance | ±0.05 mm | ±0.015 mm |

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the right material for CNC machining is critical to achieving optimal performance, durability, and cost-efficiency in high-precision components. At Wuxi Lead Precision Machinery, we specialize in machining aluminum, steel, and titanium—each offering distinct advantages depending on the application requirements. Understanding the mechanical properties, machinability, and compatibility with surface treatments such as anodizing enables engineers and procurement teams to make informed decisions.

Aluminum stands out as the most widely used material in precision CNC machining due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly favored in aerospace, automotive, and electronics industries where lightweight yet rigid components are essential. The 6061 and 7075 aluminum alloys are among the most commonly machined grades, offering good weldability and high tensile strength. Aluminum is also highly compatible with anodizing, a surface treatment that enhances wear resistance and provides electrical insulation. Type II and Type III (hard coat) anodizing are routinely applied to aluminum parts at our facility, delivering durable, corrosion-resistant finishes in various colors.

Steel, particularly stainless steel grades such as 304 and 316, is selected when superior strength, hardness, and resistance to high temperatures or corrosive environments are required. While heavier than aluminum, steel offers exceptional durability and is ideal for industrial machinery, medical devices, and structural components. Its machinability is moderate compared to aluminum, requiring more robust tooling and slower cutting speeds, but we employ advanced CNC strategies to maintain tight tolerances and surface quality. Unlike aluminum, steel cannot be anodized but can be treated with passivation, plating, or powder coating for enhanced protection.

Titanium, though more challenging and costly to machine, is indispensable in mission-critical applications such as aerospace, defense, and biomedical engineering. Known for its outstanding strength-to-density ratio and resistance to extreme environments, titanium maintains integrity under high stress and temperature. Its low thermal conductivity, however, leads to heat buildup during machining, necessitating specialized tooling and precise process control. While titanium does not support conventional anodizing, it can undergo specialized oxide layer treatments for improved surface hardness and biocompatibility.

Below is a comparative overview of key properties for these materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Anodizing Compatible | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Excellent | Yes (Type II & III) | Aerospace, Electronics, Automotive |

| Steel 304 | 8.0 | 505 | Moderate | No | Medical, Food Processing, Industrial |

| Titanium Gr5 | 4.5 | 895 | Poor | No (special oxide only) | Aerospace, Defense, Biomedical |

At Wuxi Lead Precision Machinery, we support comprehensive material and finish selection based on functional requirements, environmental exposure, and production volume. Our engineering team collaborates closely with clients to ensure every machined component meets the highest standards of precision and performance.

Manufacturing Process & QC

Precision Aluminum CNC Machining: From Concept to Flawless Production

Precision begins at conception. Our aluminum CNC machining process integrates engineering rigor with manufacturing excellence, ensuring every component meets aerospace and medical-grade standards. The journey starts with collaborative design review, where our engineers analyze CAD models for manufacturability, material efficiency, and thermal stability specific to aluminum alloys. We identify potential stress points, optimize tool paths to minimize chatter, and validate tolerances against ISO 2768-mK standards. This phase eliminates 90% of downstream errors before metal is cut, reducing client risk and accelerating time-to-market.

Prototyping transforms validated designs into physical benchmarks. Using HAAS and DMG MORI 5-axis CNC centers, we machine initial units from client-specified aluminum grades under controlled conditions. Each prototype undergoes rigorous dimensional verification via Zeiss CONTURA CMMs and surface roughness testing per ISO 1302. Critical features—such as thin walls, complex cavities, or tight-tolerance bores—are stress-tested for deflection and thermal expansion. Feedback loops between our metrology lab and programming team refine G-code for mass production, ensuring thermal compensation algorithms account for aluminum’s 23.1 µm/m°C coefficient of linear expansion. Only when prototypes achieve zero deviations against the digital twin do we proceed.

Mass production executes with uncompromising zero-defect discipline. Our Wuxi facility employs Statistical Process Control (SPC) monitoring in real-time: Renishaw probes verify workpiece alignment within ±2µm before each operation, while in-process gauging checks critical dimensions after every 10 cycles. All aluminum parts—particularly 6061-T6 and 7075-T7351—undergo 100% post-machining inspection against ASME Y14.5 GD&T callouts. Automated coolant filtration maintains chip-free surfaces, and humidity-controlled storage prevents oxidation. This closed-loop system, certified to ISO 9001:2015 and IATF 16949, delivers consistent Cpk >1.67 across 10,000+ part runs.

Aluminum CNC Machining Specifications

| Parameter | Capability | Standard Tolerance | Material Options |

|---|---|---|---|

| Max Work Envelope | 1200 x 800 x 650 mm | ±0.005 mm | 6061-T6, 7075-T6, 2024, 5052 |

| Positional Accuracy | ±0.003 mm (5-axis) | ±0.002 mm | Custom aerospace alloys |

| Surface Finish | Ra 0.4 µm (as-machined) | Ra 0.8 µm | Anodizing-ready preps |

| Feature Complexity | Multi-face, deep cavities, micro-threads | ±0.01 mm (±0.0004″) | Heat-treated variants |

This end-to-end control—from digital validation to metrology-backed production—eliminates scrap, rework, and supply chain delays. At Wuxi Lead, aluminum isn’t merely machined; it’s perfected through engineered predictability. Partner with us to convert design intent into defect-free reality, backed by China’s most responsive precision infrastructure.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Aluminium CNC Machining in China

When it comes to high-precision aluminium components for aerospace, automotive, medical, and industrial applications, the choice of manufacturing partner directly impacts product performance, compliance, and time to market. At Wuxi Lead Precision Machinery, we specialize in delivering mission-critical aluminium CNC machined parts with micron-level accuracy, superior surface finishes, and full traceability. Our advanced manufacturing ecosystem, combined with decades of engineering expertise, positions us as the preferred partner for global OEMs and tier-one suppliers seeking reliable, scalable, and high-quality production in China.

Our facility in Wuxi is equipped with a comprehensive range of CNC machining centers, including 3-, 4-, and 5-axis vertical and horizontal machines, enabling us to tackle complex geometries and tight-tolerance requirements with ease. We process a wide array of aluminium alloys—such as 6061, 7075, 2024, and 5052—tailored to meet specific mechanical, thermal, and corrosion-resistant needs. Every component undergoes rigorous in-process and final inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers, ensuring adherence to ISO 9001:2015 and customer-specific quality standards.

We understand that precision is only one dimension of excellence. Responsiveness, scalability, and technical collaboration are equally vital. Our engineering team works closely with clients from design for manufacturability (DFM) analysis through prototyping and full production, reducing lead times and minimizing costly iterations. With streamlined logistics and export experience across North America, Europe, and Asia, we ensure on-time delivery without compromise.

Whether you require low-volume prototypes or high-volume production runs, our flexible manufacturing model supports rapid turnaround and consistent repeatability. We maintain full material certifications, first-article inspection (FAI) reports, and production part approval processes (PPAP) upon request, providing complete documentation for regulated industries.

Below are key technical specifications we consistently achieve in aluminium CNC machining:

| Specification | Capability |

|---|---|

| Tolerance | ±0.005 mm (±0.0002″) |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6″) |

| Spindle Speed | Up to 24,000 RPM |

| Axis Configuration | 3, 4, and 5-axis simultaneous |

| Materials | Aluminium 6061, 7075, 2024, 5052, and custom alloys |

| Quality Standards | ISO 9001:2015, FAI, PPAP, RoHS compliant |

Partnering with Wuxi Lead Precision Machinery means gaining a transparent, technically proficient, and results-driven manufacturing ally. We are committed to elevating your production capabilities with precision-engineered aluminium solutions built to perform.

For engineering support, quotes, or technical collaboration, contact us today at [email protected]. Let’s build precision, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.