Technical Contents

Engineering Guide: Aluminium And Titanium Alloy

Engineering Insight: Precision in Aluminium and Titanium Alloy Manufacturing

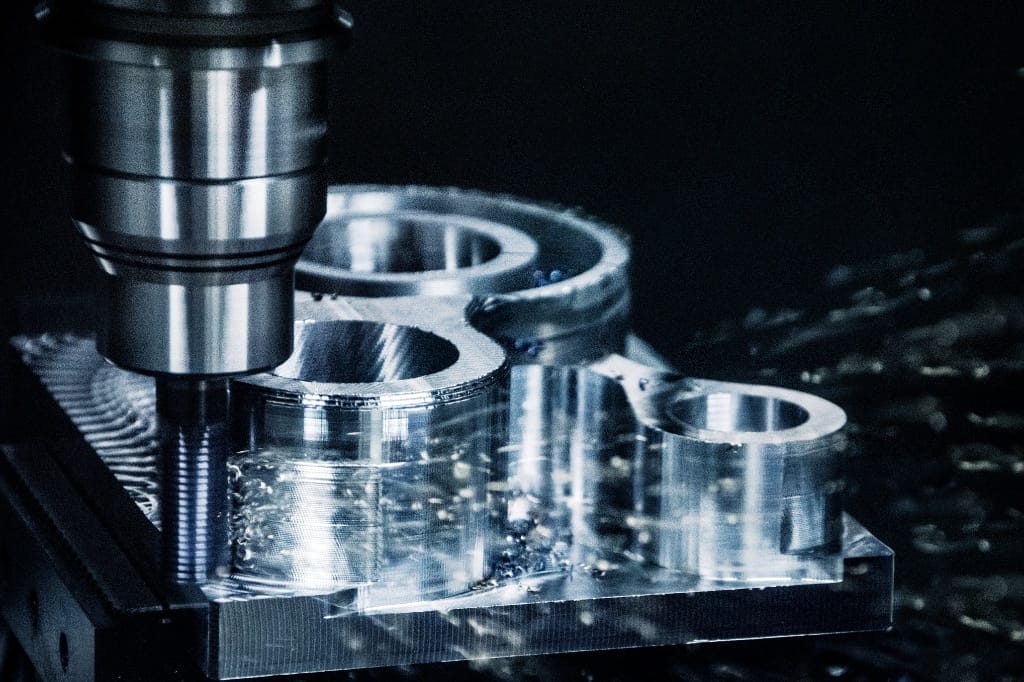

In high-performance industries such as aerospace, defense, and elite sports equipment, the selection of materials is only the beginning. The true determinant of component success lies in the precision of manufacturing—especially when working with advanced alloys like aluminium and titanium. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise structural integrity, fatigue resistance, and operational reliability. This is why our engineering philosophy centers on uncompromising precision, particularly when machining aluminium 7075-T6 and titanium Grade 5 (Ti-6Al-4V), two of the most demanding yet rewarding alloys in modern engineering.

Aluminium alloys offer an exceptional strength-to-weight ratio, making them ideal for applications where weight reduction is critical without sacrificing durability. However, their relatively low melting point and high thermal conductivity demand precise toolpath control and cooling strategies to prevent warping or tool build-up. Titanium, while significantly stronger and more corrosion-resistant, presents its own challenges: extreme work-hardening tendencies, low thermal conductivity, and high chemical reactivity at elevated temperatures. These properties necessitate slow, deliberate machining parameters, rigid setups, and specialized tooling—all of which we have mastered through years of refinement.

Our experience extends beyond commercial applications. Wuxi Lead has delivered mission-critical components for military-grade UAVs and structural elements used in Olympic-level sporting equipment, where the margin for error is zero. These projects demanded not only adherence to tight tolerances—often within ±0.005 mm—but also full traceability, repeatable process validation, and compliance with international quality standards such as ISO 9001 and AS9100. Our CNC machining centers, equipped with high-precision spindles and real-time monitoring systems, ensure dimensional stability across both prototyping and high-volume production runs.

Material selection, while important, is secondary to process control. We employ dynamic fixture systems to minimize part deflection, utilize cryogenic cooling in select titanium operations to reduce thermal expansion, and apply adaptive machining algorithms that adjust feed rates based on real-time tool load feedback. These techniques, combined with our engineers’ deep metallurgical understanding, allow us to extract maximum performance from each alloy.

Below is a comparison of key physical and machining characteristics for the two alloys we most frequently process:

| Property | Aluminium 7075-T6 | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|

| Tensile Strength (MPa) | 570 | 900 |

| Density (g/cm³) | 2.81 | 4.43 |

| Thermal Conductivity (W/m·K) | 130 | 6.7 |

| Elastic Modulus (GPa) | 71.7 | 114 |

| Typical Machining Tolerance | ±0.010 mm | ±0.005 mm |

| Common Applications | Aerospace frames, UAVs | Jet engines, medical implants |

At Wuxi Lead Precision Machinery, we do not merely cut metal—we engineer performance. Our proven expertise in aluminium and titanium alloy machining, backed by real-world success in Olympic and military programs, positions us as a trusted partner for clients who demand excellence in every dimension.

Precision Specs & Tolerances

Technical Capabilities: Precision Machining for Demanding Alloys

Wuxi Lead Precision Machinery delivers uncompromising precision for critical aluminium and titanium alloy components demanded by aerospace, medical, and high-performance industrial sectors. Our core strength lies in mastering the unique challenges posed by these materials, particularly 7075-T6 aluminium and Ti-6Al-4V titanium, which require specialized expertise to achieve stringent tolerances while maintaining structural integrity and surface finish. We leverage advanced 5-axis CNC machining technology as the foundation of our capability, enabling the production of complex, near-net-shape geometries in a single setup. This eliminates cumulative errors inherent in multi-operation processes, significantly enhancing part accuracy and reducing lead times for intricate components such as monolithic structural brackets, fluid manifolds, and implant substructures. Our Haas UMC-750 and DMG MORI CTX beta 1250 5-axis platforms feature high-torque spindles, thermal compensation systems, and rigid constructions specifically optimized for the high cutting forces and heat management critical when machining titanium and the tendency for aluminium to gall.

Precision is non-negotiable in mission-critical applications. Our machining processes consistently achieve tight tolerances across diverse feature types. The table below details our standard achievable capabilities for critical features under controlled production conditions, reflecting the synergy between our advanced equipment, proprietary toolpath strategies, and experienced programming team. It is understood that final achievable tolerance is influenced by specific part geometry, material batch consistency, and feature accessibility.

| Material | Feature Type | Standard Tolerance (mm) | Wuxi Lead Capability (mm) |

|---|---|---|---|

| Aluminium Alloy | Linear Dimension | ±0.025 | ±0.005 |

| Aluminium Alloy | Hole Diameter (Reamed) | ±0.012 | ±0.003 |

| Aluminium Alloy | Profile / Form | ±0.050 | ±0.010 |

| Titanium Alloy | Linear Dimension | ±0.050 | ±0.010 |

| Titanium Alloy | Hole Diameter (Reamed) | ±0.025 | ±0.005 |

| Titanium Alloy | Profile / Form | ±0.100 | ±0.020 |

Verification of this precision is paramount. Every critical dimension undergoes rigorous validation using state-of-the-art Coordinate Measuring Machines (CMM), including our Zeiss CONTURA G2 equipped with VAST XT gold sensor technology. Our inspection regime is not merely a final check; it is integrated throughout the manufacturing process. First-article inspections are mandatory, and in-process checks ensure dimensional stability during extended machining cycles, especially vital for thin-walled titanium structures prone to deflection. All inspection data is meticulously documented against the client’s CAD model, generating comprehensive AS9102 or client-specific dimensional reports. This closed-loop quality process guarantees that every component shipped meets or exceeds the specified requirements, providing our clients with absolute confidence in part performance and regulatory compliance. Partnering with Wuxi Lead means your most demanding aluminium and titanium alloy components are manufactured and verified to the highest standards of dimensional accuracy and repeatability.

Material & Finish Options

Material Selection for High-Performance Precision Components

In high-end custom metal manufacturing, selecting the appropriate material is critical to achieving optimal performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision components for aerospace, medical, and advanced industrial applications where material integrity directly impacts operational success. Among the most widely used materials in our production are aluminum alloys, titanium alloys, and high-strength steels—each offering unique mechanical and chemical properties suited to specific engineering demands.

Aluminum alloys are favored for their excellent strength-to-weight ratio, thermal conductivity, and machinability. Series such as 6061 and 7075 are commonly selected for structural and aerospace components where lightweight performance is essential. These alloys respond well to heat treatment and are highly compatible with precision CNC machining, enabling tight tolerances and complex geometries. When enhanced surface durability is required, aluminum components are typically anodized—a controlled electrochemical process that increases surface hardness, improves corrosion resistance, and allows for color coding in assembly lines.

Titanium alloys, particularly Grade 5 (Ti-6Al-4V), are chosen for extreme environments due to their exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility. These properties make titanium ideal for aerospace, defense, and medical implant applications. While more challenging to machine than aluminum due to work hardening and low thermal conductivity, titanium’s performance under high stress and elevated temperatures justifies its use in mission-critical systems. Specialized tooling and machining parameters are employed at Wuxi Lead to ensure dimensional accuracy and surface integrity.

Stainless and alloy steels remain indispensable in applications requiring high tensile strength, wear resistance, and structural reliability. Materials like 304, 316, and 4140 steel are routinely used in industrial machinery, hydraulic systems, and tooling. Their machinability and response to heat treatment allow for tailored mechanical properties. For enhanced surface performance, additional treatments such as passivation, nitriding, or coating may be applied.

Below is a comparative overview of key material properties relevant to precision manufacturing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 276 | Moderate (improved with anodizing) | Aerospace frames, enclosures |

| Aluminum 7075-T6 | 2.8 | 572 | 503 | Moderate | High-stress structural parts |

| Titanium Ti-6Al-4V | 4.4 | 900 | 830 | Excellent | Aircraft engines, implants |

| Stainless 316 | 8.0 | 580 | 290 | Excellent | Marine, chemical processing |

| Steel 4140 | 7.8 | 655 | 415 | Low (requires coating) | Shafts, tooling, machinery |

Material selection must be guided by functional requirements, environmental exposure, and lifecycle demands. At Wuxi Lead Precision Machinery, our engineering team collaborates with clients to match material characteristics with application needs, ensuring reliability and performance in every component we produce.

Manufacturing Process & QC

Precision Manufacturing Process for Aluminum and Titanium Alloys

At Wuxi Lead Precision Machinery, our production process for critical aluminum and titanium alloy components is engineered for uncompromising quality and zero defects. This rigorous methodology spans three integrated phases: Design, Prototyping, and Mass Production, each governed by stringent aerospace and medical-grade standards. We begin with collaborative engineering during the Design phase. Our team utilizes advanced CAD/CAM software integrated with material science expertise to optimize part geometry, wall thickness, and feature placement specifically for aluminum 7075-T6 or titanium Ti-6Al-4V alloys. Finite Element Analysis (FEA) predicts stress points and thermal behavior, while toolpath simulation ensures machinability and minimizes residual stress. Crucially, we define precise Geometric Dimensioning and Tolerancing (GD&T) callouts and surface finish requirements upfront, establishing the zero-defect baseline for all subsequent stages. Material certification and traceability from approved mills are non-negotiable starting points.

Prototyping transforms the digital model into physical validation. We employ multi-axis CNC milling centers with high-stability spindles and specialized tooling designed for each alloy’s unique properties. Aluminum requires high-speed strategies to manage heat and chip evacuation, while titanium demands lower RPM, rigid setups, and precise coolant application to prevent galling and maintain metallurgical integrity. Every prototype undergoes comprehensive dimensional verification using calibrated Coordinate Measuring Machines (CMM) and surface profilometers. Functional testing, including pressure or load checks where applicable, confirms performance against specifications. This phase is iterative; data from prototype inspection feeds immediate design or process adjustments, eliminating potential failure modes before scaling.

Mass Production leverages the validated process under closed-loop control. Dedicated production cells run on state-of-the-art CNC machines with real-time tool wear monitoring and in-process probing. For aluminum, we implement high-efficiency roughing and ultra-precise finishing cycles. Titanium production utilizes specialized carbide grades, controlled depth-of-cut strategies, and continuous coolant flood to manage heat and ensure surface integrity. Every component undergoes 100% critical dimension inspection via automated CMMs or vision systems integrated into the production line. Statistical Process Control (SPC) charts monitor key parameters like hole diameter or flatness in real-time, triggering automatic process correction at the first sign of drift. Full material traceability, from ingot batch to finished part serial number, is maintained throughout. This systematic approach, combining predictive design, validated prototyping, and tightly controlled mass production, guarantees the zero-defect outcomes demanded by aerospace, medical, and high-performance industrial applications.

Critical Material Properties for Precision Machining

| Property | Aluminum 7075-T6 | Titanium Ti-6Al-4V | Machining Impact |

|---|---|---|---|

| Tensile Strength (MPa) | 500 – 570 | 900 – 1000 | Titanium requires higher machine rigidity & lower feeds |

| Density (g/cm³) | 2.81 | 4.43 | Titanium generates higher cutting forces |

| Thermal Conductivity (W/m·K) | 130 | 7 | Aluminum dissipates heat rapidly; Titanium requires aggressive cooling |

| Modulus of Elasticity (GPa) | 71.7 | 114 | Titanium springs back more, demanding precise tool compensation |

| Typical Surface Finish (Ra µm) | 0.4 – 1.6 | 0.8 – 3.2 | Titanium requires finer tooling & parameters for equivalent smoothness |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Aluminium and Titanium Alloy Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom-engineered components in aluminium and titanium alloys—materials renowned for their strength-to-weight ratios, corrosion resistance, and performance under extreme conditions. As a trusted partner in the global manufacturing ecosystem, we serve industries where precision and reliability are non-negotiable: aerospace, medical technology, defense, and high-performance automotive.

Our advanced CNC machining capabilities, combined with rigorous quality control and material science expertise, allow us to transform complex designs into mission-critical parts with micron-level accuracy. Whether you’re prototyping a new aerospace component or scaling production for medical implants, our engineering team collaborates closely with yours to ensure every specification is met—and exceeded.

We understand that in high-end manufacturing, tolerances are tight, timelines are critical, and compliance is mandatory. That’s why we invest in state-of-the-art 5-axis CNC machines, coordinate measuring machines (CMM), and in-process inspection systems. Our ISO 9001:2015 and ISO 13485 certifications underscore our commitment to quality, traceability, and repeatable precision across every production run.

Our facility in Wuxi, China, is equipped to handle everything from low-volume, high-mix orders to large-scale production, all while maintaining full material certification and documentation. We process a wide range of aluminium alloys—including 2024, 6061, 7075—and titanium grades such as Ti-6Al-4V (Grade 5), commercially pure titanium (Grade 2), and specialized high-strength variants. Surface treatments like anodizing, passivation, and precision polishing are available to meet your functional and aesthetic requirements.

Below are key technical capabilities for our aluminium and titanium alloy machining services:

| Specification | Detail |

|---|---|

| Material Types | Aluminium Alloys (2024, 6061, 7075), Titanium Alloys (Ti-6Al-4V, Grade 2, Grade 5, Grade 9) |

| Machining Processes | 3-axis to 5-axis CNC milling, turning, multi-tasking |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finish | As low as Ra 0.4 µm (16 µin), with polishing to mirror finish |

| Quality Standards | ISO 9001:2015, ISO 13485, full first-article inspection (FAI) reports |

| Certifications | Material test reports (MTR), PPAP, APQP, NDT available on request |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally. Our team is fluent in English and technical documentation standards used globally, ensuring seamless communication and compliance with international requirements.

For your next high-performance component in aluminium or titanium alloy, contact us today. Send your RFQ or design files to [email protected] and receive a detailed technical review and quotation within 24 hours. Let Lead Precision be the foundation of your next breakthrough in advanced manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.