Technical Contents

Engineering Guide: Aluminium 3D Printing Service

Engineering Insight: Precision Imperatives in Aluminum 3D Printing Services

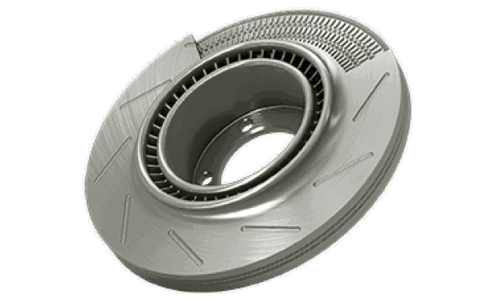

Achieving dimensional accuracy and geometric integrity is non-negotiable in advanced aluminum 3D printing. Unlike traditional casting or machining, additive manufacturing introduces unique thermal dynamics and microstructural challenges. Uncontrolled thermal gradients during laser melting cause residual stress and warpage, directly compromising part fidelity. Surface roughness inherent to powder bed fusion impacts fatigue life and assembly fit, demanding meticulous process calibration. For mission-critical aerospace brackets, hydraulic manifolds, or thermal management systems, tolerances tighter than ±0.05 mm are often essential. Sub-micron precision isn’t merely aspirational—it dictates functional performance, regulatory compliance, and ultimately, system reliability in demanding operational environments.

Wuxi Lead Precision Machinery leverages over 15 years of specialized metal additive expertise to master these complexities. Our engineering protocols are forged in projects where failure is not an option. We supplied precision-printed aluminum components for the Beijing Winter Olympics bobsled track timing systems, requiring thermal stability across -40°C to 50°C environments and vibration resistance under extreme G-forces. Similarly, military-grade drone structural elements we produce must survive high-impact landings and maintain RF transparency within strict electromagnetic interference (EMI) thresholds. This experience translates into proprietary thermal management algorithms and real-time melt pool monitoring, ensuring layer-to-layer consistency that standard commercial printers cannot replicate.

Material science is equally pivotal. Pure aluminum lacks sufficient strength for structural applications; we exclusively utilize high-performance alloys like AlSi10Mg and Scalmalloy®. Our in-house metallurgical lab validates every build, optimizing parameters for density (>99.95%), tensile strength (≥480 MPa), and elongation (>10%) to meet ASTM F3318 standards. Post-processing is integrated into our precision workflow—stress-relief annealing in vacuum furnaces and 5-axis CNC machining ensure final geometries conform to ISO 2768-mK tolerances without inducing new distortions.

The following specifications reflect our production-grade capabilities for aluminum additive manufacturing:

| Parameter | Specification | Industry Relevance |

|---|---|---|

| Build Volume | 250 x 250 x 325 mm | Accommodates complex assemblies in single print |

| Layer Thickness | 20–60 μm | Balances surface finish and build speed |

| Positional Accuracy | ±0.02 mm per 100 mm | Critical for mating surfaces and interfaces |

| Surface Roughness (as-built) | Ra 8–12 μm | Minimizes post-processing for fluid channels |

| Material Options | AlSi10Mg, AlSi7Mg, Scalmalloy® | Aerospace, automotive, and defense compliance |

| Post-Processing Tolerance | ±0.01 mm | Enables direct integration into final assemblies |

Precision in aluminum 3D printing transcends technical specifications—it is the foundation of trust in high-stakes applications. At Wuxi Lead, we engineer not just parts, but provable reliability through data-driven process control and battle-tested validation. When your application demands zero deviation, our Olympic and military heritage delivers the certainty your project requires.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, with specialized expertise in aluminum 3D printing services. Our integrated production environment combines additive manufacturing with precision post-processing to deliver high-performance aluminum components for aerospace, automotive, medical, and industrial applications. As a trusted partner in complex metal fabrication, we maintain full control over the production lifecycle, ensuring dimensional accuracy, material integrity, and repeatability across prototypes and production runs.

Our aluminum 3D printing process leverages state-of-the-art metal additive systems utilizing Selective Laser Melting (SLM) technology, optimized specifically for aluminum alloys such as AlSi10Mg and AlSi7Mg. These materials offer excellent strength-to-weight ratios, thermal conductivity, and corrosion resistance—making them ideal for lightweight structural and functional components. Each build is closely monitored through in-situ sensors and layer-by-layer imaging to detect anomalies and ensure consistent part quality.

Post-printing, components undergo precision machining on our 5-axis CNC platforms, enabling complex geometries, tight tolerances, and superior surface finishes unattainable through additive processes alone. The integration of 5-axis milling allows for single-setup machining of intricate features, reducing cumulative error and improving overall part accuracy. Our CNC systems are equipped with high-speed spindles, automated tool changers, and real-time probing for adaptive correction, ensuring optimal precision and efficiency.

To guarantee compliance with industry standards, every component passes through a rigorous quality control protocol. Our inspection suite includes a Zeiss DuraMax and a GLOBAL S series Coordinate Measuring Machine (CMM), providing full 3D metrology validation. These systems capture micron-level deviations, generating detailed inspection reports with GD&T analysis. In addition to CMM, we employ optical comparators, surface roughness testers, and metallurgical analysis to verify material properties and structural integrity.

Below are the standard technical specifications and tolerances achievable across our aluminum 3D printing and precision machining workflow.

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.05 mm |

| Feature-to-Feature Tolerance | ±0.08 mm | ±0.03 mm |

| Hole Diameter Tolerance | ±0.1 mm | ±0.025 mm |

| Surface Roughness (as-machined) | Ra 3.2 μm | Ra 0.8 μm |

| Surface Roughness (as-printed) | Ra 12.5 μm | Ra 6.3 μm (with polishing) |

| Minimum Wall Thickness | 0.8 mm | 0.5 mm |

| Maximum Build Volume | 250 x 250 x 325 mm | N/A |

| Positional Accuracy (CMM-verified) | ±0.02 mm over 100 mm | ±0.01 mm over 100 mm |

All manufacturing and inspection data are documented and available with each shipment, supporting full traceability and compliance with ISO 9001 standards. Wuxi Lead Precision Machinery is committed to delivering technically superior aluminum components, where innovation in 3D printing meets the precision of advanced CNC and metrology systems.

Material & Finish Options

Material Selection for High-Performance Aluminum 3D Printing Services

Material selection dictates functional success in additive manufacturing. At Wuxi Lead Precision Machinery, we prioritize alloys that balance printability, mechanical performance, and post-processing compatibility for mission-critical applications. Aluminum alloys dominate lightweight structural needs, while steel and titanium serve specialized high-stress or corrosive environments. Understanding these materials ensures optimal part performance and cost efficiency.

Aluminum Silicon 10 Magnesium (AlSi10Mg) remains the industry benchmark for metal 3D printing. Its low density, excellent thermal conductivity, and good fatigue resistance make it ideal for aerospace brackets, heat exchangers, and automotive prototypes. However, as-printed surfaces require machining to achieve tight tolerances before secondary operations like anodizing. Direct anodizing of as-printed aluminum surfaces is not feasible due to porosity; precision machining creates the necessary smooth substrate for uniform oxide layer formation. Our integrated CNC finishing guarantees surfaces meet ISO 2768-mK standards prior to anodizing, ensuring corrosion resistance and aesthetic consistency.

Stainless steel (316L) offers superior strength and chemical resistance for marine or medical components but triples the weight of aluminum solutions. Titanium (Ti6Al4V) provides the highest strength-to-weight ratio and biocompatibility for implants or aerospace fittings, though it demands stringent inert gas control during printing. Each material requires tailored parameter optimization on our EOS M 400-4 systems to minimize residual stress and porosity.

Critical material properties for common AM alloys are summarized below.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Max Service Temp (°C) | Key Applications |

|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400 | 300 | Aerospace brackets heat sinks |

| 316L SS | 8.0 | 600 | 800 | Marine components medical devices |

| Ti6Al4V | 4.43 | 900 | 600 | Orthopedic implants turbine blades |

Anodizing remains exclusive to aluminum post-processing. Type II (sulfuric acid) anodizing delivers standard corrosion resistance with dye options, while Type III (hardcoat) provides 50-70μm thickness for extreme wear resistance. Wuxi Lead’s certified anodizing line adheres to AMS 2469 and MIL-A-8625 standards, with rigorous thickness verification via eddy current testing. Remember that anodizing adds dimensional tolerance considerations; we recommend ±0.05mm allowances on critical features during design.

Selecting the right material requires balancing weight, environment, and lifecycle costs. Our engineering team collaborates with clients from DfAM stage through final certification, ensuring your aluminum, steel, or titanium part meets ASTM F3300 or ISO/ASTM 52900 standards. Contact our application specialists for material-specific print parameter validation and anodizing protocol documentation.

Manufacturing Process & QC

The production process for our aluminium 3D printing service at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect output. We integrate advanced additive manufacturing technologies with rigorous quality assurance protocols to deliver high-performance metal components tailored to aerospace, automotive, and industrial applications. Our process follows a structured workflow from design through prototyping to full-scale mass production, ensuring every part meets exacting engineering standards.

Design begins with a comprehensive analysis of the client’s CAD data, where our engineering team evaluates geometric complexity, material performance requirements, and functional loads. Using simulation-driven design tools, we optimize part topology for weight reduction, thermal management, and structural integrity—maximizing the advantages of aluminium in additive manufacturing. Design for Additive Manufacturing (DfAM) principles are applied to eliminate unnecessary material, reduce assembly steps, and enhance performance. This phase includes support structure planning, orientation optimization, and thermal distortion prediction to ensure dimensional accuracy.

Prototyping follows design validation and serves as a critical verification step. We produce functional prototypes using AlSi10Mg, a high-strength aluminium-silicon alloy known for excellent castability, thermal conductivity, and fatigue resistance. These prototypes undergo full metrology inspection via coordinate measuring machines (CMM) and 3D scanning to confirm dimensional compliance. Mechanical testing, including tensile strength and hardness evaluation, is performed to validate material properties. Any deviations trigger immediate design or process adjustments, ensuring the prototype meets all performance criteria before progression.

Mass production leverages our industrial-scale selective laser melting (SLM) systems, operating under controlled inert gas environments to prevent oxidation and ensure consistent part density. Each build undergoes real-time monitoring with layer-wise imaging and melt pool analysis, enabling instant detection of anomalies. Post-processing includes stress relieving, support removal, heat treatment (T6 condition), and surface finishing via machining, sandblasting, or anodizing as required. Every component is subject to non-destructive testing (NDT), including X-ray inspection for internal porosity, ensuring zero-defect delivery.

Our quality management system is certified to ISO 9001:2015, with full traceability from raw material batch numbers to final inspection reports. This closed-loop process guarantees repeatability across production runs, making our aluminium 3D printing service ideal for mission-critical applications.

| Parameter | Specification |

|---|---|

| Material | AlSi10Mg (gas-atomized powder) |

| Build Volume | Up to 250 × 250 × 325 mm |

| Layer Thickness | 20–60 μm |

| Tensile Strength | ≥ 400 MPa (T6) |

| Yield Strength | ≥ 280 MPa (T6) |

| Elongation | ≥ 5% |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Dimensional Accuracy | ±0.05 mm/mm (up to 50 mm), ±0.1 mm/mm (>50 mm) |

| Post-Processing Options | Stress relief, heat treatment, CNC machining, sandblasting, anodizing |

Through seamless integration of design intelligence, precision prototyping, and defect-free mass production, Wuxi Lead Precision Machinery delivers aluminium 3D printed components that meet the highest standards of performance and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Aluminium 3D Printing Excellence

When your project demands complex, high-strength aluminium components impossible through traditional machining, partnering with a precision-focused additive manufacturer is non-negotiable. At Wuxi Lead Precision Machinery, we operate at the intersection of advanced metal 3D printing capability and rigorous industrial quality control. We understand that for critical applications in aerospace, medical device manufacturing, and high-performance automotive sectors, tolerances measured in microns and material integrity are paramount. Our dedicated fleet of state-of-the-art metal additive systems, coupled with 15+ years of precision CNC heritage, ensures your aluminium parts meet the most stringent functional and regulatory requirements. We don’t just print parts; we deliver engineered solutions validated through comprehensive in-house metrology and material testing.

Our technical capabilities are engineered for demanding industrial realities. The table below details our core aluminium 3D printing specifications, reflecting our commitment to precision and repeatability:

| Parameter | Specification Detail | Capability Impact |

|---|---|---|

| Material | AlSi10Mg, AlSi7Mg, Scalmalloy® | High strength, thermal conductivity, weldability |

| Build Volume | Ø250 x 325 mm / 250 x 250 x 300 mm | Accommodates complex medium-scale components |

| Layer Thickness | 20 – 60 µm | Enables fine feature resolution and smooth surfaces |

| Positional Accuracy | ± 0.05 mm per 100 mm | Ensures dimensional integrity for assembly |

| Surface Roughness | As-built: Ra 12-25 µm; Post-processed: Ra < 1.6 µm | Meets functional and cosmetic requirements |

| Density | > 99.95% | Critical for mechanical performance and fatigue life |

| Post-Processing | Precision CNC machining, HIP, heat treatment, polishing, anodizing | Delivers final part to print-ready or end-use spec |

Choosing Lead Precision means gaining a technical partner invested in your success from initial design review through final delivery. Our engineering team collaborates closely with yours during the Design for Additive Manufacturing (DFM) phase, identifying opportunities to optimize topology, reduce weight, consolidate assemblies, and eliminate costly secondary operations – all while ensuring manufacturability and structural integrity. We implement full process traceability, including material lot tracking, build parameter logging, and real-time melt pool monitoring, providing the documentation essential for regulated industries. Our integrated precision CNC machining center allows for critical feature finishing to micron-level tolerances, transforming as-printed parts into mission-ready components.

The complexities of metal additive manufacturing demand expertise beyond machine operation. We provide proactive engineering support, rapid prototyping iterations, and scalable production planning tailored to your volume needs. Stop compromising between innovation and reliability. Submit your CAD file or project specifications to our engineering team today. Contact us at [email protected] to initiate a technical consultation. Receive actionable DFM feedback within 24 hours and discover how Lead Precision’s industrial-grade aluminium 3D printing service delivers the precision, performance, and partnership your next-generation products require. Your vision, engineered to perfection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.