Technical Contents

Engineering Guide: Alu Cnc

Engineering Insight: Precision Imperatives in Aluminum CNC Machining

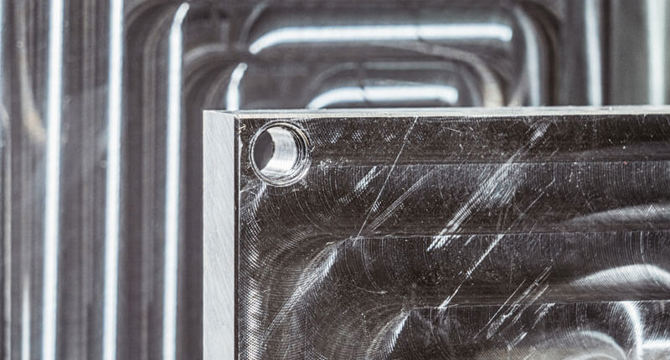

Aluminum CNC machining demands exceptional precision due to the material’s inherent thermal conductivity and low density. Minute thermal fluctuations during high-speed cutting can induce micro-deformations, compromising dimensional stability in critical components. At Wuxi Lead Precision Machinery, we treat precision not as a specification but as a non-negotiable engineering discipline. Our proprietary thermal compensation algorithms actively counteract heat-induced expansion, maintaining tolerances within ±0.001mm even during extended production runs. This capability is vital for aerospace hydraulic manifolds or medical implant interfaces where a single micron of deviation risks system failure.

The challenge intensifies with complex geometries common in modern aluminum parts. Thin-walled structures amplify vibration sensitivity, while pocketing operations risk chatter marks that degrade surface integrity. Our 5-axis milling platforms integrate real-time force feedback systems to dynamically adjust feed rates, ensuring consistent micro-finishes below Ra 0.4µm. This level of control prevents stress concentrations that could initiate fatigue cracks in high-cycle applications.

Wuxi Lead’s precision pedigree is validated through mission-critical deployments. We engineered timing system components for the Beijing Winter Olympics where nanosecond synchronization accuracy was mandatory across sub-zero environments. Similarly, our defense sector partnerships require adherence to MIL-STD-810G vibration and thermal shock protocols for avionics housings. These projects demanded not just machine capability but holistic process validation—from raw billet traceability to in-process CMM verification at every machining phase.

Our investment in metrology infrastructure ensures repeatability beyond standard industry practice. All production cells operate within ISO Class 7 cleanrooms, with environmental controls maintaining ±0.5°C stability. This infrastructure supports clients in semiconductor tooling and satellite subsystems where particle contamination or thermal drift could invalidate millions in R&D investment.

Below outlines the technical foundation enabling our aluminum precision standards:

| Parameter | Specification | Industry Standard | Lead Precision Standard |

|---|---|---|---|

| Positioning Accuracy | ±0.005mm | ±0.008mm | ±0.001mm |

| Repeatability | 0.003mm | 0.005mm | 0.0005mm |

| Surface Roughness (Ra) | 0.8µm | 1.6µm | 0.2–0.4µm |

| Thermal Compensation | Basic offset | None | Real-time 3D mapping |

| Process Capability (CpK) | ≥1.33 | ≥1.00 | ≥2.00 |

Precision in aluminum CNC transcends machine capability—it requires integrating material science, environmental control, and closed-loop verification. At Wuxi Lead, we engineer this ecosystem to transform aluminum’s challenges into competitive advantages for clients where failure is not an option. Partner with us to convert demanding specifications into flawless deliverables, backed by documented success in the world’s most exacting applications.

Precision Specs & Tolerances

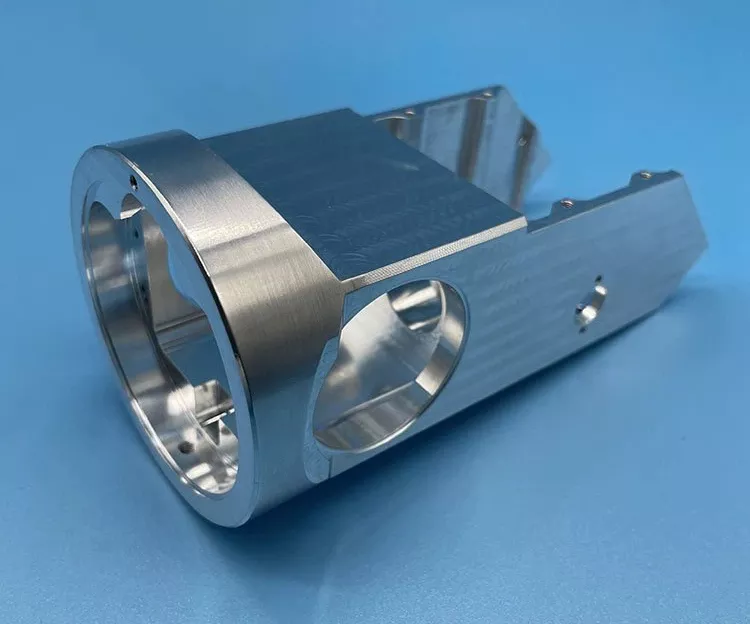

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, specializing in high-complexity components for aerospace, medical, automotive, and industrial applications. Our core strength lies in the integration of 5-axis CNC machining technology, enabling the production of intricate geometries with superior accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC centers allow simultaneous movement across multiple planes, reducing the need for part repositioning and ensuring tighter tolerances throughout the machining cycle.

Our 5-axis CNC machines are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain optimal cutting conditions. This advanced setup supports a wide range of aluminum alloys, including 6061, 7075, and 2024, ensuring material integrity and dimensional stability. The ability to approach a workpiece from multiple angles in a single setup not only enhances precision but also significantly reduces lead times and improves overall part consistency.

To maintain the highest quality standards, every component undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machine (CMM) technology. Our CMM systems provide full 3D metrology validation, ensuring that each part conforms to the original CAD specifications. Data from CMM inspections is documented and traceable, supporting full compliance with ISO 9001 and AS9100 quality management standards. This closed-loop quality control process allows for immediate corrective actions, minimizing deviations and ensuring repeatable accuracy across production batches.

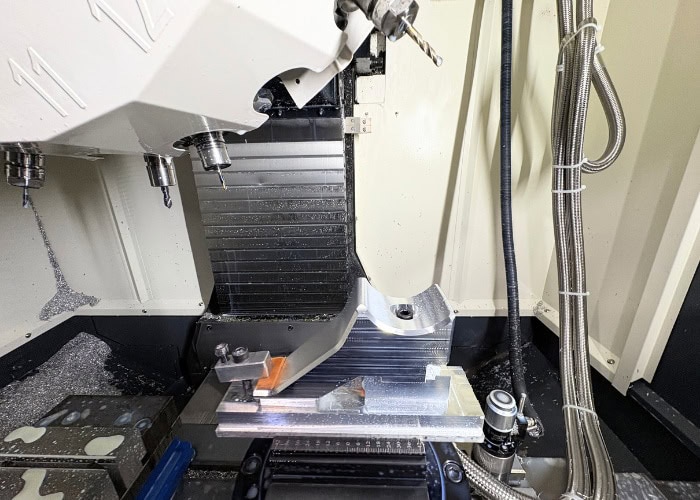

In addition to advanced equipment and inspection protocols, our engineering team employs sophisticated CAM software to optimize toolpaths, minimize tool wear, and maximize material removal rates. This digital integration ensures efficient machining strategies tailored to the unique requirements of each alu CNC project.

The following table outlines the standard technical specifications and tolerances achievable with our 5-axis CNC machining process for aluminum components:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per 100 mm) | ±0.01 mm |

| Angular Tolerance | ±0.02° |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish available) |

| Maximum Work Envelope | 1,200 x 800 x 600 mm |

| Material Compatibility | Aluminum Alloys (6061, 7075, 2024, etc.) |

| Inspection Method | CMM (Coordinate Measuring Machine) |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with disciplined quality assurance to deliver alu CNC components that meet the most demanding engineering requirements. Our technical capabilities are designed to support innovation, reliability, and precision in every manufactured part.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in precision CNC components. At Wuxi Lead Precision Machinery, our engineering expertise ensures material properties align precisely with your application’s mechanical, environmental, and regulatory demands. Aluminum remains the dominant choice for high-volume, lightweight structural parts due to its exceptional strength-to-weight ratio, thermal conductivity, and inherent corrosion resistance. Grades like 6061-T6 offer excellent weldability and machinability for general aerospace and automotive housings, while 7075-T6 delivers superior strength for critical flight components. Steel alloys, particularly 303 and 304 stainless, provide unmatched durability, wear resistance, and structural integrity for high-stress industrial machinery and medical devices requiring stringent biocompatibility. Titanium, though more challenging to machine, is indispensable in extreme environments—such as aerospace actuators or medical implants—where its corrosion resistance, biocompatibility, and strength at elevated temperatures outweigh higher material and processing costs. Each material demands specific CNC parameters; improper tooling or speeds can cause work hardening, poor surface finish, or dimensional instability.

Critical Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Common Grades |

|---|---|---|---|---|

| Aluminum | 2.7 | 125-570 | Excellent (A) | 6061-T6, 7075-T6 |

| Stainless Steel | 7.9 | 505-860 | Moderate (C) | 303, 304, 17-4 PH |

| Titanium | 4.5 | 900-1100 | Poor (D) | Gr2, Gr5 (Ti-6Al-4V) |

Surface finishing, particularly anodizing for aluminum, significantly enhances functional performance. Type II (sulfuric acid) anodizing provides robust corrosion and wear resistance with dyeing capability for identification, while Type III (hard coat) delivers superior abrasion resistance for hydraulic components or high-wear interfaces. Crucially, anodizing adds dimensional thickness (typically 0.0002-0.001 inches per surface), requiring precise pre-machining allowances to maintain critical tolerances. Our certified anodizing partners adhere to AMS 2469 and ISO 7599 standards, ensuring uniform coating thickness and adhesion. For steel, passivation or electropolishing meets medical ISO 13485 requirements, while titanium often requires specialized etching prior to anodizing for optimal results.

Material choice directly impacts manufacturability, lead time, and total cost of ownership. Aluminum’s machinability allows faster cycle times and lower tooling wear, making it ideal for complex geometries at scale. Steel necessitates rigid setups and carbide tooling to manage heat and chip control, while titanium requires reduced feeds/speeds and coolant optimization to prevent galling. Wuxi Lead integrates material science with advanced 5-axis CNC capabilities and stringent in-process metrology (up to ±0.0002 inches) to mitigate these challenges. We collaborate early in your design phase to recommend materials and finishes that balance performance requirements with production efficiency, ensuring components meet aerospace AS9100 or medical certification demands without over-engineering. Consult our engineering team to optimize your material specification for yield, reliability, and total value.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the production process for aluminum CNC components begins with a meticulous design phase. Our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models. Utilizing advanced software such as SolidWorks, AutoCAD, and Siemens NX, we ensure that every geometric feature, tolerance, and surface finish aligns with functional and manufacturing constraints. Design for Manufacturability (DFM) analysis is conducted early to identify potential challenges, optimize tool paths, and reduce material waste. This proactive approach ensures that the final design is not only technically sound but also cost-efficient for high-volume production. Thermal expansion properties of aluminum alloys are factored in to maintain dimensional stability under operational conditions.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototype development using high-precision 5-axis CNC machining centers. Prototypes are produced from the same aerospace-grade aluminum alloys—such as 6061-T6 and 7075-T6—as intended for mass production, ensuring material consistency. Each prototype undergoes rigorous in-house inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Functional testing, including fit checks, thermal cycling, and load simulation, verifies performance under real-world conditions. Feedback from this stage is integrated into the final process validation, minimizing risk during full-scale production. The prototype phase is critical in achieving our zero-defect objective, allowing us to refine processes before committing to volume runs.

Mass Production: Precision, Consistency, Zero Defects

With design and prototype approval, we transition to mass production on automated CNC cells equipped with tool wear monitoring, in-process gauging, and robotic part handling. Our facility in Wuxi operates under ISO 9001-certified quality management systems, ensuring full traceability from raw material to finished component. Every production batch is subjected to statistical process control (SPC), with real-time data tracking key parameters such as spindle load, tool life, and dimensional drift. We implement a zero-defect philosophy through layered quality checks: 100% visual inspection for surface defects and automated dimensional verification on critical features. Any deviation triggers immediate process correction, preventing non-conforming parts from progressing.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6, 2024-T3, 5052-H32 |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (customizable) |

| Max Work Envelope | 1200 x 800 x 600 mm |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| Quality Standards | ISO 9001, ISO 14001, RoHS compliant |

| Production Capacity | Up to 50,000 units/month |

Through seamless integration of design validation, precision prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers aluminum CNC components that meet the most demanding industrial standards. Our process is engineered for repeatability, reliability, and zero defects—every time.

Why Choose Wuxi Lead Precision

Elevate Your Aluminum Manufacturing with Precision Partnership

Aluminum CNC machining demands more than standard equipment—it requires engineering mastery to overcome material challenges like thermal expansion, chip evacuation, and surface integrity. At Wuxi Lead Precision Machinery, we transform these complexities into competitive advantages for global manufacturers. Our dedicated focus on aluminum alloys—from 6061-T6 to 7075 aerospace grades—ensures components meet exacting functional and aesthetic standards while optimizing production economics. As your technical partner, we integrate deep metallurgical knowledge with agile manufacturing processes, eliminating costly iterations and delays inherent in generic CNC services.

Our facility operates under ISO 9001:2015 and IATF 16949 frameworks, with engineering teams trained in German precision methodologies. This commitment translates to measurable outcomes: reduced scrap rates, accelerated time-to-assembly, and seamless scalability from prototypes to high-volume runs. Below details our core aluminum machining capabilities:

| Specification | Performance Range |

|---|---|

| Material Compatibility | 6061, 7075, 2024, 5052, 2014 |

| Tolerance Control | ±0.005 mm (micron repeatability) |

| Max Work Envelope | 1200 x 800 x 650 mm |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm |

| Spindle Speed | 24,000 RPM (optimized for Al) |

| Certifications | ISO 9001:2015, IATF 16949 |

Unlike conventional suppliers, we prioritize collaborative engineering from the quotation stage. Share your CAD files or functional requirements, and our application specialists will conduct a manufacturability analysis within 24 hours—identifying cost-saving design refinements without compromising performance. Our Hangzhou-based technical hub operates on a 24/7 support model, ensuring real-time communication across all time zones. This proactive approach has driven 30% faster project launches for clients in medical device, aerospace, and electric vehicle sectors.

The true value of precision lies not in isolated machine specs, but in a partner’s ability to anticipate your production ecosystem. We invest in your success through rigorous first-article inspections, documented process validation, and dedicated account engineering—turning supply chain risk into strategic reliability. When your project demands uncompromising accuracy in aluminum components, the margin for error vanishes.

Initiate your precision partnership today. Email [email protected] with your project specifications or component drawings. Our engineering team will respond within 4 business hours with a detailed capability assessment and actionable timeline. For urgent requirements, reference “ALU-URGENT” in your subject line to trigger our rapid-response protocol. Trust Wuxi Lead Precision Machinery to deliver not just parts, but engineered solutions that advance your manufacturing objectives.

Contact us now: [email protected]

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.