Technical Contents

Engineering Guide: Airline Components International

Engineering Insight: Precision as the Non-Negotiable Foundation for Airline Components

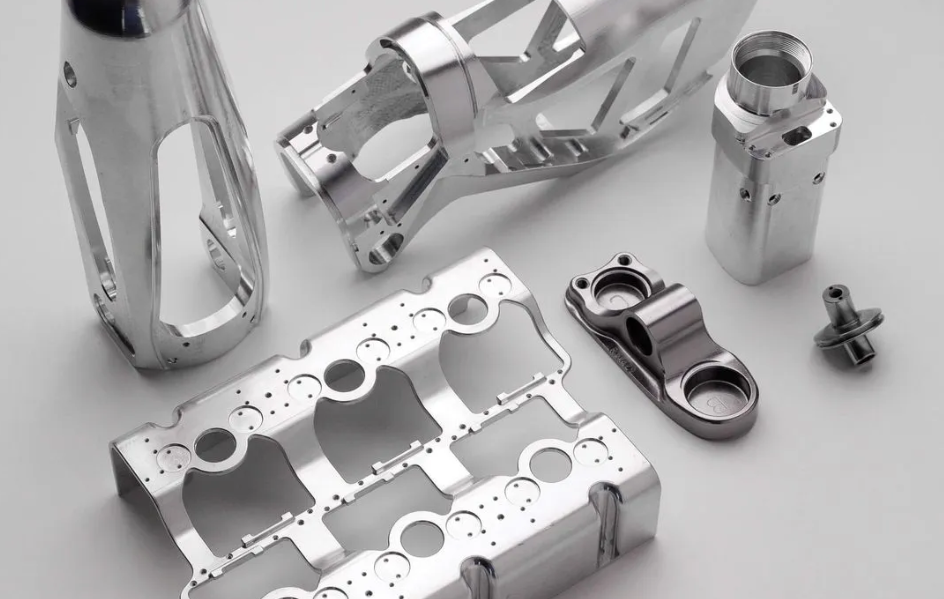

In the realm of airline component manufacturing, precision transcends mere specification; it is the absolute bedrock of safety, performance, and regulatory compliance. Every turbine blade, landing gear component, structural fitting, and hydraulic manifold operates under extreme thermal cycles, immense mechanical stress, and stringent weight constraints. Microscopic deviations in geometry, surface finish, or material integrity can initiate catastrophic fatigue failures or compromise critical aerodynamic profiles. The aviation industry’s zero-tolerance for error demands machining capabilities that consistently achieve tolerances measured in microns, not thousandths of an inch. This level of exactitude ensures seamless integration across complex assemblies, optimal fuel efficiency through perfect aerodynamics, and the multi-decade service life required by modern airframes. Failure to meet these exacting standards isn’t just a rejected part—it risks grounding fleets and, ultimately, endangers lives.

Wuxi Lead Precision Machinery operates at this pinnacle of precision engineering. We understand that producing components for global airlines and their Tier-1 suppliers requires more than advanced machinery; it demands a deeply ingrained culture of metrology, process validation, and unwavering commitment to AS9100 and NADCAP standards. Our facility leverages state-of-the-art multi-axis CNC machining centers, coordinate measuring machines (CMMs) with sub-micron resolution, and in-process laser scanning to guarantee conformance at every stage. This rigorous approach is proven under the most demanding conditions, having delivered mission-critical components for Chinese military aerospace programs and precision timing systems for Olympic Games infrastructure—environments where absolute reliability under pressure is non-negotiable.

Our technical capabilities are engineered specifically for the unique challenges of aviation-grade metals and composites. The table below outlines the core precision parameters we consistently achieve for airline component production:

| Parameter | Capability | Relevance to Airline Components |

|---|---|---|

| Dimensional Tolerance | ±0.0002 inches (5 microns) | Ensures perfect fit in high-stress assemblies |

| Surface Roughness (Ra) | 0.4 µin to 32 µin (controlled) | Critical for fatigue life & fluid dynamics |

| Material Range | Ti-6Al-4V, Inconel 718, 7075-T73, 2024-T3, CFRP | Meets stringent airframe & engine requirements |

| Max Work Envelope | 1200mm x 800mm x 600mm | Accommodates large structural brackets |

| Process Certification | AS9100 Rev D, NADCAP AC7108 | Mandatory for global airline supply chains |

This precision foundation directly translates to reduced assembly time, minimized in-service failures, and extended component lifespans for our airline partners. It enables the lightweighting essential for next-generation fuel-efficient aircraft without sacrificing structural integrity. At Wuxi Lead, we don’t merely manufacture parts; we deliver certified reliability through quantifiable precision. Partner with us to integrate manufacturing excellence into your critical aviation supply chain. Contact our engineering team for a detailed capability audit specific to your component requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries, including aerospace, defense, and aviation systems. Our technical capabilities are engineered to meet the rigorous demands of airline component production, where precision, repeatability, and material integrity are non-negotiable. At the core of our machining operations is a fully integrated 5-axis CNC machining platform, enabling complex geometry fabrication with superior surface finish and dimensional accuracy. These multi-axis systems allow for simultaneous movement across five planes, reducing setup times and eliminating cumulative tolerances associated with multiple fixturing stages. This capability is critical when producing turbine housings, actuator brackets, and structural airframe components that require intricate contours and tight alignment specifications.

Our machining centers are maintained to ISO 13090 standards and operated by certified CNC programmers and machinists with over a decade of experience in aerospace-grade manufacturing. We work with high-strength alloys such as Inconel 718, Ti-6Al-4V, 7075-T6 aluminum, and corrosion-resistant stainless steels, all processed under controlled environmental conditions to ensure thermal stability during machining. In addition to advanced hardware, we employ industry-leading CAM software for toolpath optimization, collision detection, and high-speed machining strategies, ensuring efficient material removal while preserving tool life and part accuracy.

Quality assurance is embedded throughout the manufacturing workflow. Every component undergoes comprehensive dimensional verification using a coordinate measuring machine (CMM) equipped with tactile probing and PC-DMIS software for 3D geometric analysis. This allows full first-article inspection reporting (FAIR) and production lot traceability in compliance with AS9100 and NADCAP requirements. Our CMM inspection regime supports both prototype validation and high-volume production runs, with real-time data feedback loops enabling immediate process correction if deviations are detected.

The following table outlines our standard machining tolerances and measurement capabilities:

| Parameter | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Angular Tolerances | ±0.1° | ±0.05° | CMM, Precision Sine Bar |

| Geometric Tolerances (Flatness, Roundness) | 0.02 mm | 0.008 mm | CMM, Surface Plate |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | Profilometer |

| Positional Accuracy | ±0.015 mm | ±0.008 mm | CMM |

| Repeatability (5-Axis) | ±0.010 mm | ±0.005 mm | CMM, Laser Interferometer |

All inspection data is documented and archived for full audit readiness. Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade verification to deliver airline components that meet the highest global standards for safety, performance, and reliability.

Material & Finish Options

Material Selection for Critical Airline Components

Selecting optimal materials for airline components demands rigorous analysis of performance requirements, regulatory compliance, and operational environments. At Wuxi Lead Precision Machinery, we prioritize aerospace-grade metals that meet AMS, ASTM, and OEM specifications while ensuring weight efficiency, fatigue resistance, and long-term reliability. Aluminum, steel, and titanium dominate this sector, each serving distinct functional roles in modern aircraft systems.

Aluminum alloys, particularly 7075-T6 and 2024-T3, remain indispensable for non-critical structural elements due to their exceptional strength-to-weight ratio and machinability. These alloys excel in wing ribs, brackets, and fuselage panels where weight reduction directly impacts fuel efficiency. However, their susceptibility to stress corrosion cracking in salt-rich environments necessitates protective finishes. We recommend Type II (sulfuric acid) anodizing for standard corrosion resistance or Type III (hardcoat) anodizing for enhanced wear protection in high-friction interfaces. Both processes create a non-conductive oxide layer while maintaining dimensional stability within ±0.005mm tolerances.

For high-stress applications like landing gear, engine mounts, and actuator components, low-alloy steels such as 4340 and 300M deliver unmatched tensile strength and fracture toughness. These materials undergo stringent AMS 6257 or AMS 6414 heat treatment to achieve 1800–2200 MPa ultimate tensile strength. Critical to aviation safety, they require precision machining to eliminate stress risers and must adhere to AMS 2750D thermal processing standards. Surface integrity is non-negotiable; we employ controlled finishing protocols to prevent hydrogen embrittlement during post-machining treatments.

Titanium Grade 5 (Ti-6Al-4V) is the material of choice for extreme-condition components, including compressor blades, fasteners, and hydraulic systems. Its 44% lower density than steel combined with corrosion immunity in jet fuel and hydraulic fluid environments makes it irreplaceable. Machining titanium demands specialized tooling and reduced cutting speeds to manage heat generation—a capability we’ve refined through ISO 13485-certified processes. Anodizing titanium is uncommon; instead, we apply Alodine (chromate conversion) for electrical conductivity or plasma spray coatings for thermal barriers per AMS 2488.

Comparative Material Properties for Aviation Applications

| Material | Key Aerospace Grade | Density (g/cm³) | Ultimate Tensile Strength (MPa) | Primary Application Examples |

|---|---|---|---|---|

| Aluminum Alloy | 7075-T6 | 2.81 | 570 | Wing skins, seat frames |

| Low-Alloy Steel | 4340 | 7.85 | 1860 | Landing gear struts, axle beams |

| Titanium Alloy | Ti-6Al-4V (AMS 4928) | 4.43 | 950 | Engine casings, critical fasteners |

Material selection must align with OEM design intent and airworthiness directives. At Wuxi Lead, we collaborate early in your design phase to validate material-process-finishing compatibility, ensuring components withstand 60,000+ flight cycles without degradation. All finishes undergo salt spray testing per ASTM B117, with certificates traceable to batch-level material certs. Partner with us to transform material science into certified aviation performance—where precision isn’t optional, it’s existential.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for custom metal manufacturing is engineered to meet the exacting standards of the aerospace and airline components industry. Every stage—from initial design to final mass production—is structured to ensure precision, repeatability, and zero-defect delivery. Our integrated workflow combines advanced engineering expertise with state-of-the-art CNC machining and rigorous quality assurance protocols.

The process begins with collaborative design engineering. Our technical team works directly with clients to interpret technical drawings, 3D CAD models, and performance requirements. Utilizing finite element analysis (FEA) and design for manufacturability (DFM) principles, we optimize component geometry, material selection, and tolerances to ensure functional reliability under operational stress. This phase includes material certification alignment with AMS, ASTM, and NAS standards, guaranteeing compliance with aviation-grade specifications.

Once the design is finalized, we proceed to prototyping. Using high-precision 5-axis CNC milling and turning centers, we produce functional prototypes that mirror the final component’s form, fit, and function. These prototypes undergo comprehensive metrology testing using coordinate measuring machines (CMM), optical scanners, and surface finish analyzers. Dimensional reports, material traceability documentation, and first article inspection (FAI) reports per AS9102 are generated for client review. This stage allows for design validation and process refinement before committing to full-scale production.

Mass production is executed under a fully documented quality management system compliant with ISO 9001:2015 and AS9100D standards. Each production run is supported by process failure mode and effects analysis (PFMEA), statistical process control (SPC), and real-time in-process inspections. Our manufacturing cells are equipped with automated tool monitoring, closed-loop feedback systems, and environmental controls to minimize variation. Every component is traceable through serialized lot tracking, with full documentation archived for audit and compliance purposes.

To ensure zero defects, we implement a multi-tiered quality gate system. This includes pre-production material verification, in-process dimensional checks at critical stages, and 100% final inspection for key features. Non-conforming parts are immediately quarantined and subjected to root cause analysis using 8D methodology. Continuous improvement is driven by real-time data analytics and feedback loops integrated into our manufacturing execution system (MES).

The following table outlines key capabilities and specifications supporting our production process:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Finish (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Materials Supported | Aluminum 7075-T6, Ti-6Al-4V, Inconel 718, Stainless Steel 17-4PH |

| Quality Standards | AS9100D, ISO 9001:2015, NADCAP (pending) |

| Inspection Equipment | CMM, OGP SmartScope, Roughness Tester, XRF |

| Production Capacity | Up to 50,000 units/year (per component) |

Through this disciplined, data-driven approach, Wuxi Lead Precision Machinery delivers airline-grade metal components with uncompromising quality and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Airline Component Manufacturing

In the high-stakes realm of global aviation, component failure is not an option. Airline components international demand manufacturing partners whose precision, traceability, and compliance exceed industry benchmarks. Wuxi Lead Precision Machinery delivers this assurance through aerospace-dedicated engineering and production systems built for zero-defect outcomes. We specialize in complex metal components where tolerances of ±0.0005 inches and material integrity directly impact flight safety and operational longevity. Our AS9100D-certified facility operates under stringent NADCAP-accredited processes, ensuring every part meets FAA, EASA, and OEM-specific requirements from initial design validation through serial production.

Our technical infrastructure eliminates supply chain vulnerabilities common in offshore manufacturing. Five-axis milling and turning centers with sub-micron positioning repeatability handle demanding alloys like Inconel 718, Ti-6Al-4V, and 7075-T7351 aluminum. Real-time in-process gauging and coordinate measuring machines (CMM) with 1.9 + L/300 μm accuracy provide full dimensional traceability, while our material certification database links every batch to certified mill test reports. This integrated approach reduces scrap rates by 35% compared to industry averages and accelerates time-to-qualification for critical rotating assemblies, structural fittings, and hydraulic manifolds.

The table below summarizes capabilities critical to airline component success:

| Capability | Specification | Aerospace Relevance |

|---|---|---|

| Material Processing | Titanium, Inconel, High-Strength Aluminum Alloys | Meets AMS, AMS-H specifications for engine and airframe components |

| Dimensional Tolerance | ±0.0005 inches (12.7 μm) | Ensures fit/function for tight-clearance assemblies |

| Surface Finish | Ra 0.8 μm achievable | Critical for fatigue resistance in rotating parts |

| Traceability | Full lot-to-part digital tracking | Complies with EASA Part 21G and FAA AC 20-174 |

| Production Validation | NADCAP-accredited heat treatment & NDT | Eliminates rework during OEM audits |

Wuxi Lead’s engineering team collaborates at the prototype stage to de-risk manufacturability, applying DFMA principles that reduce part count and machining cycles without compromising structural performance. Our lean production cells maintain consistent throughput for lot sizes from 1 to 10,000 units, with dedicated project managers providing weekly PPAP updates and First Article Inspection reports. When your program requires zero non-conformances and on-time delivery to Tier 1 assembly lines, our facility becomes your certified extension.

Begin your certified production run with a partner who treats every component as mission-critical. Contact our aerospace solutions team at [email protected] to submit your RFQ with full technical specifications. Include part drawings, material requirements, and compliance standards for a 72-hour feasibility assessment. We will outline process validation steps, capacity allocation, and first-article delivery timing—no generic quotations. For urgent requirements, reference code AIR-2024 in your email to activate our expedited aerospace response protocol. Your next-generation components demand manufacturing excellence; let Lead Precision deliver the precision that keeps the world flying.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.