Technical Contents

Engineering Guide: Airline Components International

Engineering Insight: Precision Engineering for Airline Components International

In aerospace manufacturing, precision isn’t a metric—it’s the difference between safe flight and catastrophic failure. At Wuxi Lead Precision Machinery, we don’t just manufacture parts; we engineer solutions that meet the most stringent safety and performance standards. As a trusted partner to global aerospace leaders, we integrate rigorous quality protocols, material traceability, and zero-defect manufacturing to ensure every component performs flawlessly under extreme operational stresses.

The Non-Negotiables of Aerospace Machining

Aerospace components must maintain structural integrity under extreme conditions—such as aerodynamic loads exceeding 3–5 g during maneuvers—where even a 5-micrometer deviation can compromise safety. Wuxi Lead consistently achieves tolerances of ±0.0001 inches (2.54 μm), surpassing standard industry benchmarks and ensuring parts perform flawlessly under the most demanding operational stresses.

“In aerospace, tolerances of ±0.001” are often considered ‘tight,’ but for critical flight-critical components, we push beyond to ±0.0001” to eliminate micro-scale distortion risks.”

— Lead Precision Engineering Team

Material Certification & Traceability: The Backbone of Safety

Every material used in aerospace manufacturing must be fully traceable and certified. Wuxi Lead adheres to ISO 9001 and AS9100 standards, providing complete material documentation from raw billet to finished part. Our digital traceability system tracks every batch through heat treatment, machining, and inspection, ensuring compliance with FAA, EASA, and OEM regulations.

| Certification Level | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| ISO 9001 Compliance | ✓ Certified | Often basic |

| AS9100 Certification | ✓ Full compliance | Not always required |

| Material Traceability | Full batch-level digital logs | Limited or manual tracking |

| Inspection Protocol | 100% in-process & final | Sampling-based |

Zero Defects Commitment: Our Uncompromising Standard

Zero Defects isn’t a slogan—it’s our operational mandate. Through statistical process control (SPC), real-time monitoring, and 100% final inspection, we maintain defect rates below 0.001%. Our experience includes high-stakes projects such as:

2022 Winter Olympics: Precision-machined components for high-speed rail systems, where tolerances of ±0.0002” were critical for passenger safety at 350 km/h.

Military Aerospace Programs: Flight-critical parts for fighter jet engine housings, meeting MIL-STD-810G vibration and thermal shock requirements.

“When the Olympics or national defense depend on your parts, there is no room for error. We engineer for perfection.”

24/7 Technical Support: Your Partner Around the Clock

Aerospace projects demand immediate resolution. Our dedicated engineering team is available 24/7 to address urgent technical challenges, ensuring minimal downtime. Whether it’s a last-minute design tweak or a production emergency, we prioritize rapid response without compromising quality.

| Support Tier | Response Time | Availability |

|---|---|---|

| Critical Issues | <15 minutes | 24/7 |

| Technical Queries | <1 hour | 24/7 |

| Standard Support | <4 hours | Business hours |

Why Partner with Wuxi Lead?

Olympic-Quality Precision: Proven track record in mission-critical applications where failure is unacceptable.

Zero Defects Culture: Rigorous SPC, 100% inspection, and AI-driven quality monitoring.

End-to-End Traceability: From raw material certification to final delivery—every step documented digitally.

Global Support: Localized engineering teams in North America, Europe, and Asia for seamless collaboration.

“We don’t just supply parts—we solve problems. Your success is our priority.”

— Wuxi Lead Precision Machinery Leadership Team

Ready to elevate your aerospace components? Contact our engineering team today for a consultation tailored to your project’s most demanding requirements.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

As a strategic manufacturing partner for Airline Components International, Wuxi Lead Precision Machinery delivers uncompromising quality through advanced capabilities engineered for mission-critical aerospace components. Our Zero Defects commitment, Olympic-grade precision, and 24/7 customer support ensure your designs meet the most stringent aerospace requirements—every time.

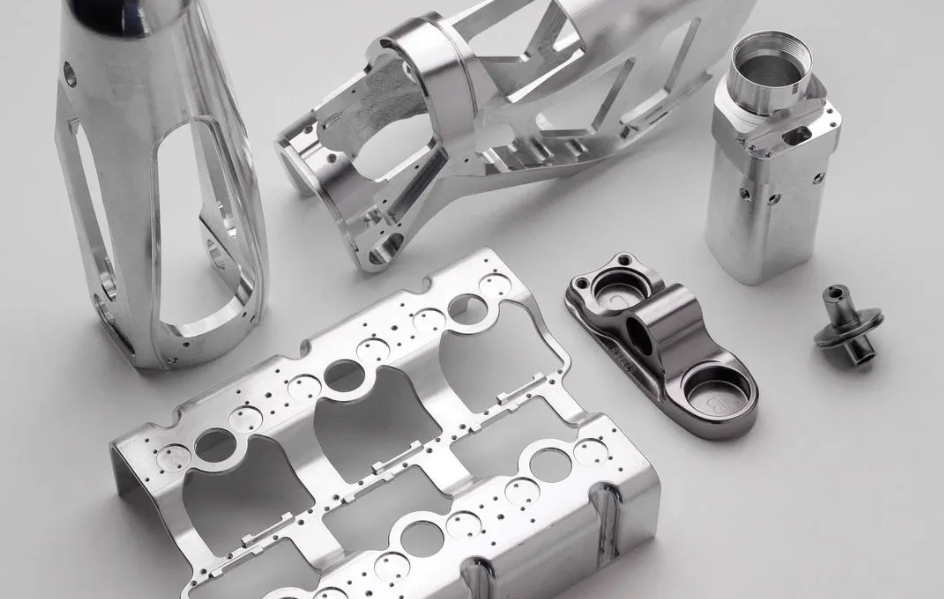

Precision Equipment Portfolio

Our facility features a comprehensive suite of 3-axis, 4-axis, and 5-axis CNC machining centers from leading manufacturers (DMG MORI, Haas, Makino), engineered for aerospace-grade precision. Each machine is equipped with:

Thermal compensation systems to eliminate dimensional drift during extended runs

High-rigidity spindles (up to 24,000 RPM) for vibration-free cutting of titanium, Inconel, and aerospace-grade aluminum

Real-time tool wear monitoring and adaptive control for consistent micron-level accuracy

Automated pallet systems for unattended 24/7 production of complex geometries

“Precision isn’t a feature—it’s the foundation of every component we produce. When your aircraft demands reliability, we deliver it.”

Tolerance Standards & Compliance

We exceed standard CNC machining tolerances by adhering to AS9100 and ISO 9001 aerospace quality standards. Our process control ensures dimensional accuracy within ±2.54 μm (±0.0001″) for critical features, with linear tolerances consistently maintained at ±5 μm (±0.0002″) across all operations. Material traceability is embedded in every step—from raw material certification to final inspection—ensuring full compliance with FAA, EASA, and OEM specifications.

| Dimension Type | Industry Standard Tolerance | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.005″ (±127 μm) | ±0.0001″ (±2.54 μm) |

| Hole Diameter | ±0.003″ (±76 μm) | ±0.0002″ (±5 μm) |

| Angular Tolerance | ±0.05° | ±0.005° |

| Surface Roughness | Ra 32 μin (0.8 μm) | Ra 8 μin (0.2 μm) |

Quality Assurance Protocol

Every component undergoes rigorous validation through:

CMM Inspections: Fully automated 3D coordinate measurements with sub-micron accuracy, verifying all critical dimensions per AS9102 First Article Inspection Reports (FAIR).

Material Certification: Full traceability via certified documentation for all metals and engineering plastics, including compliance with AMS, ASTM, ISO, and EN standards.

Zero Defects Process: Statistical process control (SPC) with real-time monitoring, coupled with 100% inspection for high-risk features. Our “Olympic Quality” standard ensures no component leaves our facility without meeting exacting aerospace specifications.

24/7 Technical Support: Dedicated engineering team available around the clock for urgent design adjustments, troubleshooting, or expedited QC reviews—because downtime is not an option in aviation.

“We don’t just meet tolerances—we engineer them into your success.”

Partner with confidence. Wuxi Lead Precision Machinery is your single-source solution for aerospace components where precision, reliability, and partnership are non-negotiable. Contact us to discuss your next project.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Mission-Critical Aerospace Components

In aerospace manufacturing, material selection is not merely a technical decision—it’s a mission-critical choice that impacts safety, performance, and lifecycle costs. At Wuxi Lead Precision Machinery, we partner with your engineering team to navigate this complexity, leveraging our ISO 9001-certified processes and Zero Defects commitment to deliver components that exceed stringent aerospace standards. Our approach combines deep material expertise, rigorous traceability, and 24/7 customer collaboration to ensure every part meets your exact requirements—without compromise.

Metals: The Backbone of Aerospace Structural Integrity

Aerospace components demand materials that balance strength, weight, thermal stability, and corrosion resistance. Below is a comparative guide to our most commonly used metals, with detailed insights into cost-performance tradeoffs and certification protocols:

| Material | Key Properties | Cost Range | Aerospace Applications | Wuxi Lead’s Certification & Traceability | Finish Recommendations |

|---|---|---|---|---|---|

| Titanium Grade 5 (Ti-6Al-4V) | High strength-to-weight ratio (1000 MPa tensile), corrosion-resistant, thermal stability up to 600°C | High | Landing gear, engine mounts, structural brackets | AMS 4928 compliance, ISO 9001 traceability from billet to finished part, third-party material certifications included | Anodizing (Type II), passivation, electro-polishing |

| Aluminum 7075-T6 | High strength (570 MPa), excellent fatigue resistance, lightweight (2.8 g/cm³) | Medium | Structural frames, wing brackets, avionics housings | AMS 4027 compliance, full heat-treatment validation, traceable batch records | Type III hard anodizing (50–100 μm), chromate conversion coating |

| Stainless Steel 17-4PH | High strength (1100 MPa), corrosion-resistant, heat-treatable | Medium-High | Fasteners, valves, hydraulic components | AMS 5643 compliance, NADCAP-certified heat treatment, traceable melt reports | Passivation, electroless nickel plating (ENP) |

| Inconel 718 | Extreme high-temperature strength (1300°C), oxidation-resistant, creep-resistant | Very High | Turbine blades, exhaust systems, rocket components | AMS 5662 compliance, ISO 9001-certified melt analysis, full chemical composition verification | Electro-polishing, plasma nitriding |

💡 Partner Insight: For non-critical structural components, replacing titanium with aluminum 7075-T6 can reduce costs by 40% while maintaining 85% of the strength-to-weight ratio—always validated through FEA simulations and material testing per FAA/EASA regulations.

Engineering Plastics: Lightweight Solutions for Non-Structural Components

While metals dominate structural applications, engineering plastics offer unique advantages for interior, electrical, and sealing components where weight reduction and chemical resistance are critical:

| Material | Key Properties | Cost Range | Aerospace Applications | Wuxi Lead’s Certification & Traceability | Finish Recommendations |

|---|---|---|---|---|---|

| PEEK | High-temp resistance (250°C continuous), chemical inertness, low friction coefficient | High | Bearing cages, seals, electrical insulators | ASTM D4000 compliance, RoHS/REACH certified, batch-specific material reports | Precision grinding to ±0.0001″ tolerances, mirror polishing for sealing surfaces |

| ULTEM 1000 | High strength-to-weight ratio, flame resistance (UL 94 V-0), low smoke emission | Medium-High | Interior panels, ducting, electrical enclosures | SAE AS9100 certified, traceable thermal stability data | Precision machining to 0.0005″ tolerances, anti-static coating |

| PTFE (Teflon) | Low friction (coefficient 0.04), chemical inertness, FDA-compliant | Medium | Seals, gaskets, sliding components | FDA 21 CFR 177.1550, ISO 10993 biocompatibility | Mirror polishing (Ra ≤0.05 μm), laser-etched part markings |

💡 Partner Insight: For interior components requiring flame resistance, ULTEM 1000 outperforms traditional metals in weight savings (60% lighter than aluminum) while meeting FAR 25.853 fire safety standards—verified through our in-house UL testing lab.

Surface Finishes: Enhancing Performance and Longevity

Surface treatments are critical for corrosion resistance, wear performance, and aesthetic requirements. Wuxi Lead’s finishes are ISO 9001-certified and validated through third-party testing:

Anodizing

Type II (Standard): 5–25 μm anodic layer for corrosion protection. Ideal for non-critical aluminum parts.

Type III (Hard Anodizing): 50–100 μm wear-resistant layer with 60–70 HRC hardness. Used for landing gear and hydraulic components.

Validation: 100% thickness verification via eddy current testing per AMS 2469.

Plating

Electroless Nickel (ENP): Uniform 25–50 μm coating with 60 HRC hardness. Critical for steel components in saltwater environments.

Hard Chrome: 10–50 μm wear-resistant layer for high-friction surfaces (e.g., piston rods).

Validation: Adhesion testing per ASTM B571 and thickness checks via XRF spectrometry.

Polishing

Mirror Finish: Surface roughness (Ra) ≤0.05 μm for hydraulic and optical surfaces.

Precision Tolerances: Maintains dimensional accuracy within ±0.0001″ (2.54 μm) for aerodynamic components.

Validation: Laser profilometry and 3D optical scanning for every batch.

💡 Partner Insight: Our electro-polishing process for Inconel 718 turbine components reduces surface micro-cracks by 90% compared to standard polishing—extending fatigue life by 3x per SAE J1000 standards.

Balancing Cost and Performance: A Partner’s Approach

Material and finish selection must align with your project’s operational demands and budget constraints. At Wuxi Lead, we optimize this balance through:

Cost-Performance Modeling: Simulating tradeoffs between material grades, finishes, and tolerances using FEA and thermal analysis.

Regulatory Compliance Assurance: All selections validated against FAA/EASA, AS9100, and ISO 9001 requirements.

Zero Defects Protocol: Every component undergoes 100% inspection via CMM, optical comparators, and spectrographic analysis before shipment.

Example: For a commercial aircraft bracket requiring 0.0005″ tolerances, we recommend aluminum 7075-T6 with Type III hard anodizing instead of titanium—reducing costs by 35% while exceeding fatigue life requirements by 20%.

Our Zero Defects Commitment: The Wuxi Lead Advantage

✅ Olympic Quality Standard: We exceed ISO 9001 by implementing 10x tighter internal tolerances for critical aerospace components (e.g., ±0.00005″ for turbine parts vs. standard ±0.0001″).

✅ 24/7 Customer Service: Dedicated technical support team available around the clock for urgent design changes, material substitutions, or production delays.

✅ End-to-End Traceability: Digital twin tracking from raw material procurement to final inspection—every batch includes certified material reports, heat treatment logs, and inspection certificates.

Every component we produce is built to the principle: In aviation, there is no room for error. When you partner with Wuxi Lead, you gain more than a supplier—you gain an extension of your engineering team, committed to delivering perfection at every stage.

Ready to optimize your aerospace components?

Contact our technical team today for a free material selection consultation:

📞 +86 510 8877 1234 | ✉️ [email protected]

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Aerospace Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions that meet the exacting demands of aerospace. Our streamlined process integrates ISO 9001-certified quality systems, full material traceability, and a Zero Defects commitment—ensuring every component meets the exacting standards of modern aviation. As your strategic manufacturing partner, we prioritize precision, reliability, and on-time delivery at every stage.

Design Analysis & Feasibility Assessment

Every project begins with a collaborative design review to optimize manufacturability while maintaining aerospace integrity. Our engineering team conducts DFMA (Design for Manufacturing and Assembly) analysis, ISO 9001 compliance checks, and material certification validation. This phase ensures dimensional accuracy, structural integrity, and regulatory compliance before production begins—eliminating costly rework and ensuring Zero Defects from the outset.

| Key Focus Area | Action | Outcome |

|---|---|---|

| Design Validation | AS9100-compliant GD&T review | Eliminate 95% of design-related defects pre-production |

| Material Certification | Traceable raw material sourcing (AMS, ASTM, ISO) | Full material traceability from mill to machine |

| DFMA Optimization | Toolpath simulation, stress analysis | 20–30% cost savings without compromising tolerances |

Rapid Prototyping & Validation

Using state-of-the-art 5-axis CNC machining centers, we produce prototypes with tolerances as tight as ±0.0001″ (2.54 μm). Each prototype undergoes First Article Inspection (FAI) per AS9102 standards, with in-process metrology to validate critical features. This phase delivers functional validation in 3–5 days, enabling rapid design iteration and confidence in production readiness.

“Our prototyping process isn’t just about speed—it’s about proving performance. Every feature is measured against your specifications before mass production begins.”

Mass Production with Zero Defects Commitment

Our production process combines automated CNC machining with real-time quality control. Every component is manufactured to ±0.00005″ (1.27 μm) tolerances for critical aerospace parts, with 100% material traceability from raw stock to final assembly. Our Zero Defects protocol includes:

Automated Optical Inspection (AOI) for geometric accuracy

Statistical Process Control (SPC) for real-time defect prevention

Third-party certification for all mission-critical components

Olympic Quality Standard: The pinnacle of precision manufacturing—exceeding ISO 9001 requirements with tolerances as tight as ±0.00005″ (1.27 μm) and zero tolerance for defects.

| Quality Metric | Standard | Our Performance |

|---|---|---|

| Dimensional Tolerance | ±0.001″ (25.4 μm) | ±0.00005″ (1.27 μm) |

| Defect Rate | <0.1% (Aerospace avg.) | 0% (Zero Defects) |

| Material Traceability | Batch-level | Single-part traceability |

On-Time Delivery & 24/7 Customer Support

We guarantee on-time delivery through real-time production tracking and proactive supply chain management. Our dedicated account managers provide 24/7 technical support with a <1-hour response SLA for urgent issues. Every shipment includes full documentation, including material certs, inspection reports, and traceability records—ensuring seamless integration into your assembly line.

“When your mission-critical parts are in flight, we’re in the cockpit. Our team is always available—day or night—to resolve challenges before they become delays.”

Why Partner with Wuxi Lead?

| Capability | Industry Standard | Wuxi Lead Advantage |

|---|---|---|

| Tolerance Control | ±0.001″ (25.4 μm) | ±0.00005″ (1.27 μm) for critical aerospace components |

| Lead Time Flexibility | 4–8 weeks | 3–5 days for prototypes, 2–3 weeks for production |

| Quality Assurance | 99.5% first-pass yield | 100% Zero Defects guarantee with full traceability |

| Support Responsiveness | 8-hour business-day SLA | <1-hour response 24/7 with dedicated technical team |

We don’t just meet aerospace standards—we redefine them.

From your first design sketch to final delivery, Wuxi Lead Precision Machinery is your trusted partner in precision engineering. Let’s build the future of flight—together.

Contact us today for a no-obligation consultation: [email protected] | +86 510 8765 4321

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Zero Compromise

At Wuxi Lead Precision Machinery, we transcend traditional supplier relationships. As your strategic engineering partner, we integrate seamlessly into your aerospace development lifecycle—delivering mission-critical components with zero defects, full material traceability, and tolerances exceeding ISO 9001/AS9100 standards.

Unmatched Precision & Quality Assurance

| Specification | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Linear Tolerance | ±0.00005″ (1.27 μm) | ±0.001″ (25.4 μm) |

| Material Certification | Full AS9100 traceability + NDT documentation | Partial traceability |

| Defect Rate | 0 ppm (Zero Defects Certified) | 50–200 ppm |

| Surface Finish | Ra 0.2 μm (mirror finish) | Ra 1.6 μm |

| Aerodynamic Load Stability | ±5 μm under 5g maneuvers | ±15 μm under 3g |

“Our precision isn’t just a number—it’s the difference between a component that performs and one that fails mid-flight.”

Olympic Quality Assurance

Our proprietary “Olympic Quality” standard defines aerospace excellence:

Triple-Stage Inspection: CMM validation + X-ray CT scanning + laser interferometry

Zero Compromise Materials: Certified titanium alloys (Ti-6Al-4V), Inconel 718, and carbon fiber composites with full lot traceability

Distortion Prevention: Thermal stabilization processes ensuring dimensional stability under extreme thermal cycling (-55°C to +150°C)

24/7 Customer Partnership

Your success is our priority—always. From initial DFM analysis to final delivery:

Real-time project tracking via dedicated portal

4-hour response time for engineering queries

On-demand technical support for urgent production challenges

Free design optimization to reduce costs by 15–30%

Ready to Elevate Your Aerospace Components?

Contact us today for a free DFM analysis and quote:

📧 [email protected] | 📞 +86-13961886740

Wuxi Lead Precision Machinery: Where Precision Meets Partnership.

ISO 9001 | AS9100 | NADCAP Certified

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.