Technical Contents

Engineering Guide: Affordable Machining

Engineering Insight: The Role of Precision in Affordable Machining

In the realm of custom metal manufacturing, affordability should never come at the expense of precision. At Wuxi Lead Precision Machinery, we define affordable machining not as the lowest price point, but as the optimal balance between cost efficiency and uncompromised engineering accuracy. True affordability lies in producing high-performance components consistently, with minimal waste, reduced rework, and long-term reliability—objectives that are only achievable through precision-driven processes.

Precision machining is the backbone of modern industrial applications, especially in sectors where failure is not an option. Our experience delivering components for Olympic-grade equipment and mission-critical military systems has reinforced a fundamental truth: tolerances measured in microns directly impact functionality, safety, and system longevity. Whether producing lightweight aerospace housings or high-strength defense actuators, our machining protocols adhere to international standards such as ISO 2768 and AS9100, ensuring dimensional stability and repeatability across production runs.

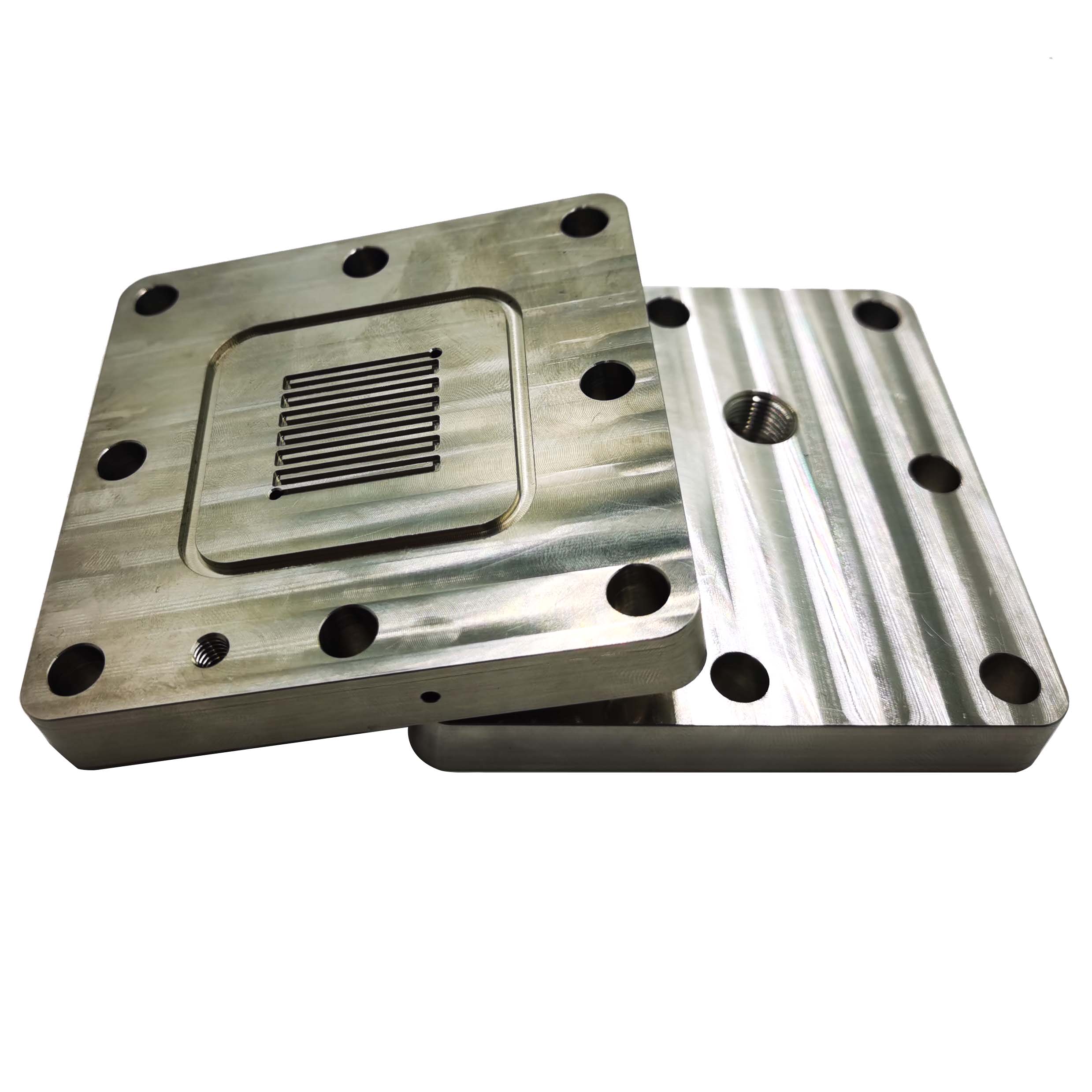

Affordable machining, when executed correctly, leverages advanced CNC technology, optimized toolpaths, and skilled engineering oversight to reduce cycle times and material waste—without sacrificing accuracy. At Lead Precision, we utilize 3-, 4-, and 5-axis CNC milling and turning centers equipped with laser tool measurement and in-process probing. These systems enable tight tolerances and complex geometries while minimizing human intervention, thus improving throughput and lowering unit costs over volume.

Our engineering team conducts thorough Design for Manufacturability (DFM) reviews on every project, identifying opportunities to simplify features, select cost-effective materials, and streamline setups—all while preserving the functional intent of the design. This proactive approach prevents costly iterations and ensures that affordability is built into the process from day one.

Material selection further enhances cost-performance balance. We routinely work with aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 5), and engineering plastics such as PEEK and Delrin. Each material is matched to the application’s mechanical, thermal, and environmental demands, ensuring optimal performance without over-engineering.

Below are typical precision capabilities achieved across our standard production envelope:

| Specification | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Surface Roughness (Ra) | 0.8 – 3.2 µm (adjustable) |

| Maximum Part Size (mm) | 1200 x 800 x 600 |

| Minimum Feature Size | 0.3 mm (drilling/milling) |

| CNC Milling Accuracy | ±0.008 mm (repeatability) |

| Lead Time (Standard) | 7–15 days (varies by complexity) |

Precision is not a luxury—it is a necessity that enables affordability through efficiency, consistency, and reliability. At Wuxi Lead Precision Machinery, decades of experience in high-stakes manufacturing have taught us that the most cost-effective part is the one that performs perfectly the first time, every time. This philosophy drives our commitment to precision in every custom machining project we undertake.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Cost-Optimized Production

At Wuxi Lead Precision Machinery, our definition of affordable machining centers on eliminating waste through superior technical execution, not compromising on capability. True affordability in custom metal manufacturing is achieved when complex parts are produced correctly the first time, minimizing scrap, rework, and secondary operations. Our integrated technical infrastructure, built around advanced 5-axis CNC machining and rigorous quality control, delivers this efficiency consistently for demanding industrial applications.

Our core manufacturing capability leverages a modern fleet of high-torque, high-precision 5-axis CNC machining centers. This technology is fundamental to our cost-saving proposition. Unlike traditional 3-axis systems requiring multiple setups and fixtures, our 5-axis platforms machine complex geometries—including deep cavities, intricate contours, and undercuts—in a single, uninterrupted operation. This drastically reduces non-cut time, fixture costs, and the cumulative error inherent in multi-stage processes. We handle a wide range of engineering metals, including aerospace-grade aluminum alloys, stainless steels, titanium, and hardened tool steels, maintaining tight tolerances across diverse material properties. The simultaneous multi-axis movement ensures optimal tool engagement, enhancing surface finish, extending tool life, and enabling faster material removal rates, all contributing to lower per-part costs without sacrificing quality.

Precision is meaningless without verification. Every component undergoes a comprehensive quality assurance protocol centered on Zeiss and Hexagon Coordinate Measuring Machines (CMMs). Our inspection process is not a final checkpoint but an integrated part of production planning. Critical dimensions and geometric tolerances defined in your CAD model are programmed directly into the CMM inspection routine, ensuring objective, repeatable measurement against your specifications. This data-driven approach provides full traceability and identifies any process drift before significant material is consumed, preventing costly batch failures. Statistical process control (SPC) data from CMM inspections is actively used to refine machining parameters, continuously optimizing yield and consistency.

The achievable precision directly impacts your project’s cost structure by reducing scrap and assembly time. The table below outlines our standard and tight tolerance capabilities across common materials, reflecting real-world production feasibility under controlled conditions:

| Material Category | Standard Tolerance (±) | Tight Tolerance (±) | Maximum Achievable (Typical) | Notes |

|---|---|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | 0.025 mm / 0.001″ | 0.012 mm / 0.0005″ | 0.005 mm / 0.0002″ | GD&T achievable per ISO 1101; Ra < 0.8 µm |

| Stainless Steel (e.g., 304, 316, 17-4PH) | 0.025 mm / 0.001″ | 0.010 mm / 0.0004″ | 0.005 mm / 0.0002″ | Includes hardened grades; Ra < 0.8 µm |

| Titanium Alloys (e.g., Ti-6Al-4V) | 0.030 mm / 0.0012″ | 0.015 mm / 0.0006″ | 0.008 mm / 0.0003″ | Optimized for low thermal distortion; Ra < 1.6 µm |

| Engineering Plastics (e.g., PEEK, Delrin) | 0.050 mm / 0.002″ | 0.025 mm / 0.001″ | 0.012 mm / 0.0005″ | Material stability dependent; Ra < 1.6 µm |

These specifications represent our standard production capability under normal operating conditions. Achieving the tightest tolerances consistently requires collaborative design for manufacturability (DFM) reviews, where our engineering team optimizes your part geometry and tolerance stack-ups for the most efficient production path. This proactive technical partnership is where Wuxi Lead transforms the concept of affordable precision into tangible cost savings and on-time delivery for your critical metal components.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing performance, durability, cost, and lead time. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of aluminum, steel, and titanium—three of the most widely used materials in high-performance industrial applications. Each material offers unique mechanical properties and cost profiles, making them suitable for different use cases across aerospace, automotive, medical, and industrial equipment sectors.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is commonly selected for prototypes and structural components due to its weldability and moderate strength. For more demanding environments, 7075-T6 provides higher tensile strength, making it ideal for aerospace applications. Aluminum’s low density and high thermal conductivity also make it a top choice for heat sinks and electronic enclosures.

Steel remains the backbone of heavy-duty manufacturing. We work primarily with 303, 304, and 316 stainless steel, as well as 4140 and 1045 carbon steel. Stainless grades offer superior corrosion resistance and are widely used in medical devices and food processing equipment. 316 stainless, in particular, performs exceptionally in marine and chemical environments due to its molybdenum content. Carbon steels like 4140 are selected for high-stress applications such as shafts and gears, where toughness and wear resistance are paramount.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an outstanding balance of strength, low weight, and corrosion resistance. It is the material of choice in aerospace, defense, and biomedical implants. While more challenging and costly to machine due to its low thermal conductivity and high chemical reactivity, titanium’s performance in extreme environments justifies its use where reliability is non-negotiable.

Surface finishing further enhances material performance. Anodizing is a key treatment for aluminum components. It increases surface hardness, improves wear resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat anodizing) delivers a thicker, more durable layer suitable for industrial and military-grade applications. Anodized layers are electrically insulating and can be masked for selective treatment.

Below is a comparative overview of key material properties:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Moderate | Enclosures, brackets, frames |

| Aluminum 7075-T6 | 570 | 2.8 | Moderate | Aerospace structures |

| Stainless 304 | 505 | 8.0 | High | Medical, food processing |

| Stainless 316 | 570 | 8.0 | Very High | Marine, chemical equipment |

| Steel 4140 | 655 | 7.85 | Low | Shafts, tooling, gears |

| Titanium Ti-6Al-4V | 900 | 4.43 | Excellent | Aerospace, implants |

Selecting the right material and finish requires balancing performance needs with production efficiency. At Wuxi Lead, we support clients in making informed decisions by providing material certifications, prototyping services, and expert consultation tailored to volume, environment, and functional requirements.

Manufacturing Process & QC

Precision Production Pathway: Design to Zero Defects Manufacturing

At Wuxi Lead Precision Machinery, achieving true affordability in custom metal manufacturing stems from an integrated, defect-preventative production process. We define affordability not as minimal cost, but as optimal value through rigorous engineering and flawless execution. Our disciplined pathway—Design, Prototyping, Mass Production—ensures dimensional accuracy, material integrity, and on-time delivery while systematically eliminating waste and rework costs. This methodology delivers high-performance components at competitive rates without compromising the Zero Defects standard demanded by aerospace, medical, and automation sectors.

The process commences with comprehensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with client CAD data, scrutinizing geometries, material selections, and tolerance stacks. We identify potential machining complexities, thermal distortion risks, or assembly conflicts early, proposing refinements that enhance producibility and reduce cycle times. This proactive engineering phase prevents costly downstream errors and establishes a robust foundation for cost-effective production. Material procurement follows stringent ISO 9001 protocols, ensuring certified alloys meet exact specifications before any metal is cut.

Prototyping is not a mere formality but a critical validation stage. Utilizing our advanced 5-axis CNC mills and turning centers, we produce functional prototypes mirroring final production conditions. Each prototype undergoes exhaustive metrology: CMM inspection, surface roughness testing, and first-article reporting against all critical dimensions. Dimensional stability under simulated operating conditions is verified. This iterative step catches 95% of potential issues, allowing design or process adjustments before committing to full-scale production, thereby safeguarding against mass defect scenarios and associated financial losses.

Mass production leverages the validated process under our Zero Defects Management System. Every machine center operates with automated tool compensation, in-process probing, and real-time SPC (Statistical Process Control) monitoring. Our MES (Manufacturing Execution System) tracks component genealogy, machine parameters, and inspection data for full traceability. Final inspection employs calibrated CMMs and optical comparators against the approved prototype baseline. Components exceeding tolerance bands trigger immediate process correction, not sorting. This closed-loop control ensures every part shipped meets specification, eliminating scrap, rework, and warranty costs—the true drivers of long-term affordability.

Core Production Capabilities

| Parameter | Capability Range | Key Technology Applied |

|---|---|---|

| Materials | Aluminum, Steel, Stainless, Titanium, Inconel, Brass, Plastics | Material Science Database & DFM |

| Tolerances | ±0.005 mm (Standard), ±0.001 mm (Precision) | 5-Axis CNC, In-Process Probing |

| Lead Time (Proto) | 7-15 Days (Complex Geometry) | Rapid Tooling & Setup |

| Lead Time (Volume) | 15-30 Days (1,000 pcs) | Optimized Cell Manufacturing |

| Max Work Envelope | 1200 x 800 x 650 mm | High-Volume 5-Axis Platforms |

| Quality Standard | Zero Defects (PPM < 50) | SPC, CMM, Full FAI Reporting |

Affordability at Wuxi Lead is engineered through precision, predictability, and prevention. By perfecting the process upstream and controlling variation relentlessly downstream, we deliver components where cost efficiency and uncompromised quality are intrinsically linked. This is the foundation of sustainable, high-value manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Metal Manufacturing You Can Trust

At Wuxi Lead Precision Machinery, we understand that in high-end manufacturing, performance, reliability, and value are not compromises—they are expectations. As a leading custom metal manufacturing partner based in China, we specialize in delivering precision CNC machining, turning, milling, and fabrication services that meet the exacting standards of industries such as aerospace, medical devices, automation, and industrial equipment. Our mission is to provide affordable machining without sacrificing quality, consistency, or technical excellence.

When you choose to partner with Lead Precision, you gain more than a supplier—you gain a committed engineering ally. Our team of experienced CNC engineers and production specialists work closely with clients from concept through to final delivery, ensuring every component meets tight tolerances, material specifications, and functional requirements. Whether you need low-volume prototypes or high-volume production runs, our flexible manufacturing systems and lean processes allow us to scale efficiently while maintaining cost control.

Affordable machining does not mean cutting corners. It means optimizing processes, leveraging advanced technology, and maintaining rigorous quality assurance. Our facility is equipped with state-of-the-art CNC centers, multi-axis machines, automated inspection systems, and in-house metrology labs. We adhere to international quality standards, including ISO 9001:2015, and every part undergoes thorough dimensional and material verification before shipment.

We serve global clients who demand precision, speed, and transparency. From design for manufacturability (DFM) feedback to real-time production updates and on-time delivery, we ensure a seamless experience. Our engineering team is available to review your drawings, suggest cost-saving design improvements, and help reduce lead times—all while maintaining the integrity of your application.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Processes | CNC Milling (3-axis to 5-axis), CNC Turning, Wire EDM, Grinding |

| Materials | Aluminum, Stainless Steel, Carbon Steel, Titanium, Brass, Plastics (PEEK, Delrin, etc.) |

| Tolerances | Up to ±0.005 mm |

| Max Work Envelope | 1200 x 800 x 600 mm (Milling), Ø300 x 600 mm (Turning) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Passivation |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP, ISO 17025 Calibration |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Your next project deserves a manufacturing partner who combines technical precision with cost-effective solutions. At Wuxi Lead Precision Machinery, we are committed to delivering value at every stage of production.

Contact us today at [email protected] to discuss your requirements, request a quote, or schedule a virtual factory tour. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.