Technical Contents

Engineering Guide: Affordable Injection Molding

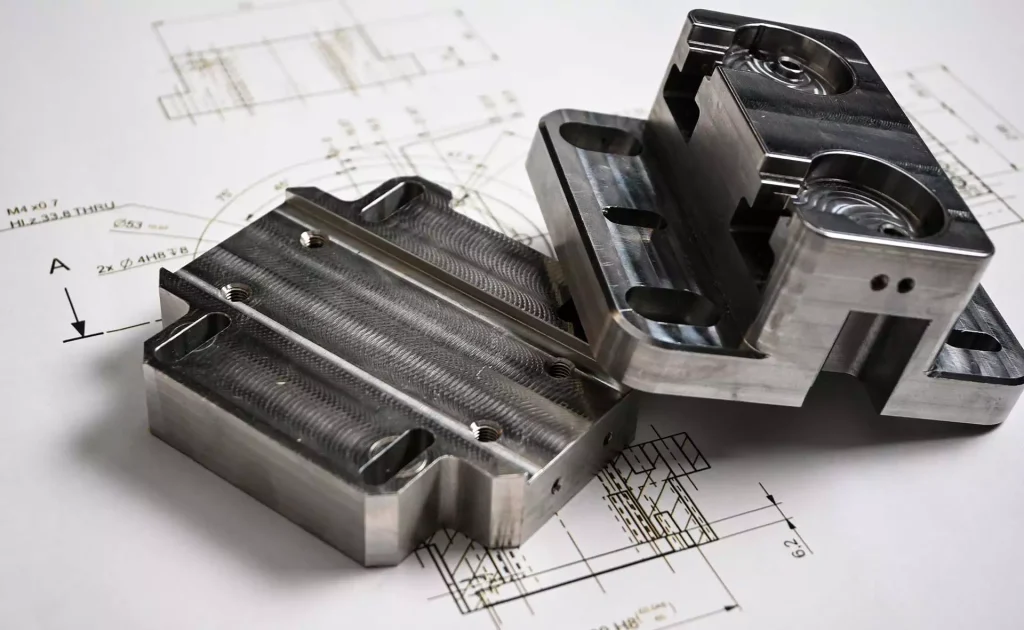

Engineering Insight: The Role of Precision in Affordable Injection Molding

When discussing affordable injection molding, the term “affordable” should never be mistaken for compromise in quality or precision. At Wuxi Lead Precision Machinery, we define affordability not as a reduction in standards, but as an optimization of engineering efficiency, material utilization, and manufacturing repeatability. True cost-effectiveness in injection molding is achieved not by cutting corners, but by maximizing precision at every stage—from mold design to final part production.

Precision is the cornerstone of reliable, high-volume injection molding. Even micron-level deviations in mold geometry can lead to part warpage, flash, or inconsistent wall thickness, resulting in increased scrap rates, higher rework costs, and ultimately, greater total expenditure. Our engineering teams leverage advanced CNC machining, coordinate measuring machines (CMM), and 3D metrology to ensure that every mold cavity adheres to exacting tolerances. This level of control enables consistent part replication across thousands or even millions of cycles, reducing unit cost without sacrificing integrity.

Our experience in high-stakes manufacturing environments—including supplying precision components for Olympic-grade sports equipment and mission-critical military hardware—has reinforced the non-negotiable role of accuracy. In these applications, failure is not an option. The same rigor we apply to aerospace-grade titanium components or ballistic protection systems is extended to our injection molding solutions. This heritage allows us to deliver molds and parts that meet ISO 9001 and IATF 16949 standards, ensuring reliability for automotive, medical, and industrial clients.

Affordability also stems from longevity. A precisely machined mold from Wuxi Lead can exceed one million cycles with minimal maintenance, drastically reducing downtime and replacement costs. By investing in high-grade tool steels such as H13, S136, and 2738, and applying surface treatments like nitriding or PVD coating, we enhance wear resistance and corrosion protection—key factors in extending mold service life.

Below are key technical specifications that define our standard for precision in injection mold manufacturing:

| Parameter | Specification |

|---|---|

| Typical Tolerance | ±0.005 mm |

| Surface Roughness (cavity) | Ra 0.05–0.1 µm (mirror finish available) |

| Mold Base Materials | LKM, FUTABA, or custom steel blocks |

| Tool Steel Options | P20, 718H, H13, S136, 2344, NAK80 |

| Cooling Channel Design | Conformal or optimized linear layouts |

| Lead Time (Standard Mold) | 25–35 days (depending on complexity) |

| Mold Life Expectancy | 500,000 – 1,000,000 cycles |

| Quality Standards | ISO 9001, IATF 16949, PPAP documentation |

At Wuxi Lead, we integrate decades of metal manufacturing expertise with data-driven process control to deliver injection molding solutions that are both technically superior and economically sustainable. Affordability, when engineered correctly, is the result of precision—not its adversary.

Precision Specs & Tolerances

Precision Manufacturing Capabilities: Delivering Cost-Efficient Excellence

At Wuxi Lead Precision Machinery, we redefine affordability in high-end metal manufacturing through uncompromising technical precision and process optimization. Our approach eliminates waste without sacrificing quality, ensuring complex components meet stringent industry requirements at competitive costs. Central to this capability is our advanced 5-axis CNC machining infrastructure, featuring DMG MORI and MAZAK systems with integrated thermal stability compensation. These platforms enable single-setup machining of intricate geometries in aerospace-grade titanium, medical stainless steel, and hardened tool steels, reducing lead times by 30–40% compared to conventional 3-axis methods. Multi-axis simultaneous motion ensures optimal tool engagement, minimizing tool wear and material waste while achieving surface finishes down to Ra 0.4 µm. This capability is critical for producing net-shape components with undercuts, organic contours, and tight internal features—common in hydraulic manifolds, turbine blades, and surgical instrumentation—where secondary operations would inflate costs and introduce error accumulation.

Quality control is engineered into every phase, not merely inspected at the endpoint. Our Zeiss CONTURA CMMs, equipped with VAST XT gold probes and Calypso software, perform full 3D dimensional verification against CAD models with traceable NIST-certified accuracy. Automated GD&T analysis ensures conformity to ASME Y14.5 standards, while real-time SPC data from in-process probes trigger immediate corrective actions. This closed-loop system reduces scrap rates by 25% and eliminates costly rework, directly contributing to cost efficiency. Material certifications, first-article inspections, and batch traceability are standard, providing auditable proof of compliance for ISO 13485, AS9100, and IATF 16949 frameworks.

The following table details our standard and achievable tolerance capabilities across common production scenarios. These values reflect our balance of precision, repeatability, and economic viability—proven across 12,000+ annual production runs for global clients.

| Material Type | Typical Production Tolerance | Maximum Capability (Validated Process) | Critical Feature Control |

|---|---|---|---|

| Aluminum Alloys | ±0.005 mm | ±0.002 mm | ±0.001 mm (GD&T) |

| Stainless Steel | ±0.008 mm | ±0.003 mm | ±0.0015 mm (GD&T) |

| Titanium Alloys | ±0.010 mm | ±0.004 mm | ±0.002 mm (GD&T) |

| Hardened Tool Steel | ±0.012 mm | ±0.005 mm | ±0.0025 mm (GD&T) |

Affordability at Wuxi Lead stems from eliminating hidden costs: reduced handling through 5-axis consolidation, minimized inspection failures via predictive metrology, and optimized material utilization via nested programming. We partner with clients during DFM stages to identify tolerance relaxation opportunities without functional compromise—transforming precision engineering into measurable cost savings. For mission-critical applications demanding micron-level accuracy, our process validation protocols ensure repeatability at scale, making high precision economically sustainable. This is how we deliver components that perform flawlessly in the field while meeting aggressive program budgets.

Material & Finish Options

Material selection is a critical decision in custom metal manufacturing, particularly when targeting affordable injection molding applications. The choice of material directly impacts part performance, tooling longevity, production cost, and surface finish quality. At Wuxi Lead Precision Machinery, we recommend evaluating aluminum, steel, and titanium based on mechanical requirements, production volume, and environmental exposure. Each material offers distinct advantages, and pairing them with appropriate finishing processes—such as anodizing—enhances durability and functionality.

Aluminum is widely used in injection molding tooling due to its excellent machinability, thermal conductivity, and lower cost compared to steel and titanium. It is ideal for low- to medium-volume production runs where rapid prototyping and faster cycle times are priorities. Grade 6061-T6 is commonly selected for its balanced strength and weldability, while 7075-T6 offers higher strength for more demanding applications. Aluminum’s lightweight nature also reduces wear on molding equipment, contributing to lower operational costs.

Steel remains the preferred choice for high-volume production molds. Its superior hardness and wear resistance ensure long service life under continuous operation. Tool steels such as P20, H13, and S136 are frequently used, with selection depending on corrosion resistance needs and mold complexity. While initial machining costs are higher than aluminum, steel’s longevity delivers a lower cost per unit over large production runs. For applications requiring extreme durability, hardened steel molds justify their investment through minimal maintenance and dimensional stability.

Titanium is less common in standard injection molding but offers exceptional strength-to-density ratio and corrosion resistance. It is typically reserved for specialized applications involving aggressive environments or where weight reduction is critical. While titanium’s high raw material and machining costs limit its use in cost-sensitive projects, it provides unmatched performance in niche industrial and aerospace tooling.

Anodizing is a key surface treatment for aluminum components, significantly improving wear and corrosion resistance. The process creates a durable oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) anodizing is standard for general protection, while Type III (hardcoat anodizing) delivers thicker, harder coatings suitable for high-wear tooling components.

Below is a comparative overview of key material properties relevant to injection molding applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 15–20 | 2.7 | 167 | Prototyping, low-volume molds |

| Aluminum 7075-T6 | 572 | 15–20 | 2.8 | 130 | High-strength tooling fixtures |

| P20 Steel | 1100 | 28–32 | 7.8 | 36 | Medium to high-volume molds |

| H13 Steel | 1600 | 45–50 | 7.8 | 30 | High-temperature molds |

| Titanium Grade 5 | 900 | 35–40 | 4.5 | 7.2 | Corrosion-resistant tooling |

Selecting the right material and finish ensures optimal balance between performance and cost. At Wuxi Lead Precision Machinery, we support clients in matching material properties to production demands, ensuring efficient, scalable, and economically sound manufacturing solutions.

Manufacturing Process & QC

Precision Injection Molding Process: Design to Zero-Defect Production

Achieving true affordability in custom metal injection molding (MIM) demands rigorous process control from initial concept through high-volume output. At Wuxi Lead Precision Machinery, our integrated workflow eliminates costly iterations and scrap by embedding precision engineering at every phase. Affordability is realized not through compromise, but through systematic defect prevention and optimized resource utilization. This disciplined approach ensures exceptional part quality while maximizing cost efficiency for demanding industrial applications.

The process commences with collaborative Design for Manufacturing (DFM) analysis. Our engineering team works directly with client CAD models, utilizing advanced simulation software to predict material flow, thermal behavior, and potential stress points specific to metal feedstocks. Critical factors like gate location, wall thickness transitions, and ejection strategies are optimized virtually. This phase identifies and resolves 95% of potential defects before tooling begins, significantly reducing downstream costs and accelerating time-to-market. Material selection is validated against performance requirements, ensuring the chosen alloy delivers the necessary mechanical properties and surface finish.

Prototyping leverages rapid tooling techniques like soft-metal cavities or additive manufactured inserts for initial validation. Parts produced undergo comprehensive metrology, including CMM inspection against nominal CAD data and application-specific functional testing. Dimensional stability under thermal cycling is assessed to confirm design integrity. This stage is not merely a form check; it validates the entire process window, ensuring the design is inherently manufacturable at scale. Client feedback is integrated swiftly, with design refinements implemented based on empirical data, not assumptions.

Mass production executes the perfected process under stringent Six Sigma protocols. Our automated MIM cells feature real-time process monitoring of critical parameters: injection pressure profiles, sintering furnace atmosphere control, and precise temperature gradients. Every component undergoes 100% automated optical inspection against geometric dimensioning and tolerancing (GD&T) callouts. Statistical process control (SPC) charts track key characteristics, with immediate process correction triggered by any deviation beyond established control limits. This closed-loop system guarantees consistent dimensional repeatability and material properties batch after batch.

The table below summarizes critical specifications maintained throughout our production continuum:

| Process Stage | Key Parameters | Tolerance Control | Quality Verification Method |

|---|---|---|---|

| Design & DFM | Material flow simulation, Thermal analysis, Stress prediction | ±0.05 mm initial feasibility | Virtual molding validation, DFM report |

| Prototyping | Feedstock characterization, Sintering shrinkage validation | ±0.025 mm on critical features | CMM full-scan, Functional testing, Metallurgical analysis |

| Mass Production | Injection pressure, Sintering profile, Atmosphere control | ±0.01 mm (Cpk > 1.67) | 100% AOI, SPC monitoring, Batch destructive testing |

This seamless integration of design validation, empirical prototyping, and statistically controlled mass production is the foundation of our zero-defect mandate. By preventing errors at their source and leveraging data-driven process refinement, Wuxi Lead delivers genuine affordability through exceptional yield rates and minimized total cost of ownership. Your complex metal components achieve the precision and reliability demanded by aerospace, medical, and automotive sectors without premium pricing penalties.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision-Driven, Cost-Optimized Injection Molding Solutions

At Wuxi Lead Precision Machinery, we redefine what affordable injection molding means in high-end custom metal manufacturing. Our mission is simple: deliver precision, reliability, and scalability without the premium price tag. We specialize in producing complex, high-tolerance metal components using advanced injection molding techniques tailored to industries such as aerospace, medical devices, automotive, and industrial automation. By integrating lean manufacturing principles with state-of-the-art CNC and MIM (Metal Injection Molding) technologies, we provide a seamless pathway from prototype to full-scale production—ensuring faster time-to-market and lower unit costs.

Affordability at Lead Precision does not mean compromise. It means efficiency, intelligent design, and vertical integration. Our in-house capabilities span material selection, mold design, sintering, CNC finishing, and comprehensive quality assurance. This end-to-end control allows us to minimize overhead, reduce lead times, and pass the savings directly to our clients—without sacrificing the tight tolerances or material integrity your applications demand.

We understand that every project is unique. That’s why our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, identifying cost-saving opportunities early in the development cycle. Whether you require small, intricate metal parts in stainless steel, titanium, or specialty alloys, or need high-volume production runs with consistent repeatability, we offer scalable solutions backed by ISO 9001-certified processes and rigorous in-process inspections.

Our clients choose Lead Precision not only for our technical capabilities but for our commitment to partnership. We act as an extension of your engineering team, providing transparent communication, real-time production updates, and responsive technical support. From initial concept to final delivery, we ensure every component meets your exact specifications—on time and within budget.

Below are key technical specifications that define our Metal Injection Molding capabilities:

| Specification | Detail |

|---|---|

| Material Options | 17-4 PH, 316L, 304L, 17-4PH, 420, 440C, Ti-6Al-4V, Inconel 718 |

| Tolerance Range | ±0.3% of nominal dimension (typical) |

| Part Weight Range | 0.1 g to 200 g |

| Minimum Feature Size | 0.2 mm (holes, ribs, threads) |

| Surface Finish | As-sintered: Ra 3.2 μm; Polished: Ra 0.2 μm |

| Production Capacity | Up to 500,000 units per month |

| Secondary Operations | CNC machining, heat treatment, plating, laser marking |

Ready to transform your manufacturing strategy with a partner that delivers precision, performance, and value? Contact us today at [email protected] to discuss your next project. Our engineering team is standing by to provide a free DFM analysis and competitive quotation. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we build partnerships that drive innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.