Technical Contents

Engineering Guide: Affordable Cnc Machine

Engineering Insight: Redefining Affordability in Precision CNC

The term “affordable CNC machine” often triggers skepticism within high-stakes manufacturing. True affordability in precision machining is not synonymous with low initial cost or compromised capability. It is defined by the total cost of ownership and the machine’s ability to consistently deliver parts within stringent tolerances, minimizing scrap, rework, and downtime. At Wuxi Lead Precision Machinery, we engineer affordability through exceptional build quality and intelligent design, ensuring our machines achieve micron-level precision reliably over their operational lifespan. This precision is the cornerstone of profitability; a machine incapable of holding 0.005mm tolerances on critical aerospace or medical components generates waste, delays, and reputational damage far exceeding any initial purchase price savings. Affordability is realized when the machine becomes a predictable, high-yield asset, not a source of recurring cost.

Precision directly translates to competitive advantage. Consider the demands of producing components for Olympic timing systems or critical military subsystems – environments where Wuxi Lead has consistently delivered. A timing sensor housing requiring 0.002mm flatness tolerance cannot tolerate machine-induced vibration or thermal drift. A military-grade actuator component failing due to inconsistent hole concentricity jeopardizes system performance. Our engineering heritage, forged through these exacting projects, informs every machine we build. We understand that “affordable” means the machine sustains its precision under real-world production loads, 24/7, without constant recalibration or environmental control extremes. This reliability eliminates hidden costs associated with quality failures and production stoppages, delivering genuine value.

Achieving this level of dependable precision requires fundamental engineering excellence, not cost-cutting shortcuts. The table below outlines critical specifications where Wuxi Lead machines deliver the performance necessary for true affordability in high-mix, high-precision environments:

| Specification | Wuxi Lead Precision Standard | Typical “Budget” Machine Impact |

|---|---|---|

| Positioning Accuracy | ±0.003 mm (ISO 230-2) | ±0.010 mm or worse |

| Repeatability | ±0.002 mm | ±0.005 mm |

| Thermal Growth Compensation | Active, Dual-Sensor System | Passive or None |

| Machine Bed Material | Meehanite M70 Grade Cast Iron | Lower Grade Cast Iron |

| Lead Screw Preload | Dynamically Adjusted | Fixed Preload |

This foundation enables manufacturers to confidently bid on and produce the most demanding components. Our Olympic project experience demanded absolute reliability in timing data; our military contracts required zero-defect output under harsh conditions. These aren’t just badges of honor – they are proof that Wuxi Lead machines are engineered to perform where precision is non-negotiable, yet operational cost efficiency is paramount. True affordability arrives when the machine consistently hits target, part after part, shift after shift, maximizing throughput of saleable product. It is the marriage of uncompromised precision engineering with robust, long-term value – a standard we meet daily for the world’s most demanding manufacturers. Choose precision engineered for productivity, not merely a low sticker price.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Machining

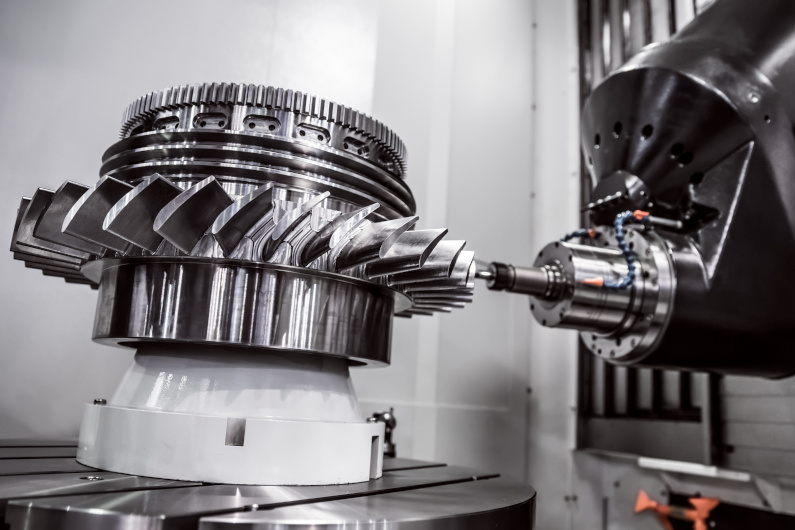

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to deliver uncompromising accuracy and repeatability in high-complexity manufacturing environments. Central to our capabilities is a fully integrated fleet of 5-axis CNC machining centers, enabling us to produce intricate geometries with superior surface finishes and minimal setup transitions. These machines combine simultaneous multi-axis motion with high-speed spindles and advanced tool path control, allowing for efficient machining of complex contours, deep cavities, and organic forms commonly found in aerospace components, medical devices, and precision automation systems.

Our 5-axis platforms are equipped with high-resolution feedback systems and thermal compensation technology, ensuring dimensional stability across extended production runs. The ability to approach parts from virtually any angle reduces the need for custom fixtures and secondary operations, significantly improving throughput while maintaining tight tolerances. We utilize industry-leading CAM software to optimize tool paths, minimize cycle times, and extend tool life—critical elements in delivering cost-effective precision at scale.

To ensure every component meets exacting standards, we employ a rigorous quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems are calibrated to ISO 17025 standards and operated by certified metrology technicians. Full first-article inspections, in-process checks, and final batch validations are standard practice. These inspections generate comprehensive reports traceable to international standards, including GD&T analysis, surface roughness verification, and 3D deviation mapping against CAD models.

Material versatility further enhances our technical scope. We routinely machine aluminum alloys, stainless steels, titanium, Inconel, and high-performance engineering plastics such as PEEK and ULTEM. Each material is processed using optimized cutting strategies and tooling selections tailored to its mechanical properties, ensuring structural integrity and dimensional accuracy.

All manufacturing and inspection data is managed within a centralized digital quality management system, enabling full traceability from raw material to final shipment. This integration supports compliance with AS9100, ISO 9001, and other industry-specific quality mandates.

The result is a precision manufacturing ecosystem that balances advanced technology, disciplined process control, and deep engineering expertise—delivering high-complexity parts with consistent quality and competitive turnaround times.

| Specification | Capability |

|---|---|

| Maximum Work Envelope (5-axis) | 1200 × 800 × 600 mm |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.4 μm (polished), typical 1.6–3.2 μm |

| Standard Tolerances (Machined Features) | ±0.01 mm (general), ±0.005 mm (critical) |

| Geometric Tolerances (GD&T) | ±0.01 mm (flatness, concentricity, true position) |

| Minimum Wall Thickness (Metal) | 0.5 mm (stable over 10 mm depth) |

| Minimum Hole Diameter | 0.3 mm (drilled), 0.1 mm (EDM) |

| CMM Measurement Uncertainty | < 0.002 mm (at 95% confidence) |

| Lead Time (Prototype to Production) | 7–15 days (standard), expedited options available |

Material & Finish Options

Material Selection for Cost-Effective Precision CNC Machining

Selecting the optimal material is fundamental to achieving both performance and cost efficiency in precision CNC machining. At Wuxi Lead Precision Machinery, we understand that “affordable” does not equate to compromise; it demands intelligent material strategy aligned with part function, volume, and machining complexity. The right choice minimizes waste, reduces cycle times, and ensures the finished component meets stringent specifications without unnecessary expenditure. Aluminum, steel, and titanium represent core material families where strategic selection delivers significant value.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications requiring an excellent strength-to-weight ratio, superior thermal conductivity, and exceptional machinability. Their lower density reduces raw material costs and machine load, while high chip evacuation rates enable faster spindle speeds and feed rates, directly lowering per-part machining costs. Aluminum is ideal for aerospace brackets, heat sinks, enclosures, and consumer electronics components. The inherent corrosion resistance of many alloys is frequently enhanced cost-effectively through anodizing, adding surface hardness and aesthetic options without significant process complexity.

Carbon and alloy steels, such as 1018, 1045, and 4140, are indispensable for applications demanding high strength, wear resistance, and structural integrity under load. While generally slower to machine than aluminum due to higher hardness and toughness, steels offer superior durability for gears, shafts, hydraulic components, and tooling fixtures. Optimizing toolpaths and utilizing appropriate carbide tooling on modern CNC machines mitigates machining time penalties. Post-machining treatments like heat treating or plating are often necessary, but careful material grade selection upfront can minimize secondary operations, balancing initial material cost with total processing expense.

Titanium alloys, primarily Grade 2 and Grade 5 (Ti-6Al-4V), present unique challenges and opportunities. Renowned for exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium is critical for aerospace, medical implants, and high-performance automotive parts. However, its low thermal conductivity and chemical reactivity necessitate specialized CNC machining parameters, slower speeds, and rigid setups, increasing machining time and cost. Affordability here is achieved through meticulous process planning, premium tooling, and minimizing material removal – leveraging CNC precision to near-net-shape the expensive billet. Anodizing titanium is less common but specialized processes exist for specific coloration or minor wear enhancement.

Anodizing remains the most prevalent and cost-effective surface finish for aluminum components. This electrochemical process creates a durable, corrosion-resistant oxide layer that can be dyed various colors. Type II (sulfuric acid) anodizing offers a good balance of thickness, hardness, and cost for general industrial use. Type III (hardcoat) anodizing provides significantly greater wear resistance for demanding applications, though at a higher cost. The process is highly scalable, compatible with high-volume production, and adds minimal lead time, making it a strategic choice for enhancing aluminum part longevity and appearance affordably.

The table below summarizes key comparative properties influencing cost-effective machining decisions:

| Material Family | Typical Density (g/cm³) | Typical Tensile Strength (MPa) | Machinability Rating (Relative to 1212 Steel = 100%) | Relative Material Cost Index |

|---|---|---|---|---|

| Aluminum (6061-T6) | 2.7 | 310 | 90-100% | 1.0 (Baseline) |

| Steel (1045) | 7.8 | 570 | 50-60% | 0.8-1.0 |

| Titanium (Ti-6Al-4V) | 4.4 | 900 | 20-30% | 5.0-8.0 |

Wuxi Lead Precision Machinery leverages advanced CNC technology and deep process expertise to optimize machining strategies across these critical materials. We partner with clients to analyze application requirements, ensuring the material and finish selection delivers the required performance at the most competitive total cost, proving that precision and affordability are achievable in tandem.

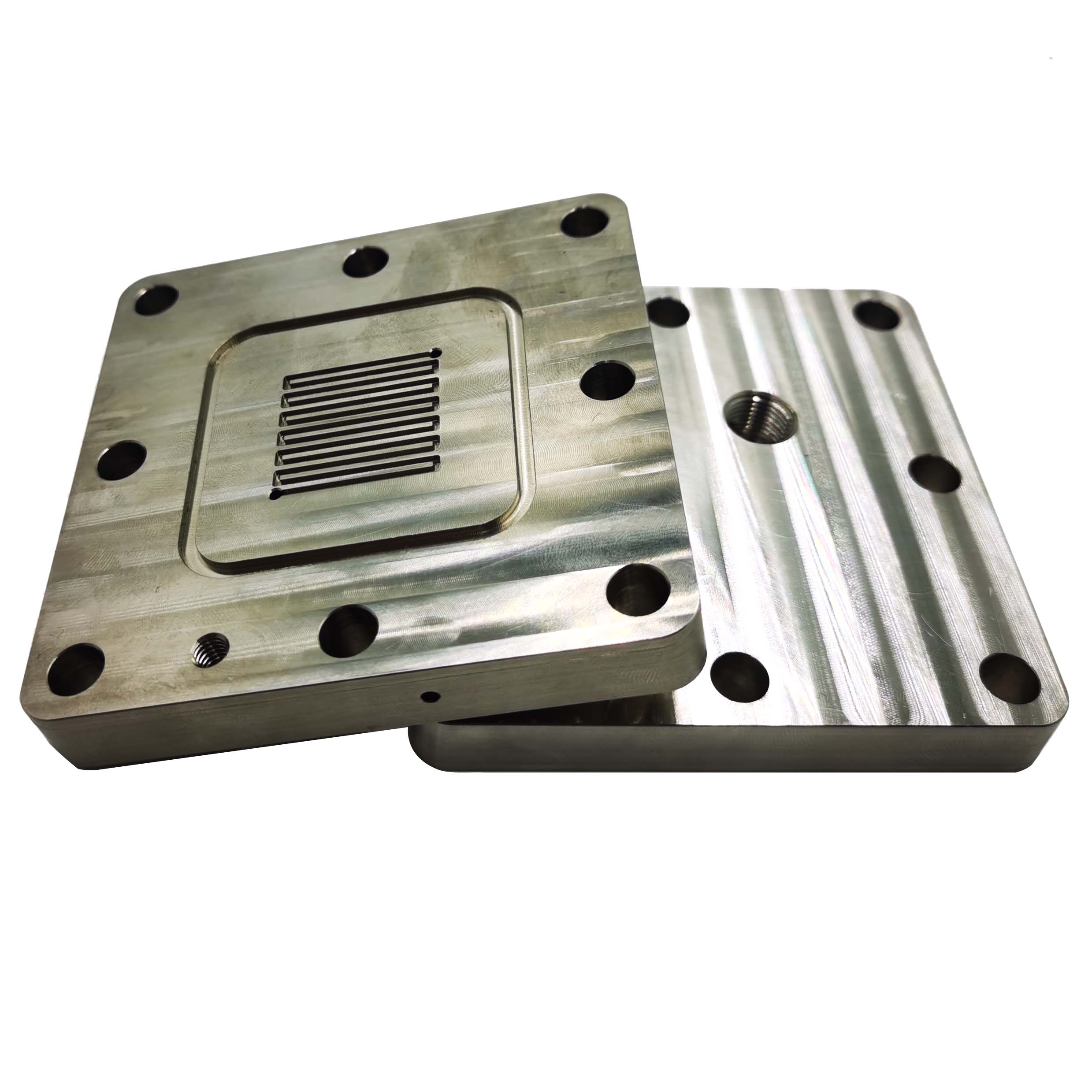

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process is engineered for precision, consistency, and zero-defect outcomes. Every CNC machining project follows a disciplined workflow that begins with design and culminates in high-volume mass production. This structured approach ensures that our clients receive components that meet exacting specifications while maintaining affordability without compromising quality.

The process begins with Design Engineering, where our team collaborates closely with clients to analyze CAD and CAM files. We conduct thorough Design for Manufacturability (DFM) reviews to identify potential issues early, optimize toolpaths, and select the most suitable materials and tolerances. This stage is critical in reducing waste, minimizing machining time, and ensuring that the design is both functional and cost-effective to produce. Our engineers use advanced simulation software to validate the machining strategy, ensuring dimensional accuracy and surface finish compliance before any material is cut.

Next comes Prototyping, a phase dedicated to validating the design in physical form. Using high-precision 3-, 4-, and 5-axis CNC machines, we produce a limited run of prototype parts. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We verify dimensional accuracy, material integrity, and functional fit. Client feedback is integrated at this stage, allowing for rapid iterations and refinements. The goal is to achieve a perfect match between design intent and physical output, ensuring that the final product performs as expected in real-world applications.

Once the prototype is approved, we transition seamlessly into Mass Production. Our automated CNC cells operate under strict process controls, with real-time monitoring systems that track tool wear, spindle load, and environmental conditions. Each part is traceable through our Quality Management System (QMS), which complies with ISO 9001 standards. In-process inspections and final audits are conducted at defined intervals to maintain zero-defect performance. Our lean manufacturing principles reduce cycle times and inventory waste, enabling us to offer affordable CNC machining without sacrificing precision or reliability.

Throughout the entire production lifecycle, data transparency and continuous improvement are embedded into our operations. We provide clients with detailed inspection reports, process capability (Cp/Cpk) data, and material certifications, ensuring full traceability and compliance.

Below are key specifications of our CNC machining capabilities:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Spindle Speed | Up to 24,000 rpm |

| Tolerance Range | ±0.003 mm to ±0.01 mm (depending on feature) |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Plastics |

| Quality Standard | ISO 9001:2015, Full CMM Inspection |

| Lead Time (Prototyping) | 5–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume dependent) |

This end-to-end process ensures that Wuxi Lead Precision Machinery delivers affordable, high-quality CNC components with zero defects—on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Engineered Affordability Without Compromise

In precision CNC machining, the pursuit of affordability must never equate to sacrificing capability or longevity. At Wuxi Lead Precision Machinery, we engineer solutions where strategic cost optimization aligns with uncompromised engineering integrity. Our machines deliver aerospace-grade tolerances and industrial-strength reliability at a total cost of ownership that redefines value for mid-volume production environments. This balance is achieved through vertical integration of critical components, lean manufacturing protocols in our Wuxi facility, and decades of motion control expertise embedded in every axis. We eliminate hidden costs associated with frequent recalibration, premature wear, or production downtime—ensuring your investment yields consistent throughput from day one.

Unlike generic “budget” CNC systems, Lead Precision machines undergo rigorous thermal stability testing and 72-hour continuous load validation before shipment. Our proprietary vibration-dampening bed castings and pre-loaded THK linear guides maintain sub-micron repeatability across shifts and seasons. This engineering discipline translates directly to reduced scrap rates, lower maintenance overhead, and predictable part quality—critical metrics for contract manufacturers competing on both price and precision. When affordability is engineered into the core architecture rather than stripped from peripheral features, your production floor gains a sustainable competitive edge.

The following specifications demonstrate how our LP Series achieves this equilibrium for demanding applications in medical device manufacturing, hydraulic components, and automation subsystems:

| Model | Positioning Accuracy | Repeatability | Max Spindle Speed | Rapid Traverse | Work Envelope (mm) | Starting Price Range (FOB China) |

|---|---|---|---|---|---|---|

| LP-500 VMC | ±0.003 mm | ±0.001 mm | 12,000 RPM | 48 m/min | 500 x 400 x 350 | $48,000 – $62,000 |

| LP-800 VMC | ±0.004 mm | ±0.002 mm | 10,000 RPM | 42 m/min | 800 x 500 x 450 | $78,000 – $94,000 |

| LP-630 HMC | ±0.005 mm | ±0.002 mm | 8,000 RPM | 36 m/min | 630 x 500 x 500 | $115,000 – $138,000 |

These figures reflect real-world performance validated by third-party metrology reports—not theoretical benchmarks. Each system includes our LeadOS control interface with predictive maintenance modules and seamless CAD/CAM integration, eliminating costly software add-ons. Our global service network further ensures minimal disruption through certified technicians in North America, Europe, and Southeast Asia, providing on-site support within 72 hours of request.

The true measure of affordability lies in sustained productivity, not the initial invoice. Wuxi Lead Precision Machinery invites you to validate our claim through a no-obligation production trial. Submit your most challenging component drawing, and we will machine a sample part at our facility—demonstrating surface finishes, geometric tolerances, and cycle times that meet your exact requirements. This is how we prove that precision engineering and operational economy are not trade-offs but synergistic outcomes.

Contact our engineering team directly at [email protected] to initiate your trial request or schedule a virtual facility tour. Include your annual part volume and critical tolerance specifications for a tailored ROI analysis. Let us show how Lead Precision transforms perceived cost barriers into measurable production advantages—engineered for your success, delivered without compromise.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.