Technical Contents

Engineering Guide: Aerospace Parts Companies

Engineering Insight: Precision as the Non-Negotiable Foundation in Aerospace Manufacturing

In the aerospace sector, precision transcends mere specification; it is the absolute bedrock of safety, performance, and regulatory compliance. The operational environment for aircraft and spacecraft components demands unwavering dimensional accuracy and surface integrity. Tolerances measured in microns directly impact aerodynamic efficiency, structural fatigue life, and the seamless integration of complex assemblies. A deviation of even 0.005mm in a turbine blade root or a landing gear fitting can initiate catastrophic failure modes under extreme stress, vibration, and thermal cycling. Regulatory bodies like the FAA and EASA enforce stringent standards (AS9100 Rev D) where traceability and process validation are as critical as the final part geometry. For aerospace parts companies, achieving and consistently proving this level of precision is not optional—it is the fundamental requirement for market entry and sustained operational viability. The cost of failure, both in human terms and financial liability, mandates manufacturing processes engineered for zero-defect outcomes from raw material to final inspection.

Wuxi Lead Precision Machinery operates at this exacting standard daily. Our CNC machining centers, maintained to micron-level calibration, are supported by a quality management system rigorously certified to AS9100 Rev D and ISO 9001. This commitment is proven through our delivery of mission-critical components where failure is inconceivable. We have manufactured precision elements for national defense systems, meeting the uncompromising demands of military aerospace programs where reliability directly impacts national security. Similarly, our work on components for Olympic timing systems demonstrates our capability to achieve the sub-micron repeatability required for applications where milliseconds define success. This experience translates directly to commercial aerospace manufacturing, ensuring every part we produce meets the sector’s most demanding geometric and material property requirements.

Our core machining capabilities are engineered specifically for aerospace-grade metals and complex geometries. The table below outlines key performance parameters relevant to critical aerospace components:

| Specification Category | Performance Capability | Relevance to Aerospace Parts |

|---|---|---|

| Dimensional Tolerance | ± 0.001 mm (± 0.00004 inches) | Critical for turbine assemblies, bearing fits, structural interfaces |

| Surface Roughness (Ra) | As low as 0.2 µm (8 µin) | Essential for fatigue-critical parts, sealing surfaces, aerodynamic profiles |

| Material Expertise | Titanium (Gr 2,5,23), Inconel 718/625, Aerospace Alloys (2024, 7075), High-Strength Steels | Meets stringent material certification requirements for airframes and engines |

| Process Certification | AS9100 Rev D, ISO 9001, NADCAP Accredited Processes | Mandatory for supply chain qualification and traceability |

Partnering with a manufacturer possessing demonstrable, certified experience in high-consequence precision engineering mitigates program risk. At Wuxi Lead Precision Machinery, our processes, technology, and engineering culture are built upon the understanding that in aerospace, precision is not a target—it is the only acceptable outcome. We provide aerospace parts companies with the verified capability and documented pedigree to confidently meet the industry’s relentless demands.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining for Aerospace-Critical Components

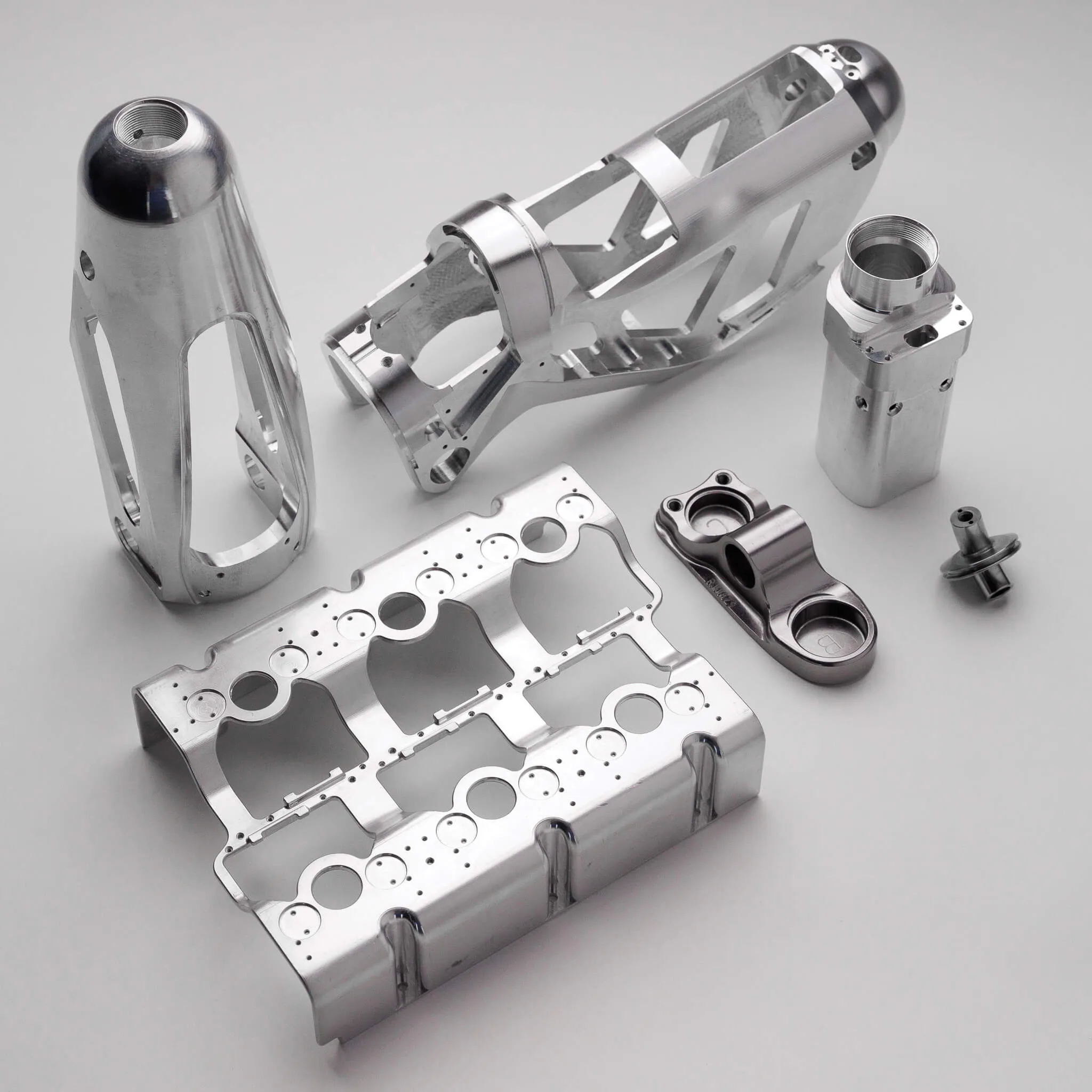

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the exacting demands of the aerospace industry. We specialize in high-precision custom metal manufacturing, with a core focus on complex, mission-critical components that require superior dimensional accuracy, repeatability, and material integrity. Our facility is anchored by state-of-the-art 5-axis CNC machining centers, enabling us to produce intricate geometries with seamless multi-directional tool access. This advanced capability eliminates the need for multiple setups, reduces human error, and ensures consistent part quality across both prototyping and full-scale production runs.

Our 5-axis machining systems support simultaneous motion across all rotational and linear axes, allowing for the precise fabrication of contoured surfaces, deep cavities, and compound angles commonly found in turbine housings, structural brackets, fuel system components, and flight control mechanisms. We work with a wide range of aerospace-grade materials, including titanium alloys (Ti-6Al-4V), Inconel 718 and 625, aluminum 7075-T6, and high-strength stainless steels. Each machining program is optimized using industry-leading CAM software to ensure toolpath efficiency, minimal thermal distortion, and maximum material removal rates without compromising surface finish or tolerance.

To guarantee compliance with aerospace quality standards, every production phase is supported by a rigorous quality control protocol. Our coordinate measuring machine (CMM) inspection system provides full 3D metrology verification, capturing critical dimensions, geometric tolerances, and positional accuracies down to micrometer-level resolution. All inspections are documented with detailed first-article inspection (FAI) reports, adhering to AS9102 standards, and are available for full traceability. Additionally, our quality management system is ISO 9001:2015 and AS9100D certified, ensuring full alignment with aerospace regulatory requirements.

We maintain tight process control through continuous in-process monitoring, tool wear compensation, and environmental stabilization within our machining cells. This holistic approach enables us to deliver components that not only meet but exceed the performance expectations of Tier 1 and OEM aerospace partners.

Precision Tolerances and Technical Specifications

| Parameter | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm (±0.0002″) |

| Linear Dimensional Tolerance | ±0.01 mm (±0.0004″) |

| Geometric Tolerance (GD&T) | Down to 0.012 mm (0.0005″) |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) |

| Feature Repeatability | ±0.003 mm (±0.0001″) over batch runs |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| CMM Measurement Accuracy | ±2.5 + L/300 µm (per ISO 10360-2) |

Our technical infrastructure, combined with deep engineering expertise, positions Wuxi Lead Precision Machinery as a trusted partner for aerospace manufacturers requiring precision, reliability, and compliance in every component delivered.

Material & Finish Options

Material Selection for Critical Aerospace Components

Material choice directly impacts flight safety, component longevity, and operational efficiency in aerospace applications. At Wuxi Lead Precision Machinery, we prioritize materials meeting AMS, ASTM, and NADCAP standards to ensure compliance with stringent aerospace requirements. Below, we detail key properties of aluminum, steel, and titanium alloys alongside anodizing specifications critical for part performance.

Aluminum alloys like 7075-T6 dominate airframe structures due to their exceptional strength-to-weight ratio. This alloy achieves ultimate tensile strength of 572 MPa while maintaining low density, reducing fuel consumption without compromising structural integrity. Its machinability allows complex geometries, though surface protection via anodizing is essential for corrosion resistance in humid or salt-laden environments.

High-strength steels such as 4340 and 300M are indispensable for landing gear and engine mounts. These alloys deliver yield strengths exceeding 1,240 MPa and withstand extreme cyclic loads. While heavier than aluminum, their fatigue resistance and fracture toughness under high stress justify their use in safety-critical zones. Passivation or specialized coatings mitigate corrosion risks in these high-carbon alloys.

Titanium Grade 5 (Ti-6Al-4V) balances near-steel strength with 40% less weight, making it ideal for compressor blades and fasteners. Its natural oxide layer provides inherent corrosion resistance, but anodizing enhances surface hardness for wear-prone areas. Titanium’s biocompatibility and non-magnetic properties further suit it for avionics housings.

Anodizing transforms aluminum surfaces into durable, corrosion-resistant barriers. Type II (sulfuric acid) anodizing offers moderate wear resistance for non-structural parts, while Type III (hard coat) anodizing achieves 50–70 μm thickness with hardness exceeding 500 HV. This is mandatory for components like wing brackets exposed to abrasive debris. Our NADCAP-accredited facility controls pore sealing and dyeing to meet AMS 2469 specifications, ensuring dimensional stability within ±0.005 mm.

Critical Material Properties for Aerospace Applications

| Material | Density (g/cm³) | Ultimate Tensile Strength (MPa) | Max Operating Temp (°C) | Key Aerospace Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 2.81 | 572 | 125 | Wing spars, fuselage frames |

| Steel 4340 | 7.85 | 1,100 | 425 | Landing gear, engine shafts |

| Titanium Ti-6Al-4V | 4.43 | 900 | 600 | Compressor disks, fasteners |

Material selection must align with stress analysis, environmental exposure, and regulatory mandates. Wuxi Lead Precision Machinery combines metallurgical expertise with ISO 9001:2015-certified processes to validate each material batch through tensile testing, spectrographic analysis, and microstructure verification. Partner with us to navigate these complexities—our engineering team collaborates from design to delivery, ensuring your components exceed aerospace performance thresholds while optimizing cost efficiency.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering mission-critical metal components to aerospace parts companies with uncompromising precision and reliability. Our end-to-end production process is engineered for performance, traceability, and zero-defect outcomes. From initial concept to full-scale manufacturing, every phase is governed by strict quality protocols aligned with international aerospace standards.

The process begins with collaborative design engineering. Our team works directly with aerospace clients to interpret technical blueprints, material specifications, and performance requirements. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry for structural integrity, weight efficiency, and manufacturability. This stage includes Design for Manufacturability (DFM) reviews to preempt production challenges and ensure compliance with AS9100 and NADCAP requirements.

Prototyping follows design validation, serving as both a functional and dimensional benchmark. We employ 5-axis CNC milling, precision turning, and additive manufacturing techniques to produce high-fidelity prototypes from flight-grade materials such as Inconel 718, Ti-6Al-4V, and 7075-T6 aluminum. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and non-destructive testing (NDT) methods including fluorescent penetrant and X-ray inspection. This phase confirms material behavior, tolerances, and assembly fit, allowing for iterative refinement before launch into mass production.

Once prototype approval is secured, we transition seamlessly into high-volume manufacturing. Our automated CNC production cells operate under real-time monitoring systems that track tool wear, thermal drift, and process capability. Statistical Process Control (SPC) ensures every machining parameter remains within defined control limits, minimizing variability. Each batch is traceable to raw material heat numbers, machine logs, and inspection records, supporting full documentation for FAA and EASA certification audits.

Throughout all stages, quality is embedded into the process—not inspected in. Our zero-defect philosophy is enforced through redundant inspection checkpoints, operator certification programs, and a closed-loop corrective action system. Any deviation triggers immediate containment and root cause analysis, preventing non-conforming parts from progressing.

The result is a scalable, auditable, and highly repeatable manufacturing flow that meets the extreme demands of aerospace applications. Below are key process specifications we maintain across all production runs.

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ISO 2768, ASME Y14.5 |

| Surface Finish | Ra 0.4 µm (typical), down to Ra 0.1 µm | ASTM E2516, ISO 1302 |

| Materials | Ti-6Al-4V, Inconel 718, 7075-T6, 300M, Waspaloy | AMS, ASTM, MIL-DTL |

| Max Part Size | 800 mm × 600 mm × 500 mm | Customizable per requirement |

| Production Capacity | Up to 10,000 units/month (per part) | Scalable with automation |

| Inspection Coverage | 100% critical dimensions | CMM, NDT, in-process gauging |

| Lead Time (Prototype) | 10–15 business days | Expedited options available |

| Lead Time (Mass Production) | 4–6 weeks (after PPAP approval) | JIT delivery supported |

Wuxi Lead Precision Machinery stands as a trusted partner in aerospace manufacturing, where precision is not optional—it is essential.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Aerospace Components

The aerospace industry operates under uncompromising standards where component failure is not an option. Achieving the required levels of precision, material integrity, and traceability demands a manufacturing partner with deep technical expertise, rigorous quality systems, and a proven commitment to aerospace excellence. Wuxi Lead Precision Machinery stands ready to be your strategic partner in China, delivering custom metal components that meet and exceed the stringent demands of global aviation, defense, and space applications. We understand that your reputation hinges on the reliability of every part we produce, which is why we integrate aerospace-grade processes into the core of our operations from initial design consultation through final inspection and delivery.

Our facility in Wuxi is engineered specifically for high-complexity aerospace manufacturing. We combine advanced multi-axis CNC machining centers, Swiss-type lathes, and precision grinding equipment with a quality management system certified to AS9100D and ISO 9001:2015 standards. This foundation ensures consistent production of components featuring tight geometric tolerances, superior surface finishes, and full material traceability – critical requirements for flight-critical hardware. Our engineering team collaborates closely with your design and procurement staff, providing DFM feedback early in the process to optimize manufacturability without sacrificing performance, ultimately reducing time-to-market and mitigating production risks. We manage complex supply chain logistics with transparency, ensuring on-time delivery while safeguarding your intellectual property through robust confidentiality protocols.

The technical capabilities required for modern aerospace manufacturing are non-negotiable. Below are key specifications demonstrating our readiness for your most demanding projects:

| Capability | Specification Detail | Aerospace Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (sub-micron repeatability) | Critical for fuel systems, actuators, landing gear |

| Max Work Envelope | 1200 x 800 x 650 mm (5-axis machining) | Accommodates structural brackets, housings |

| Material Expertise | Inconel 718/625, Ti-6Al-4V, 17-4PH, 300M, Aluminum 7075 | Full spectrum of aerospace alloys |

| Surface Finish | Ra 0.2 µm achievable (precision grinding) | Essential for fatigue-critical surfaces |

| Quality Certification | AS9100D, ISO 9001:2015, NADCAP (pending) | Mandatory compliance for Tier 1/2 suppliers |

Choosing a manufacturing partner is a strategic decision impacting program success, regulatory compliance, and long-term supply chain resilience. Wuxi Lead Precision Machinery offers more than machining services; we provide engineering partnership, unwavering quality commitment, and the operational agility required in today’s dynamic aerospace sector. Our strategic location in China provides logistical advantages without compromising Western quality expectations, supported by an English-fluent engineering and project management team.

Do not let manufacturing complexities delay your next critical project. Contact our aerospace solutions team today to discuss how Lead Precision can deliver the precision, reliability, and partnership your program demands. Reach out to [email protected] for a confidential consultation and technical capability review. Let us prove why leading aerospace innovators trust Lead Precision for components where perfection is mandatory. Precision isn’t optional in aerospace – it’s the foundation of flight. Partner with the team that engineers it into every part.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.