Technical Contents

Engineering Guide: Aerospace Laser Cutting Services

Engineering Insight: Aerospace Laser Cutting Services

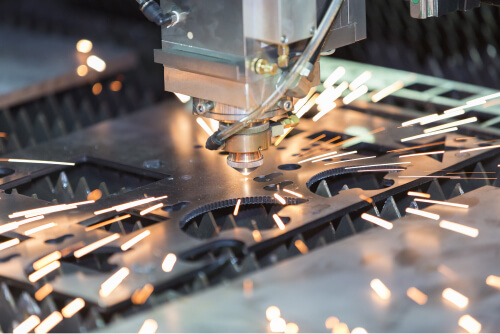

In the aerospace industry, where performance, safety, and reliability are non-negotiable, the role of precision in manufacturing cannot be overstated. Every component, from structural brackets to engine housings, must meet exacting dimensional tolerances and material integrity standards. This demand places aerospace laser cutting services at the forefront of advanced sheet metal fabrication. At Wuxi Lead Precision Machinery, we understand that precision is not just a specification—it is a foundational requirement that drives every stage of production.

Laser cutting offers unparalleled accuracy, especially when working with high-strength alloys such as titanium, Inconel, and aluminum commonly used in aerospace applications. The non-contact nature of the laser process minimizes mechanical stress on materials, preserving their structural properties while enabling intricate geometries and tight tolerances. Our fiber laser systems are calibrated to maintain ±0.05 mm dimensional accuracy, ensuring repeatability across high-mix, low-volume production runs typical in aerospace programs.

Our facility in Wuxi integrates state-of-the-art laser cutting platforms with automated material handling and real-time monitoring systems. This integration ensures consistent beam quality, optimal kerf width control, and minimal heat-affected zones—critical factors when fabricating components destined for flight-critical environments. Moreover, our process validation protocols comply with AS9100D and NADCAP standards, reinforcing our commitment to aerospace-grade quality.

Wuxi Lead Precision Machinery brings over 15 years of experience in high-precision manufacturing, serving sectors where failure is not an option. Our work has supported mission-critical applications, including components for China’s national defense systems and structural elements used in infrastructure for the Olympic Games. These projects demanded not only technical excellence but also rigorous documentation, traceability, and adherence to strict delivery timelines—capabilities we have refined and institutionalized across our aerospace operations.

We specialize in processing materials up to 25 mm in thickness with clean edge quality, eliminating the need for secondary finishing in many cases. Our engineers work closely with design teams to optimize part layouts, reduce material waste, and ensure manufacturability—adding value beyond the cutting stage.

The table below outlines key technical specifications of our aerospace laser cutting services:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Maximum Power | 12 kW |

| Material Thickness Range | 0.5 mm – 25 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Cutting Tolerance | ±0.05 mm |

| Supported Materials | Aluminum, Titanium, Inconel, Stainless Steel, Carbon Steel |

| Quality Standards | AS9100D, NADCAP, ISO 9001 |

| Software Integration | CAD/CAM, ERP, MES |

Precision in aerospace laser cutting is more than a technical benchmark—it is a commitment to excellence. At Wuxi Lead Precision Machinery, we combine advanced technology, proven expertise, and a culture of quality to deliver components that meet the highest demands of flight safety and performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Aerospace Laser Cutting

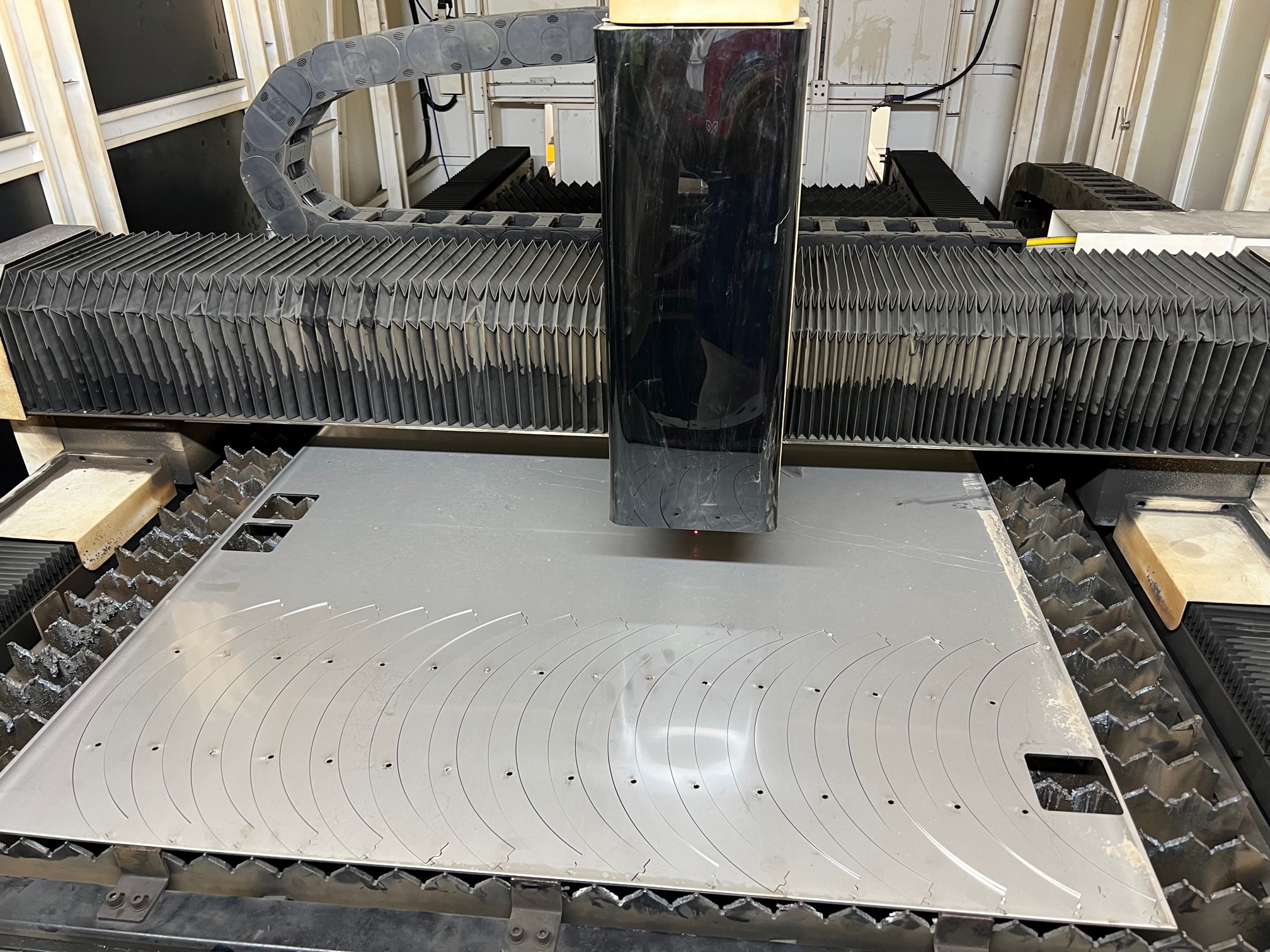

Wuxi Lead Precision Machinery delivers mission-critical laser cutting solutions engineered specifically for aerospace component manufacturing. Our advanced 5-axis CNC fiber laser systems process complex geometries in titanium alloys, aluminum alloys, Inconel, and specialty steels up to 25mm thickness with uncompromising accuracy. The integration of 5-axis motion control eliminates secondary operations for contoured parts, reducing lead times while maintaining geometric integrity across multi-faceted features. High-power resonators with adaptive beam control ensure minimal heat-affected zones and burr-free edges, critical for fatigue-sensitive airframe and engine components. All cutting parameters are monitored in real-time via integrated sensors, with closed-loop feedback adjusting power, gas pressure, and focal position to counter material variances. This closed-loop process guarantees consistent edge quality and dimensional stability across production runs, directly supporting aerospace weight-reduction initiatives without sacrificing structural reliability.

Rigorous quality assurance begins with material certification traceability to mill test reports. Every critical dimension undergoes verification using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), providing NIST-traceable metrology with 2.5 + L/300 µm accuracy. Our AS9100D-certified quality management system mandates first-article inspection (FAI) to AS9102 standards and in-process checks at defined control points. Statistical process control (SPC) charts monitor key characteristics, ensuring capability indices (CpK) consistently exceed 1.67 for critical features. All inspection data is digitally archived for full lot traceability, meeting stringent aerospace audit requirements including NADCAP AC7101 compliance.

The following table details our certified tolerance capabilities for aerospace laser cutting:

| Material Thickness Range | Linear Tolerance | Angular Tolerance | Feature Position Tolerance | Process Capability Index (CpK) |

|---|---|---|---|---|

| 0.5 – 3.0 mm | ±0.05 mm | ±0.2° | ±0.10 mm | ≥ 1.85 |

| 3.1 – 10.0 mm | ±0.08 mm | ±0.3° | ±0.15 mm | ≥ 1.75 |

| 10.1 – 25.0 mm | ±0.12 mm | ±0.5° | ±0.20 mm | ≥ 1.67 |

These specifications apply to aerospace-grade materials including Ti-6Al-4V, 7075-T6 aluminum, Inconel 718, and 300M steel under controlled environmental conditions. Our engineering team collaborates with clients during DFM reviews to optimize part geometry for laser processing, ensuring manufacturability while meeting stringent airworthiness standards. This integrated approach—combining 5-axis precision, real-time process control, and aerospace-grade metrology—delivers components ready for assembly with zero rework. Wuxi Lead’s commitment to technical excellence ensures your most demanding laser cutting requirements are met with engineering rigor and documented quality assurance.

Material & Finish Options

Material Selection for Aerospace Laser Cutting Services

In aerospace manufacturing, precision, reliability, and performance under extreme conditions are non-negotiable. Selecting the right material for laser cutting is a critical decision that directly impacts component strength, weight, corrosion resistance, and overall system efficiency. At Wuxi Lead Precision Machinery, we specialize in high-precision sheet metal fabrication tailored to the stringent demands of the aerospace industry. Our expertise in laser cutting enables consistent, clean, and dimensionally accurate results across a range of advanced materials.

Aluminum is one of the most widely used materials in aerospace applications due to its excellent strength-to-weight ratio and natural corrosion resistance. Grades such as 6061-T6 and 7075-T6 are commonly selected for structural components, fuselage panels, and internal frameworks. These alloys respond exceptionally well to fiber laser cutting, producing smooth edges with minimal thermal distortion. Aluminum’s lightweight nature contributes to fuel efficiency, a key performance metric in aerospace design.

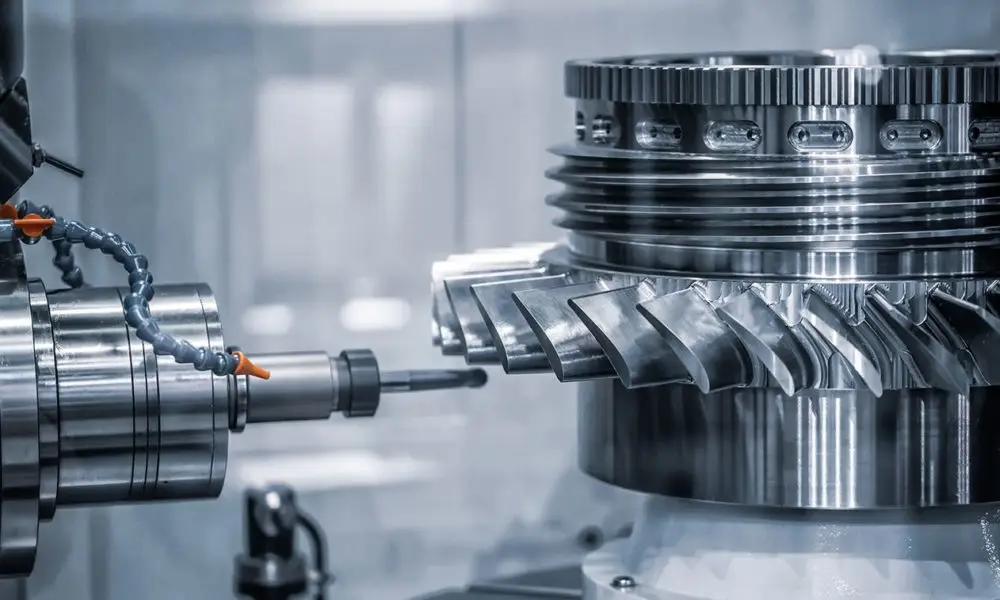

Steel, particularly stainless steel grades like 304 and 316, is employed where higher strength and temperature resistance are required. While heavier than aluminum, stainless steel offers superior durability and oxidation resistance, making it ideal for engine components, hydraulic systems, and landing gear supports. High-precision laser cutting ensures tight tolerances and clean kerf edges, essential for parts that undergo further welding or assembly.

Titanium and its alloys, such as Grade 5 (Ti-6Al-4V), are critical in high-stress, high-temperature environments. Known for their exceptional strength-to-density ratio and resistance to fatigue and corrosion, titanium components are commonly found in jet engines, airframes, and fastening systems. Laser cutting titanium requires advanced control systems to manage heat input and prevent oxidation, a capability we deliver through our state-of-the-art fiber laser platforms equipped with inert gas assist.

Post-cut surface finishing further enhances performance and longevity. Anodizing is the preferred surface treatment for aluminum components, providing increased corrosion resistance, improved wear properties, and electrical insulation. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly specified, with the latter offering thicker, more durable coatings suitable for high-wear aerospace applications. Our integrated finishing solutions ensure uniform coating thickness and adherence to MIL-A-8625 standards.

The following table outlines key material properties and laser processing parameters relevant to aerospace fabrication.

| Material | Common Grades | Thickness Range (mm) | Tensile Strength (MPa) | Laser Type | Typical Assist Gas |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 0.5 – 12 | 310 – 570 | Fiber Laser | Nitrogen |

| Stainless Steel | 304, 316 | 0.8 – 15 | 505 – 620 | Fiber Laser | Nitrogen / Oxygen |

| Titanium | Grade 2, Grade 5 | 0.8 – 10 | 345 – 1000 | Fiber Laser | Argon |

Material selection must align with functional requirements, environmental exposure, and regulatory standards. At Wuxi Lead Precision Machinery, we support aerospace clients with material certification, process validation, and full traceability to ensure compliance with AS9100 and NADCAP standards.

Manufacturing Process & QC

Aerospace Laser Cutting Production Process: Precision Engineered for Zero Defects

At Wuxi Lead Precision Machinery, our aerospace laser cutting process is a rigorously controlled sequence designed from inception to guarantee Zero Defects compliance. This critical standard is non-negotiable for flight-critical components where material integrity and dimensional accuracy are paramount. Our integrated workflow spans Design, Prototyping, and Mass Production, each phase fortified with aerospace-grade quality gates.

The process initiates with collaborative Design refinement. Our engineering team conducts in-depth Design for Manufacturability (DFM) analysis, scrutinizing CAD models against material behavior, thermal dynamics, and laser physics specific to aerospace alloys. We identify potential stress concentrations, kerf deviations, or heat-affected zone risks early, ensuring the design is inherently producible to AS9100 tolerances. Material selection validation against AMS and ASTM specifications occurs concurrently, confirming suitability for extreme operational environments. This phase prevents downstream errors by embedding manufacturability into the blueprint.

Prototyping transitions validated designs into physical reality under full production conditions. Utilizing our high-power fiber laser systems, we produce initial components with the exact parameters planned for series production. Every prototype undergoes comprehensive metrology verification using CMMs and optical comparators traceable to NIST standards. Critical dimensions, edge squareness, surface roughness, and dimensional stability post-cutting are measured against the original CAD model and aerospace material certifications. This stage is not merely validation; it is a stress test of the entire process chain, allowing micro-adjustments to laser power, gas pressure, and feed rates before committing to volume. Only prototypes achieving 100% conformance to all specifications advance.

Mass Production leverages the perfected parameters within a closed-loop quality ecosystem. Our automated laser cells operate under strict environmental controls, with real-time monitoring of beam quality, assist gas purity, and thermal compensation. Statistical Process Control (SPC) charts track key variables like positional accuracy and kerf width per lot, triggering immediate process correction if trends approach tolerance limits. Full material traceability from certified mill certs through every production step is maintained via barcode systems. Each part undergoes 100% visual inspection under magnification and selective CMM rechecks per AS9102 First Article Inspection protocols. This relentless focus on process stability and verification ensures every component, from the first to the last, meets the Zero Defects mandate.

The table below summarizes key capabilities for aerospace-grade laser cutting:

| Parameter | Capability Range | Aerospace Standard Compliance |

|---|---|---|

| Material Types | Titanium (Gr 2,5), Inconel 625/718, Aluminum 2024/7075, Stainless Steel 304/316L | AMS, ASTM, MIL-SPEC |

| Thickness Range | 0.5 mm to 25.4 mm (0.020″ to 1.0″) | Per drawing requirements |

| Positional Accuracy | ±0.05 mm (±0.002″) over 1000×2000 mm | AS9100 Rev D |

| Edge Quality | Burr-free, Ra ≤ 1.6 µm (63 µin) | Aerospace drawing callouts |

| Max Throughput | 25,000+ parts/week (varies by geometry) | On-time delivery > 99.5% |

This seamless integration of engineering foresight, empirical validation, and statistically managed production forms the backbone of our Zero Defects commitment. Wuxi Lead delivers not just cut parts, but certified readiness for the most demanding aerospace assemblies.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Aerospace Laser Cutting Services You Can Trust

In the high-stakes world of aerospace manufacturing, precision, traceability, and consistency are non-negotiable. At Wuxi Lead Precision Machinery, we understand the rigorous demands placed on component integrity, dimensional accuracy, and material performance. Our aerospace laser cutting services are engineered to meet and exceed the exacting standards required by global aviation, defense, and space technology sectors. When you partner with us, you gain more than a supplier—you gain a precision-focused collaborator committed to your project’s success from prototype to full-scale production.

Our advanced fiber laser cutting systems deliver micron-level accuracy across a wide range of aerospace-grade materials, including titanium alloys, Inconel, aluminum 7075 and 6061, and high-strength stainless steels. With cutting capabilities up to 30 mm in thickness and positional repeatability within ±0.02 mm, our CNC-controlled platforms ensure every cut meets your engineering specifications. We maintain full NDT traceability and adhere to AS9100D and ISO 9001:2015 quality management standards, ensuring compliance with aerospace regulatory frameworks.

What sets Wuxi Lead Precision Machinery apart is our integrated approach to sheet metal fabrication. Beyond laser cutting, we offer precision bending, robotic welding, surface treatment, and full assembly services—all under one roof. This vertical integration reduces lead times, minimizes supply chain risk, and ensures consistent quality control throughout the manufacturing process. Our engineering team collaborates directly with your design and manufacturing personnel to optimize part geometry, reduce material waste, and accelerate time-to-market.

We serve Tier 1 aerospace suppliers, drone manufacturers, satellite system integrators, and R&D institutions worldwide. Whether you require low-volume, high-mix prototyping or high-volume serial production, our scalable infrastructure and agile production planning support your operational needs without compromise.

Contact us today to discuss your next critical aerospace component. Our engineering team is ready to review your technical drawings, provide DFM feedback, and deliver a precision manufacturing solution tailored to your program requirements. At Wuxi Lead Precision Machinery, we don’t just cut metal—we enable innovation.

For project inquiries, technical consultations, or quoting requests, email us at [email protected]. Let’s build the future of aerospace, one precise cut at a time.

Aerospace Laser Cutting Capabilities

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser (Trumpf & Bystronic Grade) |

| Max Cutting Thickness | 30 mm (mild steel), 25 mm (stainless/titanium) |

| Cutting Area | Up to 4000 mm × 2000 mm |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Materials Supported | Aluminum, Titanium, Inconel, Stainless Steel, Alloy Steel |

| Edge Quality (Ra) | < 3.2 µm (mirror finish achievable) |

| Tolerance Compliance | ASME Y14.5, ISO 2768-m, customer-specific GD&T |

| Quality Standards | AS9100D, ISO 9001:2015, NDT Traceability |

| Production Capacity | Prototype to 50,000+ units/month |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.