Technical Contents

Engineering Guide: Aerospace Injection Mold

Engineering Insight: Aerospace Injection Molds – The Critical Role of Precision in Mission-Critical Applications

In the aerospace industry, injection molding is not merely a manufacturing process—it is a precision engineering discipline. Components produced through injection molding must meet extreme tolerances, material integrity standards, and environmental resilience requirements. These parts often serve in flight-critical systems where even a micron-level deviation can compromise performance, safety, or certification. At Wuxi Lead Precision Machinery, we understand that aerospace injection molds are not just tools; they are the foundation of reliability in high-stakes operations.

Precision in aerospace injection molding begins with mold design. Every cavity, runner, vent, and cooling channel must be engineered to exacting specifications to ensure consistent part geometry, minimal warpage, and optimal material flow. Thermal management is critical—uneven cooling can induce internal stresses, leading to part failure under operational loads. Our engineering team leverages advanced simulation software and finite element analysis (FEA) to model thermal and pressure behavior, ensuring mold designs deliver repeatability across thousands of cycles.

Material selection is equally vital. Aerospace components often require high-performance polymers such as PEEK, PEI, or PPS, which offer exceptional strength-to-weight ratios, flame resistance, and stability across wide temperature ranges. These materials demand molds with superior surface finishes and tight thermal control to prevent degradation and ensure dimensional accuracy. At Lead Precision, our molds are manufactured using aerospace-grade tool steels, including H13 and S136, treated to achieve hardness levels between 48 and 52 HRC for extended service life and resistance to wear and corrosion.

Our experience in mission-critical manufacturing has been validated through participation in high-profile projects, including components used in Olympic timing systems and defense-grade avionics enclosures. These applications demanded zero-defect performance under rigorous environmental testing—conditions we met through disciplined process control, in-house metrology, and full traceability from raw material to final inspection.

We maintain a Class 10,000 cleanroom environment for mold assembly and conduct 100% inspection using coordinate measuring machines (CMM) and optical comparators. Our quality management system is certified to AS9100D, ensuring compliance with aerospace-specific design and production requirements.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra ≤ 0.2 µm (mirror polish available) |

| Tool Steel Options | H13, S136, 420SS, Maraging Steel |

| Hardness Range | 48–52 HRC |

| Cooling Channel Design | Conformal cooling with thermal simulation |

| Quality Standard | AS9100D, ISO 9001:2015 |

| Inspection Equipment | CMM, Optical Comparator, Laser Scanning |

At Wuxi Lead Precision Machinery, we combine decades of custom metal manufacturing expertise with a deep understanding of aerospace demands. Our molds are not only tools for production—they are engineered systems that ensure every molded component meets the highest standards of performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Manufacturing for Aerospace Injection Molds

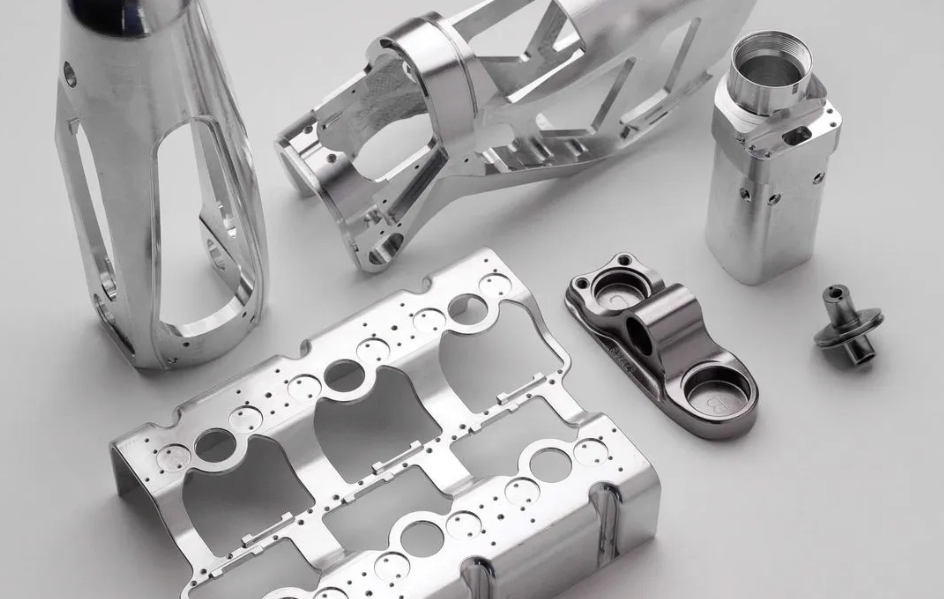

Wuxi Lead Precision Machinery delivers mission-critical metal components for aerospace injection molding applications where failure is not an option. Our specialized facility integrates advanced 5-axis CNC machining centers with rigorous quality control protocols, specifically engineered to meet the stringent demands of aerospace polymer processing. We focus exclusively on high-value, low-volume production of mold cores, cavities, inserts, and structural components requiring exceptional dimensional stability and surface integrity under extreme thermal cycling and pressure conditions. Our expertise spans challenging aerospace-grade materials including hardened tool steels (e.g., H13, S7), stainless alloys (17-4PH, 15-5PH), and exotic superalloys (Inconel 718, Titanium Ti-6Al-4V), ensuring compatibility with high-temperature engineering polymers and composite resins.

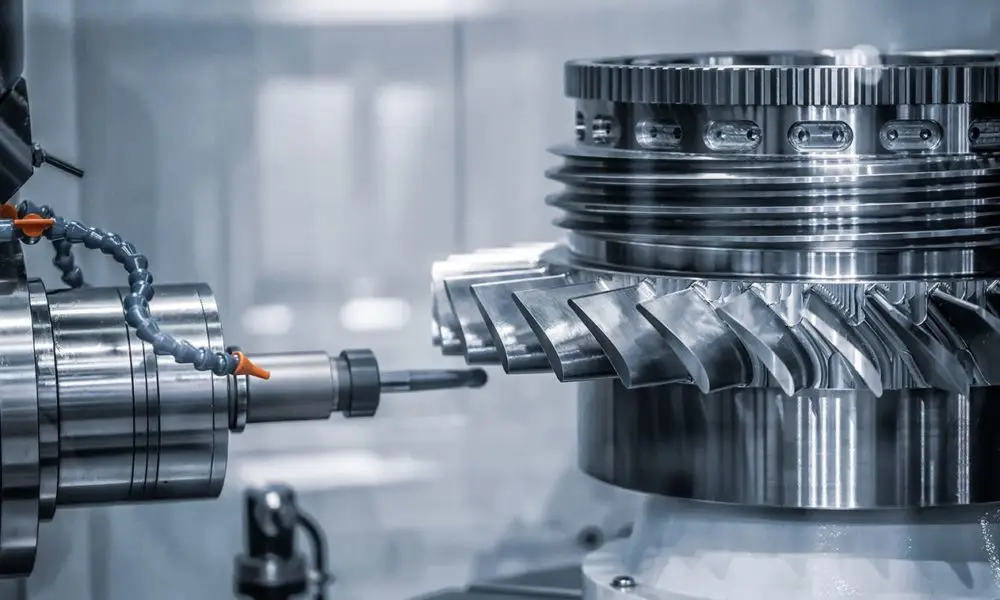

Our core manufacturing capability centers on state-of-the-art 5-axis simultaneous CNC machining. This technology enables the precise fabrication of complex organic geometries, deep ribs, undercuts, and micro-features inherent in modern aerospace mold designs—eliminating the need for multiple setups that compromise accuracy. Utilizing high-rigidity machines with sub-micron positioning accuracy and advanced thermal compensation systems, we achieve consistent part replication across the entire work envelope. Integrated high-speed spindles and optimized toolpath strategies ensure superior surface finishes directly off the machine, minimizing secondary operations while maintaining critical draft angles and venting requirements essential for defect-free part ejection and material flow.

Quality assurance is non-negotiable in aerospace tooling. Every critical feature undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMM) with sub-5-micron volumetric accuracy. Our AS9100-compliant inspection process includes full 3D geometric dimensioning and tolerancing (GD&T) analysis against CAD models, surface roughness profiling, and material hardness validation. All measurement data is meticulously documented within our traceable quality management system, providing clients with complete first-article inspection (FAI) reports per AS9102 standards. This rigorous QC protocol ensures molds perform reliably over extended production cycles, significantly reducing scrap rates and costly downtime during aircraft component manufacturing.

The following table outlines our standard achievable tolerances for aerospace injection mold components, reflecting our commitment to exceeding industry benchmarks:

| Feature Type | Standard Tolerance Range | Surface Finish (Ra) | Inspection Standard |

|---|---|---|---|

| Core/Cavity Dimensions | ±0.005 mm (±0.0002″) | 0.2 – 0.8 µm | ISO 2768-mK / ASME Y14.5 |

| Critical Alignment Pins | ±0.002 mm (±0.00008″) | 0.1 – 0.4 µm | GD&T Per Drawing |

| Cooling Channel Position | ±0.010 mm (±0.0004″) | 1.6 – 3.2 µm | ISO 2768-mK |

| Parting Line Flatness | 0.005 mm per 100 mm | N/A | ASME B46.1 |

| Threaded Features | Class 4h/4H | 0.8 – 1.6 µm | ISO 965-2 |

This precision foundation translates directly into operational success for our aerospace partners. Our molds consistently achieve first-article approval, support extended production runs exceeding 500,000 cycles, and deliver the geometric fidelity required for lightweight, high-strength composite and polymer components used in flight-critical systems. Partner with Wuxi Lead to transform complex aerospace molding challenges into certified, production-ready solutions.

Material & Finish Options

Material Selection for Aerospace Injection Molds: Precision Engineering by Wuxi Lead

In the aerospace industry, injection molds must meet uncompromising standards for dimensional stability, thermal conductivity, and resistance to wear and corrosion. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the rigorous demands of aerospace applications. Selecting the appropriate material—aluminum, steel, or titanium—is critical to achieving long service life, consistent part quality, and cost-efficiency in high-volume production environments.

Aluminum alloys, particularly 7075 and 6061, are widely used in prototype and low-to-medium volume production molds due to their excellent machinability and high thermal conductivity. These properties enable faster cooling cycles, reducing overall cycle times. While aluminum lacks the durability of steel or titanium, it remains an optimal choice for initial design validation and short-run manufacturing where rapid turnaround is essential. When paired with hard anodizing, aluminum molds gain enhanced surface hardness and wear resistance, extending their operational life.

Tool steels such as H13, P20, and S136 are the standard for high-volume aerospace injection molding. These materials offer superior hardness, toughness, and resistance to thermal fatigue. H13 steel, in particular, is favored for its excellent performance under repeated thermal cycling, making it ideal for molds exposed to high processing temperatures. Steel molds provide exceptional dimensional stability and can withstand thousands of cycles with minimal degradation, ensuring consistent part accuracy over time. Surface treatments such as nitriding or chrome plating further improve corrosion resistance and release properties.

Titanium and its alloys are employed in niche aerospace mold applications where extreme strength-to-density ratios and corrosion resistance are paramount. While more challenging to machine and significantly more expensive, titanium molds offer unparalleled longevity in aggressive environments, especially when processing high-temperature engineering plastics. Their use is typically justified in mission-critical components where failure is not an option.

Anodizing is a key surface treatment for aluminum molds. The hard anodizing process creates a dense, ceramic-like oxide layer that increases surface hardness up to 600 HV, improves wear resistance, and enhances corrosion protection. This finish is especially beneficial when molding abrasive composites or flame-retardant resins commonly used in aerospace systems.

At Wuxi Lead, we evaluate each project’s production volume, material requirements, and environmental conditions to recommend the optimal mold material and finish. Our precision CNC machining and quality control systems ensure that every mold meets aerospace-grade tolerances and performance standards.

Material Properties Comparison

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Typical Use Case | Common Finish |

|---|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | 570 | Prototyping, low-volume production | Hard Anodizing |

| H13 Steel | 48–52 | 35 | 1600 | High-volume, high-temp molding | Nitriding, Chrome Plating |

| P20 Steel | 28–32 | 28 | 1100 | Medium-volume production | Polishing, Chrome |

| Titanium Ti-6Al-4V | 36–41 | 7 | 900 | Corrosive environments, critical parts | TiN Coating, Polishing |

Manufacturing Process & QC

Aerospace Injection Mold Production Process: Zero Defects Execution

Aerospace injection molding demands uncompromising precision where component failure is not an option. At Wuxi Lead Precision Machinery, our production process rigorously integrates Design, Prototyping, and Mass Production under a single Zero Defects mandate. This structured workflow ensures every mold and component meets stringent AS9100 and AMS material specifications before entering flight-critical service.

The Design phase begins with collaborative engineering utilizing advanced CAD/CAE tools. We conduct exhaustive mold flow analysis and structural simulations to predict material behavior under extreme thermal and pressure cycles. Critical factors like gate location, cooling channel optimization, and ejection dynamics are validated against aerospace-specific polymer requirements. Design for Manufacturability (DFM) reviews with the client eliminate potential weaknesses early, incorporating material traceability and hermetic sealing criteria essential for avionics housings or fuel system components. This phase concludes with a fully documented, simulation-verified design package approved by both engineering teams.

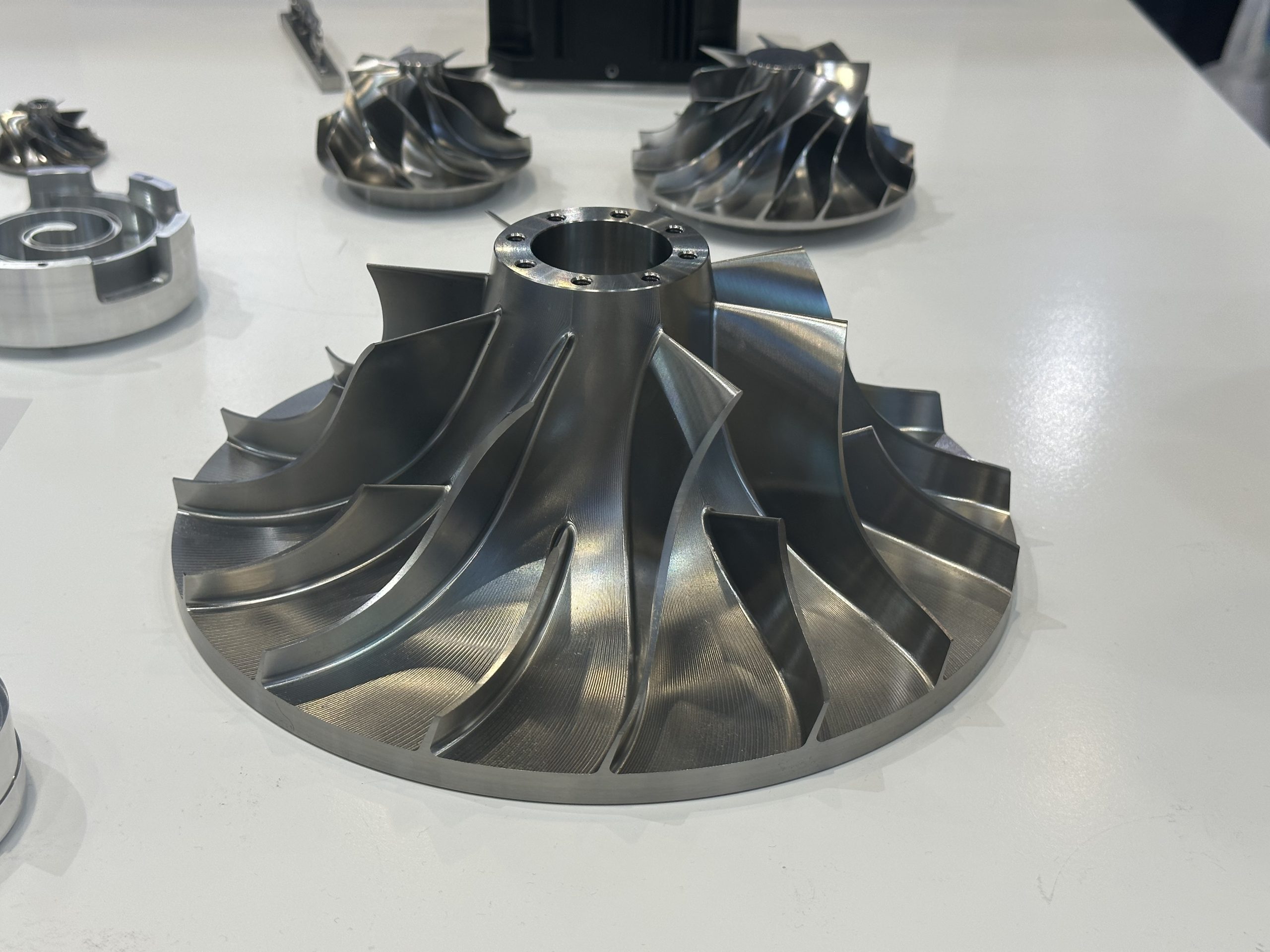

Prototyping transitions the validated design into physical reality using selective laser melting (SLM) for conformal-cooled mold inserts or precision-machined tool steel prototypes. Each prototype undergoes rigorous functional testing in our climate-controlled metrology lab. We perform dimensional validation against CAD models using 5-axis CMMs and analyze part warpage, sink marks, and surface finish under simulated production conditions. Material lot certifications are cross-referenced, and first-article inspections adhere to PPAP Level 3 requirements. Only prototypes demonstrating full conformance to aerospace drawing tolerances advance to mass production.

Mass Production leverages our automated, IoT-enabled molding cells with real-time process monitoring. Every production cycle is governed by closed-loop control systems tracking cavity pressure, melt temperature, and clamp force within predefined aerospace windows. In-line vision systems and automated part gauging reject non-conforming units before secondary operations. Full material traceability from raw pellet to finished component is maintained via blockchain-secured logs. Final inspection includes destructive testing of sacrificial samples for mechanical properties and non-destructive X-ray for internal voids, ensuring zero defects reach the assembly line.

Critical Production Specifications for Aerospace Molds

| Parameter | Specification | Validation Method | Tolerance Range |

|---|---|---|---|

| Mold Cavity Dimension | Hardened P20/H13 tool steel | 5-Axis CMM + Optical Comparator | ±0.002 mm |

| Surface Finish | SPI-A1 (Mirror) to SPI-C3 (Blasted) | Profilometer + Visual Standard Match | Ra 0.025 – 1.60 µm |

| Cooling Uniformity | Conformal channels via metal AM | Infrared Thermal Mapping | ΔT ≤ 2°C |

| Part Dimensional Stability | Post-molding 72h stabilization test | Climate Chamber + CMM Re-measurement | ±0.005 mm @ 23°C |

Zero Defects is not aspirational at Wuxi Lead; it is engineered into every phase. Our closed-loop process, from digital design validation through statistically controlled mass production, delivers aerospace molds where reliability is quantifiable and traceable. Partner with us to transform stringent requirements into flight-proven components.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Aerospace Injection Mold Manufacturing Excellence

In the highly demanding aerospace industry, precision, reliability, and compliance are non-negotiable. When it comes to manufacturing critical components through injection molding, the margin for error is virtually zero. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions engineered to meet the rigorous standards of aerospace applications. Our expertise in aerospace injection mold development ensures that every mold we produce supports high-integrity part performance, repeatable accuracy, and long-term durability under extreme conditions.

We understand that aerospace programs require more than just tooling—they demand a strategic manufacturing partner with deep technical insight, advanced capabilities, and a proven track record. Our engineering team works closely with aerospace OEMs and Tier 1 suppliers to design and build injection molds that meet AS9100 and ISO 9001 standards, with full traceability, material certification, and stringent quality control protocols. From concept to validation, we integrate precision CNC machining, advanced surface treatments, and real-time process monitoring to deliver molds that perform consistently across thousands of cycles.

Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis machining centers, EDM systems, and metrology equipment, enabling us to achieve tolerances down to ±0.002 mm and complex geometries required in aerospace components. Whether you’re developing fuel system housings, sensor enclosures, or interior cabin components, our molds are built to support high-performance thermoplastics such as PEEK, PEI, and PPS—materials commonly used in aerospace due to their thermal stability and flame resistance.

We don’t just manufacture molds—we engineer long-term success. Our collaborative approach ensures that design for manufacturability (DFM) is integrated early in the process, minimizing risk, reducing time-to-market, and optimizing production efficiency. With in-house mold flow analysis, rapid prototyping, and comprehensive testing, we provide full technical documentation and validation reports to support your certification requirements.

Below are key technical specifications that define our aerospace injection mold capabilities:

| Specification | Detail |

|---|---|

| Maximum Mold Size | 1200 × 800 × 700 mm |

| Tolerance | ±0.002 mm |

| Materials | H13, S136, 2344, 2714, Stainless Steel, Hardened Tool Steels |

| Surface Finish | Mirror polish (Ra ≤ 0.05 µm), Textured, EDM finish |

| Lead Time | 6–10 weeks (depending on complexity) |

| Standards Compliance | ISO 9001:2015, AS9100D, RoHS |

| Cavity Configuration | Single to 8-cavity, family molds |

| Hot Runner Systems | Yudo, Mold-Masters, Husky (customizable) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a committed engineering ally focused on your program’s success. Our global clients rely on us for technical transparency, on-time delivery, and responsive support throughout the product lifecycle.

Contact us today at [email protected] to discuss your aerospace injection mold requirements. Let us help you achieve precision, performance, and peace of mind.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.