Technical Contents

Engineering Guide: Aerospace Fabrication

Engineering Insight: Precision in Aerospace Sheet Metal Fabrication

In the aerospace industry, where performance, safety, and reliability are non-negotiable, the role of precision in sheet metal fabrication cannot be overstated. Every component, from structural brackets to engine housings, must conform to exacting dimensional tolerances and material specifications. Even a deviation of a few micrometers can compromise aerodynamic efficiency, structural integrity, or system integration. At Wuxi Lead Precision Machinery, we understand that aerospace fabrication demands more than advanced machinery—it requires an engineering mindset rooted in consistency, traceability, and uncompromising quality.

Our experience in high-precision manufacturing has been rigorously tested through participation in mission-critical projects, including components for Olympic-grade equipment and defense applications. These endeavors have forged our capability to meet and exceed the stringent requirements of aerospace clients who demand zero-defect production. Our facility in Wuxi integrates state-of-the-art CNC turret presses, laser cutting systems, and automated bending cells, all calibrated to maintain tolerances within ±0.05 mm. This level of precision ensures repeatability across production runs, essential for aerospace OEMs managing global supply chains.

Material integrity is equally critical. Aerospace components often utilize high-strength alloys such as aluminum 7075, titanium Grade 5, and corrosion-resistant stainless steels. These materials present unique challenges in formability and stress management during fabrication. Our engineering team applies finite element analysis (FEA) and digital prototyping to simulate deformation and springback, optimizing tool paths and bend sequences before any metal is cut. This proactive approach minimizes trial-and-error, reduces waste, and accelerates time-to-market.

Quality assurance is embedded at every stage. We adhere to AS9100D standards, with full documentation of material certifications, process parameters, and inspection reports. In-process inspections using coordinate measuring machines (CMM) and laser scanning ensure compliance with geometric dimensioning and tolerancing (GD&T) callouts. Our clean-room assembly zones further protect sensitive components from contamination, a necessity for avionics enclosures and fuel system parts.

The following table outlines key capabilities relevant to aerospace sheet metal fabrication at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Cutting/Bending) | ±0.05 mm |

| Maximum Forming Area | 1500 mm × 3000 mm |

| Supported Materials | Aluminum (2024, 5052, 7075), Stainless Steel (304, 316), Titanium (Gr2, Gr5), Cold-Rolled Steel |

| Surface Finishes | Anodizing, Passivation, Powder Coating, Brushing |

| Quality Standards | ISO 9001:2015, AS9100D, RoHS Compliance |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

Precision in aerospace fabrication is not merely a technical benchmark—it is a commitment to safety, innovation, and trust. At Wuxi Lead Precision Machinery, our proven track record in high-stakes manufacturing environments positions us as a reliable partner for aerospace innovators who demand excellence in every dimension.

Precision Specs & Tolerances

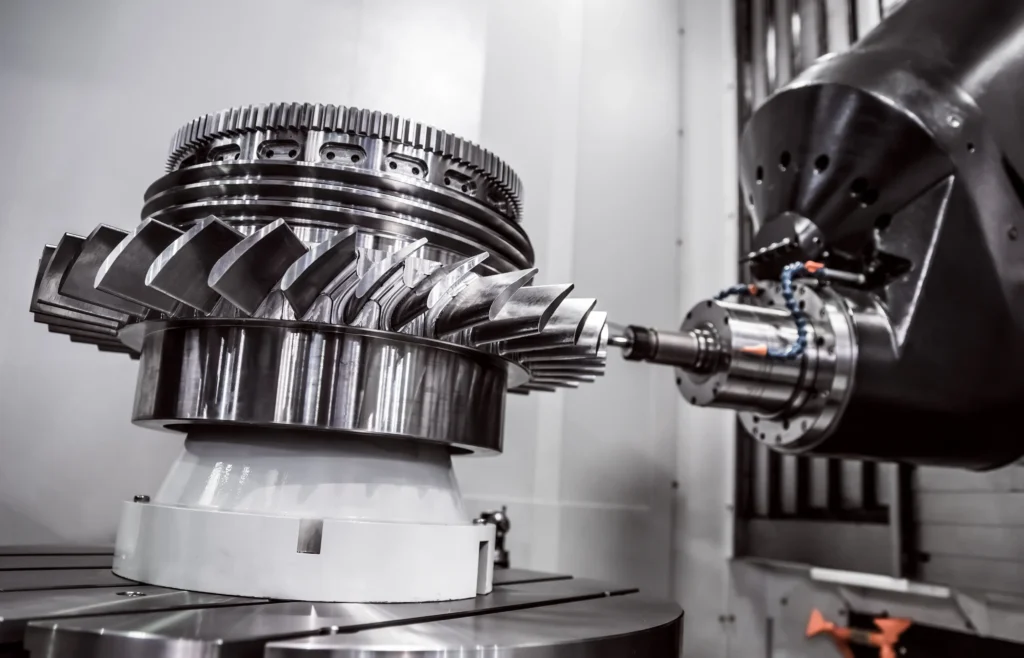

Advanced 5-Axis CNC Machining for Aerospace Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision for critical aerospace sheet metal components through our state-of-the-art 5-axis CNC machining centers. These systems enable simultaneous multi-axis interpolation, eliminating repositioning errors and ensuring geometric integrity for complex contours, deep pockets, and compound angles inherent in aircraft structural brackets, fuel system housings, and control surface assemblies. Our DMG MORI and MAZAK platforms feature high-torque spindles and advanced thermal compensation, maintaining micron-level accuracy during extended machining cycles on demanding aerospace alloys including Aluminum 2024-T3, 7075-T6, Titanium Grade 5 (Ti-6Al-4V), and Inconel 718. This capability significantly reduces lead times by consolidating operations traditionally requiring multiple setups, while minimizing material waste through optimized toolpaths and near-net-shape processing.

Integrated Metrology for Zero-Defect Assurance

Precision is validated through our closed-loop quality control system anchored by Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMM). Every critical aerospace component undergoes 100% first-article inspection against AS9100D and NADCAP standards, with real-time dimensional data fed directly into our production database. Our CMMs utilize tactile probing and optical scanning to verify complex GD&T callouts, surface profiles, and positional tolerances down to ±0.005 mm. This metrology integration ensures traceability from raw material to finished part, with comprehensive inspection reports including 3D deviation maps and statistical process control (SPC) analysis provided to clients.

Aerospace-Grade Tolerance Specifications

Our machining and forming processes consistently achieve the stringent tolerances required for flight-critical applications. Key capabilities are summarized below:

| Parameter | Material Range | Thickness Range | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|---|---|

| Linear Dimensions | Al, Ti, Stainless Steel | 0.5–12.7 mm | ±0.05 mm | ±0.025 mm |

| Hole Position | All aerospace alloys | 0.8–10.0 mm | ±0.08 mm | ±0.03 mm |

| Flatness | Sheet metal components | ≤6.0 mm | 0.1 mm/m² | 0.05 mm/m² |

| Angular Features | Complex 3D geometries | All thicknesses | ±0.1° | ±0.05° |

| Surface Roughness (Ra) | Critical mating surfaces | All | 1.6 µm | 0.4 µm |

Operational Excellence in High-Mix Production

We combine this technical infrastructure with aerospace-specific process controls: dedicated clean-room staging for titanium machining, humidity-controlled storage for moisture-sensitive composites, and AS9100-certified documentation protocols. Our engineers collaborate with clients during DFM stages to optimize manufacturability without compromising design intent, ensuring components meet both dimensional requirements and fatigue life specifications. This integrated approach—merging 5-axis capability, rigorous metrology, and aerospace process discipline—enables Wuxi Lead to deliver mission-ready sheet metal fabrications where precision directly translates to flight safety and system reliability. Clients receive certified components with full material traceability and inspection data, reducing program risk and accelerating certification timelines.

Material & Finish Options

Material Selection in Aerospace Sheet Metal Fabrication

In aerospace sheet metal fabrication, material selection is a critical engineering decision that directly impacts performance, safety, and lifecycle cost. At Wuxi Lead Precision Machinery, we specialize in high-precision fabrication of advanced alloys tailored to the rigorous demands of aerospace applications. The most commonly specified materials include aluminum, stainless steel, and titanium, each offering distinct advantages depending on structural requirements, environmental exposure, and weight constraints.

Aluminum alloys, particularly 2024-T3 and 7075-T6, are widely used in aircraft skins, fuselage frames, and wing components due to their high strength-to-weight ratio and excellent machinability. These alloys provide optimal performance in non-corrosive and mildly corrosive environments, making them ideal for commercial and military aviation structures. However, aluminum’s lower melting point and reduced performance at elevated temperatures limit its use in high-heat zones.

Stainless steel, especially grades 304 and 321, is selected for applications requiring high strength, thermal resistance, and corrosion resilience. Commonly used in engine mounts, exhaust systems, and landing gear components, stainless steel maintains structural integrity under extreme mechanical stress and elevated temperatures. While heavier than aluminum and titanium, its durability and resistance to oxidation justify its use in critical high-load or high-temperature zones.

Titanium and its alloy Ti-6Al-4V dominate in advanced aerospace systems where extreme strength, corrosion resistance, and low density are paramount. Used in jet engines, airframes, and critical fasteners, titanium performs reliably in cryogenic and high-temperature environments (up to 600°C). Its excellent fatigue resistance and compatibility with composite materials make it a preferred choice in next-generation aircraft design. Despite higher raw material and processing costs, titanium’s long-term reliability justifies its use in mission-critical applications.

Surface finishing is equally vital in aerospace fabrication. Anodizing is the most prevalent finish for aluminum components, enhancing wear resistance, corrosion protection, and adhesion for paint or primers. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly specified, with Type III offering superior thickness and hardness for high-wear parts. All anodized finishes must comply with aerospace standards such as AMS 2469 and MIL-A-8625 to ensure consistency and performance.

At Wuxi Lead Precision Machinery, we integrate material expertise with advanced CNC forming, laser cutting, and finishing technologies to deliver aerospace-grade components with tight tolerances and certified quality. Our engineering team collaborates with clients to select optimal material-finish combinations that meet technical specifications and regulatory compliance.

Typical Material Properties for Aerospace Sheet Metal Applications

| Material | Alloy/Grade | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Common Applications | Key Advantages |

|---|---|---|---|---|---|---|

| Aluminum | 7075-T6 | 2.81 | 570 | 505 | Wing skins, fuselage panels | High strength-to-weight ratio |

| Stainless Steel | 321 | 8.00 | 570 | 275 | Engine components, exhaust systems | High temperature and corrosion resistance |

| Titanium | Ti-6Al-4V | 4.43 | 900 | 830 | Jet engines, airframes | Excellent strength, low density, corrosion resistance |

Manufacturing Process & QC

Aerospace Sheet Metal Fabrication: Zero Defects Production Process

At Wuxi Lead Precision Machinery, aerospace fabrication demands an uncompromising, integrated production process where Zero Defects is not a goal but the operational baseline. Our rigorous methodology spans Design, Prototyping, and Mass Production, ensuring every component meets stringent AS9100 and NADCAP requirements while optimizing cost and lead time. This seamless flow eliminates waste and prevents errors before they occur.

The process begins with collaborative Design for Manufacturability (DFM). Our engineering team partners directly with client aerospace designers during the conceptual phase. We rigorously analyze CAD models for geometric complexity, material suitability (primarily aluminum alloys 2024, 7075, and titanium Grade 5 per AMS 4928), and manufacturability constraints inherent to precision sheet metal forming. Critical factors like bend allowances, minimum flange lengths, hole-to-edge distances, and laser cutting kerf are validated against our machine capabilities and aerospace material behavior. This proactive DFM review prevents costly downstream revisions and identifies potential stress points or tolerance stack-ups early, establishing a foundation for inherent quality.

Prototyping transitions validated designs into physical reality under full production conditions. We utilize the same CNC fiber laser cutters, precision press brakes with CNC-controlled backgauges, and automated deburring systems intended for the final run. Each prototype undergoes comprehensive metrology: CMM inspection against 3D CAD models, detailed GD&T verification, and non-destructive testing (NDT) like fluorescent penetrant inspection (FPI) per AMS 2644 where required. Material certifications and process parameters are meticulously documented. This phase is not merely validation; it is the critical proving ground where process windows are refined, fixture designs are confirmed, and the final inspection protocol is locked. Any deviation triggers immediate root cause analysis and process correction before mass production commences.

Mass Production executes the perfected process with relentless statistical control. Every step is governed by documented work instructions and real-time SPC (Statistical Process Control) monitoring. Laser cutting parameters, press brake tonnage and angles, and forming sequences are continuously verified against the prototype baseline. In-process inspections at defined stages, coupled with 100% final inspection using calibrated optical comparators and CMMs, ensure conformance to the tightest aerospace tolerances. Our integrated MES (Manufacturing Execution System) provides full traceability from raw material heat lot to finished part, with automated data logging for every operation. Non-conforming material is immediately quarantined via our closed-loop quality system, preventing escape and driving continuous improvement. Zero Defects is achieved through this systematic prevention, not end-of-line detection.

Critical Aerospace Sheet Metal Specifications at Wuxi Lead

| Parameter | Capability Range | Aerospace Standard Compliance |

|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | AMS 4027, AMS 4928, AMS 4911 |

| Cutting Tolerance | ±0.05 mm (laser) | AS9102 Form 3 |

| Forming Tolerance | ±0.1° (bend angle), ±0.1 mm (linear) | ASME Y14.5-2018 GD&T |

| Hole Position Tolerance | ±0.05 mm | Customer Drawing Specific |

| Surface Finish (Ra) | ≤ 0.8 µm (deburred edges) | AMS 2430, AMS-QQ-A-250/11 |

| Key Certifications | AS9100D, NADCAP AC7108 | ITAR Registered |

This disciplined progression from intelligent design through validated prototyping to statistically controlled mass production ensures Wuxi Lead delivers aerospace sheet metal components with absolute reliability. We embed quality into every stage, providing clients with confidence in every component’s performance and airworthiness.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Aerospace Sheet Metal Fabrication Solutions

In the high-stakes world of aerospace manufacturing, precision, reliability, and compliance are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering mission-critical sheet metal fabrication services tailored to the exacting standards of the global aerospace industry. From structural airframe components to intricate engine housings and interior systems, our engineering expertise ensures every part meets the rigorous demands of flight safety, performance, and regulatory compliance.

Our advanced manufacturing facility in Wuxi, China, is equipped with state-of-the-art CNC punching, laser cutting, bending, and welding technologies, enabling us to produce complex geometries with micron-level accuracy. We work extensively with aerospace-grade materials such as aluminum alloys (2024, 6061, 7075), titanium, stainless steel, and high-performance composites, ensuring optimal strength-to-weight ratios and environmental resistance. Every process is governed by strict quality control protocols aligned with ISO 9001:2015 and AS9100D standards, with full traceability from raw material to final inspection.

What sets Wuxi Lead apart is our integrated engineering approach. We don’t just fabricate—we collaborate. From initial design review and DFM optimization to prototyping and full-scale production, our team of seasoned CNC engineers and manufacturing specialists works in close partnership with your engineering staff to ensure manufacturability, reduce lead times, and lower total cost of ownership. Whether you require low-volume, high-mix production for R&D or scalable batch runs for serial aircraft production, we offer the flexibility, capacity, and technical depth to support your program’s lifecycle.

Our commitment to innovation is reflected in our investment in automation and digital manufacturing workflows. Real-time process monitoring, 3D laser scanning for first-article inspection, and automated material handling systems ensure consistent quality and on-time delivery. We understand that in aerospace, delays are not an option—our project management team provides transparent communication, milestone tracking, and rapid response to engineering changes or urgent requests.

For OEMs and Tier-1 suppliers seeking a trusted offshore manufacturing partner, Wuxi Lead Precision Machinery offers a compelling combination of technical excellence, cost efficiency, and risk-mitigated production. We are not just a vendor—we are an extension of your engineering and manufacturing team.

To begin a conversation about your next aerospace fabrication challenge, contact us today at [email protected]. Let us demonstrate how precision, partnership, and performance define the Wuxi Lead standard.

| Specification | Capability |

|---|---|

| Material Types | Aluminum (2024, 6061, 7075), Stainless Steel (304, 316, 17-4PH), Titanium, Inconel, Composites |

| Thickness Range | 0.5 mm – 12 mm |

| Tolerance | ±0.05 mm (standard), ±0.02 mm (tight-tolerance features) |

| Max Part Size | 3000 mm × 1500 mm |

| Processes | CNC Laser Cutting, CNC Punching, Precision Bending, Robotic Welding, Assembly |

| Quality Standards | ISO 9001:2015, AS9100D, FAI (First Article Inspection), PPAP Level 3 |

| Lead Time | 2–4 weeks (production), 1–2 weeks (prototyping) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.