Technical Contents

Engineering Guide: Advanced Molding

Engineering Insight: Precision as the Non-Negotiable Foundation of Advanced Molding

In advanced molding for critical metal components, precision transcends mere specification; it defines functional integrity, assembly success, and ultimate product lifecycle. Tolerances measured in microns are not an engineering luxury but an absolute requirement when molding complex geometries for aerospace actuators, medical implants, or defense systems. Sub-micron deviations can cascade into catastrophic failures under operational stress, thermal cycling, or high-frequency vibration. The molding process itself—encompassing tool design, material flow simulation, temperature control, and ejection dynamics—must be engineered with metrology-grade discipline from the first prototype. This level of control demands more than capable machinery; it requires a systemic approach where material science, process validation, and real-time in-cavity monitoring converge to eliminate variability. At Wuxi Lead Precision Machinery, we treat precision as the core constraint driving every design and manufacturing decision, not a target to be achieved after process optimization.

Our methodology integrates finite element analysis (FEA) for predictive mold flow and stress modeling with closed-loop process control systems. This ensures consistent filling patterns, minimizes residual stress, and guarantees dimensional stability across production runs. Material selection is equally rigorous, with proprietary alloys and composites qualified through extensive thermal and mechanical testing to match the exacting demands of the application environment. This systematic rigor is why Lead Precision is entrusted with projects where failure is not an option. We engineered titanium structural nodes for the Beijing Winter Olympics venue network, requiring thermal stability across -40°C to +50°C with positional accuracy under 5µm. Similarly, our molded housings for next-generation military communication systems undergo MIL-STD-810G validation, maintaining RF shielding integrity despite repeated shock loads exceeding 50G. These projects exemplify our commitment: precision engineered into the component’s DNA, validated through extreme-condition testing, and delivered with full traceability.

The following table outlines critical precision parameters achievable across our advanced molding platforms for mission-critical applications:

| Parameter | Capability Range | Measurement Standard | Typical Application Impact |

|---|---|---|---|

| Geometric Tolerance | ±0.002 mm to ±0.008 mm | ISO 2768-mK | Aerospace fuel system interfaces |

| Surface Roughness (Ra) | 0.05 µm to 0.8 µm | ISO 1302 | Medical implant biocompatibility |

| Dimensional Stability | < 0.005% per 100°C | ASTM E831 | Satellite component thermal cycling |

| Material Density | 99.95% theoretical max | ASTM B962 | High-pressure hydraulic manifolds |

| Batch Consistency (CpK) | ≥ 1.67 | ISO 22514-2 | Automotive transmission sub-assemblies |

This precision foundation directly translates to client value: reduced assembly scrap rates, extended service life in harsh environments, and accelerated time-to-market through first-pass yield excellence. For industries where component integrity dictates system reliability, partnering with a manufacturer whose engineering culture treats microns as mission-critical is not just advantageous—it is essential. Wuxi Lead Precision Machinery delivers this assurance through documented expertise, validated processes, and an unwavering focus on the physics of precision molding.

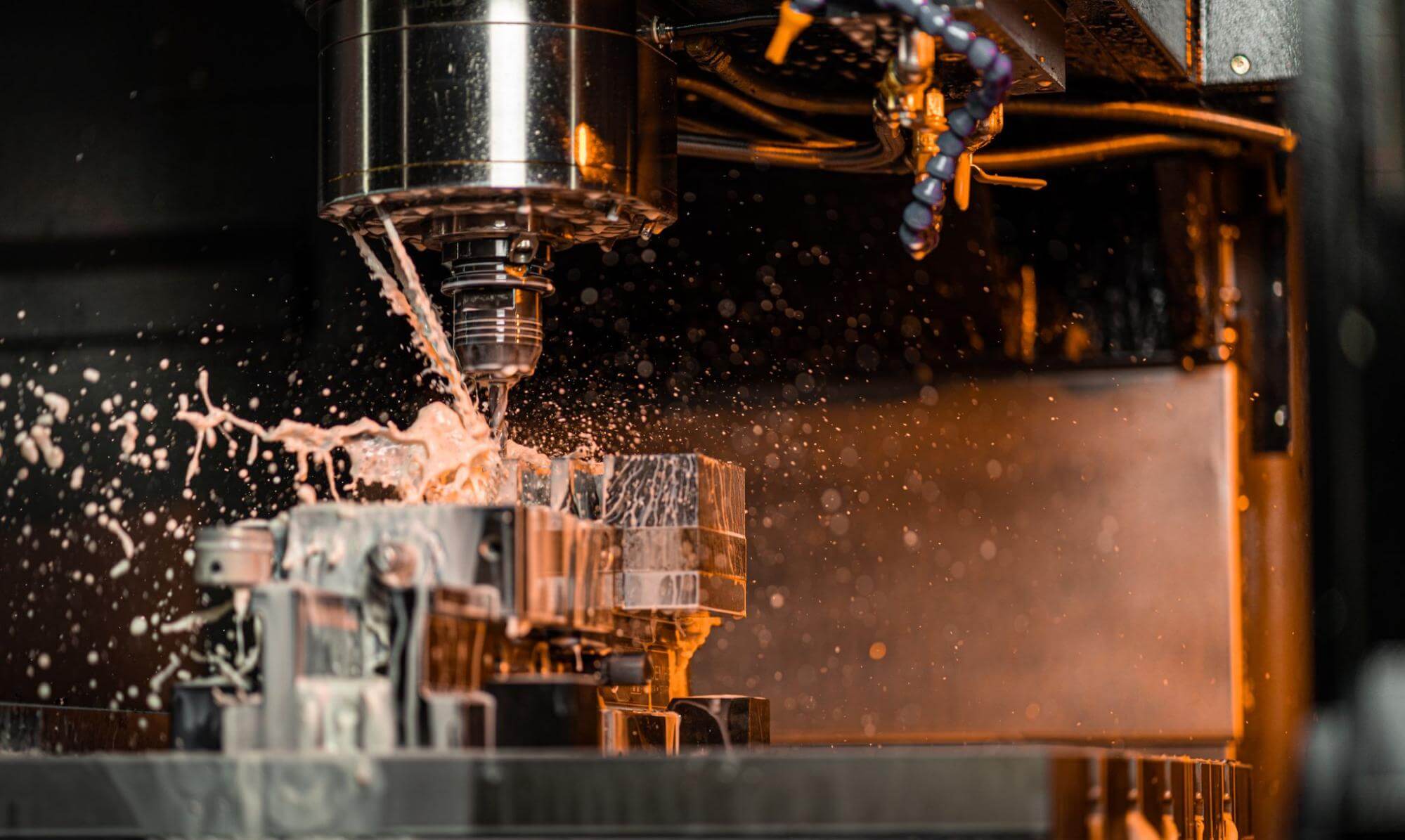

Precision Specs & Tolerances

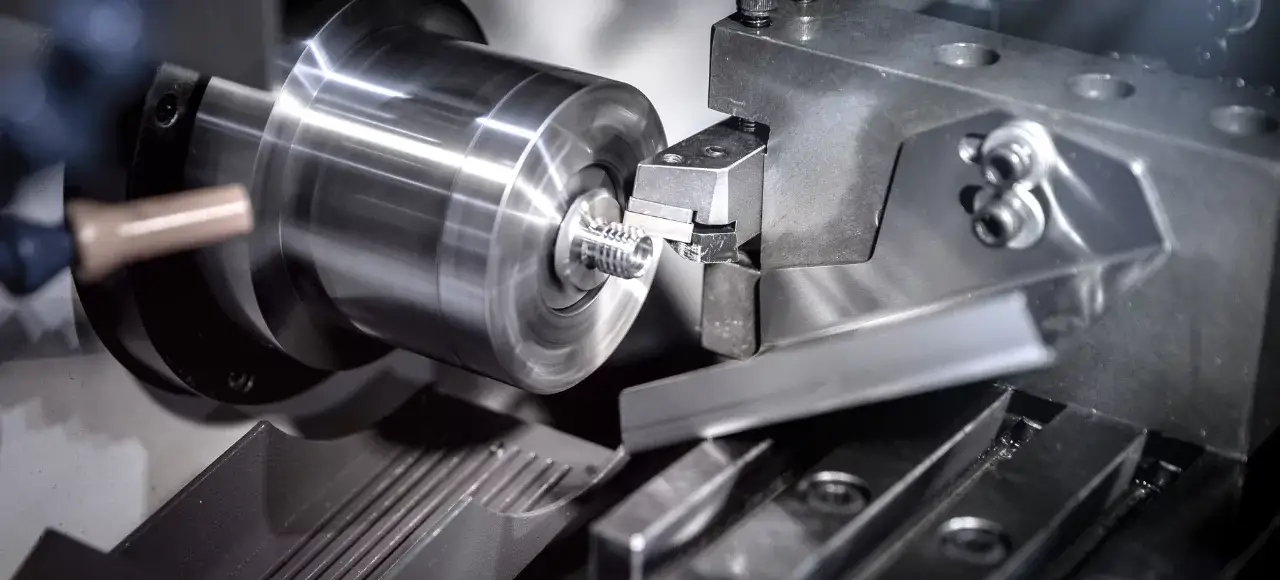

Wuxi Lead Precision Machinery delivers advanced metal manufacturing solutions tailored for high-precision industries such as aerospace, medical devices, automotive, and industrial automation. Our technical capabilities are built around a foundation of cutting-edge 5-axis CNC machining, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in tool positioning and access to intricate features that traditional 3-axis machines cannot achieve. This capability is especially critical in advanced molding applications, where conformal cooling channels, fine surface textures, and tight tolerance requirements demand the highest level of machining sophistication.

All machining operations are supported by a rigorous quality control framework, anchored by coordinate measuring machine (CMM) inspection. Our CMM systems provide full 3D metrology validation, ensuring every component conforms precisely to design intent. Each part undergoes comprehensive dimensional analysis, with inspection reports available upon request. This closed-loop quality process guarantees repeatability and compliance with international standards, including ISO 9001 and IATF 16949. Our engineering team works closely with clients during the design-for-manufacturability phase, offering feedback on geometry, material selection, and tolerance optimization to reduce lead times and improve performance.

We specialize in custom metal components from a wide range of materials, including aluminum alloys, stainless steels, titanium, tool steels, and exotic alloys. Our 5-axis machining centers are equipped with high-speed spindles, automatic tool changers, and in-process probing systems that enable unattended operation and real-time error correction. This level of automation ensures consistent part quality across both prototype and production volumes. Additionally, our facility integrates advanced CAD/CAM software to simulate toolpaths and optimize machining strategies, minimizing cycle times and material waste.

Our commitment to precision is reflected in the tolerances we consistently achieve across diverse part configurations. The following table outlines our standard and advanced capability ranges:

| Feature | Standard Tolerance | Advanced Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.005 mm |

| Positional Tolerance | ±0.020 mm | ±0.008 mm |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm |

| Circular Runout | 0.015 mm | 0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Tolerance | ±0.05° | ±0.01° |

These specifications are maintained across a maximum work envelope of 1,200 mm × 800 mm × 750 mm, accommodating a broad spectrum of component sizes. Wuxi Lead Precision Machinery combines technical excellence with responsive engineering support to meet the demanding requirements of advanced molding and other high-end manufacturing applications.

Material & Finish Options

Material Selection for Advanced Metal Molding: Precision Engineering Fundamentals

Selecting the optimal material for advanced metal molding applications requires balancing mechanical properties, environmental resistance, and cost efficiency. At Wuxi Lead Precision Machinery, we prioritize material-process synergy to ensure dimensional stability, surface integrity, and longevity in high-performance components. This guide outlines critical considerations for aluminum, steel, and titanium alloys, alongside essential finishing protocols like anodizing.

Aluminum alloys, particularly 6061-T6, dominate aerospace and automotive sectors due to their exceptional strength-to-weight ratio and machinability. With moderate corrosion resistance and excellent thermal conductivity, aluminum minimizes cycle times in molding processes while maintaining structural reliability. It is ideal for lightweight enclosures, heat sinks, and complex geometries where weight reduction is critical. However, aluminum requires protective finishes in aggressive environments to prevent oxidation.

Steel alloys, such as 4140 and 17-4 PH, deliver superior hardness and wear resistance for high-stress molding applications like tooling inserts and hydraulic components. These materials withstand extreme pressures and temperatures, ensuring extended tool life in repetitive production cycles. While steel offers unmatched durability, its susceptibility to corrosion necessitates rigorous surface treatment. For marine or chemical exposure, stainless variants (e.g., 316L) provide baseline corrosion mitigation but at higher material costs.

Titanium Ti-6Al-4V excels in mission-critical aerospace and medical applications where extreme strength, biocompatibility, and corrosion resistance are non-negotiable. Despite its premium cost and challenging machinability, titanium’s fatigue resistance and inertness in saline or acidic environments justify its use for life-support systems and deep-sea components. Note that titanium cannot undergo conventional anodizing; alternative finishes like plasma electrolytic oxidation are required.

Anodizing: Critical for Aluminum Performance

Anodizing transforms aluminum surfaces into wear-resistant, corrosion-proof barriers. Type II (sulfuric acid) anodizing provides standard decorative and protective layers (5–25 μm), while Type III (hardcoat) anodizing achieves industrial-grade thickness (25–125 μm) for components exposed to abrasion or extreme weather. Proper sealing post-anodizing is mandatory to prevent dye retention issues and maximize longevity. Always specify anodizing requirements early in design to avoid dimensional conflicts.

Material selection directly impacts molding precision, cycle efficiency, and total cost of ownership. Below are key comparative specifications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Molding Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate | Enclosures, heat exchangers, brackets |

| Steel 4140 | 7.85 | 655 | Low (uncoated) | Tooling dies, shafts, high-load fixtures |

| Titanium Ti-6Al-4V | 4.43 | 900 | Excellent | Aerospace brackets, medical implants |

Partner with Wuxi Lead Precision Machinery to align material properties with your molding process parameters. Our engineering team analyzes operational stressors, environmental exposure, and lifecycle demands to prescribe optimal material-finish combinations—reducing scrap rates and enhancing component performance. Consult our experts early in the design phase to leverage China’s most advanced CNC molding capabilities.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the advanced molding production process begins with a rigorously engineered design phase. This stage integrates comprehensive customer requirements with material science, structural analysis, and manufacturability assessments. Our engineering team employs advanced CAD/CAM software and finite element analysis (FEA) to simulate stress, thermal behavior, and mold flow dynamics. This ensures that every design is not only functionally optimal but also fully aligned with downstream manufacturing capabilities. Tolerance analysis and geometric dimensioning and tolerancing (GD&T) are applied from the outset to preemptively eliminate dimensional risks. Each design is reviewed in cross-functional collaboration, incorporating feedback from tooling, quality assurance, and production teams to guarantee a seamless transition to prototyping.

Prototyping: Validating Performance Before Scale

The prototyping phase serves as a critical validation step in our zero-defect strategy. Utilizing high-precision CNC machining, EDM, and rapid tooling techniques, we produce functional prototypes that mirror final production conditions. These prototypes undergo rigorous testing, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and mechanical performance evaluation. Mold trials are conducted under actual processing parameters to assess fill behavior, ejection integrity, and cycle consistency. Any deviations are traced using root cause analysis and corrected in real time. This iterative process ensures that design intent is fully realized and that the mold system performs reliably before mass production begins. Customer approval is obtained at this stage, confirming form, fit, and function.

Mass Production: Consistency Through Advanced Control

Once design and prototyping are validated, we transition to high-volume manufacturing with a framework built for zero defects. Our advanced molding lines are equipped with real-time process monitoring systems, including cavity pressure sensors, temperature controls, and automated vision inspection. Each production run follows standardized work instructions and is managed under ISO 9001-certified quality protocols. Statistical process control (SPC) is implemented to continuously track key parameters and detect trends before they impact quality. In-process inspections and first-article reporting are standard, while full traceability is maintained through lot numbering and digital process logs. Automation ensures repeatable precision, minimizing human variability and maximizing throughput.

The following table outlines key specifications and capabilities across our production process:

| Parameter | Design Phase | Prototyping Phase | Mass Production Phase |

|---|---|---|---|

| Tolerance Control | ±0.005 mm (GD&T applied) | ±0.01 mm (CMM verified) | ±0.01 mm (SPC monitored) |

| Lead Time | 7–14 days | 5–10 days | 15–30 days (based on volume) |

| Materials Supported | Tool steels, aluminum, stainless steel, engineered alloys | Same as production | Full industrial-grade metals |

| Quality Standards | ASME Y14.5, ISO 1101 | ISO 9001, PPAP Level 3 | ISO 9001, IATF 16949 aligned |

| Process Validation | FEA, Moldflow simulation | Mold trials, functional test | SPC, 100% automated inspection |

Through integrated design, validated prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers advanced molding solutions with uncompromising quality and zero-defect performance.

Why Choose Wuxi Lead Precision

Elevate Your Advanced Molding Capabilities Through Strategic Partnership

Wuxi Lead Precision Machinery stands as your definitive engineering partner for the most demanding custom metal manufacturing challenges within advanced molding. We transcend conventional component supply, embedding our deep expertise in precision CNC machining, metallurgy, and process optimization directly into your development lifecycle. Our focus is singular: enabling your success through components and systems engineered for unparalleled performance, longevity, and repeatability in high-pressure, high-temperature molding environments. Partnering with Lead Precision means accessing a dedicated team of senior CNC engineers and manufacturing specialists committed to solving complex problems from initial concept through volume production. We understand that success in advanced molding hinges on microscopic tolerances, exceptional material integrity, and flawless thermal management – areas where our precision engineering delivers measurable competitive advantage.

Our core strength lies in transforming intricate design requirements into physically perfect metal components. We specialize in machining complex mold cores, cavities, inserts, and structural elements from challenging materials including hardened tool steels, high-temperature alloys, and specialized composites. Every process, from multi-axis milling and grinding to micro-EDM and precision polishing, is executed under stringent environmental controls and governed by our ISO 9001-certified quality management system. This ensures absolute dimensional stability and surface finishes critical for part release, cosmetic quality, and extended mold life. The table below summarizes our key technical capabilities relevant to advanced molding applications.

| Specification Category | Capability Detail |

|---|---|

| Dimensional Tolerance | ±0.001 mm (Sub-micron achievable on critical features) |

| Surface Roughness (Ra) | As low as 0.025 µm (Mirror finish) |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Primary Materials Processed | H13, S7, 420SS, P20, Maraging Steels, Inconel 718, Titanium Alloys |

| Critical Process Control | In-process CMM verification, Thermal stability protocols, Full traceability |

Collaboration is the cornerstone of our partnership model. We initiate every engagement with a rigorous technical consultation, scrutinizing your molding process parameters, material flow dynamics, and lifecycle requirements. This allows us to proactively identify potential failure points and engineer solutions that enhance thermal efficiency, reduce wear, and minimize downtime. Our engineers work seamlessly alongside your design and production teams, providing actionable feedback during prototyping and facilitating smooth scale-up to high-volume manufacturing. We view each project as a shared mission to achieve manufacturing excellence, investing our full technical resources to ensure your molds perform optimally under the most extreme production conditions.

The complexity of modern advanced molding demands a supplier with proven engineering depth and unwavering commitment to precision. Wuxi Lead Precision Machinery provides the technical authority and manufacturing rigor required to overcome your toughest challenges. Do not compromise on the foundational elements of your molding success. Initiate a technical consultation today to explore how our precision engineering partnership can elevate your next advanced molding project. Contact our engineering team directly at [email protected] to schedule a detailed review of your specific requirements and receive actionable insights tailored to your application. Let us demonstrate the Lead Precision difference.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.