Technical Contents

Engineering Guide: Ads Sheet Metal

Engineering Insight: The Critical Role of Precision in Sheet Metal Fabrication

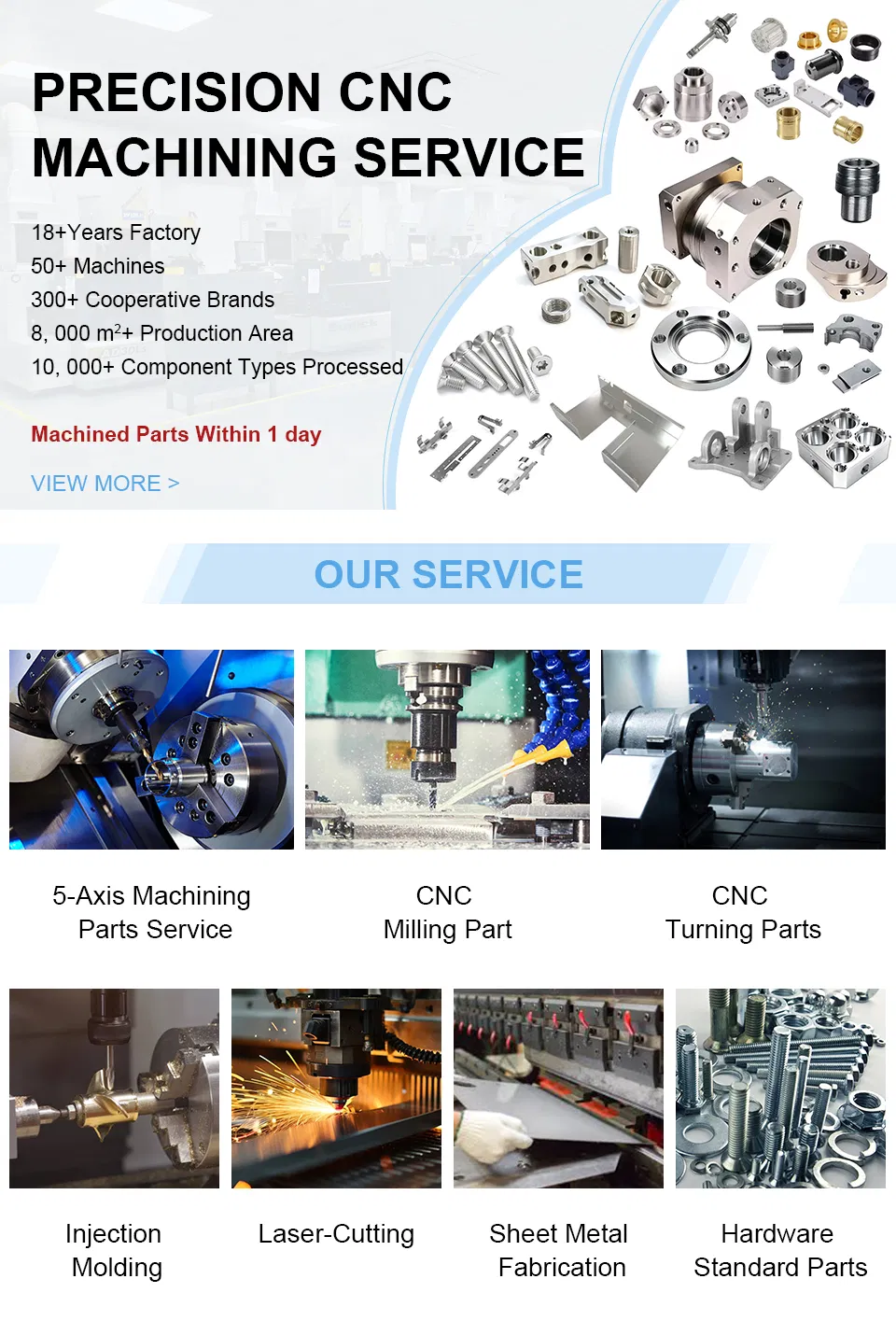

In high-performance industries such as aerospace, defense, and advanced industrial equipment, the integrity of every component is non-negotiable. Among manufacturing processes, sheet metal fabrication stands at the forefront of structural and functional reliability. At Wuxi Lead Precision Machinery, we recognize that precision is not a luxury—it is a foundational requirement. Our engineering philosophy centers on delivering micron-level accuracy, ensuring that each fabricated part meets exacting standards for fit, function, and durability.

The term ads sheet metal refers to advanced dimensional stability sheet metal components—engineered for minimal deformation under thermal, mechanical, or environmental stress. These parts are commonly used in mission-critical applications where even a 0.05 mm deviation can compromise system performance. Our approach integrates precision cutting, bending, and forming techniques with real-time quality verification, ensuring that every stage of production adheres to ISO 2768 and AS9100 tolerances.

Wuxi Lead Precision Machinery brings over two decades of experience in high-end fabrication, with a proven track record in projects requiring the highest levels of precision. We have contributed components for infrastructure supporting Olympic venues and supplied certified parts for military-grade communication enclosures. These projects demanded not only adherence to strict regulatory standards but also the ability to maintain consistency across large production runs—something only achievable through advanced CNC technology and rigorous process control.

Our facility utilizes state-of-the-art fiber laser cutting systems, automated press brakes with CNC backgauging, and robotic forming cells. These systems are calibrated daily and monitored through integrated metrology software, ensuring repeatability and traceability. Additionally, our in-house design engineering team works closely with clients during the DFM (Design for Manufacturability) phase, identifying potential risks early and optimizing geometry for both performance and manufacturability.

Beyond equipment, our quality assurance protocols include first-article inspection reports (FAIR), coordinate measuring machine (CMM) validation, and material traceability documentation. This end-to-end control allows us to guarantee performance consistency, even in low-volume, high-complexity production scenarios.

The following table outlines key precision specifications we maintain across our sheet metal fabrication services:

| Specification | Standard Capability | High-Precision Capability | Notes |

|---|---|---|---|

| Cutting Tolerance | ±0.1 mm | ±0.05 mm | Fiber laser, materials up to 25 mm |

| Bending Tolerance | ±0.2° | ±0.1° | CNC press brake with real-time feedback |

| Hole Positioning | ±0.15 mm | ±0.08 mm | Multi-hit and nest optimization |

| Surface Flatness | 0.1 mm/m² | 0.05 mm/m² | Post-forming stress relief available |

| Material Traceability | Full batch tracking | Per-part serial tracking | Optional with certification |

Precision in sheet metal fabrication is not achieved through machinery alone—it is the result of integrated engineering expertise, disciplined process control, and a culture of continuous improvement. At Wuxi Lead Precision Machinery, we combine technical excellence with real-world application experience to deliver components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising accuracy in sheet metal fabrication through integrated advanced manufacturing systems and rigorous quality validation. Our technical foundation centers on multi-axis CNC technology and metrology-grade inspection, enabling complex geometries and tight tolerances demanded by aerospace, medical, and energy sector clients. This capability suite ensures consistent part integrity from prototype to high-volume production.

Our core manufacturing platform features 5-axis CNC laser cutting and bending systems, including TRUMPF TruBend Series press brakes and AMADA CNC turret presses. These systems execute intricate 3D forming sequences within a single setup, eliminating cumulative errors from repositioning. The 5-axis bending capability handles compound angles up to ±150° with simultaneous multi-point control, achieving net-shape results for brackets, enclosures, and fluid manifolds. Laser cutting utilizes 6kW fiber sources with adaptive focus control, processing materials from 0.5mm to 25mm thickness in stainless steel, aluminum, and specialty alloys at speeds exceeding 40m/min while maintaining edge squareness within 0.05mm. Material handling automation ensures zero surface marring on sensitive finishes.

Quality assurance is anchored by Zeiss CONTURA CMM systems operating in a climate-controlled metrology lab (20°C ±0.5°C). Every critical dimension undergoes full 3D scanning against CAD models, with GD&T analysis per ASME Y14.5 standards. Statistical process control (SPC) monitors bending springback compensation in real-time, adjusting for material batch variations. First-article inspection reports include point-cloud deviation maps, surface roughness certification, and material traceability documentation. This closed-loop verification reduces scrap rates by 35% compared to conventional shop-floor QC methods.

Tolerance performance is systematically validated across all processes. The following table reflects our standard achievable specifications under controlled production conditions:

| Parameter | Standard Capability | High-Precision Option | Measurement Method |

|---|---|---|---|

| Linear Dimension (mm) | ±0.10 | ±0.03 | CMM / Optical Comparator |

| Hole Position (mm) | ±0.08 | ±0.02 | CMM |

| Bend Angle (°) | ±0.5 | ±0.2 | Angle Gauge / CMM |

| Bend Radius (mm) | ±0.2 | ±0.05 | Profile Projector |

| Surface Roughness (Ra μm) | 1.6 | 0.8 | Profilometer |

| Flatness (mm/m²) | 0.15 | 0.05 | Granite Surface Plate |

These capabilities are sustained through ISO 9001-certified workflows and operator certification programs. Our engineering team collaborates with clients during DFM analysis to optimize designs for manufacturability within specified tolerance bands, minimizing cost drivers while ensuring functional performance. This technical rigor positions Wuxi Lead as a trusted partner for mission-critical sheet metal components where dimensional stability directly impacts system reliability.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material for sheet metal fabrication is a critical decision that directly impacts the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in high-precision fabrication of aluminum, steel, and titanium—each offering distinct mechanical, thermal, and corrosion-resistant properties tailored to demanding industrial applications.

Aluminum is widely favored for its excellent strength-to-weight ratio, electrical conductivity, and natural corrosion resistance. It is particularly suitable for aerospace, electronics, and transportation sectors where lightweight design is essential. Grade 6061-T6 is among the most commonly used aluminum alloys due to its weldability and machinability, while 5052-H32 offers superior formability for complex bending operations.

Steel remains the backbone of industrial manufacturing, with carbon steel and stainless steel variants serving diverse needs. Carbon steel, such as grades SPCC and Q235, provides high tensile strength and cost-effective performance for structural enclosures and machinery frames. For environments requiring enhanced corrosion resistance, stainless steel grades like 304 and 316 are preferred. These austenitic alloys contain chromium and nickel, offering excellent resistance to oxidation and chemical exposure, making them ideal for medical, food processing, and marine applications.

Titanium, though more expensive, delivers unmatched performance in extreme conditions. Its exceptional strength-to-density ratio, coupled with outstanding resistance to high temperatures and corrosive media, makes it the material of choice for aerospace, defense, and high-performance automotive applications. Grade 2 (commercially pure) titanium is commonly used in sheet form for its balance of ductility and corrosion resistance, while Grade 5 (Ti-6Al-4V) offers superior strength for critical load-bearing components.

Surface finishing plays a pivotal role in enhancing both functional and aesthetic qualities. Anodizing is a highly effective electrochemical process primarily applied to aluminum. It increases surface hardness, improves wear resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat anodizing) delivers thick, durable layers suitable for high-wear environments. Anodized finishes are non-conductive, which must be considered in electrical enclosure designs.

Below is a comparative overview of key material properties for common sheet metal alloys used in precision fabrication.

| Material | Common Grades | Thickness Range (mm) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | 0.5 – 6.0 | 210 – 310 | High | Aerospace, Electronics, Transport |

| Carbon Steel | SPCC, Q235 | 0.8 – 12.0 | 300 – 500 | Low (requires coating) | Machinery, Enclosures, Frames |

| Stainless Steel | 304, 316 | 0.5 – 10.0 | 500 – 700 | Very High | Medical, Food, Marine |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 0.8 – 6.0 | 345 – 900 | Exceptional | Aerospace, Defense, High-Performance |

At Wuxi Lead, our engineering team collaborates closely with clients to match material and finish specifications to application requirements, ensuring optimal performance and manufacturability. Understanding these material fundamentals is essential for achieving precision, reliability, and long-term value in sheet metal components.

Manufacturing Process & QC

Advanced Sheet Metal Fabrication: The Zero Defects Production Process

At Wuxi Lead Precision Machinery, achieving zero defects in sheet metal fabrication demands a rigorously controlled sequence from initial concept to final shipment. This discipline ensures every component meets aerospace, medical, and industrial OEM specifications without compromise. Our process eliminates variability through engineering precision and systematic validation, transforming design intent into flawless physical reality.

The journey begins with collaborative engineering design. We integrate client CAD models with our deep material science expertise to perform comprehensive Design for Manufacturability (DFM) analysis. This phase identifies potential stress points, weld accessibility issues, and tolerance stack-ups before metal is cut. Material selection is validated against environmental factors like corrosion resistance and thermal expansion, ensuring suitability for the end application. Only when the digital twin demonstrates structural integrity and manufacturability do we proceed, preventing 90% of potential defects at the source.

Following validation, rapid prototyping executes the refined design using production-intent tooling and materials. This is not a proof-of-concept model but a fully functional unit subjected to simulated operational stresses. Dimensional accuracy, fitment, and functional performance undergo exhaustive testing against the original engineering requirements. Critical parameters are locked into our production database, forming the baseline for mass production.

This rigorous approach transitions seamlessly into high-volume manufacturing. Every stage employs real-time statistical process control (SPC). Laser cutting achieves ±0.1mm positional accuracy with automated edge detection. CNC press brakes utilize in-process laser micrometers for bend angle verification within ±0.25 degrees. Robotic welding systems monitor amperage, travel speed, and gas flow, with 100% weld seams inspected via penetrant testing. Final assembly occurs in a climate-controlled cleanroom, followed by multi-axis CMM validation against the original CAD model.

Our commitment to zero defects is quantifiable through measurable process controls. The following specifications define our production standards:

| Process Stage | Key Specification | Tolerance/Control Limit | Inspection Frequency |

|---|---|---|---|

| Laser Cutting | Positional Accuracy | ±0.1 mm | 100% in-process |

| CNC Bending | Bend Angle Deviation | ±0.25 degrees | SPC charted per lot |

| Robotic Welding | Penetration Depth | +0.5 / -0.2 mm | 100% visual + 20% PT |

| Final Dimensional | Geometric Tolerance (GD&T) | ±0.05 mm | 100% CMM |

| Surface Finish | Roughness (Ra) | ≤ 1.6 µm | Per AQL 1.0 sampling |

Mass production concludes only after cross-functional sign-off confirming all units meet the prototype’s validated performance. Traceability is maintained via laser-etched part IDs linked to full process data. This end-to-end methodology—where design foresight, prototyping rigor, and in-process intelligence converge—ensures Wuxi Lead delivers sheet metal components that perform flawlessly in the most demanding applications, every time. Zero defects is not a goal; it is our operational standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Excellence

In the competitive world of industrial manufacturing, precision, reliability, and speed are non-negotiable. At Wuxi Lead Precision Machinery, we don’t just meet industry standards—we redefine them. As a leading provider of high-end sheet metal fabrication services in China, we specialize in delivering custom-engineered solutions tailored to the exacting demands of global OEMs, automation integrators, and high-tech equipment manufacturers. When you partner with us, you’re not just outsourcing production—you’re gaining a strategic manufacturing ally committed to quality, innovation, and on-time delivery.

Our advanced manufacturing ecosystem integrates state-of-the-art CNC punching, laser cutting, bending, and welding technologies with rigorous quality control protocols. Every component we produce adheres to ISO 9001 standards and undergoes comprehensive inspection using precision metrology equipment. From prototype development to high-volume production runs, our team ensures dimensional accuracy, material integrity, and repeatable consistency across every batch.

We understand that your success depends on supply chain resilience and technical agility. That’s why we offer end-to-end project management, DFM optimization, and rapid turnaround times without compromising quality. Whether you’re fabricating enclosures, brackets, chassis, or complex assemblies, our engineering team collaborates closely with yours to refine designs, reduce costs, and accelerate time-to-market.

Our facility in Wuxi is equipped with cutting-edge machinery and staffed by certified technicians with decades of combined experience in precision sheet metal work. We process a wide range of materials including stainless steel, aluminum, carbon steel, and galvanized sheet, supporting diverse industry applications from medical devices to industrial automation and renewable energy systems.

Below are the key technical capabilities that define our fabrication expertise:

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Max. Processing Size | 3000 mm × 1500 mm |

| Laser Cutting Accuracy | ±0.1 mm |

| CNC Bending Tolerance | ±0.2° / ±0.1 mm |

| Punching Tonnage | Up to 30 tons |

| Supported File Formats | DXF, DWG, STEP, IGES, PDF |

| Surface Finishes | Anodizing, Powder Coating, Passivation, Zinc Plating |

| Quality Standards | ISO 9001:2015, RoHS Compliant |

At Wuxi Lead Precision Machinery, we measure success by the performance of your products and the strength of our partnership. Our commitment to continuous improvement ensures that we evolve alongside your technical and operational needs.

To begin a collaboration built on precision, trust, and performance, contact us today. Send your fabrication inquiries, drawings, or project specifications to [email protected]. Our engineering team is ready to provide a detailed quote, DFM feedback, and production timeline within 24 hours. Let us help you transform sheet metal into competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.