Technical Contents

Engineering Guide: Action Mold

Engineering Insight: The Critical Role of Precision in Action Mold Manufacturing

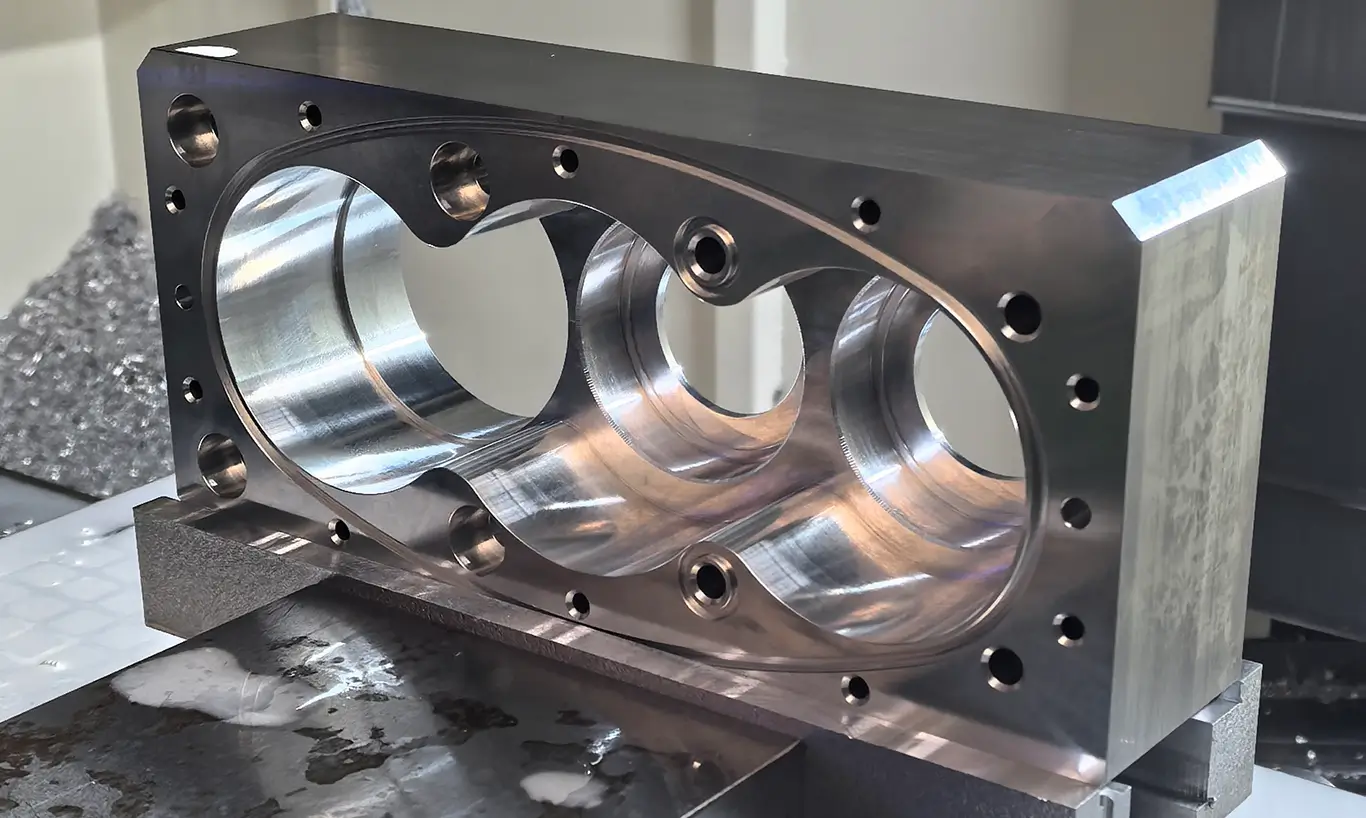

In the realm of custom metal manufacturing, the term action mold refers to highly engineered tooling systems designed for dynamic, high-cycle applications where movement, timing, and repeatability are paramount. These molds are not static forms but integrated mechanical systems—often incorporating sliders, lifters, rotating cores, and sequential actions—that enable the production of complex, multi-featured components in a single press cycle. The success of an action mold hinges on one foundational element: precision.

At Wuxi Lead Precision Machinery, we define precision not merely as tight tolerances but as the holistic alignment of design intent, material behavior, thermal management, and mechanical synchronization. In action molds, even micron-level deviations can lead to binding, premature wear, flash formation, or complete mechanical failure. Consider a mold with synchronized cam-driven sliders: if the guide pin alignment deviates by more than 0.02 mm, the resulting friction can escalate rapidly under high-speed cycling, leading to downtime and costly repairs. This level of sensitivity demands not only advanced CNC machining capabilities but also deep engineering insight into dynamic mold behavior.

Our experience in delivering mission-critical components for Olympic-standard equipment and military-grade systems has reinforced the non-negotiable nature of precision. In these applications, failure is not an option. Whether producing molds for aerospace actuators or high-performance sporting goods, we apply the same rigorous standards—finite element analysis (FEA) for stress prediction, mold flow simulation for cavity balance, and 5-axis simultaneous machining to ensure geometric fidelity.

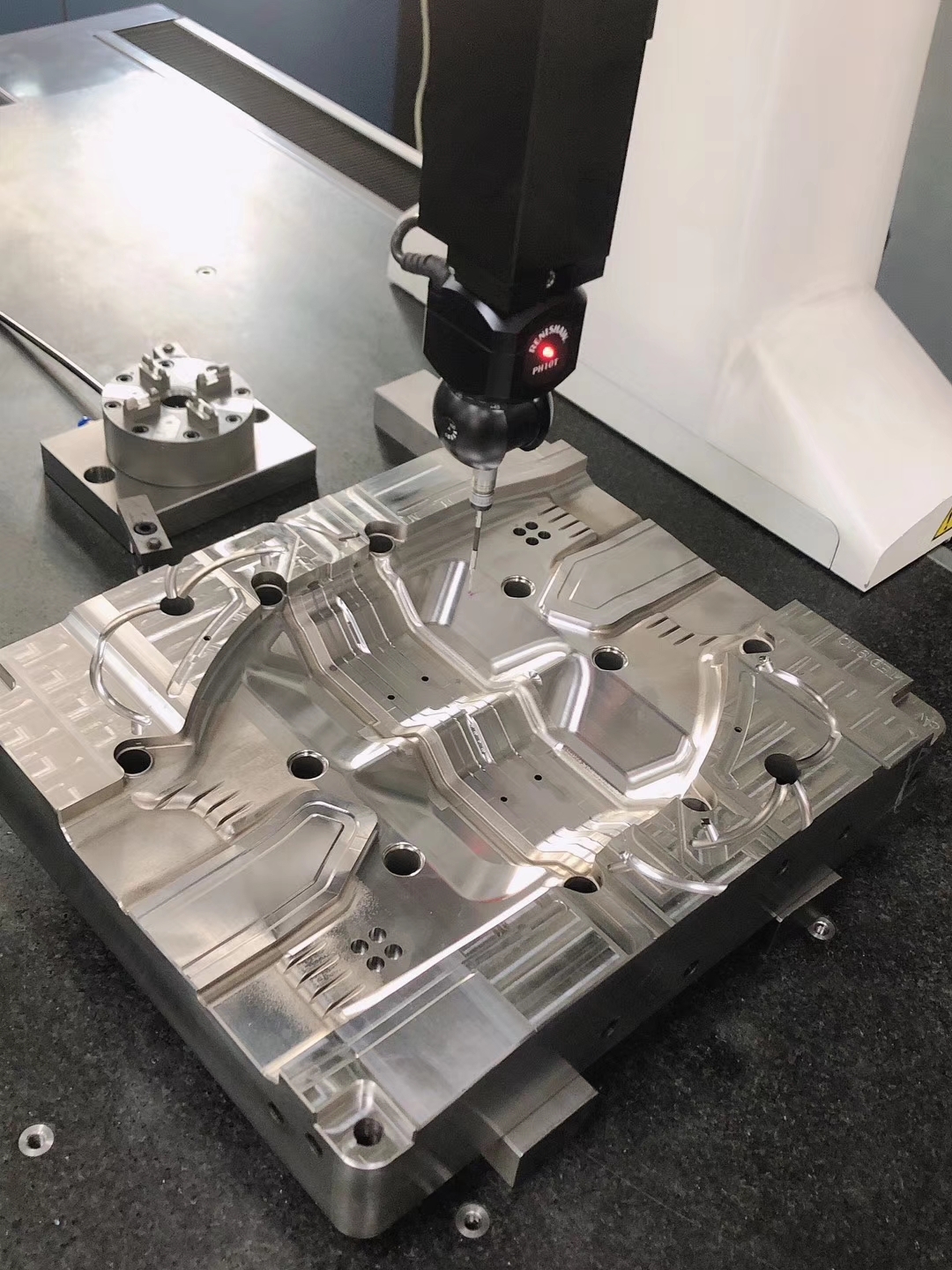

Precision also extends beyond the machining phase. At Lead Precision, we implement a closed-loop quality assurance process using coordinate measuring machines (CMM) and laser interferometry to validate every critical dimension. Our manufacturing environment is temperature-controlled to minimize thermal drift, and our toolmakers undergo continuous training in advanced mold dynamics and wear mitigation strategies.

The result is an action mold that performs reliably over millions of cycles, maintaining part consistency and minimizing maintenance intervals. This level of performance is not achieved by equipment alone—it is the product of disciplined engineering, meticulous process control, and real-world validation.

| Specification | Detail |

|---|---|

| Typical Tolerance Range | ±0.005 mm to ±0.01 mm |

| Surface Finish (Ra) | 0.05 µm to 0.4 µm |

| Materials Used | H13, S136, 2714, 1.2344, Titanium Alloys |

| Machining Capabilities | 5-Axis CNC, Wire EDM, High-Speed Milling |

| Quality Assurance | CMM, Laser Scanning, In-Process Probing |

| Applications | Aerospace Actuators, Defense Systems, High-End Sporting Equipment |

Precision in action mold manufacturing is not a luxury—it is the cornerstone of reliability, efficiency, and competitive advantage. At Wuxi Lead Precision Machinery, we bring proven expertise from the most demanding industries to ensure your molds perform flawlessly, cycle after cycle.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Action Mold Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for the demanding requirements of action mold manufacturing through integrated advanced technology and rigorous quality control. Our core competency lies in transforming complex metal components from high-grade tool steels, aluminum alloys, and specialty materials into production-ready elements meeting the exacting standards of dynamic mold systems. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers. These systems utilize simultaneous multi-axis motion, enabling the precise fabrication of intricate contours, undercuts, and deep cavities inherent in action mold cores, cavities, lifters, and slides within a single setup. This eliminates cumulative error from multiple fixtures, significantly reduces lead times, and ensures critical geometric relationships are maintained with exceptional accuracy. Our programming leverages advanced CAM software to optimize toolpaths for surface finish, material removal rates, and tool life, directly impacting mold performance and longevity.

Quality assurance is non-negotiable in action mold production where micron-level deviations impact function. Every critical component undergoes comprehensive dimensional verification using our coordinate measuring machines (CMM). These high-precision instruments, operating in a temperature-controlled metrology lab, perform full 3D geometric dimensioning and tolerancing (GD&T) analysis. Our certified metrologists execute programmed inspection routines, generating detailed reports that validate conformance to the most stringent engineering specifications. This process provides absolute traceability and documented proof of quality, essential for high-cavitation molds and applications requiring zero-defect performance. We integrate CMM data directly with our manufacturing feedback loop, enabling proactive process adjustments and continuous improvement.

The following table details the standard tolerance capabilities achievable across our production processes for action mold components. These represent our baseline for high-volume production; tighter tolerances are routinely achieved and validated for critical features upon specific project requirements.

| Feature Category | Standard Capability | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm (0.0002″) | Up to 300 mm; ±0.01 mm beyond 300 mm |

| Positional Tolerance | ±0.01 mm (0.0004″) | Hole patterns, critical feature loci |

| Geometric Form (Flatness, Roundness) | 0.005 mm (0.0002″) | Per ISO 1101 GD&T standards |

| Surface Roughness (Ra) | 0.4 μm (16 μin) | Critical sealing/mating surfaces |

| Repeatability (Cpk) | ≥ 1.67 | Validated per production batch |

This combination of 5-axis machining mastery and metrology-grade inspection forms the foundation of Wuxi Lead’s commitment to action mold excellence. We understand that dimensional integrity directly translates to mold stability, part consistency, and extended tool life in high-pressure injection environments. Our technical capabilities are designed not merely to meet drawings, but to deliver components that perform reliably under the dynamic stresses of modern molding processes, minimizing downtime and maximizing client productivity. Partner with us for precision that moves your action molds forward.

Material & Finish Options

Material Selection in High-Precision Custom Metal Manufacturing

Selecting the appropriate material is a critical decision in custom metal manufacturing, particularly for high-performance applications in aerospace, medical devices, and advanced automation. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of aluminum, steel, and titanium—each offering distinct mechanical properties, cost profiles, and compatibility with finishing processes such as anodizing. Understanding the trade-offs between these materials enables engineers and procurement teams to optimize for strength, weight, corrosion resistance, and manufacturability.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is commonly used in structural and enclosure applications due to its weldability and corrosion resistance. When enhanced surface durability is required, aluminum parts can undergo anodizing—a controlled electrochemical process that thickens the natural oxide layer. Type II (sulfuric acid) and Type III (hardcoat) anodizing offer increasing levels of wear and corrosion resistance, with hardcoat anodizing suitable for components exposed to abrasive environments. Anodized finishes also support color coding for assembly or branding purposes.

Steel remains the material of choice where high tensile strength, rigidity, and wear resistance are paramount. We routinely machine alloy steels such as 4140 and 1045, which respond well to heat treatment for enhanced hardness. While steel does not anodize, it can be treated with electroplating, passivation, or powder coating to improve surface performance. Stainless steel grades like 304 and 316 offer inherent corrosion resistance and are ideal for medical and food-grade applications.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-density performance and outstanding resistance to extreme environments, including high temperatures and corrosive media. It is extensively used in aerospace and biomedical implants. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s long-term performance justifies its use in mission-critical components. It can be anodized for color coding and minor surface protection, though this process is primarily aesthetic rather than functional.

Below is a comparative summary of key properties for commonly machined grades:

| Material | Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Finishes | Key Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Anodizing (Type II/III), Powder Coat | Enclosures, Heat Sinks, Frames |

| Steel | 1045 | 600 | 7.85 | Zinc Plating, Passivation | Shafts, Brackets, Mechanical Parts |

| Alloy Steel | 4140 | 655 | 7.85 | Hard Chrome, Nitriding | High-Stress Components |

| Stainless Steel | 316 | 580 | 8.0 | Electropolishing, Passivation | Medical, Marine, Food Processing |

| Titanium | Ti-6Al-4V | 900 | 4.43 | Anodizing (Decorative), Passivation | Aerospace, Implants, Racing Components |

Material selection directly impacts performance, lifecycle cost, and manufacturability. At Wuxi Lead Precision Machinery, we support clients from design review to final production, ensuring optimal material and finish pairing for each application.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our core commitment is delivering flawless custom metal components for demanding global industries. We achieve this through a rigorously controlled, three-phase production process designed for absolute precision and Zero Defects compliance. This methodology ensures your “action mold” or critical metal component performs reliably in the most challenging applications, from aerospace hydraulics to medical device mechanisms.

The journey begins with Collaborative Design Engineering. Our senior engineers partner directly with your team, utilizing advanced CAD/CAM software and DFM analysis. We scrutinize every geometric feature, material specification, and functional requirement against real-world manufacturability constraints. This phase identifies potential stress points, thermal behaviors, and assembly interfaces early, preventing costly iterations later. Material selection undergoes stringent validation against performance criteria like fatigue resistance, corrosion tolerance, and regulatory standards. Only when the digital twin meets our exacting internal benchmarks and your functional requirements is the design locked for prototyping.

Prototyping transitions the validated design into tangible reality under full production conditions. We employ multi-axis CNC milling, precision turning, and specialized EDM processes on the same equipment used for mass production. Each prototype undergoes exhaustive metrology using calibrated CMMs, optical comparators, and surface roughness testers against the original CAD model. Dimensional reports, material certifications, and functional test data are provided for your review. Crucially, this stage validates not just the part, but the entire manufacturing sequence and fixture strategy. Any deviation triggers immediate root cause analysis and process correction before scaling up, ensuring the prototype is a true predictor of mass production quality.

Mass Production leverages the perfected process from prototyping within our ISO 9001 and IATF 16949 certified facility. Every component is manufactured under controlled environmental conditions with real-time SPC monitoring of critical dimensions. In-process inspections occur at defined intervals using automated vision systems and manual verification. Final inspection mandates 100% dimensional verification of key features and random batch testing for material properties and surface integrity. Our Zero Defects protocol means any non-conformance halts the line; containment, analysis, and corrective action are implemented before production resumes. Traceability from raw material heat number to finished part is maintained throughout.

This integrated approach minimizes risk and total cost of ownership. The table below summarizes our core production capabilities ensuring Zero Defects outcomes.

| Specification Category | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 0.2 µm – 1.6 µm | Profilometer |

| Material Compliance | Aerospace (AMS), Medical (ASTM F86) | Mill Certificates, Spectroscopy |

| Process Control | SPC on Critical Features | Real-time Monitoring Dashboard |

| Traceability | Full Lot-to-Part | ERP Integrated System |

Wuxi Lead transforms complex metal manufacturing challenges into reliable, defect-free solutions. Our process isn’t just about making parts; it’s about guaranteeing performance where failure is not an option. Partner with us for precision that meets the highest global standards.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation are the cornerstones of success in high-end manufacturing. As a trusted leader in custom metal manufacturing based in Wuxi, China, we specialize in delivering engineered solutions that meet the exacting demands of global industries—from automotive and aerospace to medical devices and advanced automation. When you partner with Lead Precision, you’re not just sourcing components—you’re gaining a strategic manufacturing ally committed to performance, scalability, and long-term value.

Our state-of-the-art facility integrates advanced CNC machining, multi-axis milling, precision turning, and comprehensive quality assurance systems to ensure every part exceeds expectations. With over a decade of experience serving Tier-1 suppliers and OEMs worldwide, we combine deep technical expertise with agile production capabilities to support prototyping, low-volume builds, and high-volume production runs—all under strict adherence to international quality standards including ISO 9001:2015.

What sets us apart is our end-to-end engineering collaboration. From initial design review to final inspection and global logistics, our team works closely with your engineers to optimize manufacturability, reduce lead times, and control costs—without compromising on precision. Whether you require complex geometries in hardened steels, tight-tolerance aluminum housings, or corrosion-resistant stainless components, our processes are calibrated for consistency across materials and volumes.

We recognize that today’s manufacturing challenges demand more than just machines—they require insight, responsiveness, and a commitment to continuous improvement. That’s why we invest heavily in workforce development, cutting-edge metrology equipment, and real-time production monitoring to ensure transparency and traceability at every stage.

Our clients choose Lead Precision not only for our technical capabilities but for our customer-first philosophy. We pride ourselves on clear communication, on-time delivery, and solutions tailored to your unique operational needs. When you work with us, you gain a partner who is fully aligned with your goals—driving efficiency, reducing risk, and accelerating time-to-market.

Explore how we can elevate your next project with precision-engineered metal components built to perform.

| Specification | Detail |

|---|---|

| Manufacturing Capabilities | CNC Machining, Milling, Turning, Drilling, Tapping, Surface Finishing |

| Materials Supported | Aluminum Alloys, Stainless Steel, Carbon Steel, Brass, Copper, Titanium, Plastics |

| Tolerance Range | ±0.005 mm to ±0.01 mm |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection, CMM Reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

| File Formats Accepted | STEP, IGES, DWG, DXF, PDF, SolidWorks |

Contact us today to begin the conversation. Email [email protected] and connect with our engineering team to discuss your custom manufacturing requirements. Let Wuxi Lead Precision Machinery be your trusted partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.