Technical Contents

Engineering Guide: Acrylic Sheet Laser Cutting

Engineering Insight: Acrylic Sheet Laser Cutting – The Role of Precision in High-Performance Manufacturing

In the realm of advanced sheet fabrication, acrylic laser cutting stands apart as a process where optical clarity meets engineering rigor. Unlike traditional metalworking, acrylic—also known as polymethyl methacrylate (PMMA)—demands a refined balance of thermal control, motion accuracy, and beam delivery to achieve clean, polished edges without microfractures or clouding. At Wuxi Lead Precision Machinery, we understand that precision in acrylic laser cutting is not merely a performance metric—it is the foundation of functional integrity and aesthetic excellence.

Acrylic’s sensitivity to thermal gradients makes it prone to melting, charring, or stress cracking when exposed to inconsistent laser parameters. Even minor deviations in focus, speed, or power can result in edge defects that compromise both structural performance and visual quality. This is especially critical in applications such as medical enclosures, aerospace instrumentation panels, and high-end architectural glazing, where transparency and dimensional accuracy are non-negotiable.

Our engineering approach begins with high-resolution CO₂ laser systems specifically tuned for non-metallic substrates. These systems integrate dynamic focus control and closed-loop motion platforms capable of maintaining tolerances within ±0.05 mm. Coupled with optimized assist gas delivery—typically dry, oil-free air—we ensure minimal thermal impact while achieving flame-polished edges in a single pass. This level of repeatability is only possible through rigorous calibration, real-time monitoring, and decades of process refinement.

Wuxi Lead Precision Machinery brings over 18 years of advanced fabrication expertise to every project. Our work has supported mission-critical components for defense systems and precision enclosures used in Olympic-grade timing and scoring equipment—applications where failure is not an option. These experiences have shaped our understanding of how precision translates into reliability, particularly when working with materials as dimensionally stable yet thermally sensitive as acrylic.

Whether producing complex signage, optical housings, or prototype displays, our process is governed by the same standards applied to aerospace and military-grade manufacturing. Each job undergoes full digital validation prior to cutting, with nested toolpaths optimized for material utilization and edge consistency. Our facility maintains ISO 9001-certified workflows, ensuring traceability from raw sheet to finished part.

Below are key technical specifications for our acrylic laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | RF-excited CO₂, 40–100 W |

| Beam Wavelength | 10.6 μm |

| Maximum Cutting Thickness | 20 mm (acrylic) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Edge Quality | Flame-polished, no secondary finishing |

| Minimum Feature Size | 0.5 mm internal radii |

| Tolerance (Standard) | ±0.05 mm |

| Supported Sheet Sizes | Up to 1500 × 3000 mm |

At Lead Precision, we treat every acrylic component as a fusion of art and engineering. Our commitment to precision ensures that clients receive parts that meet exact optical, dimensional, and functional requirements—on time, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Acrylic Sheet Laser Cutting

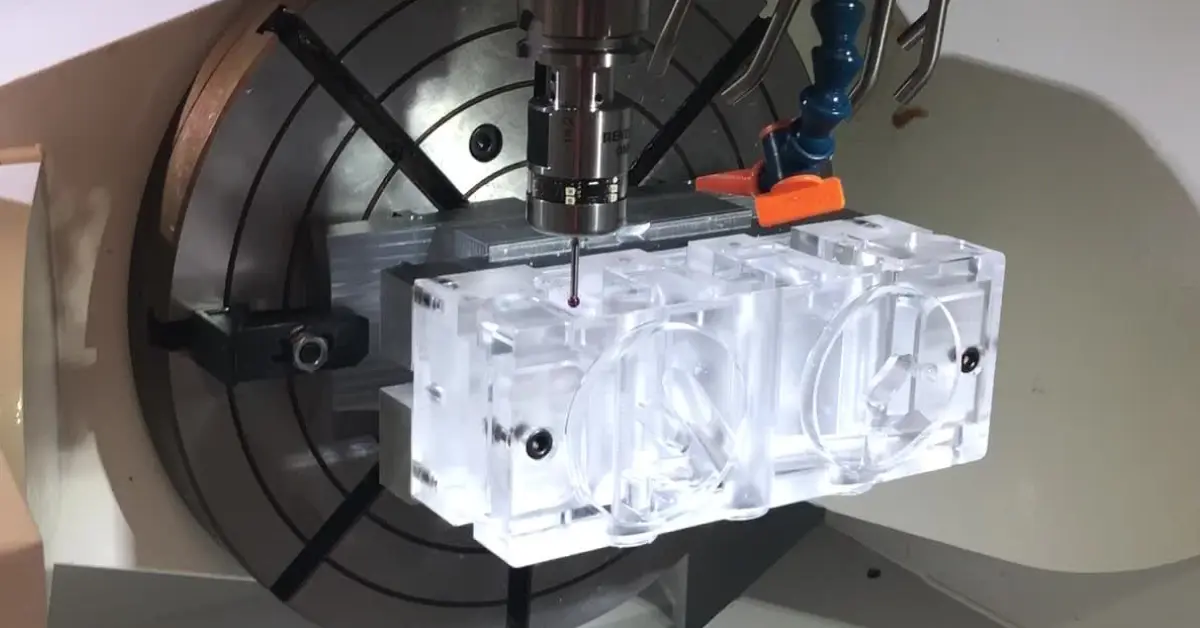

Wuxi Lead Precision Machinery delivers industry-leading acrylic sheet laser cutting through advanced 5-axis CNC technology, specifically optimized for the unique thermal and structural properties of acrylic polymers. Standard CO2 laser systems often induce thermal stress, micro-cracking, or edge clouding in acrylic due to excessive heat input and improper gas dynamics. Our solution integrates high-frequency pulsed laser sources with precisely controlled nitrogen assist gas delivery and dynamic focal point management. This proprietary parameter set minimizes the heat-affected zone (HAZ), ensuring optically clear edges with minimal post-processing requirements while maintaining dimensional stability across complex geometries. The 5-axis capability is critical for producing beveled edges, compound contours, and intricate 3D forms in a single setup—eliminating secondary operations that compromise accuracy and increase lead times. This is particularly valuable for architectural glazing, medical device housings, and high-end display fabrication where aesthetic perfection and structural integrity are non-negotiable.

Material handling is executed within a climate-controlled environment to mitigate acrylic’s hygroscopic nature, which can cause dimensional drift during processing. Vacuum tables with micro-perforated surfaces secure sheets without mechanical clamping marks, while integrated thermal monitoring systems dynamically adjust laser power to counteract localized heating. All processes adhere to ISO 13370 thermal management protocols to prevent warpage. Crucially, our QC protocol extends beyond standard in-process checks. Every critical dimension undergoes Zeiss CONTURA CMM inspection under ISO 17025 accreditation, with full traceability to NIST standards. This includes verification of edge perpendicularity, surface roughness, and geometric deviations across the entire work envelope—not just isolated test cuts. The result is consistent repeatability within micron-level tolerances, directly reducing our clients’ assembly scrap rates and accelerating time-to-market.

Key performance specifications for acrylic laser cutting are maintained across production runs as follows:

| Parameter | Specification | Critical Implementation Notes |

|---|---|---|

| Material Thickness | 1.0 mm – 25.0 mm | Optimized parameters per 0.5mm increment tier |

| Positional Tolerance | ±0.05 mm | Verified at 23°C ±1°C per ISO 1.0110 |

| Angular Tolerance | ±0.1° | Measured on beveled edges >15° |

| Edge Roughness (Ra) | ≤ 1.6 μm | Achieved without secondary polishing |

| Feature Repeatability | ±0.03 mm (3σ) | Validated over 100 consecutive parts |

| Max Work Envelope | 1500 x 3000 mm | Full 5-axis motion within envelope |

This technical foundation enables clients to specify complex acrylic components with confidence, knowing that Wuxi Lead’s process control directly translates to reduced assembly rework and superior end-product performance. We partner with engineering teams during DFM analysis to optimize part geometry for laser fabrication, ensuring manufacturability without compromising design intent. Our commitment to measurable precision—validated through rigorous CMM inspection—makes us the strategic choice for applications where acrylic clarity and dimensional fidelity define product success.

Material & Finish Options

Material selection plays a critical role in achieving precision, durability, and aesthetic quality in sheet metal fabrication, particularly when integrating laser cutting processes. At Wuxi Lead Precision Machinery, we emphasize compatibility between material properties and manufacturing techniques to ensure optimal performance across industrial applications. While acrylic sheet laser cutting is widely used in prototyping and signage, this guide focuses on high-performance metals—aluminum, steel, and titanium—commonly processed using fiber laser systems due to their superior structural characteristics and thermal response.

Aluminum is a preferred choice for lightweight, corrosion-resistant components in aerospace, automotive, and electronics industries. Its high thermal conductivity and reflectivity require precise laser parameter tuning to prevent back-reflection damage to optical components. However, when processed correctly, aluminum offers excellent edge quality and minimal dross formation. It is especially suitable for intricate geometries due to its malleability and stability during high-speed cutting.

Steel, particularly mild and stainless variants, remains a cornerstone in heavy-duty fabrication. Mild steel provides cost-effective strength for structural parts, while stainless steel delivers enhanced corrosion resistance and a polished finish ideal for medical and food-processing equipment. Carbon content influences laser absorption rates; stainless grades with higher chromium and nickel content may require nitrogen-assisted cutting to maintain oxide-free edges. Our fiber laser systems are calibrated to handle varying thicknesses, from 0.5 mm up to 25 mm, depending on alloy composition and power configuration.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to extreme environments. Commonly used in aerospace and defense applications, titanium demands stringent process control due to its reactivity at elevated temperatures. Oxygen-free assist gases such as argon or high-purity nitrogen are essential to prevent embrittlement and maintain metallurgical integrity. Despite its challenges, titanium’s compatibility with precision laser cutting enables the production of complex, high-reliability components.

Post-processing finishes further enhance functionality and appearance, with anodizing being a key treatment for aluminum. Anodizing creates a durable, corrosion-resistant oxide layer that can be dyed in various colors for identification or branding. It also improves surface hardness, making it ideal for wear-prone parts. However, anodized layers may affect laser absorption; therefore, material condition should be considered during programming.

Below is a comparative overview of key material specifications relevant to laser cutting performance:

| Material | Thickness Range (mm) | Tensile Strength (MPa) | Reflectivity | Recommended Assist Gas | Max Cutting Speed (mm/min @ 1mm) |

|---|---|---|---|---|---|

| Aluminum 6061 | 0.5 – 12 | 310 | High | Nitrogen | 18,000 |

| Stainless Steel 304 | 0.5 – 20 | 505 | Medium | Nitrogen / Oxygen | 14,000 |

| Mild Steel Q235 | 1 – 25 | 370 – 500 | Low | Oxygen | 16,000 |

| Titanium Grade 5 | 0.5 – 10 | 900 | Medium | Argon / High-Purity Nitrogen | 6,000 |

Selecting the appropriate material and finish ensures compatibility with laser parameters, reduces post-processing requirements, and maximizes part reliability. Wuxi Lead Precision Machinery supports clients in material evaluation and process optimization to achieve consistent, high-precision results across diverse industrial demands.

Manufacturing Process & QC

Acrylic Sheet Laser Cutting: Precision Production Process for Zero Defects

Achieving flawless acrylic components demands a rigorously controlled production sequence, eliminating defects before they reach the customer. At Wuxi Lead Precision Machinery, our process integrates advanced engineering with systematic quality gates, ensuring every part meets aerospace-grade validation standards from initial concept to final shipment. This structured approach is non-negotiable for high-value applications where optical clarity, dimensional accuracy, and edge quality are critical.

The process begins with meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients to review CAD files, focusing on material behavior under laser energy. We optimize kerf compensation algorithms, nesting efficiency, and vector path sequencing to prevent thermal stress fractures and micro-chipping inherent in acrylic. Critical parameters like focal point positioning and assist gas selection (typically dry nitrogen) are simulated to ensure clean, polished edges without recast layer or yellowing. This phase identifies potential weaknesses, such as unsupported geometries prone to vibration or excessive heat buildup in intricate contours, resolving them virtually before any material is cut.

Prototyping validates the digital blueprint against physical reality. Using the exact production-grade CO2 laser system and the client-specified acrylic grade (e.g., PMMA cast or extruded), we produce 1-3 physical samples. These undergo comprehensive metrology: CMM verification against nominal dimensions, optical inspection for surface defects under controlled lighting, and edge quality assessment via profilometry. Any deviation triggers immediate process recalibration – adjusting pulse frequency, power ramping, or substrate support – until the prototype achieves zero non-conformities. This step confirms thermal management strategies and proves the process capability index (Cpk > 1.67) required for mass production.

Mass production executes with embedded quality assurance. Our automated production cells run under strict statistical process control (SPC). Laser parameters are locked and monitored in real-time via IoT sensors, with automatic shutdown if deviations exceed ±2% tolerance. Every sheet undergoes pre-cut surface inspection, while in-process cameras detect edge anomalies. Post-cut, 100% of parts pass through a multi-stage quality checkpoint: dimensional verification on calibrated optical comparators, visual inspection against AQL 0.65 standards, and functional testing where applicable (e.g., light transmission measurement). All data is logged for full traceability, meeting ISO 9001 requirements. This closed-loop system ensures defect escape is physically impossible, not merely improbable.

Critical Acrylic Laser Cutting Specifications

| Parameter | Capability Range | Precision Standard | Quality Impact |

|---|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | ±0.05 mm (≤10mm) | Prevents warping, ensures structural integrity |

| Edge Quality | Optical Grade (Cast Acrylic) | Ra ≤ 0.8 µm | Eliminates light diffusion, critical for lenses |

| Dimensional Tolerance | ISO 2768-mK | ±0.1 mm (basic) | Guarantees assembly fit, no rework |

| Kerf Width | 0.1 mm – 0.3 mm | Consistent ±0.02 mm | Maintains design intent, avoids gaps |

| Production Speed | Up to 20 m/min (1mm sheet) | Optimized per thickness | Balances throughput with thermal control |

This disciplined progression – from validated design through rigorously tested prototyping to SPC-monitored mass production – forms the foundation of our Zero Defects commitment. Wuxi Lead transforms acrylic laser cutting from a fabrication step into a guaranteed precision outcome.

Why Choose Wuxi Lead Precision

When it comes to precision laser cutting of acrylic sheets, the demands of high-end manufacturing require more than standard equipment — they require expertise, advanced engineering, and a partner committed to performance and reliability. At Wuxi Lead Precision Machinery, we specialize in delivering industrial-grade laser cutting solutions tailored for the rigorous standards of modern sheet metal and acrylic fabrication.

Our CNC-controlled laser cutting systems are engineered for micron-level accuracy, thermal stability, and seamless integration into automated production environments. Whether you’re processing PMMA, cast acrylic, or extruded sheets up to 25 mm thick, our machines ensure clean, polished edges with minimal charring or residue — a critical advantage in aerospace, medical device manufacturing, signage, and high-visibility consumer applications.

Partnering with Wuxi Lead Precision Machinery means gaining access to more than just equipment. You gain a strategic manufacturing ally with over 15 years of experience in precision-driven fabrication technology. Our engineering team works closely with clients to evaluate material behavior under laser processing, optimize cutting parameters, and customize machine configurations for volume production, ensuring maximum throughput and repeatability.

We understand that downtime is not an option in high-output facilities. That’s why our laser systems are built with industrial-grade components, including sealed linear guides, high-efficiency CO₂ and fiber hybrid sources, and intelligent cooling management. Our control software features real-time monitoring, predictive maintenance alerts, and remote diagnostics — all designed to keep your operation running with minimal intervention.

Below are the key technical specifications of our flagship acrylic sheet laser cutting system:

| Specification | Detail |

|---|---|

| Laser Type | Dual-source CO₂ + Fiber (Selectable) |

| Laser Power | 150W – 600W (adjustable) |

| Cutting Area | 1300 × 2500 mm (standard), up to 3000 × 6000 mm (custom) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Maximum Cutting Speed | 120 m/min (acrylic, 10 mm) |

| Supported Materials | PMMA, cast acrylic, extruded acrylic, polycarbonate (with assist gas optimization) |

| Control System | LeadCut Pro (proprietary, Windows-based, CAD/CAM integrated) |

| Cooling System | Closed-loop chiller with dual redundancy |

| Safety Compliance | CE, ISO 60825-1, GB/T 15706 |

Every machine we deliver undergoes a 72-hour continuous load test and is calibrated using laser interferometry to guarantee performance consistency across shifts and seasons.

If you are seeking a reliable, high-precision partner to elevate your acrylic fabrication capabilities, we invite you to connect with our engineering team. At Wuxi Lead Precision Machinery, we don’t just supply machines — we deliver measurable improvements in yield, quality, and operational efficiency.

Contact us today at [email protected] to discuss your project requirements, request a sample cut, or schedule a virtual demonstration. Let us help you transform your production line with intelligent laser cutting technology built for the future of manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.