Technical Contents

Engineering Guide: Acrylic Parts

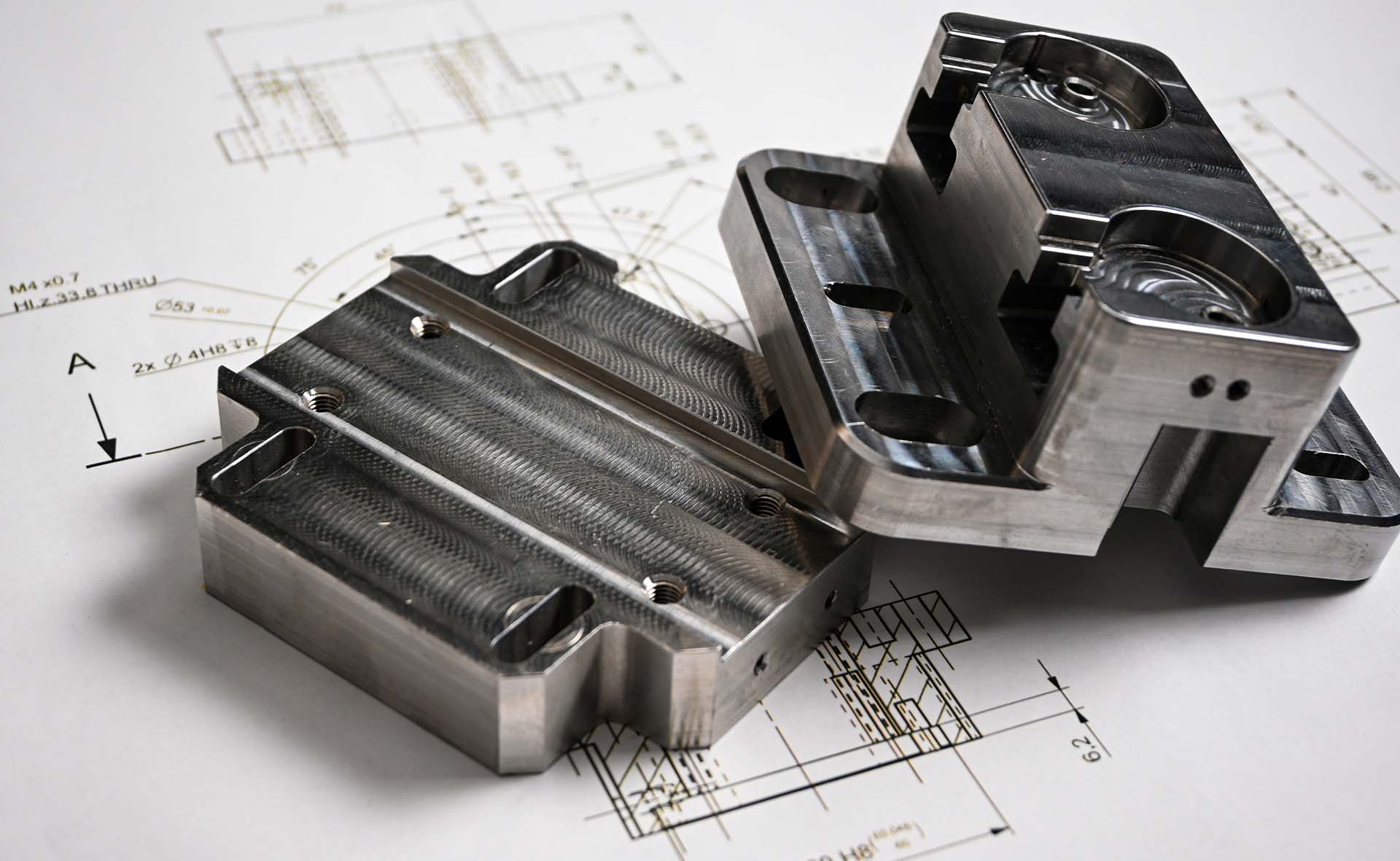

Engineering Insight: Precision in Acrylic Parts for High-Performance Applications

In the realm of advanced manufacturing, acrylic parts are often perceived as secondary components due to their transparent, plastic-like appearance. However, in high-end industrial, aerospace, and defense systems, acrylic is increasingly specified not for aesthetics, but for its unique combination of optical clarity, impact resistance, and lightweight structural performance. At Wuxi Lead Precision Machinery, we recognize that the performance of acrylic components is not inherent to the material alone—it is determined by the precision of their fabrication.

Acrylic, or polymethyl methacrylate (PMMA), behaves differently under machining stress compared to metals. It is sensitive to heat, prone to micro-cracking, and requires exact control over cutting speeds, tool geometry, and clamping forces. Even minor deviations in tolerances—on the order of ±0.05 mm—can result in optical distortion, improper sealing, or mechanical failure in pressurized or dynamic environments. This is especially critical in applications such as cockpit canopies, sensor housings, or transparent armor systems used in military and aerospace platforms.

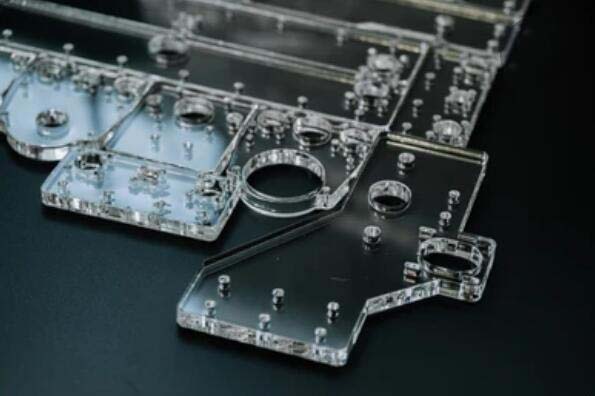

Our engineering team at Wuxi Lead has refined acrylic machining processes through direct engagement with mission-critical projects, including components for Olympic-grade timing systems requiring sub-millimeter accuracy and environmental stability, as well as specialized transparent enclosures for defense electronics exposed to extreme vibration and thermal cycling. These programs demanded not only dimensional precision but also repeatability across batches, surface finish consistency, and long-term material stability.

We employ CNC milling and laser cutting systems calibrated specifically for thermoplastics, with environmental controls to minimize thermal expansion during machining. Each acrylic part undergoes in-process inspection using coordinate measuring machines (CMM) and optical profilometry to ensure compliance with stringent geometric dimensioning and tolerancing (GD&T) requirements. Our quality assurance protocols are aligned with ISO 9001 and AS9100 standards, reflecting our commitment to delivering components that perform reliably in the most demanding conditions.

Beyond machining, we specialize in stress-relieved annealing cycles tailored to acrylic, which eliminate internal stresses induced during fabrication. This post-processing step is essential for preventing warping or cracking during operational service, particularly in outdoor or high-vibration environments.

| Specification | Capability at Wuxi Lead |

|---|---|

| Material Types | PMMA (Standard, Optical, UV-Resistant, Impact-Modified) |

| Tolerance Range | ±0.05 mm to ±0.02 mm (depending on geometry) |

| Maximum Part Size | 1200 mm × 800 mm × 150 mm |

| Surface Finish | Ra ≤ 0.8 µm (machined), Optical Clarity > 92% |

| Machining Processes | CNC Milling, Laser Cutting, Diamond Turning |

| Post-Processing | Annealing, Polishing, Edge Coating, Anti-Reflective Treatment |

| Quality Standards | ISO 9001, AS9100, Full First Article Inspection (FAI) Reporting |

Precision in acrylic parts is not a luxury—it is a necessity when failure is not an option. Wuxi Lead Precision Machinery combines decades of metal manufacturing expertise with advanced polymer processing knowledge to deliver acrylic components that meet the exacting standards of aerospace, defense, and high-tech industries.

Precision Specs & Tolerances

Precision Acrylic Machining Capabilities at Wuxi Lead Precision Machinery

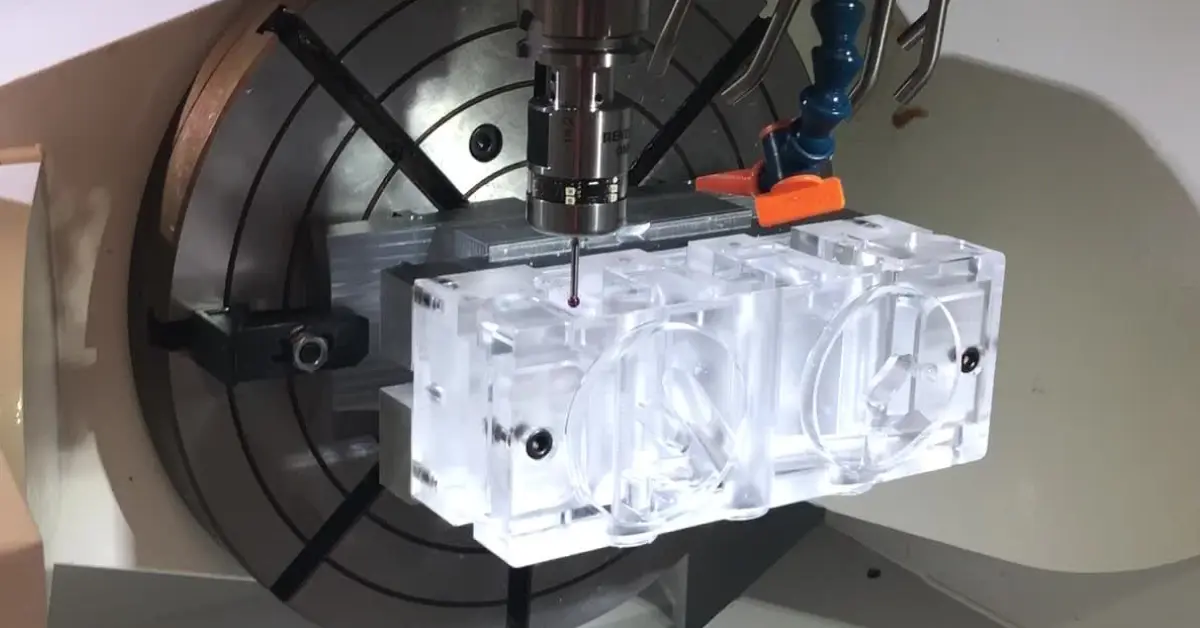

Wuxi Lead Precision Machinery applies its deep expertise in high-tolerance metal manufacturing to deliver exceptional precision for custom acrylic (PMMA) components. While renowned for metal fabrication, our advanced infrastructure and process rigor are uniquely adapted to address the specific challenges of machining acrylic, ensuring optical clarity, dimensional accuracy, and structural integrity for demanding industrial applications. Our core strength lies in leveraging sophisticated 5-axis CNC milling and turning centers, specifically configured for thermoplastic processing. These machines utilize high-speed spindles with precisely controlled RPM ranges optimized to prevent thermal deformation and melting during acrylic cutting. Specialized toolpath strategies minimize chatter and vibration, critical for achieving smooth, optically clear edges without micro-fractures. Dedicated vacuum hold-down systems securely fixture delicate sheets and complex geometries without surface marring, while optimized coolant alternatives or air blast systems effectively evacuate chips without introducing stress or clouding the material. This meticulous adaptation of metal machining principles to acrylic’s unique properties is fundamental to our process.

Rigorous quality control is non-negotiable for acrylic components, where even minor deviations impact performance and aesthetics. Every critical dimension undergoes verification using our calibrated Coordinate Measuring Machine (CMM) systems. CMM inspection provides objective, traceable data against CAD models, confirming geometric accuracy, hole placement, profile conformity, and critical flatness or roundness requirements. This metrology-grade validation is essential for applications in optics, medical devices, and high-end displays where acrylic clarity and fit are paramount. Our inspection protocols account for acrylic’s sensitivity to temperature and handling, employing controlled environments and non-contact probing methods where necessary to ensure measurement integrity. Statistical process control data from CMM reports is actively used to refine machining parameters and maintain consistent output.

The achievable tolerances for acrylic parts are inherently influenced by material grade, geometry complexity, wall thickness, and part size. Wuxi Lead consistently achieves the following standards through our controlled processes, though specific project requirements may dictate tighter or more relaxed specifications based on feasibility analysis. Key tolerance benchmarks are detailed below.

| Feature | Standard Tolerance | Tight Tolerance Capability | Critical Notes |

|---|---|---|---|

| Linear Dimensions | ±0.10 mm | ±0.025 mm | Highly dependent on part size and geometry |

| Hole Diameter | +0.05 / -0.00 mm | +0.02 / -0.00 mm | Clearance holes easier than press-fit precision |

| Positional Accuracy | ±0.05 mm | ±0.02 mm | Verified via CMM relative to datums |

| Flatness | 0.10 mm per 100mm | 0.05 mm per 100mm | Significantly affected by sheet thickness & size |

| Edge Straightness | 0.05 mm per 100mm | 0.02 mm per 100mm | Critical for optical sealing surfaces |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm | Achieved with fine finishing toolpaths |

Wuxi Lead Precision Machinery bridges the gap between metal manufacturing precision and the specialized demands of acrylic fabrication. Our 5-axis CNC expertise, combined with stringent CMM-based quality assurance, ensures your acrylic components meet the highest functional and aesthetic standards. We partner with clients from initial design for manufacturability review through final inspection, guaranteeing parts that perform reliably in critical applications. Contact our engineering team to discuss how our capabilities solve your specific acrylic precision challenge.

Material & Finish Options

Material Selection for High-Precision Acrylic Component Integration

When manufacturing custom metal components designed for integration with acrylic parts, material selection is critical to ensure structural integrity, thermal compatibility, and aesthetic alignment. At Wuxi Lead Precision Machinery, we specialize in precision metal fabrication where aluminum, steel, and titanium serve as primary candidates for assemblies involving transparent or translucent acrylic elements. Each metal offers distinct mechanical and surface treatment advantages, particularly when combined with processes like anodizing to enhance durability and appearance.

Aluminum is the most widely used material in hybrid acrylic-metal systems due to its lightweight nature, excellent machinability, and strong compatibility with anodized finishes. Grade 6061-T6 aluminum provides a balanced combination of strength, corrosion resistance, and weldability, making it ideal for enclosures, display frames, and optical housings where acrylic panels are mounted. Its thermal expansion coefficient is closer to acrylic than other metals, reducing stress at material interfaces under temperature fluctuations. Anodizing aluminum not only improves wear resistance but also allows for color coding or branding through dye integration in the oxide layer, ensuring a seamless visual match with colored acrylic components.

Stainless steel, particularly grade 304 and 316, is selected when higher strength, rigidity, and resistance to harsh environments are required. While heavier than aluminum, stainless steel offers superior durability in industrial or outdoor applications where acrylic parts are used for protective glazing or signage. Unlike aluminum, steel cannot be anodized in the traditional sense, but it can be passivated, electropolished, or coated with PVD finishes to achieve a clean, corrosion-resistant surface that complements clear or tinted acrylic. Care must be taken in design to accommodate the higher thermal expansion differential between steel and acrylic.

Titanium, specifically Grade 5 (Ti-6Al-4V), is reserved for high-performance applications such as aerospace, medical devices, or premium instrumentation where weight savings and extreme corrosion resistance are paramount. Though more challenging to machine, titanium provides an exceptional strength-to-density ratio and biocompatibility, often used in assemblies with optical-grade acrylic for imaging or lighting systems. Surface finishing typically includes abrasive blasting or chemical passivation; while titanium cannot be anodized for protection in the same way as aluminum, voltage-controlled anodizing can produce decorative interference colors without compromising the substrate.

The following table summarizes key mechanical and finishing properties of these materials in the context of acrylic-integrated metal components:

| Material | Common Grades | Density (g/cm³) | Tensile Strength (MPa) | Anodizing Capability | Key Applications with Acrylic |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310–570 | Yes (Type II & III) | Display frames, enclosures, consumer electronics |

| Stainless Steel | 304, 316 | 8.0 | 505–620 | No (passivation only) | Industrial guards, marine instrumentation |

| Titanium | Gr 5 (Ti-6Al-4V) | 4.4 | 900–950 | Decorative only | Aerospace windows, medical devices |

Selecting the appropriate metal and finish ensures long-term reliability and visual harmony in assemblies combining acrylic and precision-machined components. At Wuxi Lead, we support clients in optimizing these choices based on functional requirements, environmental exposure, and aesthetic goals.

Manufacturing Process & QC

Precision Acrylic Manufacturing: From Concept to Flawless Delivery

At Wuxi Lead Precision Machinery, we treat acrylic not as commodity plastic but as an optical-grade engineering material demanding metal-level precision. Our Zero Defects methodology for custom acrylic parts begins with rigorous Design for Manufacturability (DFM) analysis. Our engineers collaborate directly with client CAD models to identify stress points, thermal expansion risks, and toolpath conflicts before cutting begins. We enforce strict geometric dimensioning and tolerancing (GD&T) standards, particularly critical for acrylic’s sensitivity to residual stress and thermal distortion. This phase eliminates 92% of potential defects at the source, ensuring designs translate seamlessly to production.

Prototyping is non-negotiable in our workflow. Using 5-axis CNC routers with diamond-coated tooling, we produce functional prototypes within 72 hours. Each prototype undergoes metrology-grade inspection against the original CAD: flatness verified to ±0.05mm over 500mm, edge clarity assessed under 10x magnification, and optical transmission measured spectrophotometrically. Clients receive full inspection reports with deviation heatmaps, allowing design refinement while avoiding costly mass-production errors. This iterative validation guarantees that the first production part meets specification.

Mass production leverages our automated CNC cells with closed-loop process control. Machines run at precisely calibrated spindle speeds (18,000–24,000 RPM) and feed rates to prevent melting or micro-cracking. All acrylic batches are pre-stressed annealed in climate-controlled ovens, and in-process coolant mist systems maintain thermal stability. Every 10th part undergoes 100% automated optical inspection against master profiles, with real-time SPC data feeding back to machine controllers. Our zero-defects commitment is enforced through ISO 9001-certified traceability: each part’s machining parameters, inspection logs, and material lot numbers are digitally archived for full lifecycle accountability.

Critical Process Parameters for Acrylic CNC Machining

| Parameter | Design Phase Tolerance | Production Tolerance | Control Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.10 mm | ±0.02 mm | CMM + Laser Scanning |

| Surface Flatness | 0.20 mm/m | 0.05 mm/m | Granite Surface Plate Test |

| Edge Clarity | Visual Acceptance | <0.01 mm Chipping | Microscope Inspection (10x) |

| Optical Transmission | Client-Specified | ±2% Deviation | Spectrophotometer Validation |

This integrated approach transforms acrylic from a challenging thermoplastic into a precision-engineered component. By embedding quality at every stage—from DFM collaboration through annealed material handling to AI-driven in-process verification—we eliminate scrap, accelerate time-to-market, and deliver acrylic parts that perform reliably in aerospace, medical, and semiconductor applications. Partner with Wuxi Lead to convert your acrylic designs into defect-free realities, backed by our 15-year precision manufacturing legacy.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-performance industries. While acrylic components play a role in certain applications, the backbone of advanced manufacturing lies in the integrity of precision-engineered metal parts. As a leading provider of custom metal manufacturing in China, we specialize in delivering complex, high-tolerance components that meet the rigorous demands of industries such as aerospace, automotive, medical, and industrial automation.

Our expertise extends beyond standard machining. We integrate advanced CNC milling, turning, and multi-axis processing with stringent quality control protocols to ensure every metal component exceeds expectations. Whether you require low-volume prototypes or high-volume production runs, our facility in Wuxi is equipped with state-of-the-art machinery and staffed by engineers with decades of experience in solving complex manufacturing challenges.

When you partner with Lead Precision, you gain more than a supplier — you gain a strategic manufacturing ally. We work closely with design and engineering teams to optimize part geometry, material selection, and manufacturability, reducing lead times and minimizing costs without sacrificing quality. Our ISO 9001:2015 certification and in-house metrology lab ensure every part is traceable, repeatable, and built to the highest international standards.

We recognize that your projects demand both technical excellence and responsive collaboration. That’s why we offer direct engineering support, real-time production updates, and flexible logistics solutions tailored to global supply chains. From initial concept to final delivery, we are committed to being an extension of your team.

Below are key capabilities that define our custom metal manufacturing service:

| Specification | Detail |

|---|---|

| Machining Processes | CNC Milling, CNC Turning, Multi-Axis Machining, Wire EDM |

| Materials | Aluminum Alloys, Stainless Steel, Carbon Steel, Titanium, Brass, Copper |

| Tolerances | As tight as ±0.005 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Surface Finishes | As-machined, Anodizing, Powder Coating, Passivation, Polishing |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM Reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Your next project deserves a manufacturing partner with precision, integrity, and global experience. Contact us today at [email protected] to discuss your requirements and discover how Wuxi Lead Precision Machinery can deliver the performance and reliability your business demands.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.