Technical Contents

Engineering Guide: Acrylic Molded

Engineering Insight: Precision in Acrylic Molded Components for Demanding Applications

In the realm of custom metal manufacturing, the integration of acrylic molded components demands an exceptional level of engineering precision and material expertise. While acrylic is often associated with consumer-facing applications due to its optical clarity and aesthetic versatility, its use in high-performance industrial, defense, and infrastructure systems requires a far more rigorous approach. At Wuxi Lead Precision Machinery, we understand that precision in acrylic molding is not merely about dimensional accuracy—it is about consistency, structural integrity, and long-term reliability under extreme conditions.

Acrylic, or polymethyl methacrylate (PMMA), presents unique challenges in molding processes. Its thermal sensitivity, shrinkage behavior, and stress-cracking tendencies require tightly controlled molding parameters. Even minor deviations in temperature, pressure, or cooling rates can result in warping, internal stresses, or surface defects that compromise both function and durability. For mission-critical applications—such as transparent armor systems, aerospace canopies, or protective enclosures in military and Olympic-grade facilities—these imperfections are unacceptable.

Our experience at Lead Precision extends beyond standard manufacturing. We have engineered and delivered acrylic molded solutions for projects associated with Olympic infrastructure and military-grade protective systems. These engagements demanded not only adherence to international material standards but also full traceability, environmental resilience testing, and zero-failure tolerance. Our in-house R&D team works closely with material scientists and structural engineers to simulate real-world stress scenarios, ensuring that every molded component performs under high impact, UV exposure, and extreme temperature fluctuations.

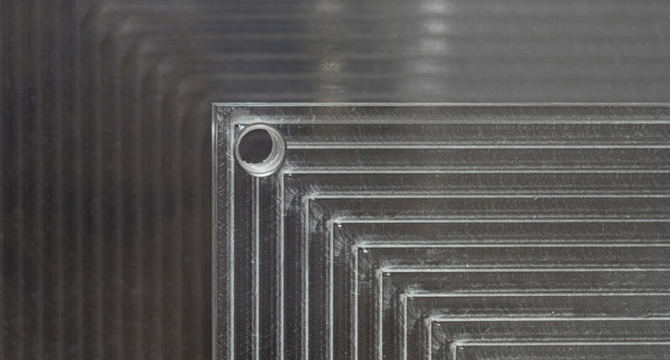

Precision begins with mold design. Using advanced CAD/CAM software and 5-axis CNC machining, we fabricate molds with micron-level tolerances. This ensures uniform wall thickness, optimal flow dynamics during injection, and minimal post-processing—factors critical to maintaining the optical and mechanical properties of acrylic. We also employ cleanroom molding environments for optical-grade components, eliminating particulate contamination that could weaken structural performance.

Our process is further validated through rigorous quality assurance protocols, including laser profilometry, stress analysis via polarized light inspection, and environmental aging tests. These measures ensure that every component meets or exceeds customer specifications, particularly in applications where failure is not an option.

The table below outlines key performance specifications for our precision acrylic molded components:

| Parameter | Standard Tolerance | High-Precision Option | Testing Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.1 mm | ±0.05 mm | Laser Scanning |

| Optical Clarity (Haze %) | <1.5% | <0.8% | Spectrophotometry |

| Impact Resistance (Izod) | 15 J/m | 18 J/m | ASTM D256 |

| Thermal Deflection Temp (°C) | 90°C @ 1.82 MPa | 95°C @ 1.82 MPa | ASTM D648 |

| UV Resistance (2,000 hrs) | <5% Transmission Loss | <3% Transmission Loss | QUV Accelerated Weathering |

At Wuxi Lead Precision Machinery, we treat every acrylic molded component as a high-stakes engineering challenge. Our track record in Olympic and military projects reflects our commitment to precision, reliability, and innovation in custom manufacturing.

Precision Specs & Tolerances

Technical Capabilities for Precision Acrylic Machining

Wuxi Lead Precision Machinery leverages advanced metal manufacturing expertise to deliver exceptional acrylic molding and machining services. While our core specialization lies in custom metal components, our precision engineering rigor extends seamlessly to acrylic and other engineering plastics. This cross-material proficiency ensures clients receive consistent quality, dimensional stability, and surface finish critical for high-end optical, medical, and industrial applications where acrylic’s clarity and chemical resistance are paramount. Our integrated approach mitigates common plastic machining challenges—such as thermal deformation and stress-induced warpage—through material-specific process protocols developed over 15 years of precision manufacturing.

Central to our acrylic capabilities is a dedicated fleet of 5-axis CNC machining centers. These systems enable single-setup production of complex geometries—including contoured lenses, fluidic channels, and multi-faceted housings—eliminating cumulative errors from multiple fixturing operations. High-speed spindles with micron-level positional accuracy maintain consistent feed rates to prevent melting or chipping, while specialized toolpaths and coolant strategies manage acrylic’s low thermal conductivity. All machines operate under strict environmental controls to minimize thermal drift, ensuring repeatability across production runs. Material handling protocols prevent surface scratching, and custom vacuum or low-pressure mechanical fixturing avoids distortion during machining.

Quality validation is non-negotiable. Every acrylic component undergoes full CMM inspection against CAD nominal data, with reports traceable to ISO 17025-certified standards. Our Zeiss CONTURA CMMs measure critical features—radii, angles, and surface profiles—with sub-10-micron resolution, capturing 3D deviation maps for first-article approval and batch verification. Statistical process control (SPC) monitors trend data to preemptively adjust machining parameters, maintaining conformance even for volumes exceeding 10,000 units. Dimensional stability is further assured through controlled post-machining annealing cycles that relieve internal stresses without compromising optical clarity.

The following table details achievable tolerances for machined acrylic components under standard production conditions. Tighter tolerances are attainable with engineered process modifications, subject to material grade and part geometry validation.

| Feature | Standard Tolerance | Tight Tolerance | Notes |

|---|---|---|---|

| Linear Dimension | ±0.05 mm | ±0.01 mm | Up to 300 mm; annealed material only |

| Angular Accuracy | ±0.1° | ±0.05° | Verified via CMM vector measurement |

| Hole Diameter | +0.03 / -0.00 mm | +0.01 / -0.00 mm | Reamed features; excludes blind holes |

| Flatness | 0.05 mm/m | 0.02 mm/m | Measured per ISO 1101; annealed stock |

All tolerances assume ASTM D792-compliant cast acrylic sheet (e.g., Plexiglas® GS) in thicknesses from 3–100 mm. Injection-molded acrylic substrates require pre-machining stress-relief certification. Wuxi Lead’s engineering team collaborates pre-production to optimize designs for manufacturability, ensuring your acrylic components meet functional requirements without unnecessary cost escalation. Our process delivers certified precision—proven across aerospace lighting assemblies, diagnostic equipment housings, and semiconductor fluidics—where dimensional integrity directly impacts system performance.

Material & Finish Options

Material Selection for Precision Acrylic Molded Components

In the high-precision manufacturing of acrylic molded tooling and support components, material selection is critical to ensuring dimensional stability, thermal performance, and long-term durability. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that support advanced molding applications, particularly where aluminum, steel, and titanium form the backbone of mold construction and auxiliary systems. These materials are chosen not only for their mechanical properties but also for compatibility with surface treatments such as anodizing, which enhances wear and corrosion resistance.

Aluminum is the most widely used material in acrylic molding applications due to its excellent thermal conductivity, lightweight nature, and ease of machining. Grade 6061-T6 is preferred for mold bases and frames, offering good structural integrity and weldability. For high-wear areas, 7075-T6 provides superior strength, though with reduced corrosion resistance. Aluminum’s natural affinity for anodizing makes it ideal for environments where surface hardness and oxidation resistance are required. Hard anodizing (Type III) can increase surface hardness up to 60 HRC, significantly extending mold life in repetitive production cycles.

Steel, particularly tool steels like H13 and P20, is selected when extreme durability and resistance to deformation under high pressure and temperature are necessary. H13 steel excels in hot work environments, making it suitable for molds exposed to elevated thermal cycling. P20 is commonly used for pre-hardened mold plates requiring moderate toughness and good polishability. While steel does not anodize, it benefits from nitriding, chrome plating, or PVD coatings to enhance surface performance. Steel components are often integrated into aluminum molds to reinforce critical wear zones, combining the best properties of both materials.

Titanium, though less common due to cost and machining complexity, offers an unmatched strength-to-density ratio and exceptional corrosion resistance. Grade 5 (Ti-6Al-4V) is typically used in specialized mold components exposed to aggressive environments or where weight reduction is mission-critical. Titanium does not undergo conventional anodizing for wear protection but can be treated with plasma electrolytic oxidation (PEO) to develop a hard, ceramic-like surface layer.

The choice of material must align with production volume, part complexity, cycle time, and environmental exposure. Below is a comparative overview of key properties.

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Common Finishes | Typical Mold Application |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 167 | 95 | Anodizing, Hard Coat | Mold bases, cooling plates |

| Aluminum 7075-T6 | 572 | 130 | 150 | Hard Anodizing (Type III) | High-stress mold inserts |

| H13 Steel | 1,700 | 35 | 250 | Nitriding, Chrome Plating | Hot runner systems, core cavities |

| P20 Steel | 950 | 30 | 280 | Polishing, Chrome Coating | Pre-hardened mold plates |

| Ti-6Al-4V | 900 | 7.2 | 360 | Plasma Electrolytic Oxidation | Corrosion-prone or weight-sensitive parts |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on functional requirements and lifecycle cost. Our engineering team ensures optimal material pairing with precise tolerances and surface treatments to maximize performance in acrylic molding operations.

Manufacturing Process & QC

Acrylic Molded Component Production: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, producing flawless acrylic molded components for demanding industrial applications requires a rigorously controlled process integrating our core metal manufacturing expertise. Acrylic’s optical clarity and structural properties demand exceptional precision in mold tooling and process control, far exceeding standard plastic molding. Our methodology ensures dimensional accuracy, surface perfection, and material integrity critical for aerospace, medical, and high-end instrumentation sectors. We treat acrylic molding with the same zero-defect discipline applied to critical metal components, recognizing that microscopic imperfections are unacceptable in final assemblies.

The process commences with collaborative Design for Manufacturability (DFM). Our engineering team works directly with client CAD models, analyzing wall thickness transitions, gate locations, and ejection strategies specific to acrylic’s high viscosity and thermal sensitivity. We simulate mold flow using advanced software to predict and eliminate potential sinks, warpage, or internal stresses that could compromise optical clarity or structural performance. Material selection is critical; we specify certified optical-grade acrylic pellets meeting ASTM D4802, ensuring UV stability and minimal birefringence. This phase establishes the foundation for defect prevention, not correction.

Prototyping utilizes CNC-machined aluminum molds fabricated in-house on our high-accuracy machining centers. This allows rapid iteration while maintaining tight tolerances impossible with soft tooling. Each prototype undergoes comprehensive metrology: CMM verification against nominal CAD data, optical distortion analysis under controlled lighting, and functional testing for assembly interfaces. We meticulously document process parameters – melt temperature, injection speed, packing pressure, cooling cycles – correlating them directly to measured part characteristics. Client feedback on these physically validated prototypes is essential before committing to production tooling.

Mass Production leverages hardened steel molds, precision-ground and polished to SPI-A1 or A2 standards, manufactured entirely within our Wuxi facility under strict ISO 9001 controls. The molding process operates within narrow, empirically validated parameter windows. Real-time monitoring of cavity pressure and temperature ensures consistency. Crucially, our zero-defect commitment is enforced through integrated quality gates: 100% visual inspection under calibrated lighting for surface defects, automated dimensional checks on critical features at defined intervals, and periodic destructive testing for material properties. Statistical Process Control (SPC) charts track key variables, triggering immediate process adjustment if trends approach specification limits.

The transition from prototype validation to volume production is defined by controlled parameter scaling and enhanced inspection rigor. The table below outlines critical specification shifts:

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Mold Material | Aluminum (7075-T6) | Hardened Tool Steel (H13) |

| Dimensional Tolerance | ±0.05 mm | ±0.025 mm (Critical Features) |

| Surface Finish (SPI) | A2 (6000 Grit) | A1 (8000+ Grit / Diamond Polished) |

| Inspection Frequency | 100% First Article | 100% Visual / SPC Dimensional |

| Process Validation | 30 Consecutive Good Parts | 300 Consecutive Good Parts |

This structured, metrology-driven approach, rooted in precision metal manufacturing discipline, guarantees acrylic components meeting the most stringent performance and aesthetic requirements. Wuxi Lead transforms complex acrylic molding challenges into reliable, zero-defect production outcomes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation are non-negotiable in high-end industrial manufacturing. As a trusted leader in custom metal fabrication, we specialize in delivering engineered solutions that meet the most demanding specifications—particularly for advanced applications involving materials like acrylic molded components integrated with precision metalwork. Our commitment to excellence is rooted in over a decade of experience, cutting-edge CNC technology, and a deep understanding of global industry standards.

When you partner with Lead Precision, you are not just sourcing parts—you are gaining a strategic manufacturing ally. Our facility in Wuxi, China, operates under strict ISO 9001 quality management protocols, ensuring every component we produce meets exact dimensional tolerances, surface finish requirements, and functional performance criteria. From prototyping to full-scale production, our team of senior CNC engineers and production specialists collaborates closely with clients to optimize designs, reduce lead times, and enhance manufacturability—especially critical when working with hybrid systems where acrylic molding interfaces with metal assemblies.

We serve industries where precision is paramount: medical device manufacturing, semiconductor equipment, automation systems, and high-end consumer electronics. Our capabilities include 5-axis CNC milling, precision turning, EDM cutting, and custom finishing processes—all tailored to support complex, low-to-medium volume production runs with exceptional repeatability.

Below are key technical specifications that define our manufacturing capacity:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 3.2 μm (custom finishes available) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis milling) |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, and compatible acrylic-molded interface materials |

| Production Volume | Prototype to 10,000 units annually |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reports, PPAP documentation available |

Our engineering team excels in solving complex integration challenges—such as aligning optically clear acrylic molded elements with tightly toleranced metal housings or mounting structures. We offer DFM analysis, rapid iteration, and comprehensive metrology using CMM, optical comparators, and laser scanning to ensure every part performs as intended in your final assembly.

For global clients seeking a responsive, technically advanced manufacturing partner, Lead Precision delivers quality without compromise. We communicate in English, support international shipping, and maintain full traceability across every production batch.

Contact us today to discuss your next project. Send your drawings, specifications, or inquiry to [email protected] and receive a detailed technical evaluation within 24 hours. Let Wuxi Lead Precision Machinery be the foundation of your precision manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.