Technical Contents

Engineering Guide: Abs Plastic Mold

Engineering Insight: ABS Plastic Mold Design and the Critical Role of Precision

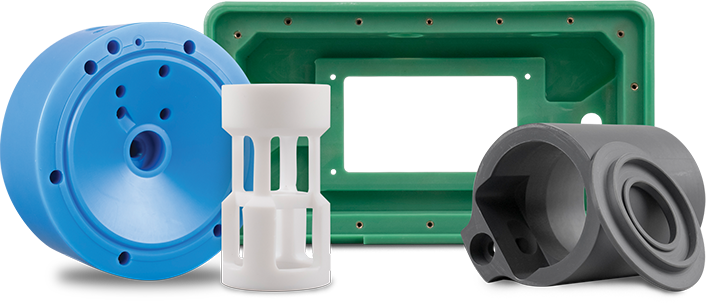

In high-end custom metal manufacturing, the production of ABS plastic molds demands an uncompromising commitment to precision, material science, and process control. Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer widely used in automotive, consumer electronics, medical devices, and industrial equipment due to its excellent impact resistance, dimensional stability, and surface finish. However, the performance and longevity of ABS-molded components are directly tied to the accuracy and quality of the mold itself—making precision engineering not just a technical requirement, but a strategic advantage.

At Wuxi Lead Precision Machinery, we specialize in the design and fabrication of high-tolerance ABS plastic molds using advanced CNC machining, EDM, and metrology systems. Our engineering team applies decades of experience in tight-tolerance manufacturing, developed through rigorous projects for defense, aerospace, and Olympic-grade equipment suppliers. These high-stakes applications have instilled a culture of zero-defect manufacturing, where every micron matters and repeatability is non-negotiable.

Precision in ABS mold making begins with thermal and structural analysis. ABS undergoes significant thermal expansion during injection, and even minor deviations in cavity dimensions can result in part warpage, sink marks, or flash. Our in-house simulation tools predict material behavior under processing conditions, allowing us to pre-compensate for shrinkage and optimize cooling channel placement. This predictive capability ensures consistent part geometry across production runs exceeding hundreds of thousands of cycles.

Equally critical is surface finish and ejection system design. ABS tends to adhere to polished surfaces, increasing ejection forces and wear. We utilize mirror-finish tool steels with precision-ground ejector pins and balanced draft angles to minimize stress during part release. Our molds are built using P20, 718H, or H13 steels, depending on production volume and part complexity, with hardness levels optimized for wear resistance and machinability.

All molds undergo rigorous quality validation using CMM (Coordinate Measuring Machines) and 3D scanning to verify tolerances down to ±0.002 mm. This level of control is essential not only for functional performance but also for regulatory compliance in industries such as medical and defense, where traceability and documentation are mandatory.

Wuxi Lead’s experience in mission-critical manufacturing has equipped us with the technical rigor and process discipline to deliver ABS molds that exceed international standards. Whether supporting rapid prototyping or high-volume production, our molds are engineered for performance, durability, and repeatable accuracy.

Typical ABS Plastic Mold Specifications

| Parameter | Standard Specification |

|---|---|

| Material Options | P20, 718H, H13, S136 |

| Tolerance | ±0.002 mm to ±0.005 mm |

| Surface Finish (Cavity) | SPI A1 (Mirror) to B2 (Satin) |

| Hardness | 28–52 HRC (depending on steel) |

| Gate Types | Pin, Tunnel, Edge, Hot Runner |

| Cycle Time Optimization | Integrated conformal cooling |

| Mold Life | 500,000 to 1,000,000+ cycles |

| Standards Compliance | ISO 9001, ASTM D638, ISO 294-4 |

Precision is not an outcome—it is engineered into every phase of mold development. At Wuxi Lead Precision Machinery, we build molds that perform under the most demanding conditions, backed by a legacy of excellence in advanced manufacturing.

Precision Specs & Tolerances

Technical Capabilities for ABS Plastic Mold Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in ABS plastic mold production through integrated advanced manufacturing and rigorous quality assurance. Our facility specializes in complex mold bases, cavities, and cores requiring micron-level accuracy, leveraging 5-axis CNC machining as the cornerstone of our process. This technology enables single-setup machining of intricate geometries, eliminating cumulative errors from multiple fixtures and ensuring superior part consistency. Critical undercuts, organic contours, and multi-faceted surfaces are executed with seamless transitions, directly translating to reduced cycle times and extended mold life in high-volume ABS injection applications. All machining operations utilize hardened tool steels and pre-hardened alloys optimized for thermal stability during ABS processing, with spindle speeds and feed rates precisely calibrated to minimize residual stress and micro-vibration.

Quality control is systematically embedded at every phase, starting with raw material certification and culminating in full CMM inspection of finished components. Our Zeiss CONTURA CMM systems perform 3D scanning with 0.5μm volumetric accuracy, validating dimensional conformity against CAD models and generating comprehensive GD&T reports. This data-driven approach ensures geometric integrity across all mold features, including critical shut-off surfaces, cooling channels, and ejection systems. Statistical process control (SPC) monitors machine performance in real-time, enabling proactive adjustments to maintain tolerance bands. Traceability is enforced via laser-etched part IDs linked to digital inspection records, providing full audit trails for aerospace, medical, and automotive clients where regulatory compliance is mandatory.

The table below outlines our standard and critical feature tolerances for ABS mold components. These specifications reflect our adherence to ISO 2768-mK and ISO 10110 standards, with tighter control applied to sealing surfaces and optical-grade cavities.

| Parameter | Standard Tolerance | Critical Feature Tolerance |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Angular Dimensions | ±0.05° | ±0.02° |

| Flatness | 0.01 mm/m | 0.005 mm/m |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm |

| Hole Position | ±0.015 mm | ±0.008 mm |

| Profile of Surface | 0.02 mm | 0.01 mm |

Our process excellence extends beyond machining and inspection. Pre-machining design validation identifies potential ABS flow issues, while post-CMM thermal analysis simulates molding conditions to preempt warpage. This holistic methodology ensures molds achieve first-article approval rates exceeding 98% and sustain 500,000+ cycles with minimal wear. For mission-critical ABS applications demanding zero-defect performance, Wuxi Lead provides engineered solutions where precision is non-negotiable. Partner with us to transform complex mold requirements into production-ready assets with documented reliability.

Material & Finish Options

Material Selection for ABS Plastic Molds: Aluminum, Steel, and Titanium

When manufacturing precision molds for ABS plastic injection, material selection plays a decisive role in performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we engineer custom metal molds using high-grade aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental exposure. Understanding the mechanical and thermal properties of these materials ensures optimal mold performance and part consistency.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume production molds. Their excellent thermal conductivity allows for faster cooling cycles, reducing cycle times and increasing throughput during trial runs. Aluminum is also easier to machine, enabling complex geometries with tight tolerances. However, its lower hardness makes it less suitable for long production runs or abrasive additives in ABS formulations. With proper surface treatment such as hard anodizing, aluminum molds can achieve improved wear resistance and extended service life.

Steel remains the standard for high-volume ABS molding applications. Tool steels like P20, H13, and S136 offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. These properties make steel ideal for molds expected to produce millions of cycles. While steel has lower thermal conductivity than aluminum, resulting in slightly longer cooling times, its durability offsets this in large-scale manufacturing. Additionally, steel molds maintain fine surface finishes and intricate details over extended use, critical for consumer-grade plastic parts.

Titanium, though less common due to cost and machinability challenges, offers exceptional strength-to-density ratio and corrosion resistance. It is typically reserved for specialized applications where weight reduction or extreme environmental resistance is required. In standard ABS molding, titanium is rarely used for full mold construction but may be applied in critical inserts or cores exposed to high stress or corrosive additives.

Surface finish selection further enhances mold performance. Anodizing—particularly hard anodizing—is a key finishing process for aluminum molds. It creates a durable, non-conductive oxide layer that improves surface hardness up to 600 HV and increases resistance to wear and corrosion. Different anodizing types yield varied results.

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Finishes |

|---|---|---|---|---|

| Aluminum 7075 | 150 | 130 | 10,000 – 100,000 | Hard Anodizing, Polishing |

| P20 Steel | 280–320 | 30 | 500,000 – 1,000,000+ | Mirror Polish, Texturing |

| H13 Steel | 230–260 | 35 | 1,000,000+ | Nitriding, Coating |

| Titanium (Grade 5) | 360 | 7.2 | Specialized Inserts Only | TiN Coating, Passivation |

At Wuxi Lead, we match material and finish to your production goals, ensuring reliable mold performance and superior ABS part quality.

Manufacturing Process & QC

ABS Plastic Mold Production: Precision Engineering for Zero Defects

At Wuxi Lead Precision Machinery, we execute ABS plastic mold production through a rigorously controlled three-phase workflow. This integrated approach ensures dimensional accuracy, material integrity, and flawless part replication from concept to high-volume output. ABS presents specific challenges including moisture sensitivity, variable shrinkage rates, and susceptibility to sink marks. Our process directly addresses these through systematic engineering controls, eliminating defects before they reach client production lines.

The Design phase begins with comprehensive analysis of the client’s part geometry, material specifications, and functional requirements. We utilize advanced CAD/CAM software coupled with mold flow simulation to predict resin behavior, optimize gate locations, cooling channel layouts, and ejection systems. Critical factors like ABS thermal stability, shrinkage compensation (typically 0.4-0.7%), and warpage mitigation are modeled extensively. This virtual validation prevents costly physical iterations, ensuring the mold architecture inherently supports zero-defect production. All design outputs undergo cross-functional review against international standards including ISO 20457.

Prototyping transitions the validated design into physical form using our high-precision CNC machining centers and wire EDM systems. We fabricate the initial mold core, cavity, and critical inserts to exacting tolerances, employing hardened P20 or H13 tool steels suitable for ABS processing temperatures. The prototype mold undergoes rigorous first-article testing on our in-house injection molding machines. We monitor key parameters including melt temperature stability (210-250°C for ABS), injection pressure consistency, and cooling cycle times. Dimensional inspection of prototype parts against CAD data is performed using CMM and optical comparators, verifying critical features meet ±0.02mm tolerances. Any deviations trigger immediate design or process adjustments.

Mass Production leverages the perfected mold design and process parameters within our certified cleanroom environment. We implement real-time cavity pressure monitoring and automated SPC (Statistical Process Control) on every production cycle. Each mold cavity is individually tracked for pressure curves, temperature profiles, and cycle time stability. Our quality assurance protocol mandates 100% automated visual inspection for surface defects and critical dimension checks at defined intervals. Material drying protocols strictly adhere to ABS requirements (80-90°C for 2-4 hours) to prevent hydrolysis. This closed-loop system guarantees consistent part quality meeting automotive or medical-grade standards.

Our commitment to Zero Defects is quantifiable through measurable process capability. The table below outlines key production specifications maintained throughout high-volume runs.

| Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm (critical) | CMM, Optical Comparator |

| Surface Finish (Cavity) | Ra 0.2 – 0.4 µm | Profilometer |

| Mold Temperature Control | ±1.0°C stability | Embedded Thermocouples |

| Cavity Pressure Deviation | < 2% max variation | Real-time Sensor Network |

| Process Capability (Cpk) | ≥ 1.67 | SPC Data Analysis |

This disciplined progression from virtual design validation through physical prototyping to monitored mass production forms the foundation of Wuxi Lead’s zero-defect guarantee. We transform ABS molding challenges into reliable, high-yield manufacturing outcomes for global industrial clients.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Your ABS Plastic Mold Manufacturing Needs

When it comes to high-performance ABS plastic mold manufacturing, precision, consistency, and engineering excellence are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions tailored to the exacting demands of industries ranging from automotive and consumer electronics to medical devices and industrial equipment. Our expertise in ABS plastic injection molding combines advanced CNC machining, mold flow analysis, and rigorous quality control to ensure every mold meets the highest standards of durability, dimensional accuracy, and surface finish.

Our engineering team collaborates closely with clients from concept to production, offering end-to-end support including 3D modeling, material selection, mold design optimization, and rapid prototyping. We understand that each application presents unique challenges—whether it’s achieving tight tolerances, managing complex geometries, or ensuring long production cycles without degradation. That’s why every ABS plastic mold we produce is built to your exact specifications, using premium-grade tool steels and hardened components that extend mold life and reduce downtime.

Leveraging state-of-the-art manufacturing facilities in Wuxi, China, we maintain full control over production timelines and quality assurance. Our ISO-certified processes include multi-axis CNC machining, wire EDM, surface grinding, and automated inspection using CMM and optical measurement systems. This ensures repeatability and compliance with international standards such as ISO 9001 and IATF 16949, critical for global supply chains.

We don’t just manufacture molds—we build long-term partnerships based on reliability, technical expertise, and responsive service. From initial design consultation to after-sales support, our team is committed to delivering solutions that enhance your production efficiency and reduce total cost of ownership.

Below are the key technical specifications we support for ABS plastic mold manufacturing:

| Parameter | Specification |

|---|---|

| Material Options | P20, 718H, NAK80, S136, H13, 420 Stainless Steel |

| Tolerance | ±0.005 mm (standard), ±0.002 mm (precision) |

| Surface Finish | SPI A1 (mirror), A2, B1, B2, VDI 20–28 (textured) |

| Mold Base Standards | LKM, FUTABO, DME, HASCO |

| Runner System | Cold Runner, Hot Runner (Yudo, Husky, Mold-Masters) |

| Cavities | Single to Multi-cavity (up to 16 cavities typical) |

| Part Size Range | 10 mm to 800 mm (max dimension) |

| Cycle Life | 500,000 to 1,000,000+ cycles (depending on material and design) |

| Lead Time | 25–45 days (based on complexity and cavitation) |

For engineering-grade ABS molding, where thermal stability, impact resistance, and surface quality are critical, our molds deliver consistent performance across high-volume production runs. We also support mold trials with sample parts for validation prior to shipment.

Take the next step in advancing your manufacturing capabilities. Contact us today at [email protected] to discuss your ABS plastic mold requirements with our engineering team. Let Wuxi Lead Precision Machinery be your trusted partner in precision mold manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.