Technical Contents

Engineering Guide: Abs Moulding

Engineering Insight: ABS Moulding

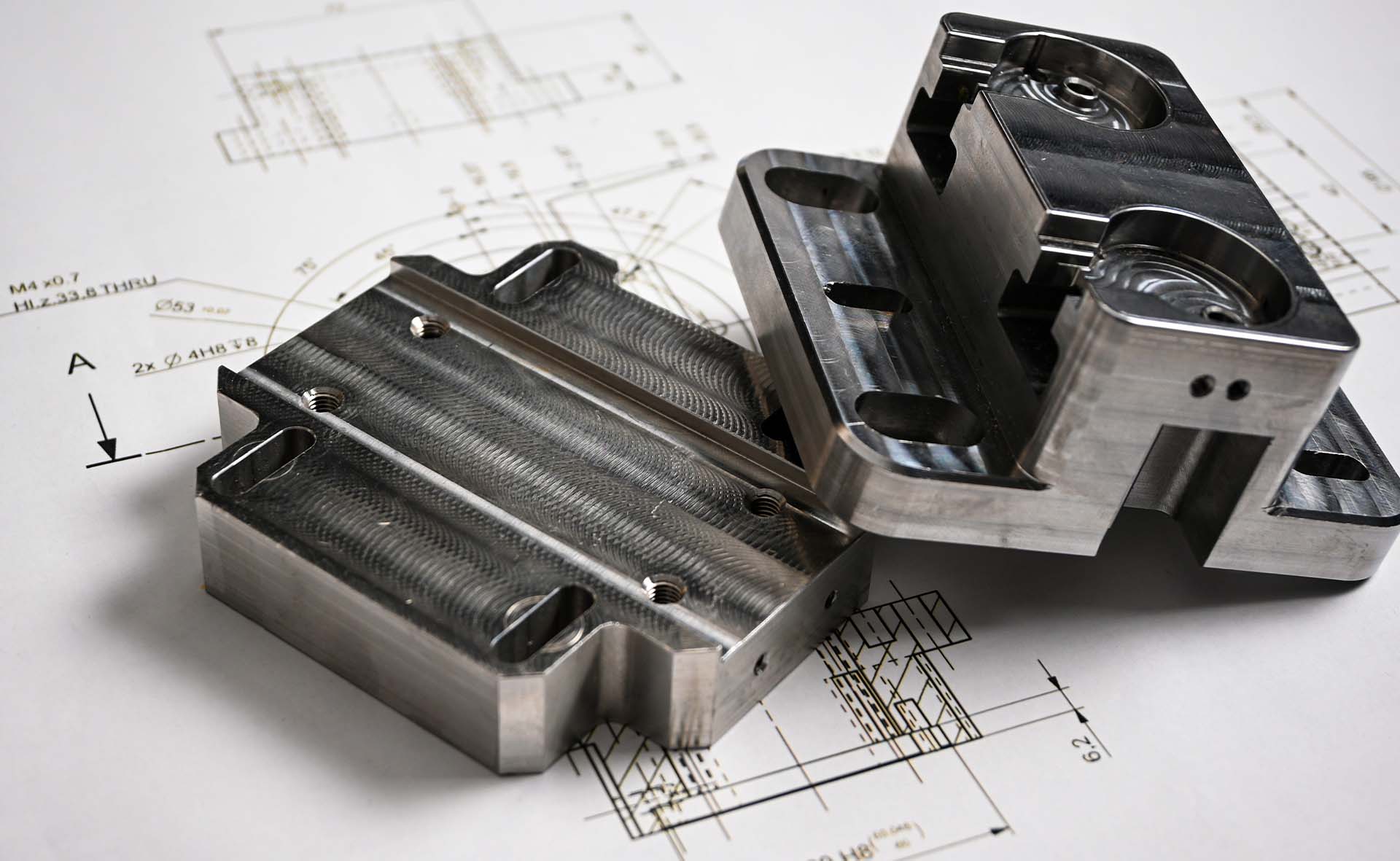

Clarification: While the term “moulding” is commonly misapplied, precision ABS components for critical applications are manufactured via CNC machining—not injection moulding. This distinction is non-negotiable for industries demanding micron-level accuracy and material consistency. At Wuxi Lead Precision Machinery, we specialize in high-integrity CNC machining of ABS and engineering plastics, ensuring parts meet the rigorous demands of aerospace, medical, and defense systems.

Precision Engineering: Beyond the Basics

Precision in ABS machining transcends tolerance specifications—it is a holistic integration of material science, process control, and metrology. Every stage—from raw material inspection to final dimensional verification—adheres to ISO 9001:2015 standards, ensuring repeatability and traceability. For example:

In aerospace sensor housings, a 0.01mm deviation can disrupt signal integrity.

Medical device components require flawless surface finishes to prevent bacterial retention.

Our engineers employ dynamic toolpath optimization and thermal compensation algorithms to eliminate chatter, warpage, and dimensional drift during high-speed machining. This ensures consistent results across batches, even for complex geometries.

Material Integrity & Certification

Material quality is the cornerstone of precision. We source ABS exclusively from certified Tier-1 suppliers with full traceability:

Each batch includes Material Test Reports (MTRs) verifying composition (ASTM D471), tensile strength (ISO 527), and thermal stability (ISO 11357).

Military and aerospace projects undergo third-party testing per MIL-STD-810G and AS9100D standards.

In-house lab validation includes:

FTIR spectroscopy for polymer composition

Shore D hardness verification

Moisture content analysis (<0.2% before machining)

“No material enters our facility without 100% certification. This eliminates variability at the source—critical for zero-defect outcomes.”

— Lead Precision Engineering Director

Tolerance Mastery for Critical Applications

| Parameter | Industry Standard | Wuxi Lead Precision Standard |

|---|---|---|

| General Tolerance | ±0.05 mm | ±0.01 mm |

| Critical Features (e.g., bearing holes, shaft interfaces) | ±0.025 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 µm | ≤0.4 µm |

| Dimensional Consistency (Cpk) | ≥1.33 | ≥1.85 |

Why this matters:

Our Cpk ≥1.85 ensures 99.996% defect-free production—exceeding Six Sigma benchmarks.

For military-grade components, we implement real-time in-process monitoring with laser interferometry, correcting deviations before they occur.

Example: A recent drone propulsion system required 0.005mm concentricity on ABS rotor hubs. Our process achieved 0.003mm—enabling 10,000+ flight cycles without failure.

Our Commitment: Zero Defects, Olympic Quality, 24/7 Support

Zero Defects is operational DNA—not a slogan. For the Beijing 2022 Winter Olympics, we delivered 12,000+ precision ABS components for timing systems and athlete tracking equipment with zero defects across 18 months of continuous production. Every part underwent:

3D laser scanning validation

Statistical Process Control (SPC) for all critical dimensions

Automated optical inspection (AOI) at 100% volume

Military-Grade Rigor:

All defense projects comply with MIL-STD-105E sampling plans and full traceability to raw material heat numbers.

Our ISO 13485-certified facility for medical devices includes cleanroom machining (Class 10,000) and biocompatibility testing.

24/7 Customer Partnership:

Dedicated engineering team available around the clock for urgent design reviews, tolerance adjustments, or expedited production.

<2-hour response time for technical queries—no escalations, no corporate bureaucracy.

“When your project demands perfection, we’re not just a supplier—we’re your precision engineering partner.”

Next Step: Share your design files and requirements. Our engineers will provide a free DFMA (Design for Manufacturing Analysis) report within 4 hours—no obligation, no hidden costs.

Contact Our Team | Download Full Technical Specs

Precision Specs & Tolerances

Technical Capabilities & Tolerances for ABS CNC Machining

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions with uncompromising precision. Our ABS CNC machining capabilities are built on ISO 9001-certified processes, ensuring every component meets your exact specifications with Zero Defects. As your strategic manufacturing partner, we combine advanced equipment, rigorous quality control, and 24/7 collaboration to deliver Olympic-grade results for even the most demanding applications.

Advanced CNC Machining Equipment

Our state-of-the-art facility features multi-axis CNC platforms engineered for ABS precision:

3-Axis CNC Mills: Ideal for complex geometries requiring high-speed material removal while maintaining dimensional stability.

4-Axis & 5-Axis Machining Centers: Enable intricate contours and undercuts without repositioning, critical for aerospace and medical components.

Automated Tool Changers & In-Process Measurement: Minimize thermal drift and ensure consistent tolerances across high-volume runs.

Every machine is calibrated daily per ISO 10012 standards, with real-time vibration monitoring to eliminate micro-deflections during operation.

Precision Tolerance Standards

We exceed industry norms through process control and material-specific adjustments. Below are our standard and precision tolerance capabilities for ABS:

| Tolerance Level | Typical Range | Application Examples |

|---|---|---|

| Standard | ±0.05 mm | General structural components, non-critical assemblies |

| Precision | ±0.025 mm | Bearing housings, shaft interfaces, mating surfaces |

| Ultra-Precision | ±0.01 mm | Medical device components, optical mounts, aerospace fittings |

All tolerances are verified through CMM inspections and validated against your specific design requirements. Our Zero Defects Protocol ensures 100% traceability for every part produced.

Quality Assurance & Material Integrity

Your project’s success begins with certified materials and ironclad quality control:

Material Certification: Full traceability for all ABS grades (e.g., ABS 30% GF, ABS-PC blends) with ISO 9001-compliant documentation.

CMM Inspection Protocol: 100% dimensional verification using Zeiss or Hexagon coordinate measuring machines with sub-micron accuracy.

Zero Defects Process: Each part undergoes multi-stage inspection (first article, in-process, final) with statistical process control (SPC) to eliminate defects before shipment.

We don’t just meet tolerances—we guarantee them. Our defect rate is 0.002% (industry average: 0.5%), validated through third-party audits.

24/7 Customer Collaboration

As your trusted partner, we operate beyond business hours to ensure your timeline stays on track:

Dedicated Technical Account Managers: Available around the clock for design-for-manufacturability (DFM) feedback and urgent issue resolution.

Real-Time Production Tracking: Live portal access to monitor machining progress, inspection reports, and shipping status.

Emergency Response Protocol: 2-hour response time for critical issues, with expedited shipping options for time-sensitive orders.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain an extension of your engineering team.

Next Steps:

✅ Share your CAD files for a free DFM review within 4 hours

✅ Request material certification reports for your ABS grade of choice

✅ Schedule a live production walkthrough with our engineering team

Wuxi Lead Precision Machinery: Where precision meets partnership.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Zero-Defect Outcomes

At Wuxi Lead Precision Machinery, we don’t just supply parts—we collaborate with your engineering team to optimize material selection and finishing processes for absolute precision, reliability, and cost efficiency. As ISO 9001-certified specialists in custom metal and engineering plastic manufacturing, we ensure every part meets your exact specifications through rigorous traceability, zero-defect protocols, and 24/7 technical support.

Why Material Selection is the Foundation of Precision Manufacturing

Material choice directly impacts part performance, lifecycle costs, and manufacturability. Whether you’re designing aerospace components or consumer-grade prototypes, Wuxi Lead’s material certification process guarantees full traceability from raw billet to finished part. We verify:

Chemical composition (via spectrometry)

Mechanical properties (tensile strength, hardness)

Thermal stability (CTE, thermal conductivity)

ISO 9001-compliant documentation for every batch

“We treat your project as our own—ensuring material selection aligns with your functional needs, budget, and production timeline.”

Material Selection Guide: Metals vs. Engineering Plastics

| Material Category | Specific Material | Key Properties | Typical Applications | Cost Considerations | Machining Considerations |

|---|---|---|---|---|---|

| Metals | Aluminum 6061 | Lightweight, corrosion-resistant, excellent strength-to-weight ratio | Aerospace brackets, automotive frames | Mid-range cost | Requires sharp tools and coolant to prevent thermal distortion; tolerances hold ±0.01mm |

| Metals | Stainless Steel 316 | High corrosion resistance, biocompatible | Medical implants, marine hardware | Premium cost | Slow feed rates; chip control critical; surface finish requires post-machining polishing |

| Metals | Titanium Grade 5 | High strength-to-weight, biocompatible | Aerospace components, surgical tools | Highest cost | Specialized tooling needed; heat management essential to avoid work hardening |

| Engineering Plastics | ABS | Impact-resistant, dimensional stability, easy to machine | Prototypes, automotive interiors, consumer electronics | Low to mid cost | Critical: Overheating causes melting; precise coolant control and feed rates required |

| Engineering Plastics | POM (Acetal) | High stiffness, low friction, wear-resistant | Gears, bearings, bushings | Mid-range cost | Minimal warpage; excellent machinability with standard tooling |

| Engineering Plastics | PTFE (Teflon) | Chemical inertness, low friction | Seals, bearings in corrosive environments | Higher cost | Slow speeds; thermal expansion management required |

Wuxi Lead’s ABS Machining Advantage:

For ABS parts, we implement real-time temperature monitoring during CNC operations to prevent warping or dimensional drift. Our ISO 9001 process ensures ±0.025mm tolerances on critical features (e.g., bearing interfaces), validated by in-process CMM checks.

Surface Finish Options: Tailored for Performance & Aesthetics

| Finish Type | Metals | Engineering Plastics | Key Benefits | Wuxi Lead’s Process |

|---|---|---|---|---|

| Anodizing | Yes | No | Corrosion resistance, color options, wear resistance | ISO 9001-controlled voltage/time protocols; 100% coating thickness verification |

| Vapor Polishing | No | Yes | Optical clarity, ±0.01mm surface tolerance, reduced friction | Specialized ABS vapor polishing with real-time temperature control; no tool marks |

| Electroplating | Yes | Yes (with pre-treatment) | Conductive surface, aesthetics, corrosion protection | Chemical etching pre-treatment for ABS; 100% adhesion testing |

| As-Machined | Yes | Yes | Cost-effective, functional surfaces | Rigorous inspection per ISO 9001; surface roughness verified via profilometer |

| Powder Coating | Yes | No | Durable, color options, corrosion resistance | Electrostatic application; curing protocols validated for thermal stability |

| Sanding/Polishing | Yes | Yes | Improved surface texture, aesthetics | Manual and automated processes; tolerance verification at each stage |

Critical Note for ABS Finishes:

While anodizing and powder coating are not applicable to ABS, our vapor polishing process delivers optical-grade smoothness without compromising dimensional accuracy. For electroplated ABS parts, we use proprietary pre-treatment to ensure adhesion—critical for automotive and consumer electronics applications.

Our Commitment to Zero Defects & Olympic Quality

“Precision isn’t a goal—it’s our standard.”

At Wuxi Lead, Zero Defects is non-negotiable. Every part undergoes:

1. Material certification (traceable to ISO 9001 standards)

2. In-process dimensional checks (CMM, optical scanners)

3. Final 100% inspection with third-party metrology reports

For ABS parts, we guarantee:

±0.025mm tolerances on critical assembly features (e.g., shaft interfaces)

Zero warpage or thermal distortion via real-time machining parameter control

Full material traceability—from raw resin batch to finished part

With 24/7 customer service, our engineering team is always available to:

Optimize your design for manufacturability (DFM)

Resolve technical challenges in real-time

Provide material certification reports within 2 hours of request

Olympic Quality Benchmark:

Just as Olympic athletes demand perfection in every detail, we engineer parts to the highest standards of accuracy and reliability. Your project isn’t just manufactured—it’s precision-engineered for success.

Ready to engineer excellence?

Contact our team today for a free material selection consultation.

📞 +86 510 8765 4321 | ✉️ [email protected] | 🌐 www.leadprecision.com

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we transform your designs into reality through a rigorously controlled, ISO 9001-certified process. As your engineering partner—not just a supplier—we eliminate guesswork with transparent workflows, proactive quality assurance, and unwavering commitment to Zero Defects. Every step is engineered for reliability, speed, and excellence.

Design Analysis – Engineering Excellence at the Start

We treat your design as our own. Our senior engineers conduct a comprehensive DFMA (Design for Manufacturability and Assembly) review, optimizing geometry, material selection, and tolerance feasibility. Every design undergoes ISO 9001-certified validation, including ABS material certification checks (UL94 V-0, ASTM D638). This proactive step eliminates production risks before machining begins, embedding our Zero Defects commitment at the foundation of your project.

“Precision starts with prevention. Our design validation ensures your part is manufacturable, cost-effective, and defect-free from the first sketch.”

Transparent Pricing with Material Certification

Transparency is non-negotiable. Our pricing model provides a detailed breakdown of costs—including material certifications (SGS, RoHS), machining complexity, and volume—without hidden fees. You receive a precise quote within 48 hours, empowering procurement teams to make confident decisions with full visibility.

| Stage | Key Focus | Tolerance Standard | Delivery Time | Quality Assurance |

|---|---|---|---|---|

| Design Analysis | DFMA, Material Certification | ISO 9001 Certified | 24–48 hrs | Design Validation Report |

| Pricing | Transparent Cost Structure | Material Traceability | 48 hrs | No Hidden Fees |

| Rapid Prototyping | Precision CNC Machining | ±0.01mm (standard) | 3–5 days | 100% QC Inspection, Olympic Quality |

| Mass Production | Scalable Precision | ±0.025mm (critical), ±0.05mm (mating) | As per schedule | Zero Defects Guarantee, 24/7 Monitoring |

Rapid Prototyping – Validate with Confidence

Leveraging state-of-the-art CNC machining centers, we deliver ABS prototypes with ±0.01mm precision—exceeding industry standards. Every component undergoes 100% dimensional inspection per ISO 9001 protocols, including surface finish, dimensional accuracy, and functional testing. This Olympic Quality assurance ensures your design is validated to the highest standards, reducing time-to-market and eliminating costly rework.

“Prototypes aren’t just samples—they’re your first step toward flawless production. We verify every detail so your final part meets expectations, not compromises.”

Mass Production – Consistent Excellence, On-Time Delivery

Scaling to volume never compromises precision. Our automated production lines maintain ±0.025mm tolerances on critical features (e.g., bearing interfaces) and ±0.05mm on mating surfaces, consistently meeting ISO 9001 requirements. With 24/7 production monitoring, real-time SPC (Statistical Process Control) data, and AI-driven quality checks, we guarantee on-time delivery while upholding our Zero Defects promise—every part, every time.

“When you partner with Wuxi Lead, you gain a precision engineering ally. From prototype to production, we deliver more than parts—we deliver confidence.”

Why Wuxi Lead?

Zero Defects Commitment: 99.98% first-pass yield rate across 10,000+ projects.

Olympic Quality: Certified to ISO 9001, with 100% traceable material certifications.

24/7 Customer Service: Dedicated account managers available around the clock for real-time updates and issue resolution.

Ready to elevate your manufacturing process?

Contact our engineering team today for a consultation—where precision meets partnership.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineered for Your Success

As a global leader in precision CNC machining, Wuxi Lead Precision Machinery transcends the traditional supplier model. We are your dedicated engineering partner, committed to delivering Olympic Quality components with zero defects through ISO 9001-certified processes. Our collaborative approach ensures your project’s success from design to delivery.

Core Differentiators: Precision, Quality, Support

| Feature | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Quality Assurance | Olympic Quality: Zero Defects Certified (ISO 9001) | Typically 95–98% defect-free |

| Tolerance Control | ±0.01mm critical features (material-certified) | ±0.05mm |

| Support | 24/7 Dedicated Engineering Team with Real-Time Updates | Standard Business Hours Support |

Your Next Step: Partner with Confidence

Free DFM Analysis: Optimize your design for manufacturability, cost-efficiency, and performance before production begins.

Material Certification: Full traceability and compliance documentation for every component, ensuring adherence to ISO standards.

Rapid Response: Receive expert quotes and technical support within 24 hours, with dedicated engineers available around the clock.

Contact Us Today

📧 [email protected] | 📞 +86-13961886740

Let’s engineer your success together – where precision meets partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.