Technical Contents

Engineering Guide: Order Metal Parts Online

Engineering Insight: The Critical Role of Precision in Custom Metal Manufacturing

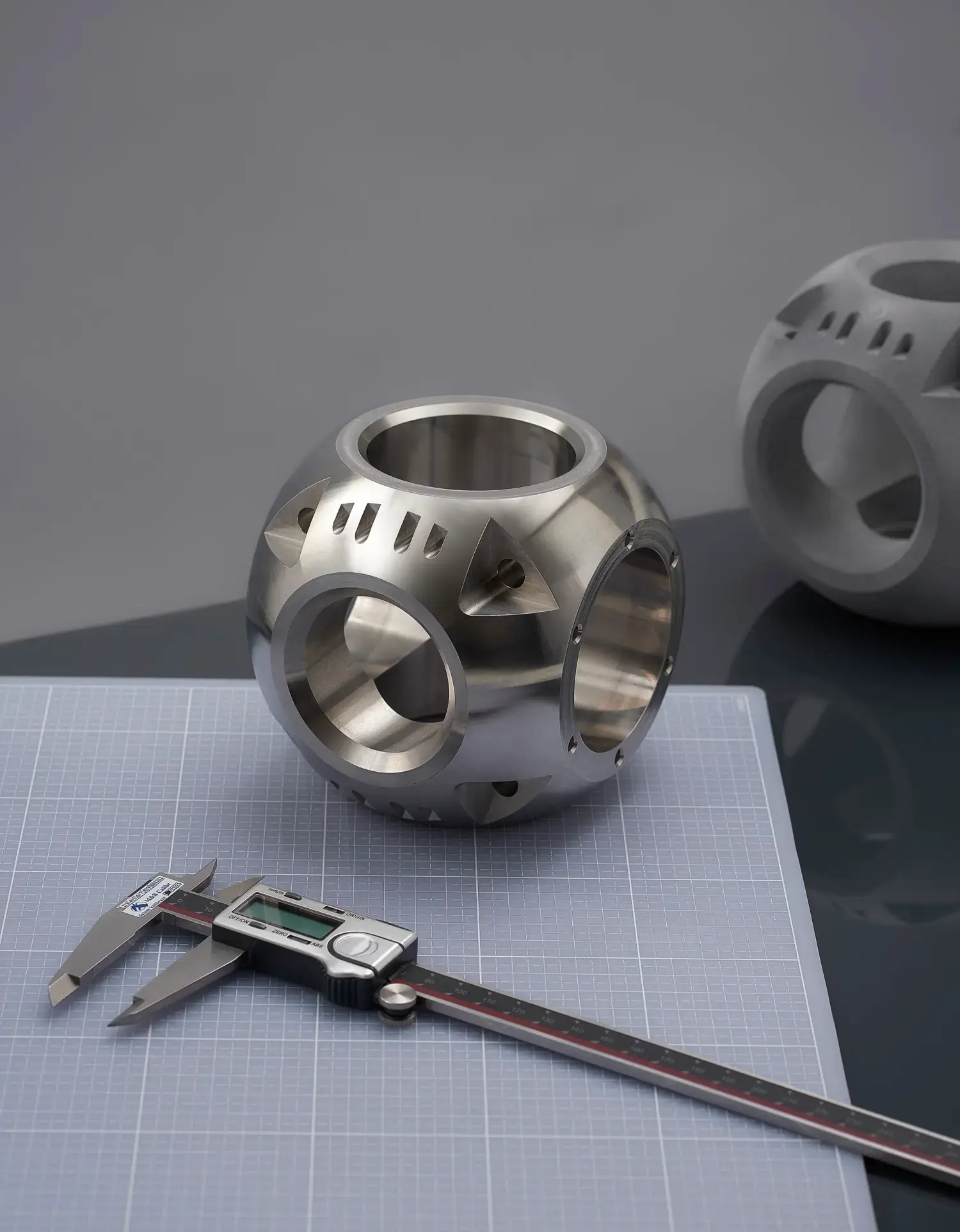

In the realm of custom metal part production, precision is not merely a performance metric—it is the foundation of reliability, safety, and long-term functionality. When businesses choose to order metal parts online, they are often balancing speed, cost, and quality. However, the most successful outcomes stem from suppliers who prioritize engineering accuracy above all else. At Wuxi Lead Precision Machinery, we understand that even a deviation of a few microns can compromise the integrity of high-stakes applications, from aerospace systems to medical devices.

Our approach to precision manufacturing is built on decades of advanced engineering expertise and a commitment to excellence that has been validated through projects with Olympic-standard equipment and military-grade components. These demanding sectors do not tolerate error. They require parts that perform consistently under extreme conditions, where predictability and durability are non-negotiable. Our involvement in such projects underscores our capability to meet the highest global standards in dimensional accuracy, material integrity, and surface finish.

When you order metal parts online, the digital interface should not compromise engineering rigor. At Lead Precision, every custom order undergoes a structured engineering review. We analyze CAD models for manufacturability, verify material compatibility, and simulate machining paths to eliminate potential errors before production begins. This proactive approach ensures that what is designed is exactly what is delivered—on time and to specification.

Our state-of-the-art CNC machining centers operate with tolerances as tight as ±0.002 mm, supported by real-time monitoring and automated quality control systems. This level of precision is not accidental; it is the result of integrating advanced technology with skilled craftsmanship and a culture of continuous improvement.

Below are key specifications that define our precision manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Standard Tolerances | ±0.005 mm |

| High-Precision Tolerances | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.4 μm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Inconel, Tool Steels |

| Machining Processes | 3-axis, 4-axis, 5-axis CNC Milling, CNC Turning, Wire EDM |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Documentation |

Precision is not just a technical requirement—it is a promise. At Wuxi Lead Precision Machinery, we deliver that promise with every custom metal component we produce. Whether you are prototyping a new design or scaling production, our engineering team ensures your parts meet the exact demands of your application. When you order metal parts online through our platform, you are not just accessing manufacturing services—you are gaining a precision engineering partner with a proven track record in the world’s most demanding industries.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical metal components through advanced manufacturing infrastructure and rigorous quality assurance. Our technical foundation centers on state-of-the-art 5-axis CNC machining, enabling the production of highly complex geometries in a single setup. This eliminates cumulative error from multiple fixtures, ensuring superior dimensional integrity for aerospace turbine blades, medical implants, and energy sector components. We operate a dedicated fleet of DMG MORI and MAZAK 5-axis vertical machining centers with 42-tool capacity, capable of machining titanium, Inconel, hardened steel, and aluminum alloys up to Ø650mm x 500mm. Integrated high-speed spindles (24,000 RPM) and dynamic tool compensation maintain micron-level precision during intricate contouring operations, directly translating your CAD models into physically flawless parts.

Quality verification is non-negotiable. Every critical feature undergoes 100% inspection using Zeiss CONTURA and Hexagon GLOBAL S 5-axis Coordinate Measuring Machines (CMM). Our AS9100-certified process employs ISO 10360-2 validated equipment, with inspection routines programmed directly from your GD&T specifications. Full traceability is maintained through our digital quality management system, providing certified inspection reports with real-time measurement data for all critical dimensions. This closed-loop approach ensures compliance with aerospace AMS, medical ISO 13485, and automotive IATF 16949 standards, mitigating risk for high-stakes applications.

Our tolerance mastery spans standard to ultra-precision requirements, consistently achieving benchmarks that exceed industry norms. The following table defines our validated capability ranges under controlled environmental conditions:

| Tolerance Category | Dimensional Tolerance (mm) | Dimensional Tolerance (in) | Surface Roughness (Ra) | Feature Applicability |

|---|---|---|---|---|

| Standard Production | ±0.05 | ±0.002 | 3.2 µm (125 µin) | Non-critical mounting surfaces, housings |

| Precision Machining | ±0.01 | ±0.0004 | 1.6 µm (63 µin) | Bearing seats, hydraulic ports, alignment features |

| Tight Tolerance | ±0.005 | ±0.0002 | 0.8 µm (32 µin) | Sealing surfaces, optical mounts, aerospace interfaces |

| Reference Standard | ISO 2768-mK | ANSI B4.1 Class 2 | ISO 1302 | All critical features per drawing |

This capability matrix reflects our commitment to engineering realism—we validate tolerances against actual production data, not theoretical machine specifications. By integrating 5-axis flexibility with metrology-grade verification, we eliminate the guesswork in online metal part procurement. Your complex designs achieve first-article success through our process stability, reducing lead times and scrap costs. Partner with Wuxi Lead to transform demanding specifications into certified, on-time deliveries where precision is the baseline, not the exception.

Material & Finish Options

Material selection is a critical step in the custom metal manufacturing process, directly influencing part performance, durability, and cost. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components tailored to meet the exact demands of industries such as aerospace, automotive, medical, and industrial automation. Understanding the properties of aluminum, steel, and titanium allows engineers and procurement managers to make informed decisions when ordering metal parts online.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications where weight reduction is essential without compromising structural integrity. Common grades like 6061 and 7075 offer versatility and are often used in aerospace and transportation components. Aluminum also responds exceptionally well to anodizing, a finish that enhances surface hardness and wear resistance while providing aesthetic options through color dyeing.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, durability, and cost-effectiveness. Carbon steel and alloy steel are commonly used for heavy-duty mechanical parts, tooling, and structural applications. Stainless steel, particularly grades 304 and 316, offers superior corrosion resistance and is ideal for environments exposed to moisture or chemicals, such as in medical or food processing equipment. While steel can be plated or painted, it does not anodize like aluminum. Instead, finishes such as passivation, zinc plating, or powder coating are recommended for enhanced protection.

Titanium stands at the premium end of the material spectrum, offering exceptional strength-to-density ratio, outstanding corrosion resistance, and performance at elevated temperatures. It is the material of choice for critical aerospace, defense, and medical implant applications. Although more challenging and costly to machine, titanium’s longevity and reliability in extreme environments justify its use in high-performance systems.

Surface finishing plays a key role in both functionality and appearance. Anodizing is a controlled electrochemical process primarily applied to aluminum, creating a durable, non-conductive oxide layer. Type II anodizing offers moderate wear resistance and dye capability, while Type III (hard anodizing) delivers superior hardness and extended service life in demanding conditions.

The table below summarizes key mechanical and finishing properties of common materials we process:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Finishes |

|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Good | Anodizing (Type II/III), Alodine |

| Steel 1045 | 600 | 7.85 | Low | Zinc plating, Paint, Oil coating |

| Stainless 304 | 515 | 8.0 | Excellent | Passivation, Polishing |

| Titanium Gr5 | 895 | 4.5 | Excellent | Anodizing, Polishing, Bead blast |

Selecting the right material and finish ensures optimal performance and longevity of your custom parts. At Wuxi Lead, we support your decision-making with expert consultation and advanced CNC capabilities to deliver precision components on time and to specification.

Manufacturing Process & QC

Precision Metal Part Production: From Concept to Flawless Delivery

At Wuxi Lead Precision Machinery, our production process for custom metal parts is engineered for uncompromising quality and efficiency, ensuring zero defects from initial concept to final shipment. This rigor is fundamental to our reputation in high-end B2B manufacturing. The journey begins with collaborative Design for Manufacturability (DFM) analysis. Our senior engineers meticulously review your CAD models and technical specifications, identifying potential machining challenges, material constraints, or tolerance conflicts before any metal is cut. We prioritize optimal material selection—aluminum alloys, stainless steels, titanium, or exotic metals—based on your part’s functional requirements, environmental exposure, and cost targets. This proactive DFM stage eliminates costly redesigns later, establishing the foundation for defect prevention.

Following design approval, we proceed to Prototyping using advanced 3-5 axis CNC milling and turning centers. This critical phase validates the manufacturability and functionality of your design under real production conditions. Each prototype undergoes First Article Inspection (FAI) against your original specifications. Dimensional accuracy, surface finish, material properties, and critical geometric tolerances are verified using calibrated Coordinate Measuring Machines (CMM) and optical comparators. We provide comprehensive inspection reports, including detailed metrology data, enabling you to confirm performance and approve the process for scale-up. This step is non-negotiable for achieving zero defects in volume production.

Upon prototype validation, Mass Production commences under stringent Statistical Process Control (SPC). Every machining parameter—tool paths, feed rates, spindle speeds, coolant application—is precisely monitored and logged in real-time. In-process inspections occur at defined intervals using calibrated gauges and automated vision systems, ensuring deviations are detected and corrected immediately. Our clean, climate-controlled facility minimizes environmental variables. Final Quality Assurance involves 100% critical dimension checks on high-risk features and random sampling for all other parameters per AS9102 or customer-specific standards. Full material traceability, from raw stock lot numbers to finished part serialization, is maintained throughout. This integrated system guarantees consistent conformance, eliminating defects before parts leave our facility.

Key inspection parameters and our achievable tolerances demonstrate this precision capability:

| Inspection Parameter | Typical Capability Range | Measurement Method |

|---|---|---|

| Dimensional Accuracy | ±0.005 mm to ±0.025 mm | CMM, High-Precision Gauges |

| Surface Roughness (Ra) | 0.4 µm to 3.2 µm | Profilometer |

| Geometric Tolerances (GD&T) | ±0.01 mm to ±0.05 mm | CMM, Optical Comparator |

| Material Certification | Full Mill Certificates | Traceability Documentation |

| Critical Feature Sampling | 100% Inspection | Automated Vision Systems |

This closed-loop production methodology—rooted in proactive design validation, rigorous prototyping, and SPC-driven mass production—ensures every part shipped meets the highest standards of precision and reliability. Partner with Wuxi Lead to transform your metal component requirements into flawless reality. Contact our engineering team to discuss your specific project and quality expectations.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Quality in Custom Metal Manufacturing

When your project demands precision-engineered metal components produced to exacting standards, partnering with Wuxi Lead Precision Machinery ensures access to advanced manufacturing capabilities, rigorous quality control, and responsive engineering support. As a leading provider of custom metal parts in China, we specialize in delivering high-integrity components for industries where performance, reliability, and repeatability are non-negotiable—ranging from aerospace and medical devices to industrial automation and energy systems.

Our facility in Wuxi integrates state-of-the-art CNC machining, multi-axis turning, milling, grinding, and sheet metal fabrication with comprehensive in-house metrology and material traceability. Every process is executed under ISO 9001:2015-certified quality management systems, ensuring consistent adherence to international standards. Whether you require low-volume prototypes or high-volume production runs, our team collaborates closely with your engineers to optimize designs for manufacturability, reduce lead times, and control costs—without sacrificing precision.

We understand that in high-end manufacturing, specifications define success. Below are the core technical capabilities that define our production floor:

| Capability | Specification Range |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, turning with live tooling |

| Tolerance | ±0.005 mm (±0.0002 in) typical, down to ±0.001 mm with special processes |

| Part Size | Max: 1200 x 800 x 650 mm (47 x 31.5 x 25.6 in); Min: micro-precision components |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316, 17-4PH), Titanium (Grade 2, 5), Brass, Copper, Inconel, Tool Steels |

| Surface Finishes | As-machined, Anodizing (Type II, Type III), Plating (Ni, Cr, Zn), Powder Coating, Passivation, Polishing |

| Secondary Operations | Welding (TIG, MIG), Heat Treatment, Insert Installation, Assembly, Laser Marking |

| Quality Inspection | CMM, Optical Comparator, Surface Roughness Tester, Hardness Testing, First Article Inspection (FAI), PPAP |

Our digital-first workflow enables seamless integration with global clients. Upload your CAD files directly through secure channels, receive detailed DFM feedback within 24 hours, and track production progress in real time. With dedicated project managers fluent in English and technical engineering, communication is clear, timely, and solution-oriented.

At Lead Precision, we don’t just manufacture parts—we build long-term manufacturing partnerships. By combining Chinese production efficiency with Western engineering standards, we deliver a hybrid advantage that global OEMs rely on for mission-critical components.

Start your next project with confidence. Contact us today at [email protected] to connect with our engineering team, request a quote, or schedule a virtual factory tour. Let Wuxi Lead Precision Machinery become your trusted partner in precision metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.