Technical Contents

Engineering Guide: Massachusetts Machine Shops

Engineering Insight: The Critical Role of Precision in Massachusetts Machine Shops

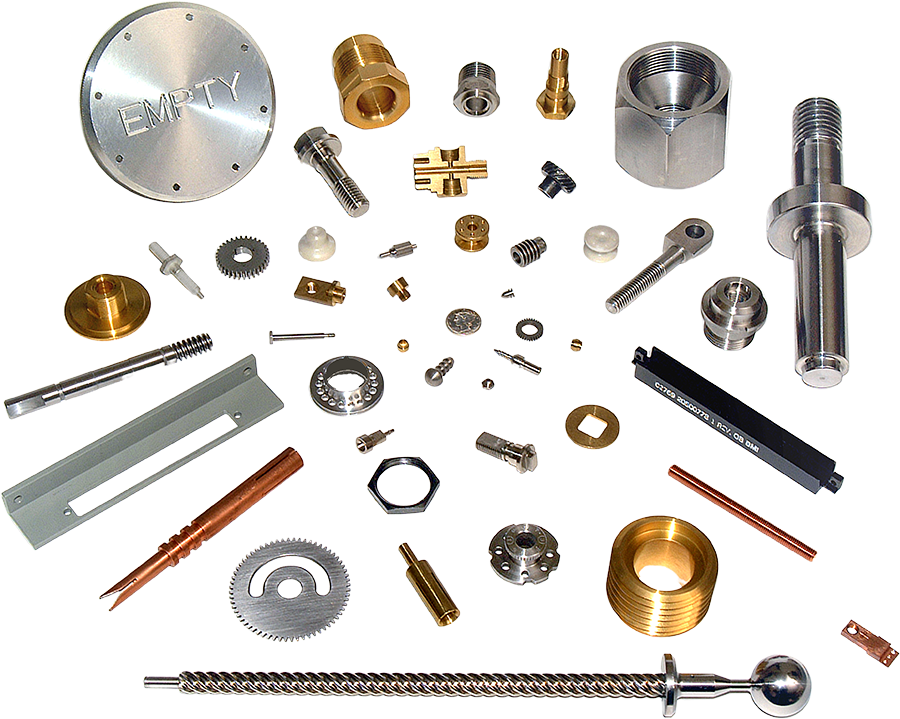

In the competitive landscape of advanced manufacturing, Massachusetts machine shops are recognized for their innovation, technical expertise, and commitment to quality. These facilities serve industries where performance and reliability are non-negotiable—ranging from aerospace and defense to medical devices and high-performance automation. At the core of their success lies an unwavering dedication to precision engineering. Tolerances measured in thousandths—or even millionths—of an inch are not merely technical specifications; they are the foundation upon which safety, functionality, and compliance are built.

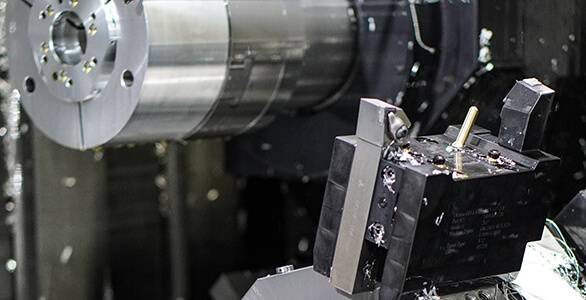

Precision in machining goes beyond the capability of advanced CNC equipment. It encompasses a holistic approach that includes material selection, thermal stability in machining environments, tooling strategy, real-time quality inspection, and the skill of engineering personnel. In high-stakes applications such as aerospace components or military-grade assemblies, even the smallest deviation can result in catastrophic system failure. This is why leading machine shops in Massachusetts invest heavily in multi-axis CNC centers, coordinate measuring machines (CMMs), and in-process probing systems to maintain control throughout production.

At Wuxi Lead Precision Machinery, we understand these demands intimately. With over 15 years of experience serving global clients in mission-critical sectors—including components for Olympic-standard timing systems and precision parts for defense applications—we have developed a manufacturing philosophy centered on repeatability, traceability, and zero-defect delivery. Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 standards, ensuring that every part meets or exceeds the expectations of even the most stringent U.S.-based engineering teams.

Our collaboration with engineering firms and machine shops in Massachusetts has demonstrated that offshore manufacturing does not mean compromising on precision. On the contrary, by combining our advanced equipment and process rigor with the design excellence of New England engineers, we deliver components that perform reliably in the most demanding environments.

Below are key capabilities that define our precision manufacturing standards:

| Specification | Detail |

|---|---|

| CNC Machining Tolerances | ±0.0001″ (2.5 μm) |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Materials Processed | Aluminum alloys, stainless steel, titanium, Inconel, brass, engineered plastics |

| Equipment | 3-axis to 5-axis CNC machining centers, Swiss lathes, wire EDM |

| Quality Control | CMM, optical comparators, surface roughness testers, first-article inspection (FAI) |

| Industry Standards Compliance | ISO 9001, IATF 16949, AS9100 (supporting documentation available) |

Precision is not a feature—it is a discipline. For Massachusetts machine shops seeking to scale production without sacrificing quality, partnering with a globally certified precision manufacturer like Wuxi Lead ensures that engineering intent is preserved from design to delivery.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Massachusetts Industry Demands

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered to meet the stringent requirements of Massachusetts aerospace, medical device, and industrial equipment sectors. Our core strength lies in high-precision 5-axis CNC machining, enabling complex geometries and tight-tolerance components in a single setup. This capability eliminates cumulative errors from multiple fixtures, significantly reducing lead times while enhancing part accuracy and surface integrity. We utilize state-of-the-art Haas and DMG MORI 5-axis vertical machining centers with travel ranges up to 1,000 x 600 x 500 mm and high-speed spindles (24,000 RPM), supporting multi-face milling, contouring, and deep cavity work on materials including titanium, Inconel, aluminum alloys, and hardened steels.

Rigorous quality control is non-negotiable. Every critical dimension undergoes verification via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with 0.0001″ (2.5 μm) accuracy. Our inspection protocols adhere to AS9102 and ISO 13485 standards, providing full first-article inspection (FAI) reports with GD&T validation. Real-time process monitoring via Renishaw probes ensures in-cycle correction, while our metrology lab maintains NIST-traceable calibration. This systematic approach guarantees compliance with Massachusetts clients’ engineering drawings and regulatory frameworks, particularly vital for FAA Part 21 and FDA 21 CFR Part 820 compliance.

The following table details our standard achievable tolerances, validated through continuous Cpk analysis across production runs. These specifications reflect our commitment to repeatability in high-mix, low-volume manufacturing environments typical of Massachusetts precision shops.

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Surface Finish (Ra) |

|---|---|---|---|

| Linear Dimensions | ±0.0004″ (0.010 mm) | ±0.0002″ (0.005 mm) | 32 μin (0.8 μm) |

| Hole Diameter | ±0.0003″ (0.008 mm) | ±0.00015″ (0.004 mm) | 16 μin (0.4 μm) |

| Positional Tolerance | ±0.0005″ (0.013 mm) | ±0.00025″ (0.006 mm) | N/A |

| Profile of Surface | ±0.0003″ (0.008 mm) | ±0.00015″ (0.004 mm) | N/A |

| Material Thickness | ±0.0005″ (0.013 mm) | ±0.0003″ (0.008 mm) | N/A |

Our technical infrastructure supports seamless integration with Massachusetts engineering workflows. We accept native CAD formats (STEP, IGES, Parasolid) and provide detailed inspection data via secure cloud portals. By combining 5-axis agility with uncompromising metrology, Wuxi Lead enables Massachusetts innovators to accelerate prototyping and production without sacrificing quality. We function as a strategic offshore extension of your manufacturing team—delivering certified precision, documentation transparency, and responsive engineering collaboration to uphold your reputation for excellence. This capability ensures your complex metal components meet exacting performance criteria, whether for defense subcontractors in Lowell or biotech OEMs in Cambridge.

Material & Finish Options

Material selection is a critical decision in precision manufacturing, directly influencing the performance, durability, and cost-efficiency of end components. For Massachusetts machine shops serving aerospace, medical, and high-performance industrial sectors, understanding the mechanical behavior and finishing compatibility of aluminum, steel, and titanium is essential. At Wuxi Lead Precision Machinery, we support advanced manufacturing partners with expert material guidance and precision CNC machining services tailored to stringent application requirements.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is widely used in aerospace and automotive applications where weight reduction is paramount. The 6061 and 7075 aluminum alloys are particularly favored—6061 for general structural components due to its weldability and moderate strength, and 7075 for high-stress environments requiring superior tensile properties. Aluminum is highly compatible with anodizing, a key surface treatment that enhances wear and corrosion resistance while allowing for color coding and improved aesthetics.

Steel, particularly in its stainless and alloy forms, offers unmatched strength, hardness, and thermal stability. 304 and 316 stainless steels are common in medical and food-processing equipment due to their hygienic properties and resistance to oxidation. For high-wear applications, tool steels and 4140 alloy steel provide excellent fatigue resistance and can be heat-treated to meet specific hardness requirements. While steel does not anodize, it benefits from alternative surface treatments such as passivation, plating, or powder coating to enhance durability and environmental resistance.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosion make it ideal for aerospace, defense, and medical implant applications. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium delivers unmatched performance in critical load-bearing components. Surface treatments such as anodizing can be applied to titanium for both functional and aesthetic purposes, including oxide layer stabilization and color differentiation without compromising material integrity.

The following table outlines key mechanical and finishing properties of commonly used materials:

| Material | Typical Alloys | Tensile Strength (MPa) | Density (g/cm³) | Common Finishes | Applications |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310 – 570 | 2.7 | Anodizing, Powder Coating | Aerospace, Automotive, Enclosures |

| Stainless Steel | 304, 316, 17-4PH | 505 – 1300 | 7.9 | Passivation, Electropolishing | Medical, Marine, Industrial |

| Alloy Steel | 4140, 4340 | 655 – 1200 | 7.85 | Hardening, Plating | Tooling, Shafts, High-Stress Parts |

| Titanium | Grade 2, Grade 5 | 345 – 1170 | 4.5 | Anodizing, Bead Blasting | Aerospace, Medical Implants |

Selecting the right material involves balancing mechanical demands, environmental exposure, manufacturability, and finishing requirements. Wuxi Lead Precision Machinery collaborates with engineering teams to ensure optimal material and finish pairings, supporting Massachusetts machine shops in delivering high-reliability components with consistent quality and performance.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Production for Massachusetts Machine Shops

For Massachusetts machine shops serving aerospace, medical, and defense sectors, consistent zero-defect output is non-negotiable. At Wuxi Lead Precision Machinery, we execute a rigorously controlled process—Design, Prototyping, Mass Production—engineered to eliminate variability and exceed AS9100 and ISO 13485 standards. Our methodology ensures seamless integration with your supply chain while mitigating offshore quality risks.

The Design Phase begins with collaborative DFM (Design for Manufacturability) analysis. Our engineers review your CAD models and technical specifications within 48 hours, identifying potential tooling conflicts, material inefficiencies, or geometric constraints. We prioritize feature tolerance alignment with your end-use requirements, leveraging Siemens NX simulation to validate stress points and thermal behavior. This phase reduces downstream rework by 30% and establishes a shared quality blueprint signed off by your engineering team.

Prototyping transitions validated designs into physical validation. Using HAAS DM-12Y 5-axis mills or DMG MORI CTX beta 1250 lathes, we produce 1–5 functional units with identical tooling and materials as final production. Every prototype undergoes CMM inspection per ISO 10360-2 standards, with full GD&T reporting against your master drawing. Dimensional deviations exceeding ±0.0004″ (10µm) trigger immediate root-cause analysis. This stage confirms process capability (CpK ≥1.67) and secures your approval before scaling.

Mass Production deploys our zero-defect framework. Each component is manufactured under SPC-controlled environments with real-time X-bar R charts monitoring critical dimensions. Our facility utilizes automated in-process gauging on Okuma MULTUS U4000 machines, rejecting out-of-tolerance parts before secondary operations. Final inspection includes 100% first-article validation and AQL 0.65 sampling per MIL-STD-1916. Traceability is maintained via laser-etched part IDs linked to material certs, heat treatments, and operator logs—ensuring full compliance for FAA or FDA audits.

Key process capabilities ensuring defect-free delivery:

| Capability | Specification | Relevance to Massachusetts Shops |

|---|---|---|

| Dimensional Tolerance | ±0.0002″ (5µm) | Meets Boeing BSS 7230 Class A aerospace specs |

| Surface Finish | Ra 0.4 µm (16 µin) | Critical for medical implant biocompatibility |

| Material Range | Titanium Ti-6Al-4V, Inconel 718, 17-4PH SS | Supports defense and energy sector demands |

| Max Part Size | Ø12″ x 24″ (305 x 610 mm) | Accommodates complex hydraulic manifolds |

| Lead Time (Mass Production) | 10–15 days after FAI approval | Reduces inventory costs for JIT programs |

Wuxi Lead’s process eliminates the quality uncertainty often associated with offshore manufacturing. With our Boston-based technical support team providing daily production dashboards and U.S.-certified QA documentation, Massachusetts machine shops gain a transparent, reliable extension of their own capabilities. Contact our sales engineering team to integrate our zero-defect workflow into your critical supply chain—without compromising on speed or compliance.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Custom Metal Manufacturing Excellence

When Massachusetts machine shops demand precision, scalability, and unwavering reliability in custom metal manufacturing, Wuxi Lead Precision Machinery stands as a globally recognized engineering partner. With over 15 years of specialization in high-tolerance CNC machining, multi-axis milling, turning, and complex fabrication, we deliver mission-critical components that meet the exacting standards of aerospace, medical, industrial automation, and defense sectors. Our ISO 9001:2015 and IATF 16949 certified facility in Wuxi, China, operates at the forefront of advanced manufacturing, combining cutting-edge technology with deep process expertise to serve clients across North America.

Our strategic partnership model is designed to extend your shop’s capabilities without capital investment or operational overhead. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing ecosystem ensures rapid turnaround, consistent quality, and full traceability. We specialize in challenging materials such as titanium, Inconel, aluminum alloys, and hardened steels, machining parts to tolerances as tight as ±0.0002” with superior surface finishes. Through real-time project tracking, detailed inspection reports, and PPAP/FAI documentation, we integrate seamlessly into your supply chain as a trusted extension of your engineering team.

Wuxi Lead Precision Machinery invests in the latest HAAS, DMG MORI, and Makino equipment, supported by automated tool management and in-process metrology systems. Our engineering team collaborates directly with your design and production staff to optimize manufacturability, reduce lead times, and lower total cost of ownership. From initial DFM analysis to final packaging and logistics, we manage every detail with precision and accountability.

For Massachusetts-based manufacturers seeking a high-performance offshore partner, we offer a proven alternative to rising domestic costs and capacity constraints. Our bilingual project managers ensure smooth communication, time-zone-aligned reporting, and compliance with ITAR, REACH, and RoHS standards when required. With over 87% of our annual output shipped to North America, we understand the expectations of U.S. industrial clients and consistently exceed them.

Partner with a manufacturer that treats your projects as mission-critical. Contact us today to discuss your next precision component challenge.

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.0002” (5µm) |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Equipment Types | 3/4/5-Axis CNC Mills, CNC Lathes, Swiss-type Machines |

| Secondary Operations | Deburring, Anodizing, Plating, Passivation, Heat Treatment |

| Quality Standards | ISO 9001:2015, IATF 16949, PPAP, FAI, First Article Inspection |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

To initiate a technical consultation or request a quote, email us at [email protected]. Let Wuxi Lead Precision Machinery become your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.