Technical Contents

Engineering Guide: Cnc Plastic Machining Services

Engineering Insight: The Critical Role of Precision in CNC Plastic Machining Services

In high-performance industries such as aerospace, medical technology, defense, and advanced instrumentation, the demand for precision-engineered plastic components has never been greater. CNC plastic machining services must meet exacting standards, where tolerances measured in microns can determine the success or failure of a mission-critical application. At Wuxi Lead Precision Machinery, we understand that precision is not merely a technical specification—it is a foundational requirement in the manufacturing of advanced plastic components.

Plastic materials behave fundamentally differently from metals during machining. They exhibit higher thermal expansion, lower stiffness, and variable creep characteristics, which necessitate a refined approach to cutting parameters, tool selection, and fixturing. Even minor deviations in temperature or feed rate can result in dimensional instability, surface imperfections, or part warpage. This sensitivity underscores the importance of advanced process control, real-time monitoring, and deep material science expertise—all of which are embedded in our CNC machining protocols.

Our engineering team at Wuxi Lead leverages over 15 years of experience in high-precision manufacturing, including specialized projects for Olympic-standard equipment and military-grade systems. These applications demand zero-defect performance under extreme conditions, driving our continuous investment in multi-axis CNC platforms, in-process metrology, and environmental stabilization. For example, components used in satellite deployment mechanisms or battlefield medical devices require not only micron-level accuracy but also long-term reliability in harsh environments. Our ability to consistently deliver to these standards has positioned us as a trusted partner in mission-critical supply chains.

We work with a broad range of engineering plastics—including PEEK, PTFE, Ultem, PPS, and polycarbonate—each selected for specific thermal, chemical, and mechanical performance. Our process begins with detailed material characterization, followed by customized toolpath strategies that minimize stress induction and maximize surface integrity. Every stage, from raw stock inspection to final packaging, adheres to ISO 9001-certified quality systems, ensuring repeatability across production runs.

The following table outlines key performance specifications we routinely achieve in our CNC plastic machining operations:

| Specification | Typical Capability | Notes |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Achieved on critical features |

| Surface Finish | Ra 0.4 µm (up to Ra 0.1 µm with polishing) | Adjustable per application |

| Maximum Part Size | 800 x 600 x 400 mm | Custom fixturing available |

| Materials Processed | PEEK, PTFE, Ultem, PPS, PC, PEI, PVC | Full material traceability |

| Quality Standards | ISO 9001:2015, RoHS, REACH | Documentation provided |

| Lead Time | 7–15 days (standard) | Expedited options available |

Precision in CNC plastic machining is not an endpoint—it is a continuous engineering pursuit. At Wuxi Lead Precision Machinery, we combine proven expertise with cutting-edge technology to deliver components that perform where it matters most.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Plastic Applications

Wuxi Lead Precision Machinery delivers exceptional CNC plastic machining services engineered specifically for the stringent demands of high-performance industries including medical device, aerospace, semiconductor, and advanced electronics. Our core strength lies in integrating advanced multi-axis technology with rigorous quality protocols to achieve micron-level precision consistently across complex polymer components. We specialize in machining challenging engineering thermoplastics such as PEEK, PEI (Ultem), PPSU, PTFE, Delrin (POM), and polycarbonate, where material behavior and thermal management are critical to final part integrity.

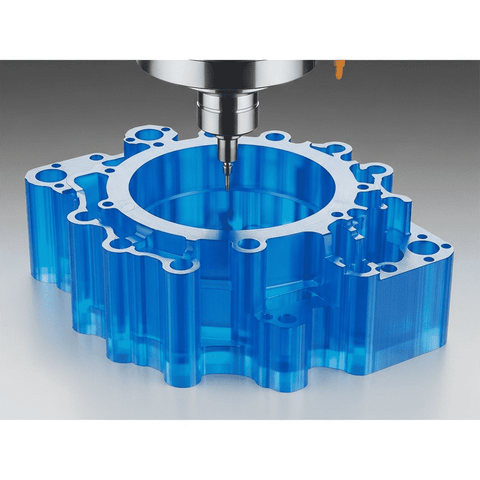

Our primary machining platform centers on state-of-the-art 5-axis CNC milling and turning centers. This capability is fundamental for producing intricate plastic geometries efficiently and accurately. The simultaneous 5-axis movement eliminates the need for multiple setups, significantly reducing cumulative error potential and part handling damage risks inherent in delicate polymers. Complex contours, deep cavities, undercuts, and precise angled features are machined in a single operation, ensuring superior dimensional coherence and surface finish. Advanced toolpath strategies specifically optimized for plastic materials minimize heat generation and vibration, preventing melting, burring, or warpage. This translates directly to higher yield rates, reduced lead times, and elimination of costly secondary operations for our clients.

Quality assurance is not an endpoint but an integrated process throughout production. Every critical dimension and geometric feature undergoes verification using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Mitutoyo CMMs provide traceable, high-accuracy measurement data against CAD models, confirming compliance with even the most demanding GD&T specifications. This systematic inspection regimen, combined with in-process checks and controlled environmental conditions within our facility, guarantees that every component shipped meets the exacting standards required for mission-critical applications. Material certification and full inspection reports are standard deliverables, providing complete traceability and confidence.

The achievable precision for plastic components is highly material-dependent due to factors like thermal expansion and inherent flexibility. The following table outlines typical tolerance capabilities under controlled machining and inspection conditions for common engineering plastics:

| Material Category | Typical Dimensional Tolerance | Typical Geometric Tolerance (e.g., Flatness, True Position) | Key Considerations |

|---|---|---|---|

| High-Performance (PEEK, PEI, PPSU) | ±0.010 mm (±0.0004″) | ±0.015 mm (±0.0006″) | Requires precise thermal stability management |

| Acetal (POM/Delrin) | ±0.008 mm (±0.0003″) | ±0.012 mm (±0.0005″) | Susceptible to moisture absorption effects |

| Polycarbonate (PC) | ±0.012 mm (±0.0005″) | ±0.018 mm (±0.0007″) | Prone to stress cracking; requires slow cool down |

| PTFE (Teflon) | ±0.025 mm (±0.001″) | ±0.040 mm (±0.0016″) | Very soft; requires specialized tooling and fixturing |

Note: Achievable tolerances depend on part geometry, size, wall thickness, and specific material grade. All measurements performed at standard 20°C (68°F) ambient temperature after stress relief.

Leveraging our 5-axis expertise and closed-loop quality control, Wuxi Lead transforms complex plastic design concepts into reality with the repeatability and accuracy essential for next-generation product development and production. We partner with clients to navigate material-specific challenges, ensuring optimal manufacturability and performance.

Material & Finish Options

Material selection is a critical factor in the success of any precision CNC machining project, particularly when working with metals such as aluminum, steel, and titanium. At Wuxi Lead Precision Machinery, we understand that the performance, durability, and cost-efficiency of a machined component begin with the right material choice. Each metal offers distinct mechanical properties, machinability characteristics, and compatibility with finishing processes such as anodizing, which must align with the end application’s environmental and functional demands.

Aluminum is one of the most widely used materials in CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is especially favored in aerospace, automotive, and electronics industries where lightweight components are essential. Grade 6061-T6 is a common choice for general-purpose applications, while 7075-T6 offers higher strength for more demanding structural uses. Aluminum is highly compatible with anodizing, a process that enhances surface hardness and corrosion resistance while allowing for color customization. This makes it ideal for both functional and aesthetic applications.

Steel, particularly in grades such as 303, 304, and 4140, provides superior strength, wear resistance, and structural integrity. It is the preferred material for applications requiring high load-bearing capacity, such as industrial machinery components and tooling. While steel is more challenging to machine than aluminum due to its hardness and tendency to work-harden, our advanced CNC equipment ensures tight tolerances and excellent surface finishes. Unlike aluminum, steel cannot be anodized but can be treated with alternatives such as passivation, plating, or powder coating to improve corrosion resistance and appearance.

Titanium, specifically Grade 5 (Ti-6Al-4V), is renowned for its exceptional strength-to-density ratio and outstanding resistance to extreme environments, including high temperatures and corrosive media. It is extensively used in aerospace, medical implants, and high-performance automotive systems. While titanium is more difficult and costly to machine due to its low thermal conductivity and high chemical reactivity, our specialized tooling and cooling strategies ensure precision and surface quality. Titanium does not anodize in the same way as aluminum, but it can undergo a form of oxide coloring for identification or aesthetic purposes.

Below is a comparative overview of key properties for these materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | 6061, 7075 | Yes | Aerospace, Electronics, Enclosures |

| Steel | 7.8 | 689 (4140) | 303, 304, 4140 | No | Industrial Machinery, Tooling |

| Titanium | 4.5 | 900 (Ti-6Al-4V) | Gr2, Gr5 | Limited (oxide coloring) | Medical, Aerospace, Motorsports |

Selecting the appropriate material involves balancing mechanical requirements, environmental exposure, and post-processing needs. At Wuxi Lead Precision Machinery, we support clients through every stage of this decision, ensuring optimal performance and cost-effectiveness in the final machined component.

Manufacturing Process & QC

Precision CNC Plastic Machining: The Zero Defects Production Process

At Wuxi Lead Precision Machinery, our CNC plastic machining services deliver uncompromising quality through a rigorously controlled production process. We eliminate defects at the source by integrating engineering expertise with advanced manufacturing protocols across three critical phases: Design, Prototyping, and Mass Production. This systematic approach ensures every component meets exacting aerospace, medical, and semiconductor industry standards.

The process begins with collaborative Design engineering. Our engineers work directly with client CAD models to conduct comprehensive Design for Manufacturability (DFM) analysis. We identify potential plastic-specific issues like warpage, sink marks, or stress concentrations before machining commences. Material compatibility, thermal behavior, and fixturing requirements are validated using simulation software, ensuring the design is optimized for both function and manufacturability. This proactive phase prevents 90% of potential quality failures by resolving conflicts in the virtual environment.

Prototyping transforms the validated design into a physical benchmark. Using the exact production-grade CNC machines, materials, and tooling planned for full-scale manufacturing, we produce functional prototypes. Each prototype undergoes stringent first-article inspection against all critical dimensions and material properties. Dimensional accuracy, surface finish, and assembly fit are verified using coordinate measuring machines (CMM) and optical comparators. This phase confirms the process capability and provides tangible validation for engineering sign-off, eliminating assumptions before committing to volume.

Mass Production leverages the perfected process blueprint from prototyping. Our automated production cells run under Statistical Process Control (SPC), continuously monitoring key parameters like tool wear, spindle load, and environmental conditions. Every component undergoes 100% critical feature inspection via in-line sensors and automated vision systems, with full traceability from raw material lot to final shipment. Non-destructive testing and batch sampling per AS9102 or ISO 13485 standards ensure sustained conformance. This closed-loop system maintains Cpk ≥ 1.67, guaranteeing Zero Defects delivery.

Process Phase Specifications

| Process Phase | Key Activities | Quality Control Metrics |

|---|---|---|

| Design | Collaborative DFM analysis, Material selection validation, Thermal/stress simulation, Fixturing strategy development | Tolerance feasibility report, Material suitability certification, Warpage risk assessment |

| Prototyping | Production-intent machining, First-article inspection (FAI), Functional testing, Assembly validation | Full AS9102/PPAP documentation, CMM reports (±0.005mm), Surface roughness (Ra ≤ 0.8µm), Material certification |

| Mass Production | SPC-monitored machining, 100% critical feature inspection, Automated in-process verification, Full traceability | Real-time SPC charts, Cpk ≥ 1.67, Zero PPM defect rate, Complete lot traceability, ISO 9001-compliant records |

This integrated methodology transforms quality from an inspection outcome into an engineered result. By controlling variables at every stage—from virtual design validation through statistically monitored production—we deliver plastic components where precision isn’t aspirational, but inherent. Wuxi Lead’s process guarantees that what you design is exactly what you receive, defect-free and ready for mission-critical assembly.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Plastic Machining Expertise

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-performance industries such as aerospace, medical devices, automation, and advanced electronics. As a leading provider of CNC plastic machining services in China, we specialize in transforming complex engineering designs into high-tolerance, repeatable components using advanced thermoplastics and engineering-grade polymers. Our commitment to excellence is reflected in every phase of production, from material selection and precision machining to final inspection and global delivery.

Our state-of-the-art CNC machining center is equipped with multi-axis milling and turning capabilities, enabling us to handle intricate geometries and tight tolerances down to ±0.005 mm. We work with a broad range of engineering plastics including PEEK, PTFE, ULTEM, PPS, POM, and nylon, ensuring material compatibility with your application’s mechanical, thermal, and chemical requirements. Whether you require rapid prototyping or high-volume production runs, our agile manufacturing system adapts to your project timeline without compromising on quality.

What sets Wuxi Lead Precision Machinery apart is our integrated quality assurance process. Every component undergoes rigorous in-process and final inspections using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Our ISO 9001:2015 certification underscores our adherence to international quality standards, giving global clients the confidence to integrate our components into mission-critical assemblies.

We operate with a client-first philosophy, offering direct engineering support, real-time project updates, and DFM (Design for Manufacturability) feedback to optimize cost, lead time, and performance. Our team of experienced CNC programmers and machinists collaborates closely with your engineers to ensure seamless execution from CAD model to finished part.

Below are key specifications that define our CNC plastic machining capabilities:

| Specification | Detail |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning |

| Tolerance | Up to ±0.005 mm |

| Standard Materials | PEEK, PTFE, ULTEM, PPS, POM (Delrin), Nylon, PC, PMMA, PEI |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Surface Finish | As low as Ra 0.4 µm (polished finishes available) |

| Secondary Operations | Drilling, tapping, threading, knurling, engraving, heat treatment |

| Quality Standards | ISO 9001:2015 certified, full inspection reporting |

| Lead Times | Prototype: 5–7 days; Production: 10–15 days (varies by volume) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to your success. We bridge the gap between innovative design and flawless execution, ensuring your plastic components meet the highest standards of performance and reliability.

For immediate assistance or to request a quote, contact us at [email protected]. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.