Technical Contents

Engineering Guide: 3003 Aluminum Sheet

Engineering Insight: The Critical Role of Precision in 3003 Aluminum Sheet Fabrication

In the demanding realm of custom metal manufacturing, the performance of 3003 aluminum sheet hinges entirely on dimensional and geometric precision. This manganese-alloyed grade, valued for its moderate strength, excellent formability, and superior corrosion resistance in non-structural applications, presents unique challenges during CNC machining, bending, and assembly. Minor deviations in flatness, thickness tolerance, or edge condition are not merely cosmetic flaws; they propagate through subsequent processes, leading to fit-up failures, compromised weld integrity, and ultimately, product rejection in mission-critical sectors. At Wuxi Lead Precision Machinery, we recognize that achieving true precision with 3003 aluminum demands far more than standard workshop practices. It requires deep material science understanding, rigorously controlled processing parameters, and metrology-grade verification at every stage.

Our extensive experience fabricating 3003 aluminum components for elite applications underscores this imperative. We supplied precision-formed 3003 sheet elements for the structural canopy framework of a major Beijing Olympic venue, where thermal expansion tolerances and wind-load deflection requirements were exceptionally stringent. Similarly, components for classified military ground support equipment demanded absolute consistency in bend radii and hole placement to ensure seamless integration under harsh environmental conditions. These projects succeeded because our engineering protocols treat the inherent characteristics of 3003 aluminum – its work-hardening rate, springback behavior, and sensitivity to tooling pressure – as fundamental design constraints, not afterthoughts. We implement real-time in-process gauging and adaptive CNC programming to counteract material variables, ensuring the final part meets the exacting flatness and dimensional specifications required for high-value assembly.

Material consistency is paramount. Below are the critical specifications we rigorously control for 3003 aluminum sheet fabrication, exceeding standard commercial tolerances to meet aerospace and defense-grade requirements:

| Specification | Standard Commercial Tolerance | Wuxi Lead Precision Tolerance | Measurement Method |

|---|---|---|---|

| Thickness Tolerance | ASTM B209: ±0.08 mm | ±0.025 mm | Laser Micrometer Array |

| Flatness (1200x2400mm) | Max 3.0 mm deviation | Max 0.5 mm deviation | CMM Scanning Platform |

| Edge Squareness | ±1.0° | ±0.25° | Precision Angle Gauge |

| Hole Position Tolerance | ±0.20 mm | ±0.05 mm | Optical Comparator |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Portable Profilometer |

The consequences of inadequate precision control in 3003 aluminum are severe in high-stakes manufacturing. Subtle thickness variations cause inconsistent bending angles, leading to assembly line stoppages. Poor flatness prevents proper sealing in fluid containment systems. Inconsistent hole patterns render expensive sub-assemblies unusable. Wuxi Lead Precision Machinery mitigates these risks through our integrated approach: material lot traceability back to certified mills, CNC processes calibrated specifically for 3003’s properties, and final inspection against the customer’s functional gauge requirements, not just nominal dimensions. This commitment to precision engineering, proven in Olympic and military programs, ensures your 3003 aluminum components perform flawlessly in the field, reducing total cost of ownership and safeguarding your reputation for quality. Precision isn’t an option; it’s the foundation of reliable manufacturing.

Precision Specs & Tolerances

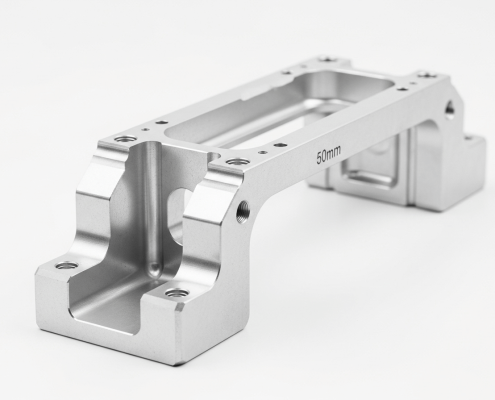

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance applications utilizing 3003 aluminum sheet, a versatile alloy known for its excellent formability, corrosion resistance, and moderate strength. As a leader in custom metal manufacturing, we specialize in transforming 3003 aluminum into precision-engineered components for aerospace, medical, electronics, and industrial equipment sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling complex geometries and tight tolerances unattainable with conventional methods.

Our 5-axis CNC machining platforms provide simultaneous multi-directional tool movement, ensuring optimal tool positioning and access to intricate features. This capability minimizes setup changes, reduces cycle times, and enhances dimensional consistency across both prototyping and high-volume production runs. The integration of high-speed spindles and advanced toolpath strategies allows for superior surface finishes and material removal efficiency, critical when working with softer alloys like 3003 aluminum to prevent material deformation and burring.

Quality assurance is embedded throughout our manufacturing workflow. Every component machined from 3003 aluminum sheet undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM). This high-precision metrology system verifies geometric accuracy, positional tolerances, and surface integrity in three-dimensional space. Our CMM inspection routines are fully programmable and repeatable, ensuring compliance with ISO 10360 standards and customer-specific quality requirements. All inspection data is documented and traceable, supporting full quality reporting for audit and certification purposes.

We maintain strict environmental and process controls within our climate-regulated production facility to minimize thermal variation during machining and inspection. This is particularly critical when achieving micron-level tolerances in aluminum, which has a relatively high coefficient of thermal expansion. In addition to CMM validation, in-process checks, first-article inspections, and final visual examinations are conducted to guarantee part integrity and consistency.

The following table outlines the standard technical specifications and achievable tolerances for 3003 aluminum sheet components processed through our 5-axis CNC and CMM-controlled workflow.

| Parameter | Specification |

|---|---|

| Material | 3003 Aluminum Sheet (H14, H16, H18 tempers available) |

| Thickness Range | 0.5 mm – 25.0 mm |

| 5-Axis CNC Positioning Accuracy | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.025 mm (standard), ±0.010 mm (precision) |

| Geometric Tolerance (GD&T) | ±0.015 mm (flatness, concentricity, position) |

| Surface Roughness (Ra) | 0.8 – 3.2 µm (machined), customizable to 0.4 µm |

| Feature Complexity | Multi-face, deep cavities, undercuts, thin walls ≥ 0.8 mm |

| CMM Measurement Accuracy | ±0.003 mm (at 20°C ±0.5°C) |

| Max Work Envelope | 1200 x 800 x 600 mm |

Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality protocols, and deep metallurgical expertise to deliver mission-critical components in 3003 aluminum sheet with unmatched precision and reliability.

Material & Finish Options

Material Selection for Precision Manufacturing: Aluminum 3003, Steel, and Titanium

Selecting the optimal material is foundational to achieving performance, cost efficiency, and longevity in custom metal components. At Wuxi Lead Precision Machinery, our engineering team rigorously evaluates application requirements against material properties to ensure the highest value solution. Aluminum 3003, carbon/stainless steel, and titanium each occupy distinct niches within precision manufacturing, driven by their inherent characteristics and suitability for specific environments and functional demands.

Aluminum Alloy 3003 stands as a versatile workhorse, particularly valued for its excellent corrosion resistance, especially in chemical and marine atmospheres, and superior workability. As a non-heat-treatable manganese alloy, it offers moderate strength (significantly higher than pure aluminum) and exceptional formability, making it ideal for deep drawing, spinning, and complex bending operations common in chemical equipment, heat exchangers, and architectural trim. Its non-sparking nature further broadens its utility in sensitive environments. While not the strongest aluminum alloy, 3003 provides the optimal balance for applications prioritizing corrosion resistance and formability over ultimate tensile strength. Anodizing significantly enhances its surface durability and aesthetic options, with Type II (sulfuric acid) anodizing being the standard for improved wear and corrosion resistance on 3003.

Carbon and stainless steels deliver higher strength and stiffness than aluminum 3003, essential for structural components, heavy machinery, and high-wear applications. Stainless grades (e.g., 304, 316) provide excellent corrosion resistance but at a higher material and machining cost compared to 3003. Titanium offers the highest strength-to-weight ratio and exceptional corrosion resistance in extreme environments, including seawater and chemical exposure, but commands a substantial premium in both material cost and machining complexity. Its use is typically reserved for aerospace, medical implants, and critical defense applications where its unique properties justify the investment.

The decision hinges on precise application analysis. For components requiring good corrosion resistance, ease of fabrication, and moderate strength at a competitive cost within non-structural or low-stress structural roles, 3003 aluminum is frequently the industry preference. Its compatibility with standard anodizing processes further extends service life and functionality. Steel becomes necessary for high-load bearing or extreme wear scenarios, while titanium addresses the most demanding weight and corrosion challenges.

Comparative Material Properties for Precision Components

| Property | Aluminum 3003 | Mild Steel (A36) | Stainless Steel 304 | Titanium (Gr 2) |

|---|---|---|---|---|

| Tensile Strength (MPa) | 110 – 150 | 400 – 550 | 505 – 860 | 345 – 450 |

| Yield Strength (MPa) | 60 – 110 | 250 | 215 – 620 | 275 – 380 |

| Corrosion Resistance | Excellent (Chem/Marine) | Poor (Rust) | Very Good | Exceptional |

| Machinability (Rating) | Very Good (A2) | Good (B) | Fair (C) | Poor (D) |

| Density (g/cm³) | 2.73 | 7.85 | 8.00 | 4.51 |

| Typical Anodizing | Type II Standard | Not Applicable | Not Standard | Type II/III Possible |

| Primary Cost Factor | Material & Processing | Material Low | Material & Machining | Material Very High |

Wuxi Lead Precision Machinery leverages this deep material science understanding alongside advanced CNC capabilities to guide clients toward the most effective and economical solution. Our process ensures 3003 aluminum, when specified correctly, delivers unmatched value through its fabrication ease, reliable performance, and compatibility with protective finishes like anodizing, directly contributing to reduced total project costs and extended component life. Consult our engineering team for application-specific material validation.

Manufacturing Process & QC

The production process for 3003 aluminum sheet components at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. This structured workflow ensures dimensional accuracy, material integrity, and zero-defect output, meeting the exacting standards of high-end industrial clients.

Design begins with a detailed engineering analysis of the client’s technical specifications, including geometric tolerances, surface finish requirements, and application environment. Our engineering team utilizes advanced CAD/CAM software to develop 3D models and perform finite element analysis (FEA) to simulate stress, thermal behavior, and formability. Special attention is given to the inherent properties of 3003 aluminum—its moderate strength, excellent workability, and corrosion resistance—to optimize part geometry and manufacturability. Design for manufacturability (DFM) reviews are conducted to eliminate potential production risks before any material is cut.

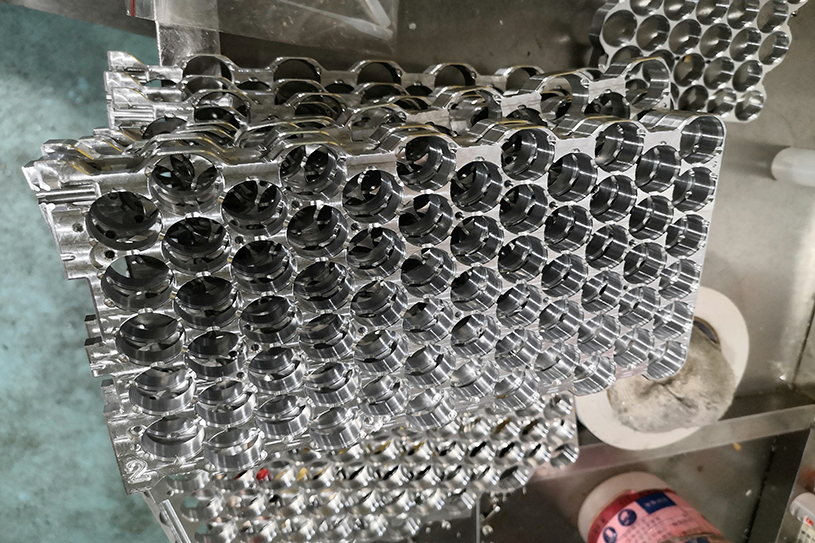

Prototyping follows the finalized design phase. A limited batch of components is produced using precision CNC machining, laser cutting, or stamping, depending on part complexity and client requirements. These prototypes are subjected to comprehensive quality verification, including coordinate measuring machine (CMM) inspection, tensile testing, and visual surface analysis. Dimensional reports and material certification are provided to the client for approval. This stage is critical for validating form, fit, and function, ensuring that any adjustments are made before full-scale production begins.

Mass production is initiated only after prototype approval. Our automated production lines leverage state-of-the-art equipment calibrated to micron-level precision. The 3003 aluminum sheets are processed under strict environmental and procedural controls to maintain consistency across batches. In-process inspections occur at defined intervals, supported by statistical process control (SPC) methodologies. Final inspection includes 100% visual checks and random sampling for dimensional and mechanical verification. Any deviation from specifications triggers an immediate corrective action protocol, ensuring zero-defect delivery.

Throughout all stages, traceability is maintained via our digital manufacturing execution system (MES), which logs material lot numbers, machine parameters, and inspection data. This end-to-end control system, combined with ISO 9001-certified processes, guarantees reliability and repeatability for every order.

Below are key material and process specifications for 3003 aluminum sheet manufacturing:

| Parameter | Specification |

|---|---|

| Alloy Type | 3003-H14 / H16 / H18 (as per requirement) |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tensile Strength | 130 – 180 MPa (H14) |

| Yield Strength | 115 – 160 MPa (H14) |

| Elongation | ≥ 10% (in 2″) |

| Processing Methods | CNC Machining, Laser Cutting, Stamping, Bending |

| Tolerance (Machined) | ±0.025 mm |

| Surface Roughness (Ra) | 0.8 – 3.2 µm (machined), 6.3 µm (stamped) |

| Quality Standard | ISO 9001:2015, ASTM B209 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched 3003 Aluminum Sheet Manufacturing

Wuxi Lead Precision Machinery stands as your definitive engineering partner for high-integrity 3003 aluminum sheet fabrication. We transcend standard metal supply by delivering fully engineered solutions where material science meets micron-level precision. Our dedicated production lines and expert metallurgical team possess deep, proven experience optimizing 3003 aluminum’s unique balance of moderate strength, excellent formability, and superior corrosion resistance for mission-critical applications. Whether your project demands intricate deep-drawn components for chemical processing equipment, seamless welded assemblies for cryogenic storage, or complex structural elements requiring reliable weldability, we control every variable from raw billet certification to final inspection. Partnering with Lead Precision means gaining a strategic extension of your engineering capability, ensuring your 3003 aluminum components consistently meet the most stringent aerospace, medical, and industrial performance standards.

Our advanced manufacturing ecosystem integrates state-of-the-art CNC machining centers, precision laser cutting, and robotic welding cells specifically calibrated for non-heat-treatable alloys like 3003. We enforce rigorous in-process quality control, including real-time thickness monitoring, chemical composition verification per ASTM B209, and comprehensive mechanical testing. This systematic approach eliminates costly scrap, ensures batch-to-batch repeatability, and accelerates your time-to-market. Our engineering team collaborates proactively during your design phase, providing critical DFM feedback to optimize material utilization, minimize secondary operations, and guarantee manufacturability without compromising structural integrity. We hold ISO 9001 certification and maintain full material traceability from mill to shipment, providing the documentation rigor demanded by regulated industries.

Critical 3003 aluminum sheet properties we consistently achieve and verify include:

| Property | Typical Value (H14 Temper) | Test Standard | Lead Precision Tolerance Control |

|---|---|---|---|

| Tensile Strength (MPa) | 130 – 180 | ASTM E8 | ±5 MPa |

| Yield Strength (MPa) | 115 – 150 | ASTM E8 | ±5 MPa |

| Elongation (%) | ≥ 12 | ASTM E8 | Min. 14% |

| Hardness (Brinell) | 35 – 50 | ASTM E10 | ±3 HB |

| Electrical Conductivity | ≥ 40% IACS | ASTM E1004 | Verified per batch |

Note: All values exceed ASTM B209 minimums. Tighter tolerances available per customer specification.

Transform your 3003 aluminum sheet project from a procurement challenge into a competitive advantage. Contact our engineering sales team today to discuss your specific requirements, material certifications, and volume needs. We provide rapid prototyping, scalable production runs, and unwavering commitment to on-time delivery. Submit your RFQ with detailed drawings and specifications to [email protected]. Our specialists will respond within 24 business hours with a comprehensive technical and commercial proposal, including optimized nesting plans and actionable DFM insights. Trust Wuxi Lead Precision Machinery to deliver not just metal, but engineered performance you can build upon. Contact us now to initiate your precision manufacturing partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.