Technical Contents

Engineering Guide: Plastic Mold Maker

Engineering Insight: The Critical Role of Precision in Plastic Mold Making

In the realm of custom metal manufacturing, plastic mold making stands as a discipline where precision is not merely a target—it is a necessity. The performance, longevity, and consistency of injection-molded plastic components are directly tied to the accuracy and quality of the molds that produce them. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can result in part defects, production delays, and increased costs for our clients. This is why our engineering philosophy centers on uncompromising precision, advanced metrology, and a deep commitment to excellence in every mold we produce.

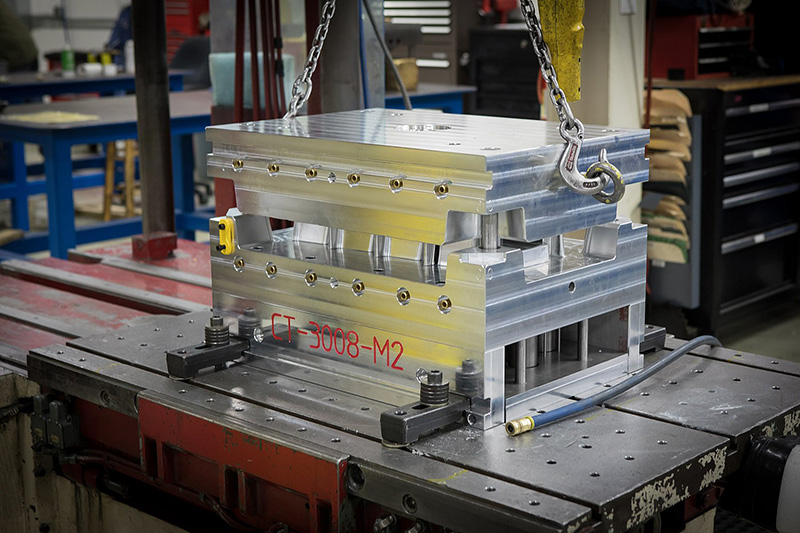

Plastic mold making is inherently complex, involving multi-axis machining, tight tolerance requirements, and the integration of cooling channels, ejection systems, and surface finishes that must align perfectly. The molds we manufacture are expected to withstand thousands—or even millions—of cycles while maintaining dimensional stability. Achieving this demands more than advanced CNC equipment; it requires a culture of precision that permeates every stage of design, material selection, machining, and quality assurance.

Our experience in high-stakes industries underscores this commitment. Wuxi Lead Precision Machinery has delivered critical components for Olympic-standard applications and precision-engineered parts for military-grade systems. These projects demanded not only extreme accuracy but also full traceability, rigorous testing, and adherence to international quality standards. The same engineering rigor we apply to aerospace and defense programs is extended to our plastic mold making services. Whether producing molds for medical devices, automotive components, or consumer electronics, we treat every project with the same level of technical scrutiny.

Our facility is equipped with state-of-the-art 5-axis machining centers, high-precision EDM systems, and laser measurement tools that ensure tolerances are held within ±0.002 mm. Every mold undergoes comprehensive inspection using coordinate measuring machines (CMM) and 3D scanning to validate conformity to design specifications.

| Specification | Capability |

|---|---|

| Maximum Mold Size | 2000 x 1500 x 1200 mm |

| Minimum Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 µm (mirror polish available) |

| Materials Supported | P20, 718, NAK80, H13, S136, Stainless Steel, Aluminum |

| Machining Equipment | 5-Axis CNC, EDM, High-Speed Milling, CNC Lathes |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) |

| Lead Time (Typical) | 4–8 weeks, based on complexity |

Precision in plastic mold making is not a singular achievement—it is the culmination of expertise, technology, and relentless attention to detail. At Wuxi Lead Precision Machinery, our proven track record in mission-critical manufacturing ensures that our clients receive molds engineered for performance, durability, and flawless repeatability.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Plastic Molds

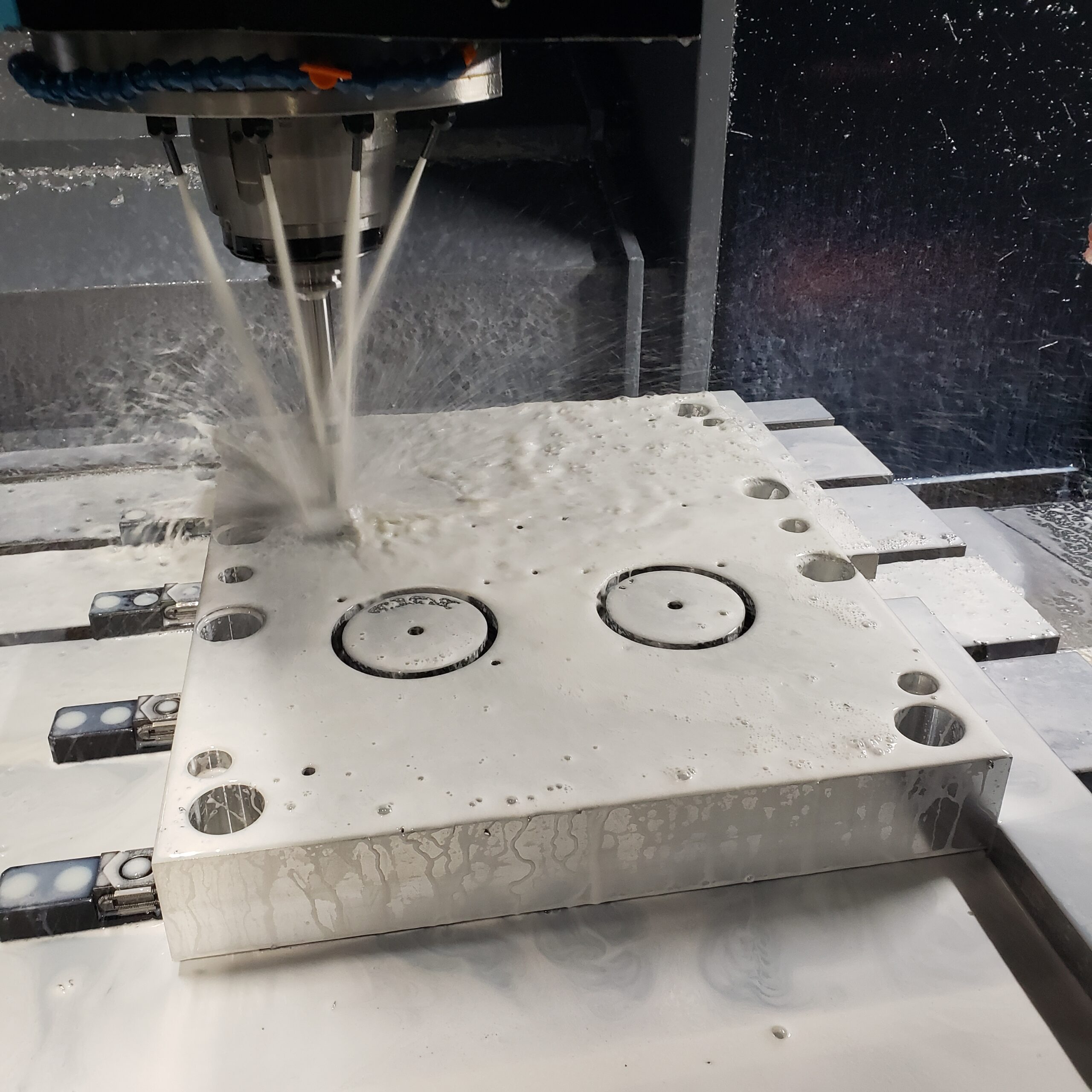

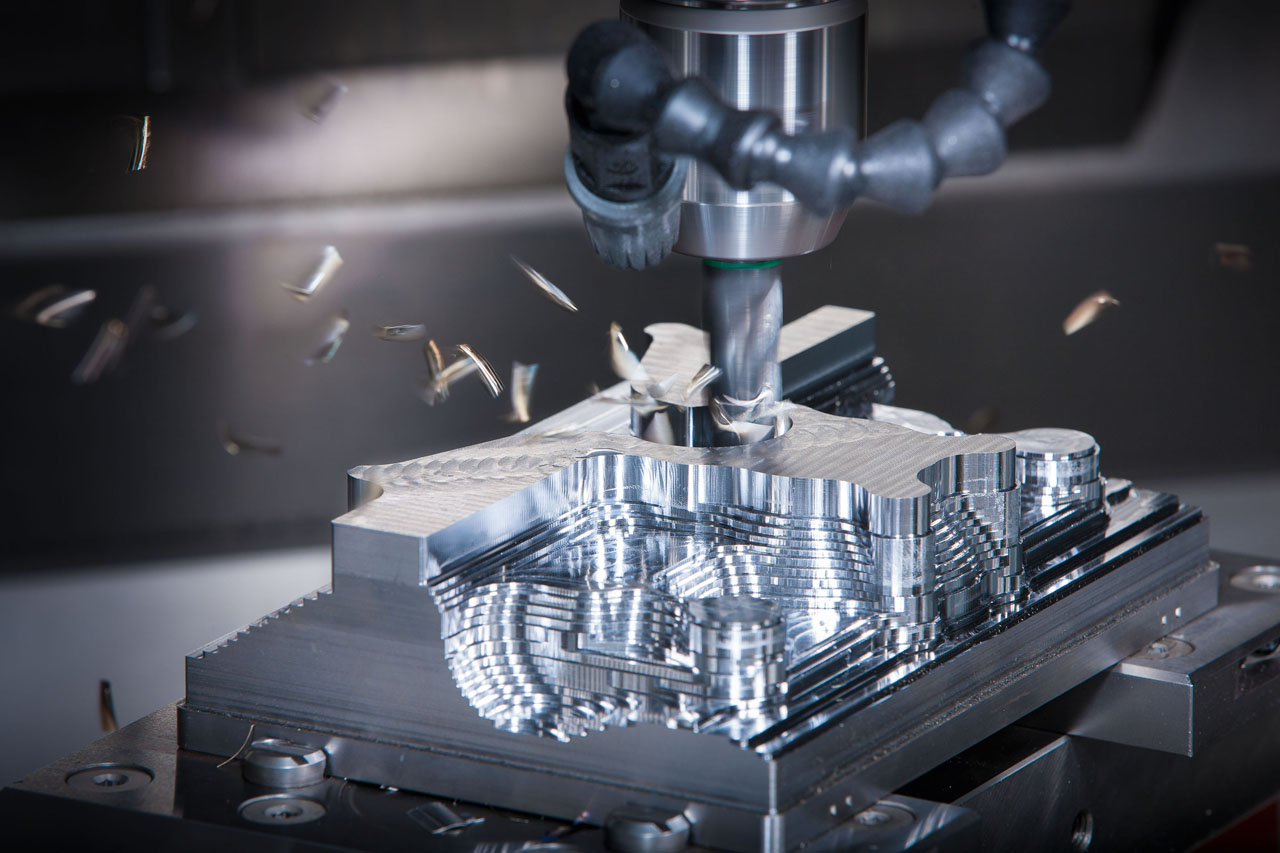

Wuxi Lead Precision Machinery delivers uncompromising precision for complex plastic injection molds through integrated advanced manufacturing and metrology systems. Our core strength lies in mastering the intricate geometries and stringent tolerances demanded by high-cavitation, multi-component, and micro-mold applications. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers, featuring high-torque spindles, sub-micron positioning accuracy, and dynamic toolpath optimization. These systems enable simultaneous multi-surface machining of hardened steel and aluminum mold bases, cavities, and cores in a single setup. This eliminates cumulative alignment errors inherent in 3-axis processes, drastically reduces lead times, and ensures perfect feature relationships critical for zero-defect molding performance. Complex undercuts, organic cooling channels, and fine surface textures are achieved with exceptional repeatability, directly translating to superior part quality and extended mold life for our clients.

Quality is not inspected in but engineered in at every stage. Our dedicated Coordinate Measuring Machine (CMM) laboratory operates under strict ISO 17025 guidelines, utilizing high-precision Zeiss and Hexagon systems for comprehensive first-article and in-process verification. Capable of full 3D geometric dimensioning and tolerancing (GD&T) analysis down to ±0.0005 mm, our CMMs validate critical mold features including cavity wall thickness consistency, ejector pin alignment, slide mechanisms, and parting line flatness. This metrology backbone ensures dimensional integrity across the entire mold assembly, preventing costly mold trials and production delays. All inspection data is digitally archived, providing full traceability and facilitating rapid root-cause analysis for continuous improvement.

Material expertise complements our equipment. We specialize in machining pre-hardened P20, H13, S136 stainless, and exotic tool steels, applying proprietary cutting strategies and coolant management to minimize thermal distortion and maximize surface finish. Our engineers collaborate closely with clients during the design-for-manufacturability phase, leveraging decades of mold-making insight to optimize part geometry, gating, and cooling for manufacturability without sacrificing performance.

The following table details our standard achievable tolerance capabilities for critical mold components, reflecting our commitment to precision exceeding typical industry benchmarks:

| Feature Type | Standard Capability (Metric) | Standard Capability (Imperial) | Typical Application Context |

|---|---|---|---|

| Cavity/ Core Profile | ±0.005 mm | ±0.0002 in | High-precision optical, medical parts |

| Parting Line Flatness | 0.003 mm per 100 mm | 0.0001 in per 4 in | Multi-cavity molds, thin-wall parts |

| Pin Bore Alignment | ±0.002 mm | ±0.00008 in | Ejector systems, core pulls |

| General Machining | ±0.010 mm | ±0.0004 in | Mold bases, non-critical interfaces |

These specifications represent our routine production capability under controlled conditions per ISO 2768 medium tolerance class, with tighter tolerances achievable for mission-critical features through specialized processes. Every mold leaving our facility undergoes rigorous dimensional validation against client CAD data, ensuring seamless integration into global production lines. Partner with Wuxi Lead to transform complex mold designs into reliable, high-yield manufacturing assets.

Material & Finish Options

Material Selection for High-Precision Plastic Mold Making

Selecting the appropriate material for plastic mold manufacturing is critical to ensuring performance, longevity, and cost-efficiency in production. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on precision-engineered molds tailored to specific application demands. The most commonly used materials in our mold fabrication are aluminum, steel, and titanium, each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is widely favored for low- to medium-volume production due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle times in injection molding. Additionally, aluminum’s lightweight nature simplifies mold handling and reduces wear on molding equipment. While not as durable as steel, modern high-grade aluminum alloys such as 7075 and 6061 provide sufficient strength and wear resistance for thousands of cycles when properly treated.

Steel remains the standard for high-volume production molds. Tool steels like P20, H13, and S136 offer superior hardness, wear resistance, and dimensional stability under prolonged use. These properties make steel ideal for complex molds requiring tight tolerances and long service life. Hardened steel molds can endure millions of cycles, especially when used in aggressive molding environments involving abrasive or corrosive resins.

Titanium, though less common, is gaining traction in specialized applications where extreme durability, corrosion resistance, and high strength-to-density ratios are required. While significantly more expensive and challenging to machine, titanium molds are ideal for aerospace, medical, and defense applications where performance under extreme conditions is non-negotiable.

Surface finish plays a pivotal role in mold performance and part quality. Anodizing is one of the most effective finishing processes for aluminum molds. It enhances surface hardness, improves wear resistance, and provides excellent corrosion protection. Type II (sulfuric acid) anodizing is typically used for general-purpose molds, while Type III (hard anodizing) delivers a thicker, denser oxide layer suitable for high-wear environments.

Below is a comparative overview of key properties for common mold materials used in precision manufacturing.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 30–35 | 310 | 167 | Prototypes, low-volume runs | Anodizing (Type II/III) |

| Aluminum 7075 | 35–40 | 570 | 130 | Medium-volume, high-stress | Hard Anodizing |

| P20 Steel | 28–32 | 900 | 36 | High-volume production | Polishing, Nitriding |

| H13 Steel | 48–52 | 1,500 | 30 | Hot-runner systems | PVD Coating, Chrome Plating |

| S136 Steel | 50–54 | 1,400 | 25 | Corrosive environments | Electropolishing |

| Titanium (Grade 5) | 36–40 | 900 | 7.2 | Aerospace, medical | TiN Coating, Anodizing |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production goals, resin type, and environmental exposure. Our engineering team ensures every mold is optimized for performance, durability, and cost-effectiveness.

Manufacturing Process & QC

Precision Mold Manufacturing: Design to Defect-Free Production

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production process for custom plastic injection molds, engineered to eliminate defects before they reach your production floor. Our methodology integrates advanced metal manufacturing with systematic validation, ensuring every mold delivers consistent part quality from the first shot to the millionth cycle.

The process begins with collaborative Design Engineering. Our team partners with your engineers to analyze part geometry, material flow, and ejection dynamics using Moldflow simulation. Critical focus areas include gate placement optimization, cooling channel efficiency, and tolerance stack-up analysis. We prioritize manufacturability by resolving potential stress points and warpage risks in the digital phase, reducing physical iterations. All designs undergo thermal stability validation to prevent deformation under high-cycle production conditions.

Prototyping transitions digital models into tangible validation. We fabricate prototype molds using the same hardened tool steels (e.g., H13, S136) and CNC processes as full production tools. This phase employs our 5-axis grinding centers to achieve ±0.001mm cavity accuracy, followed by rigorous testing:

First-article inspection against 3D CAD with CMM metrology

Mold flow analysis using actual production resins

Pressure and temperature mapping across 50+ cycles

Ejection force and part conformity validation

Defect root causes—such as sink marks or flash—are traced to mold geometry or process parameters, not material inconsistencies. Only when prototype parts meet all dimensional and cosmetic specifications do we approve tooling for mass production.

Mass Production leverages our zero-defect manufacturing ecosystem. Each mold undergoes:

Hard milling and EDM with in-process laser probing for real-time tolerance correction

Mirror polishing to SPI-A1 standards using robotic finishing cells

Cavity pressure monitoring during final assembly testing

72-hour continuous runtime validation under production-equivalent conditions

Our quality gates include 100% optical inspection of critical features and automated surface defect scanning. Statistical process control (SPC) data from every machining step is archived, enabling traceability to the micron level.

This disciplined approach ensures molds arrive production-ready, minimizing your startup delays and scrap rates. Zero defects isn’t aspirational—it’s contractual.

Critical Mold Base Specifications for Zero-Defect Performance

| Parameter | Standard Tolerance | Wuxi Lead Precision Standard | Verification Method |

|---|---|---|---|

| Cavity Flatness | ±0.015mm | ±0.003mm | Laser interferometer |

| Core Alignment | ±0.020mm | ±0.005mm | Coordinate measuring machine |

| Cooling Channel Position | ±0.10mm | ±0.02mm | X-ray tomography |

| Ejection Pin Clearance | 0.05-0.10mm | 0.01-0.03mm | Air gaging |

| Surface Roughness (Cavity) | Ra 0.4µm | Ra 0.05µm | Profilometer |

By embedding precision at every phase—from simulation to final validation—we transform mold manufacturing from a cost center into your competitive advantage. Partner with us to convert design intent into flawless production reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are the cornerstones of success in the plastic mold making industry. As a trusted leader in custom metal manufacturing based in Wuxi, China, we specialize in delivering high-precision CNC-machined components tailored to the exacting demands of mold makers worldwide. Our advanced manufacturing capabilities, combined with decades of engineering experience, enable us to support complex mold fabrication with accuracy down to ±0.002 mm and superior surface finishes that meet the highest international standards.

We serve global clients across automotive, medical, consumer electronics, and industrial equipment sectors, providing end-to-end solutions from design consultation to final production. Our state-of-the-art facility is equipped with multi-axis CNC machining centers, wire EDM, grinding machines, and comprehensive quality inspection systems, ensuring every component meets stringent tolerance and durability requirements. Whether you require hardened steel inserts, precision cavities, or complex core pins, our team applies material science and process optimization to deliver mold components that enhance performance and extend tool life.

Our commitment to excellence is reflected in every stage of production. We utilize premium-grade tool steels such as P20, 718H, S136, and H13, selected based on your application’s thermal, corrosive, and wear conditions. With in-house heat treatment and surface coating options including nitriding and PVD, we ensure dimensional stability and resistance to wear and deformation under high-cycle molding operations.

We recognize that time-to-market is critical. That’s why our streamlined workflow integrates rapid prototyping, real-time process monitoring, and agile project management to reduce lead times without compromising quality. Every project is managed by a dedicated engineering team that collaborates closely with your design and manufacturing staff, ensuring seamless communication and technical alignment.

Our clients choose Lead Precision not only for our technical capabilities but also for our customer-centric approach. We act as a true manufacturing partner—proactive, responsive, and committed to solving challenges before they impact your production.

Partner with us to elevate your mold-making capabilities with precision-engineered metal components built to perform.

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 μm (polished options available) |

| Materials | P20, 718H, S136, H13, 420SS, Aluminum 7075/T6, Brass |

| Max Workpiece Size | 1200 x 800 x 600 mm |

| Processes | CNC Milling, CNC Turning, Wire EDM, Surface Grinding, Boring |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection (FAI), CMM Reporting |

| Lead Time | 10–25 days (varies by complexity and volume) |

Contact us today to discuss your next mold project. Email [email protected] and connect with our engineering team for a detailed consultation and quotation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.