Technical Contents

Engineering Guide: French Moulding

Engineering Insight: French Moulding and the Imperative of Precision

French moulding, often referred to in high-precision metal manufacturing circles as a specialized form of decorative or functional profile forming, demands an exceptional level of engineering accuracy. Unlike standard stamping or bending processes, french moulding involves the controlled deformation of metal along a narrow, elongated channel—typically used for aesthetic detailing, edge reinforcement, or integration with sealing systems. This process requires not only advanced tooling design but also micron-level consistency in force application and material flow. At Wuxi Lead Precision Machinery, we recognize that the success of french moulding lies not in the concept, but in its flawless execution.

The complexity of french moulding arises from its dual requirement: structural integrity and visual refinement. A deviation of even 0.05 mm in depth or width can result in misalignment during assembly, compromised sealing performance, or unacceptable surface finish. Materials such as stainless steel, aluminum alloys, and high-tensile carbon steels react differently under localized stress, making real-time monitoring and adaptive control systems essential. Our CNC-controlled press technologies integrate closed-loop feedback mechanisms, ensuring that each stroke conforms precisely to the digital blueprint, batch after batch.

Wuxi Lead Precision Machinery has spent over 15 years refining this capability, serving industries where failure is not an option. Our involvement in mission-critical projects—including components for Olympic-grade sports infrastructure and precision enclosures for military communication systems—has honed our ability to deliver french moulded parts that meet ISO 2768-mK and MIL-STD-810 standards. These projects demanded not only repeatability but also full traceability, from raw material certification to final inspection reports.

Our engineering team employs finite element analysis (FEA) during the tooling design phase to simulate material behavior and preempt defects such as micro-cracking or springback. This predictive approach, combined with in-die sensing and automated dimensional verification, ensures that every french moulded profile exceeds client expectations.

Below are key technical specifications that define our french moulding capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 3.0 mm |

| Tolerance Accuracy | ±0.03 mm (standard), ±0.01 mm (tight) |

| Minimum Bend Radius | 0.3 mm (depending on material) |

| Surface Roughness (Ra) | ≤0.8 µm (polished tooling) |

| Max Part Length | 2,000 mm |

| Production Speed | Up to 40 strokes/minute (automated line) |

| Compatible Materials | SS304, SS316, AL5052, DC01, CR1045 |

Precision in french moulding is not merely a technical benchmark—it is a commitment to performance, safety, and longevity. At Wuxi Lead Precision Machinery, we combine decades of applied research with real-world validation to ensure that every formed profile meets the highest standards of modern manufacturing.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

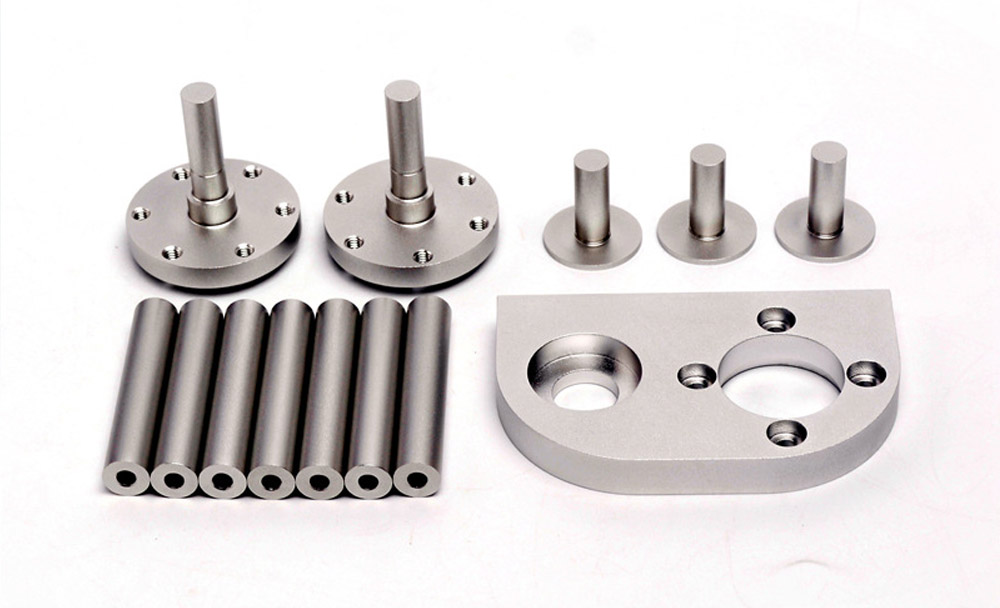

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal manufacturing, specifically engineered for complex, high-value components where dimensional accuracy and surface integrity are non-negotiable. Our core strength lies in integrating advanced multi-axis machining with rigorous metrology, ensuring every part meets the most stringent aerospace, medical, and industrial automation specifications. We specialize in transforming challenging materials like titanium alloys, Inconel, and hardened steels into mission-critical components, leveraging deep process expertise to overcome geometric complexity and thermal stability hurdles inherent in precision molding and forming applications.

Our 5-axis CNC machining center forms the technological backbone of this capability. Utilizing state-of-the-art HAAS UMC-750 and DMG MORI CTX beta 1250 systems, we achieve complete part consolidation in a single setup. This eliminates cumulative error from multiple fixtures, enabling the production of intricate organic shapes, deep cavities, undercuts, and continuous multi-surface contours impossible with 3-axis technology. Simultaneous 5-axis interpolation ensures optimal tool engagement, minimizing vibration and thermal distortion while maximizing surface finish consistency down to Ra 0.4 µm. Advanced high-speed machining strategies and adaptive toolpathing allow efficient material removal rates even in the most difficult alloys, significantly reducing lead times without sacrificing precision.

Quality assurance is embedded at every process stage, not merely a final checkpoint. All critical dimensions undergo comprehensive verification using calibrated Zeiss CONTURA G2 Coordinate Measuring Machines (CMM). Our AS9100-certified inspection protocols employ certified metrologists who perform full first-article inspections (FAI) per AS9102 standards and conduct in-process checks based on real-time SPC data. This systematic approach validates geometric dimensioning and tolerancing (GD&T), complex profile tolerances, and positional accuracy against the original CAD model, providing traceable certification packages essential for regulated industries. Material certifications and heat treatment documentation are rigorously maintained.

The following table details our standard achievable tolerance capabilities under controlled production conditions for machined features:

| Feature Type | Standard Capability | Tight Capability (Special Process) | Measurement Method |

|---|---|---|---|

| Linear Dimension | ±0.010 mm | ±0.005 mm | CMM, Micrometer |

| Geometric (Flatness) | 0.015 mm | 0.008 mm | CMM, Optical Flat |

| Geometric (Roundness) | 0.008 mm | 0.004 mm | CMM, Roundness Tester |

| Positional (Holes) | ±0.012 mm | ±0.006 mm | CMM |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

These capabilities directly support the production of high-precision mold cores, cavities, ejector systems, and structural frames requiring micron-level repeatability. Whether manufacturing turbine blade fixtures demanding thermal stability or medical implant molds requiring biocompatible surface finishes, our integrated CNC and metrology infrastructure guarantees conformance to the most exacting international standards. We partner with clients from initial DFM analysis through final validation, ensuring technical feasibility and cost-effective manufacturability for every French molding or precision metal component project.

Material & Finish Options

Material Selection for High-Precision French Moulding Applications

In the domain of custom metal manufacturing, particularly for French moulding components used in high-end industrial and architectural applications, material selection is a critical determinant of performance, longevity, and aesthetic quality. At Wuxi Lead Precision Machinery, we specialize in precision-engineered solutions that meet exacting European standards, including those required by the French market. Our expertise enables us to guide clients through optimal choices between aluminum, steel, and titanium—each offering distinct mechanical properties and finishing compatibility.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability, making it ideal for decorative and structural moulding where weight reduction and precision are paramount. It is especially well-suited for anodizing, a process that enhances surface durability and allows for color customization—critical in architectural applications demanding both elegance and resilience. Aluminum 6061-T6 and 6063-T5 are commonly specified grades due to their balanced properties and extrudability.

Steel, particularly in stainless variants such as 304 and 316, offers superior strength and wear resistance. It is preferred in environments where mechanical loading or exposure to harsh conditions necessitates robust material performance. While heavier than aluminum, stainless steel provides exceptional longevity and maintains structural integrity under stress. Its surface can be treated with polishing, brushing, or PVD coatings, though it is not suitable for anodizing in the same way as aluminum.

Titanium, though less common due to cost, delivers unmatched strength-to-density performance and extraordinary resistance to corrosion, including in marine and chemically aggressive environments. Its use in French moulding is typically reserved for high-performance sectors such as aerospace or luxury façade systems where long-term reliability justifies investment. Titanium requires specialized machining but can be finished with bead blasting or passivation to achieve a refined, durable surface.

Anodizing remains a premier surface treatment for aluminum components, creating a hard, porous oxide layer that improves wear and corrosion resistance while enabling integration of colorants for design consistency. Type II (sulfuric acid) anodizing is standard for architectural mouldings, while Type III (hardcoat) is used where extreme surface hardness is required.

Below is a comparative overview of key material properties relevant to French moulding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | High | Yes | Architectural trim, decorative profiles |

| Stainless Steel 304 | 8.0 | 505–585 | Very High | No | Structural supports, high-wear components |

| Stainless Steel 316 | 8.0 | 515–620 | Excellent (chloride) | No | Marine-facing mouldings, coastal installations |

| Titanium Grade 5 | 4.4 | 900 | Exceptional | No (but oxide stable) | Aerospace, high-end façades |

Material selection must align with functional requirements, environmental exposure, and aesthetic goals. Wuxi Lead Precision Machinery supports clients in evaluating these factors to deliver moulding solutions that combine precision, durability, and design excellence—fully compliant with French and EU manufacturing standards.

Manufacturing Process & QC

Precision French Moulding: From Concept to Zero-Defect Production

French moulding, a specialized precision metal forming process for complex geometries, demands an integrated engineering approach to achieve zero-defect outcomes. At Wuxi Lead Precision Machinery, we execute this through a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase incorporates fail-safes to eliminate errors before components reach the customer.

The process begins with collaborative design engineering. Our team conducts deep-dive feasibility studies, analyzing material behavior, tooling stresses, and thermal dynamics specific to French moulding. Using advanced simulation software, we model metal flow and predict potential defects like micro-cracks or dimensional drift. Critical tolerance stacks are validated against ISO 2768-mK standards, ensuring manufacturability before any metal is cut. This phase includes Design for Manufacturing (DFM) reviews with the client, aligning on non-negotiable quality parameters and surface finish requirements (Ra ≤ 0.8 µm).

Prototyping transitions theory into tangible validation. We produce 3–5 first-article units using production-intent tooling, not soft prototypes. Each unit undergoes full-spectrum metrology: CMM scans verify geometric dimensioning against 3D CAD models, while optical comparators inspect critical radii and undercuts inherent to French moulding profiles. Material integrity is confirmed via micro-hardness testing and cross-sectional analysis. Any deviation triggers immediate root-cause analysis—adjusting press tonnage, lubrication cycles, or dwell time—and the prototype loop repeats until statistical process capability (Cpk ≥ 1.67) is proven. This stage guarantees that the mass production blueprint is defect-proof.

Mass production leverages closed-loop control systems to maintain prototype-level perfection. Our CNC hydraulic presses operate with real-time force-displacement monitoring, automatically rejecting parts outside ±0.005 mm tolerance bands. In-process SPC (Statistical Process Control) charts track key characteristics like wall thickness consistency and edge burr levels every 15 minutes. Automated vision systems inspect 100% of output for surface anomalies, while batch traceability links each component to specific tooling sets, material lots, and operator logs. This integrated framework ensures zero escapes, with final inspection validating compliance against the client’s exact specifications.

Wuxi Lead’s methodology transforms French moulding from a high-risk process into a predictable, high-yield operation. By embedding quality at every stage—not as a checkpoint but as the core process driver—we deliver components that meet aerospace, medical, and semiconductor standards where failure is not an option.

Key Production Specifications for French Moulding

| Parameter | Capability Range | Control Standard |

|————————-|————————|———————-|

| Material Thickness | 0.1 mm – 3.0 mm | ASTM A568M |

| Geometric Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.2 µm – 1.6 µm | ISO 1302 |

| Production Volume | 1,000 – 500,000+ pcs | Lot Traceability |

| Cycle Time | 15–90 seconds | Real-Time SPC |

| First-Pass Yield | ≥ 99.85% | Zero-Defect Protocol |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in French Moulding and Custom Metal Manufacturing

When precision, consistency, and engineering excellence define your production standards, partnering with Wuxi Lead Precision Machinery becomes a strategic advantage. As a leading provider of custom metal manufacturing solutions based in China, we specialize in advanced French moulding techniques—delivering high-tolerance components that meet the rigorous demands of aerospace, automotive, medical, and industrial equipment sectors. Our engineering-driven approach ensures every project is executed with the highest level of technical accuracy and material integrity.

French moulding, known for its ability to produce complex geometries with superior surface finish and dimensional stability, requires more than just advanced machinery—it demands deep metallurgical knowledge, process control, and a commitment to quality. At Lead Precision, we combine state-of-the-art CNC forming, precision stamping, and automated inspection systems with decades of hands-on experience to deliver moulded metal components that perform under extreme conditions. Whether you’re prototyping a new design or scaling high-volume production, our team works closely with your engineers to optimize material selection, tooling design, and process parameters for maximum efficiency and reliability.

Our facility in Wuxi is equipped with ISO 9001-certified quality systems and supports full traceability from raw material to final inspection. We utilize real-time monitoring and statistical process control (SPC) to ensure every batch meets your exact specifications. With in-house tooling design, rapid prototyping, and lean manufacturing principles, we reduce lead times without compromising on precision.

We understand that every client’s needs are unique. That’s why we offer fully customizable manufacturing pathways—tailored to your product lifecycle, volume requirements, and performance criteria. From low-carbon steels to high-strength alloys, our material expertise ensures optimal performance in demanding environments.

Below are key technical capabilities that define our French moulding and custom metal manufacturing services:

| Specification | Detail |

|---|---|

| Material Types | Stainless Steel, Aluminum Alloys, Carbon Steel, Copper Alloys, Titanium |

| Tolerance Range | ±0.02 mm to ±0.1 mm (depending on geometry and size) |

| Maximum Part Size | 1200 mm × 800 mm × 300 mm |

| Minimum Wall Thickness | 0.5 mm (aluminum), 0.8 mm (steel) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (custom finishes available) |

| Production Capacity | Up to 500,000 units per month |

| Quality Standards | ISO 9001:2015, RoHS compliant, Full PPAP documentation |

| Secondary Operations | Heat treatment, plating, coating, laser marking, assembly |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we build long-term manufacturing partnerships. Our global client base trusts us for technical agility, on-time delivery, and responsive engineering support throughout the product lifecycle.

To discuss your French moulding requirements or request a detailed quote, contact us today at [email protected]. Let Lead Precision be your trusted partner in high-precision metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.