Technical Contents

Engineering Guide: Moulded Polystyrene

Engineering Insight: The Role of Precision in moulded polystyrene Applications

In high-performance industrial sectors such as aerospace, defense, and advanced consumer goods, the integration of moulded polystyrene components demands an exceptional level of precision in supporting tooling and metal manufacturing processes. While polystyrene itself is a lightweight thermoplastic often used for insulation, packaging, and prototyping, its molding process relies heavily on precisely engineered metal tooling systems—typically produced through CNC machining, stamping, or die casting. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal components that serve as the backbone for high-accuracy polystyrene molding operations, ensuring repeatability, dimensional stability, and performance under production-scale conditions.

The success of a moulded polystyrene part begins not with the plastic, but with the metal tooling used to shape it. Even minor deviations in mold geometry—measured in microns—can result in warping, incomplete fills, or part rejection. This is particularly critical in applications where polystyrene is used for structural insulation in military shelters or lightweight components in transportation systems. In such cases, consistency across thousands of units is non-negotiable. Our engineering team applies tight-tolerance machining standards, often holding tolerances within ±0.005 mm, to produce molds, inserts, and support fixtures that maintain integrity over extended production cycles.

Wuxi Lead Precision Machinery brings over 15 years of experience in serving mission-critical industries, including direct contributions to projects aligned with Olympic infrastructure developments and military-grade equipment manufacturing. These engagements required not only adherence to ISO and MIL-SPEC standards but also the ability to innovate under stringent regulatory and performance demands. Our work in support of polystyrene molding systems has included the fabrication of temperature-controlled mold plates with integrated cooling channels, precision ejector pin systems, and hardened cavity inserts resistant to thermal fatigue.

We understand that the efficiency of a molding operation is directly tied to the quality of its metal components. Surface finish, material selection, and thermal conductivity all play pivotal roles in cycle time and part quality. By leveraging advanced alloys such as P20 and H13 tool steels, and applying surface treatments like nitriding or chrome plating, we extend mold life and reduce maintenance downtime.

The following table outlines key specifications for our custom tooling systems used in polystyrene molding applications.

| Specification | Detail |

|---|---|

| Material Options | P20, H13, 718H Tool Steels, Aluminum 7075 |

| Machining Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.1 – 0.8 µm (polished to mirror finish upon request) |

| Maximum Part Size | 2000 mm × 1200 mm × 800 mm |

| Heat Treatment | Up to 52 HRC (customizable) |

| Cooling System Integration | Multi-channel, conformal cooling design |

| Coating Options | TiN, CrN, Electroless Nickel, Hard Chrome |

Precision in moulded polystyrene production is not an outcome—it is engineered. At Wuxi Lead Precision Machinery, we ensure that every metal component we deliver contributes to that precision, enabling our clients to achieve flawless replication, reduced waste, and superior end-product performance.

Precision Specs & Tolerances

Technical Capabilities for Precision Metal Components in Polystyrene Molding Applications

Wuxi Lead Precision Machinery delivers critical metal fabrication solutions for advanced polystyrene molding systems. While polystyrene itself is a polymer, our expertise lies in manufacturing the high-precision metal tooling, inserts, cavities, and structural components essential for injection, extrusion, and thermoforming processes involving moulded polystyrene. Our capabilities directly address the stringent dimensional stability, thermal management, and surface finish requirements demanded by this sector. We bridge the gap between polymer processing needs and uncompromising metal component performance.

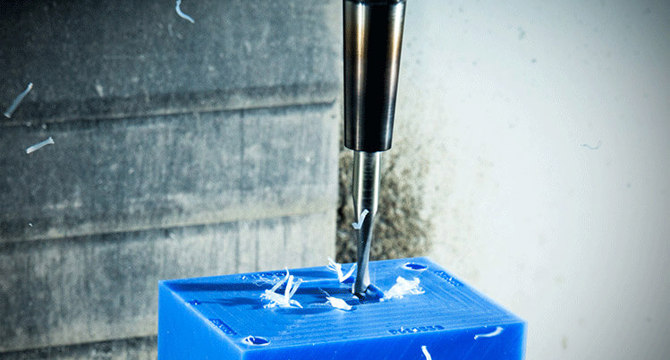

Our core strength resides in multi-axis CNC machining, specifically leveraging 5-axis technology. This allows us to produce complex geometries found in mould cores, cavities, and cooling channels with exceptional accuracy and reduced setup times. The simultaneous movement across five axes ensures intricate contours and undercuts are machined in a single operation, minimizing cumulative error and enhancing part repeatability. This is paramount for polystyrene moulds where even micron-level deviations can cause part flash, warpage, or ejection issues. We machine a wide range of tool steels, aluminum alloys, and specialty materials optimized for thermal conductivity and wear resistance in demanding molding environments.

Precision is non-negotiable in mould tooling. Our machining processes consistently achieve tight tolerances critical for polystyrene part integrity and mould longevity. The following table details our standard achievable specifications for critical features in mould components:

| Feature Category | Standard Tolerance | Precision Tolerance | Surface Finish (Ra) |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | 0.8 µm |

| Geometric Features | 0.015 mm | 0.008 mm | 0.4 µm |

| Critical Mating Surfaces | ±0.005 mm | ±0.002 mm | 0.2 µm |

| Hole Positioning | ±0.008 mm | ±0.003 mm | 0.4 µm |

Rigorous quality control is integral to our process, not an afterthought. Every critical component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs provide traceable, sub-micron level verification of dimensional accuracy, form, and positional relationships against the original CAD model. This data-driven approach guarantees that every metal part shipped meets the exact specifications required for seamless integration into polystyrene molding equipment, preventing costly downtime or part rejection downstream. We provide full inspection reports, including GD&T analysis, for complete transparency.

Wuxi Lead transforms design intent into flawless metal reality for polystyrene molding applications. Our 5-axis CNC mastery, coupled with uncompromising CMM validation, ensures the metal components underpinning your moulded polystyrene production deliver the precision, durability, and thermal performance essential for high-yield, high-quality output. Partner with us to eliminate tooling-related defects and optimize your polystyrene manufacturing process.

Material & Finish Options

Material Selection for High-Precision Moulded Polystyrene Tooling

In the production of moulded polystyrene components, the choice of tooling material is critical to ensuring dimensional accuracy, surface finish quality, and production longevity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-demand industrial applications, and our expertise enables us to guide clients through optimal material selection based on application requirements, volume, and environmental conditions.

Aluminum is frequently the preferred choice for prototyping and low-to-medium volume production runs. Its high thermal conductivity allows for faster cooling cycles, improving throughput during polystyrene molding. Additionally, aluminum is easier to machine, enabling complex geometries with tight tolerances. However, its lower hardness compared to steel limits its use in high-wear environments. For applications requiring enhanced durability while retaining thermal efficiency, we recommend hardened aluminum alloys such as 7075-T6.

Steel, particularly tool steel grades like P20 and H13, offers superior wear resistance and longevity, making it ideal for high-volume production. These steels maintain dimensional stability under repeated thermal cycling, a critical factor in polystyrene molding where consistent cavity integrity is essential. While steel has lower thermal conductivity than aluminum, proper cooling channel design can mitigate this limitation. For aggressive molding environments or corrosive additives in polystyrene compounds, stainless tool steels provide additional resistance to pitting and degradation.

Titanium is used selectively in specialized tooling applications where extreme strength-to-density ratio and corrosion resistance are paramount. Though not common in standard polystyrene molds due to cost and machining complexity, titanium finds use in insert components or high-stress structural elements within larger tool assemblies. Its biocompatibility and non-reactive surface also make it suitable for medical-grade polystyrene products.

Surface finish plays a significant role in part ejection, surface quality, and mold maintenance. Anodizing is a highly effective finish for aluminum molds, providing a hard, wear-resistant oxide layer that improves release properties and reduces galling. Type II (sulfuric acid) anodizing is standard for decorative and protective applications, while Type III (hardcoat anodizing) delivers thicker, more durable coatings suitable for industrial tooling. For steel molds, alternatives such as chrome plating or nitriding are typically employed, though anodizing remains exclusive to aluminum substrates.

Below is a comparison of key material properties relevant to moulded polystyrene tooling:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Common Finish |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | Prototyping, medium runs | Hardcoat Anodizing |

| P20 Tool Steel | 28–32 | 30 | High-volume production | Chrome Plating |

| H13 Tool Steel | 48–52 | 32 | High-temperature molding | Nitriding |

| Titanium Grade 5 | 36–40 | 7 | Specialized inserts, medical | None (as-machined) |

Selecting the appropriate material and finish directly impacts cycle time, part quality, and total cost of ownership. At Wuxi Lead Precision Machinery, we collaborate closely with clients to engineer tooling solutions optimized for performance and efficiency in polystyrene molding applications.

Manufacturing Process & QC

Precision Metal Tooling for Moulded Polystyrene Production

While polystyrene forms the end product, Wuxi Lead Precision Machinery engineers the critical metal tooling that defines its quality, consistency, and defect-free output. Our end-to-end process begins with integrated design, where cross-functional teams collaborate on manufacturability analysis. We utilize advanced CAD/CAM software and mold flow simulation to preempt sink marks, warpage, or knit lines inherent in polystyrene molding. This phase rigorously validates gate locations, cooling channel geometry, and ejection sequences against material viscosity and thermal properties, ensuring optimal cavity filling and minimal residual stress. Design sign-off requires simulation data confirming cycle time feasibility and dimensional stability within micron-level tolerances.

Prototyping transitions virtual models into physical validation. We deploy rapid steel machining for pre-hardened tool inserts, enabling functional testing under actual production parameters. Each prototype run undergoes metrological inspection via CMM and optical comparators, measuring critical dimensions against CAD data. Polystyrene’s sensitivity to temperature gradients demands iterative adjustments; we fine-tune melt temperatures, injection speeds, and cooling rates based on real-time cavity pressure sensor feedback. This phase identifies microscopic flaws—such as short shots or surface blemishes—before committing to full-scale tooling, reducing downstream rework by up to 70%.

Mass production leverages hardened, P20 or H13 steel molds built to ISO 2768-mK standards, featuring conformal cooling channels for uniform thermal management. Our CNC-machined cavities and cores maintain surface finishes down to Ra 0.2 µm, critical for glossy polystyrene aesthetics. In-process monitoring includes automated vision systems scanning every part for flash, discoloration, or dimensional drift. Statistical process control (SPC) tracks key variables like clamp tonnage and melt density, with AI-driven analytics predicting tool wear before defects occur. All production adheres to AQL 0.65 sampling, with 100% traceability via laser-etched part IDs linked to machine logs.

Zero Defects is achieved through this closed-loop methodology: design simulations prevent errors, prototyping validates solutions, and production monitoring enforces consistency. The result is polystyrene components meeting automotive or medical-grade reliability, with scrap rates consistently below 0.1%.

| Critical Parameter | Wuxi Lead Specification | Industry Standard | Quality Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm | ±0.05 mm | Ensures seamless assembly fit |

| Surface Roughness (Ra) | 0.2 µm | 0.8 µm | Eliminates post-mold polishing |

| Cycle Time Stability | ±0.8 seconds | ±2.5 seconds | Reduces thermal stress-induced warpage |

| Cavity Pressure Accuracy | ±1.5 bar | ±4.0 bar | Prevents short shots and flash formation |

| Tool Hardness (HRC) | 48–52 | 40–45 | Extends tool life beyond 500K cycles |

This systematic approach transforms polystyrene molding from a variable process into a precision science, where every component exits the press meeting exacting functional and aesthetic requirements.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Custom Metal Manufacturing Solutions in Moulded Polystyrene Applications

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions tailored to the demanding requirements of the moulded polystyrene industry. With over 15 years of engineering excellence and a deep understanding of thermal processing systems, mold tooling, and structural components used in polystyrene molding, we provide OEMs and production facilities with reliable, durable, and performance-optimized metal components that ensure consistent output and operational efficiency.

Our expertise spans the entire manufacturing lifecycle—from initial design consultation and material selection to CNC machining, surface treatment, and final quality assurance. We understand that in the polystyrene molding sector, precision is non-negotiable. Components such as mold plates, heating manifolds, cooling inserts, and support frames must meet exact dimensional tolerances and thermal stability standards to prevent defects and maximize production uptime. That’s why every part we produce undergoes rigorous inspection using coordinate measuring machines (CMM) and laser scanning technologies, ensuring compliance with ISO 9001:2015 standards.

We work closely with engineers and project managers to develop solutions that enhance system longevity, reduce maintenance cycles, and improve thermal efficiency. Whether you require hardened tool steels for high-wear applications or aluminum alloys for lightweight, thermally conductive components, our in-house metallurgical analysis ensures optimal material pairing for your specific process conditions.

Our production facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC centers, wire EDM, and automated welding systems, enabling us to deliver complex geometries with tolerances as tight as ±0.005 mm. With a lead time efficiency that outperforms industry averages and a responsive project management team, we are positioned to support both prototype development and high-volume production runs.

Below are key specifications we routinely achieve for components used in moulded polystyrene machinery:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Maximum Part Size | 2000 × 1200 × 800 mm |

| Materials Processed | 42CrMo, P20, H13, 7075 Aluminum, Stainless Steel 304/316 |

| Surface Treatments | Hardening, Nitriding, Anodizing, Zinc Plating |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports |

| Production Capacity | 500+ tons/month |

| Lead Time (Average) | 15–25 days, depending on complexity |

We invite global partners in the plastics and packaging industries to collaborate with a manufacturer that combines technical precision with scalable production capability. Whether upgrading existing systems or developing next-generation molding equipment, Wuxi Lead Precision Machinery is your trusted partner in advanced metal fabrication.

Contact us today at [email protected] to discuss your project requirements and discover how our engineering team can support your manufacturing objectives with precision, reliability, and speed.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.