Technical Contents

Engineering Guide: Molding Desing

Engineering Insight: Precision as the Non-Negotiable Foundation of Molding Design

Precision in molding design transcends mere dimensional accuracy; it is the fundamental determinant of part functionality, longevity, and cost-effectiveness in high-stakes metal manufacturing. In applications demanding micron-level tolerances—such as aerospace actuators, medical implants, or defense optics—even microscopic deviations during the molding process can trigger catastrophic cascading failures. Material flow dynamics, thermal contraction rates, and cavity pressure distribution must be engineered with absolute predictability. Ignoring these factors leads to warpage, sink marks, internal stresses, or premature tool wear, transforming theoretical designs into costly scrap. At Wuxi Lead Precision Machinery, we treat precision not as a target but as a rigorously controlled output of our integrated design-to-manufacturing workflow. Our engineers model material behavior under extreme conditions, simulating fill patterns and solidification to preempt defects before a single chip is cut.

The consequences of imprecise molding design extend far beyond the shop floor. A 0.02mm tolerance variance in a hydraulic manifold can cause seal leakage at 5,000 PSI, grounding aircraft or halting production lines. Surface finish irregularities below Ra 0.4µm compromise biocompatibility in surgical instruments. These realities demand molding cavities and cores held to tolerances exceeding standard industry practices, requiring ultra-stable machine platforms, temperature-controlled environments, and real-time process monitoring. Our facility’s ISO 9001:2015 and AS9100D certifications are baseline requirements; true precision emerges from our proprietary adaptive control algorithms that compensate for thermal drift during extended production runs.

Wuxi Lead’s commitment to this standard is validated through mission-critical projects. We engineered molding solutions for components used in the Beijing Winter Olympics’ timing systems, where sub-millisecond synchronization depended on flawless metal part geometry. Similarly, our military-grade enclosures for satellite communication systems withstand extreme vibration and thermal cycling—proof that our molding precision meets specifications where failure is not an option. This expertise stems from 18 years of refining processes for clients who measure success in nanometers, not millimeters.

Critical molding precision parameters we consistently achieve include:

| Specification Category | Standard Capability | High-Precision Capability | Typical Application |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm | Aerospace actuators, optical mounts |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Medical implants, fluid seals |

| Material Utilization | 85% | 95%+ | High-cost alloys (Inconel, Ti-6Al-4V) |

| Cavity Pressure Control | ±5% | ±1.5% | Thin-wall electronics housings |

| Tool Lifespan | 50,000 cycles | 250,000+ cycles | High-volume defense components |

Achieving this level of consistency requires treating the mold as a dynamic system, not a static tool. We integrate mold flow analysis with CNC machining verification, ensuring cavity geometry compensates for predicted material behavior. Our engineers collaborate with clients during DFM stages to optimize gate locations, cooling channels, and ejection sequences—transforming potential weaknesses into strengths. When your application demands zero-defect molding, partner with a team whose precision is proven where global standards are merely the starting point. Demand engineering-grade precision. Demand Wuxi Lead.

Precision Specs & Tolerances

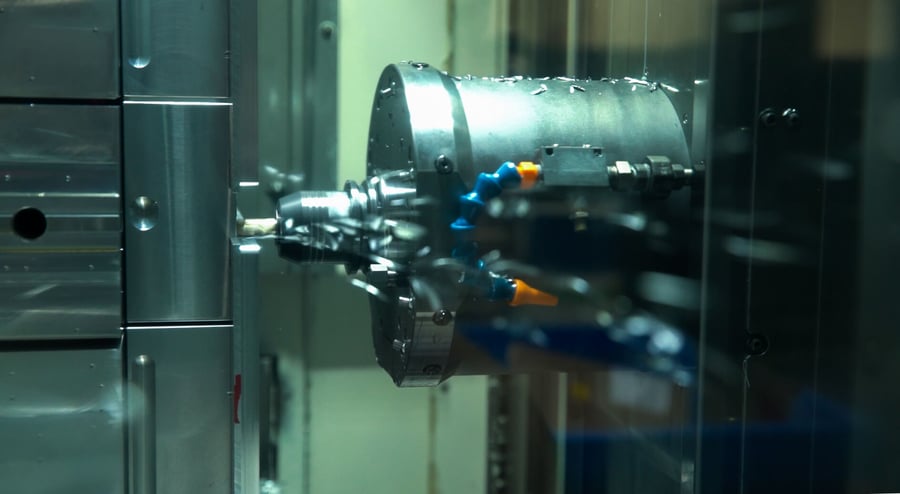

Advanced 5-Axis CNC Machining for Precision Mold Design

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the most demanding requirements in custom metal manufacturing, particularly within the field of precision mold design. Our core strength lies in high-accuracy 5-axis CNC machining, a technology that allows for the production of complex geometries with exceptional surface finish and dimensional stability. Unlike conventional 3-axis systems, our 5-axis platforms enable simultaneous movement across all five axes, allowing tools to approach the workpiece from virtually any angle. This capability is critical in mold design, where undercuts, compound curves, and intricate cavities are common. By minimizing setup changes and tool repositioning, we reduce cycle times, improve repeatability, and maintain tight tolerances across entire components.

Our machining centers are equipped with high-speed spindles, rigid thermal compensation systems, and advanced tool management software, ensuring consistent performance across long production runs. Materials such as hardened tool steels, aluminum alloys, stainless steels, and specialty alloys are routinely processed with precision and reliability. Whether producing prototype molds or high-volume production tooling, our 5-axis systems deliver the accuracy and efficiency required in modern mold manufacturing.

To ensure every component meets exacting standards, we integrate comprehensive quality control protocols throughout the production cycle. Central to our inspection process is the use of a Coordinate Measuring Machine (CMM), which provides non-contact and tactile measurement with micron-level accuracy. Each mold component undergoes full dimensional verification, including critical features such as cavity profiles, core alignment, cooling channel placement, and parting line integrity. The CMM generates detailed inspection reports, including GD&T analysis, which are provided to clients as part of our quality documentation. This data-driven approach ensures traceability, supports continuous process improvement, and guarantees compliance with international standards such as ISO 9001.

Our technical team combines decades of machining expertise with advanced CAD/CAM software to optimize toolpaths, reduce cycle times, and anticipate potential manufacturing challenges during the design phase. This proactive engineering support allows us to collaborate closely with clients, offering Design for Manufacturing (DFM) feedback that enhances mold functionality and longevity.

The following table outlines the standard precision tolerances we consistently achieve through our 5-axis CNC and quality assurance systems:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Angular Accuracy | ±0.05° | ±0.02° |

| Cavity Symmetry | ±0.012 mm | ±0.006 mm |

| Core Alignment | ±0.01 mm | ±0.005 mm |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner in high-end mold design and manufacturing, delivering precision, consistency, and technical excellence on every project.

Material & Finish Options

Material Selection for Precision Metal Molding: Performance-Driven Choices

Material selection is a foundational engineering decision directly impacting mold longevity, part quality, production efficiency, and total cost of ownership in high-precision metal molding. At Wuxi Lead Precision Machinery, we emphasize matching material properties to the specific demands of the application, production volume, and environmental exposure. Aluminum, steel, and titanium represent the core high-performance alloys for critical molding components, each offering distinct advantages. Surface finishes, particularly anodizing for aluminum, further enhance functionality and lifespan. Understanding these options ensures optimal mold performance and return on investment.

Aluminum alloys, especially 6061-T6 and 7075-T6, are preferred for prototyping, low-to-medium volume production, and applications demanding rapid heat dissipation and weight reduction. Their excellent machinability allows for complex geometries and faster lead times, significantly reducing initial tooling costs. While inherently less wear-resistant than steel, aluminum molds excel where thermal management is critical, such as in certain plastic injection or low-pressure casting scenarios. Steel, particularly H13 tool steel and stainless variants like 420 or 17-4 PH, is the standard for high-volume, high-wear molding applications. Its superior hardness, thermal stability, and exceptional resistance to abrasion and deformation under pressure ensure extended mold life measured in hundreds of thousands or millions of cycles. Steel is essential for demanding processes like high-pressure die casting or long-run plastic injection molding requiring tight tolerances over extended periods. Titanium alloys, primarily Ti-6Al-4V, offer the ultimate solution for extreme environments involving severe corrosion, very high temperatures, or where exceptional strength-to-weight ratio is non-negotiable. While significantly more expensive and challenging to machine, titanium provides unparalleled resistance to chemical attack and maintains structural integrity where other metals fail, justifying its use in aerospace, medical, and specialized chemical processing molds.

Anodizing is the critical surface enhancement process for aluminum molds. This electrochemical treatment creates a dense, hard, corrosion-resistant oxide layer integral to the base metal. Type II (sulfuric acid) anodizing provides good general protection and dyeing capability, while Type III (hardcoat) anodizing delivers dramatically increased surface hardness, wear resistance, and thermal stability, making it indispensable for aluminum molds subjected to significant mechanical contact or thermal cycling. Properly anodized aluminum molds achieve performance levels approaching steel in specific wear scenarios, bridging the gap between cost and durability.

Selecting the optimal material requires balancing technical requirements with economic factors. The following table summarizes key comparative properties:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Machinability | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | Moderate | Excellent | Prototypes, low-volume molds, heat sinks |

| H13 Tool Steel | 1300-1800 | Good (varies) | Good | High-volume plastic injection, die casting |

| Titanium Ti-6Al-4V | 900-1000 | Excellent | Poor | Extreme corrosion, high-temp, aerospace |

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and advanced CNC capabilities to guide clients through this critical selection process. Our engineering team collaborates closely with your design staff to analyze part geometry, production volume, material being molded, and environmental factors, ensuring the chosen substrate and finish deliver maximum performance and cost-effectiveness for your specific precision molding challenge. We transform material science into reliable, high-yield manufacturing solutions.

Manufacturing Process & QC

Design: Engineering Precision at the Foundation

At Wuxi Lead Precision Machinery, the molding design process begins with a comprehensive engineering phase focused on achieving zero defects from inception. Our design team collaborates closely with clients to analyze functional requirements, material behavior, and production scalability. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we simulate mold performance under real-world conditions to anticipate stress points, thermal distribution, and wear characteristics. This predictive modeling ensures that every mold geometry is optimized for longevity, dimensional accuracy, and repeatable output. All designs adhere to international standards and are reviewed through a multi-stage validation protocol, including Design Failure Mode and Effects Analysis (DFMEA), to eliminate potential flaws before physical development begins.

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, we proceed to prototype development using high-precision CNC machining, wire EDM, and surface grinding technologies. The prototype phase is not merely a form check—it is a full functional validation of the mold’s performance. We produce initial sample runs using the actual production-grade materials to assess part consistency, ejection efficiency, cooling cycle times, and surface finish quality. These trials are conducted under controlled conditions that mirror mass production environments. Data collected during prototyping feeds directly into corrective refinements, ensuring that any micro-variation is identified and resolved. Our metrology lab, equipped with CMM (Coordinate Measuring Machines) and 3D scanning systems, verifies tolerances down to ±0.002 mm, guaranteeing compliance with the strictest industry specifications.

Mass Production: Consistency Through Control

With design and prototype fully validated, we transition to mass production under a fully documented Quality Management System compliant with ISO 9001:2015. Each mold is manufactured using premium-grade tool steels such as H13, S136, or NAK80, selected based on thermal resistance, corrosion protection, and expected production volume. Our production floor integrates real-time monitoring systems that track machine parameters, temperature gradients, and cycle stability. Preventive maintenance schedules and operator checklists are enforced to sustain peak performance. Every finished component undergoes 100% visual inspection and random sampling for dimensional verification, ensuring batch-to-batch uniformity and zero-defect delivery.

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished to mirror grade if required) |

| Tool Steel Options | H13, S136, NAK80, SKD61, P20 |

| Mold Life Expectancy | 500,000 to 1,000,000 cycles (depending on material and design) |

| Cooling Cycle Optimization | Integrated conformal cooling channels for uniform heat dissipation |

| Quality Standards | ISO 9001:2015, DFMEA, PPAP, FAI (First Article Inspection) |

Through this disciplined progression—design rigor, prototype validation, and controlled mass production—Wuxi Lead Precision Machinery delivers molding solutions built for perfection, performance, and long-term reliability in high-demand industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Molding Excellence

Your molding design challenges demand more than standard manufacturing solutions. At Wuxi Lead Precision Machinery, we engineer partnerships that transform complex metal molding requirements into flawless, high-volume production realities. With 15+ years of specialized expertise in aerospace, medical, and automotive sectors, we eliminate the guesswork in precision metal molding. Our German-engineered CNC Swiss lathes, multi-spindle mills, and wire EDM systems operate under ISO 9001:2015 and IATF 16949 certified processes, ensuring every component meets micron-level tolerances. We understand that a single mold imperfection can cascade into production delays, scrap losses, and reputational damage. That is why we integrate design-for-manufacturability (DFM) analysis at the earliest stages, proactively identifying material flow, cooling efficiency, and ejection risks before tooling begins. Our engineers collaborate directly with your R&D team to refine geometries, optimize wall thickness, and select grade-specific alloys—turning theoretical designs into robust, production-ready assets.

Wuxi Lead Precision delivers where others compromise. Our facility houses 42 state-of-the-art machines with integrated CMM verification, enabling zero-defect output for critical applications. Below are core capabilities validating our readiness for your most demanding projects:

| Specification | Capability | Industry Relevance |

|---|---|---|

| Tolerance Range | ±0.002 mm | Aerospace hydraulic components |

| Material Compatibility | Titanium, Inconel, Tool Steel, Aluminum Alloys | Medical implants, turbine blades |

| Max Part Size | Ø350 mm x 500 mm | Automotive transmission housings |

| Lead Time (Prototype) | 72 hours after DFM approval | Accelerated product launch cycles |

| Surface Finish | Ra 0.1 µm (mirror-grade) | Optical sensor enclosures |

This technical rigor translates to tangible outcomes: 99.87% first-pass yield rates, 40% faster time-to-market for clients, and zero field failures in mission-critical assemblies over the past 36 months. When your molding design requires metallurgical precision, thermal stability, and repeatability at scale, our closed-loop quality system becomes your competitive advantage. We do not merely manufacture parts—we safeguard your engineering integrity through every production cycle.

Initiate your next molding project with confidence. Contact our engineering team directly at [email protected] to request a confidential DFM assessment. Include your CAD file and material specifications for a no-obligation analysis within 24 business hours. Our Senior Applications Engineers will identify cost-saving optimizations, risk mitigation strategies, and a validated production timeline—proving why global leaders trust Wuxi Lead Precision for molding designs where perfection is non-negotiable. Do not let substandard tooling undermine your innovation. Reach out today and experience precision engineered to perform.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.