Technical Contents

Engineering Guide: Fdm 3D Printing Service

Engineering Insight: FDM 3D Printing Service in High-Precision Metal Manufacturing

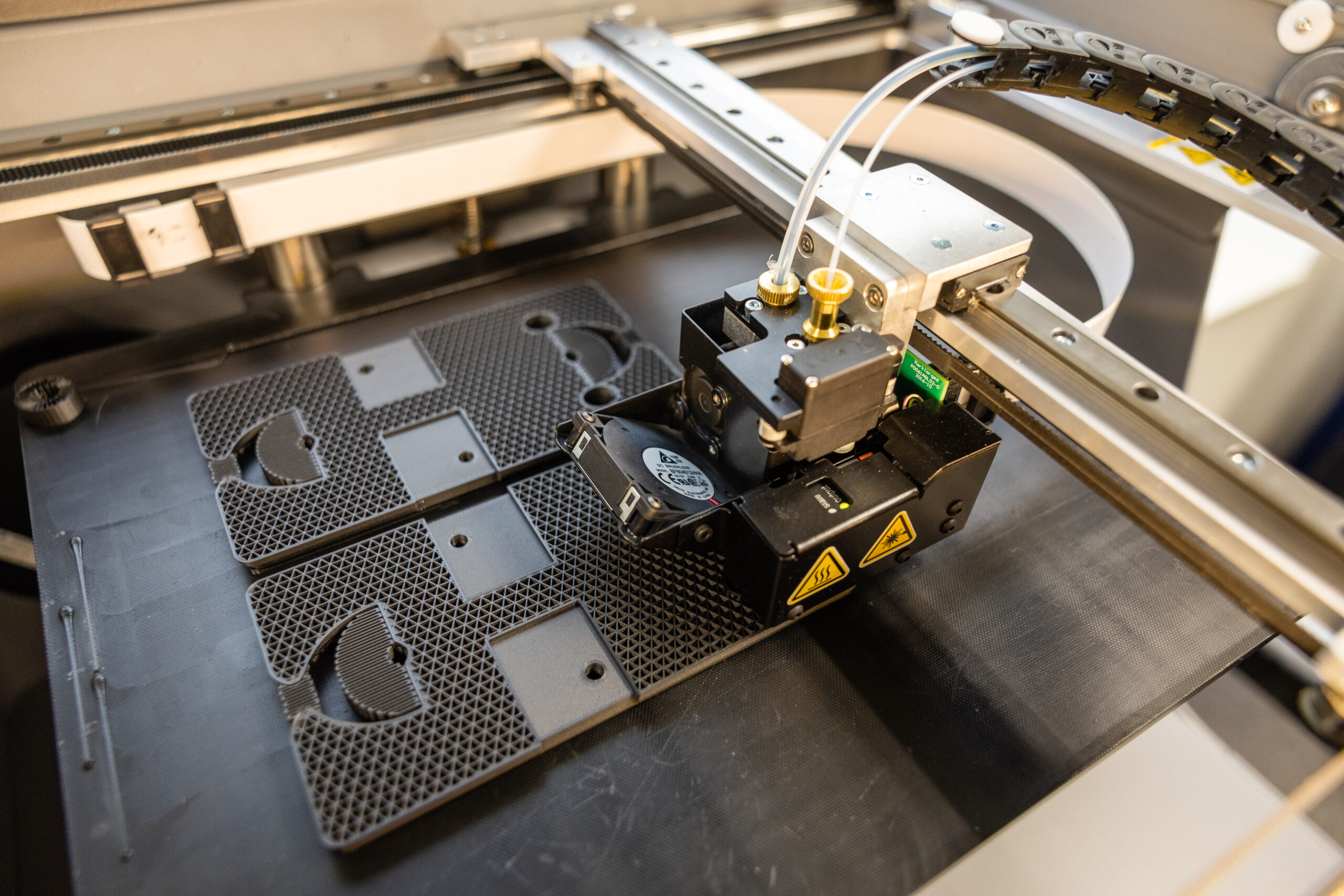

In the evolving landscape of custom metal manufacturing, Fused Deposition Modeling (FDM) 3D printing has emerged as a critical enabler of rapid prototyping, functional testing, and low-volume production. While traditionally associated with polymer-based additive manufacturing, FDM’s role in supporting high-precision metal workflows—particularly in tooling, jigs, fixtures, and pre-machining validation—cannot be overstated. At Wuxi Lead Precision Machinery, we integrate FDM 3D printing services not as an end in itself, but as a strategic step within a broader precision engineering ecosystem.

Precision in manufacturing begins long before the first metal cut. It starts with accurate, dimensionally stable prototypes and support components that mirror final design intent. FDM 3D printing allows engineers to produce durable, geometrically complex parts with tight tolerances, enabling early-stage validation of form, fit, and function. This reduces time-to-market and minimizes costly revisions during CNC machining or casting phases. However, the true value of FDM lies not in speed alone, but in the accuracy and repeatability of the printed output—attributes that are only achievable through calibrated systems, controlled environments, and engineering oversight.

At Lead Precision, our application of FDM technology is informed by over a decade of delivering mission-critical components for Olympic-grade equipment and military defense systems. These projects demand uncompromising standards, where a deviation of even 0.1 mm can result in system failure. Our FDM processes are calibrated to support such demands, using industrial-grade printers, high-performance thermoplastics (such as ABS-M30, PC, and ULTEM 9085), and post-processing techniques that ensure thermal stability and dimensional consistency.

We treat every FDM-printed component as a precision element within a larger manufacturing chain. Whether producing a custom fixture for five-axis milling or a prototype for investment casting, our engineering team applies the same rigor as if the part were final metal. This includes first-article inspection reports (FAIR), coordinate measuring machine (CMM) verification when required, and material traceability—practices honed through years of serving regulated industries.

Below are the technical specifications that define our FDM 3D printing service capabilities:

| Parameter | Specification |

|---|---|

| Layer Resolution | 0.127 mm (0.005 in) to 0.330 mm (0.013 in) |

| Build Envelope | Up to 1000 x 600 x 600 mm (39 x 23 x 23 in) |

| Typical Accuracy | ±0.1 mm for first 100 mm, ±0.05 mm per additional 100 mm |

| Supported Materials | ABS, PC, ULTEM 9085, Nylon, PETG |

| Infill Options | 10% to 100% (adjustable by structural need) |

| Post-Processing | Sanding, priming, painting, assembly support |

| Lead Time | 3–7 business days (varies by complexity) |

FDM 3D printing, when executed with engineering discipline, becomes more than a prototyping tool—it becomes a precision instrument in the manufacturing workflow. At Wuxi Lead Precision Machinery, we combine advanced additive capabilities with deep-rooted expertise in metal fabrication to deliver solutions where accuracy, reliability, and performance are non-negotiable.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing

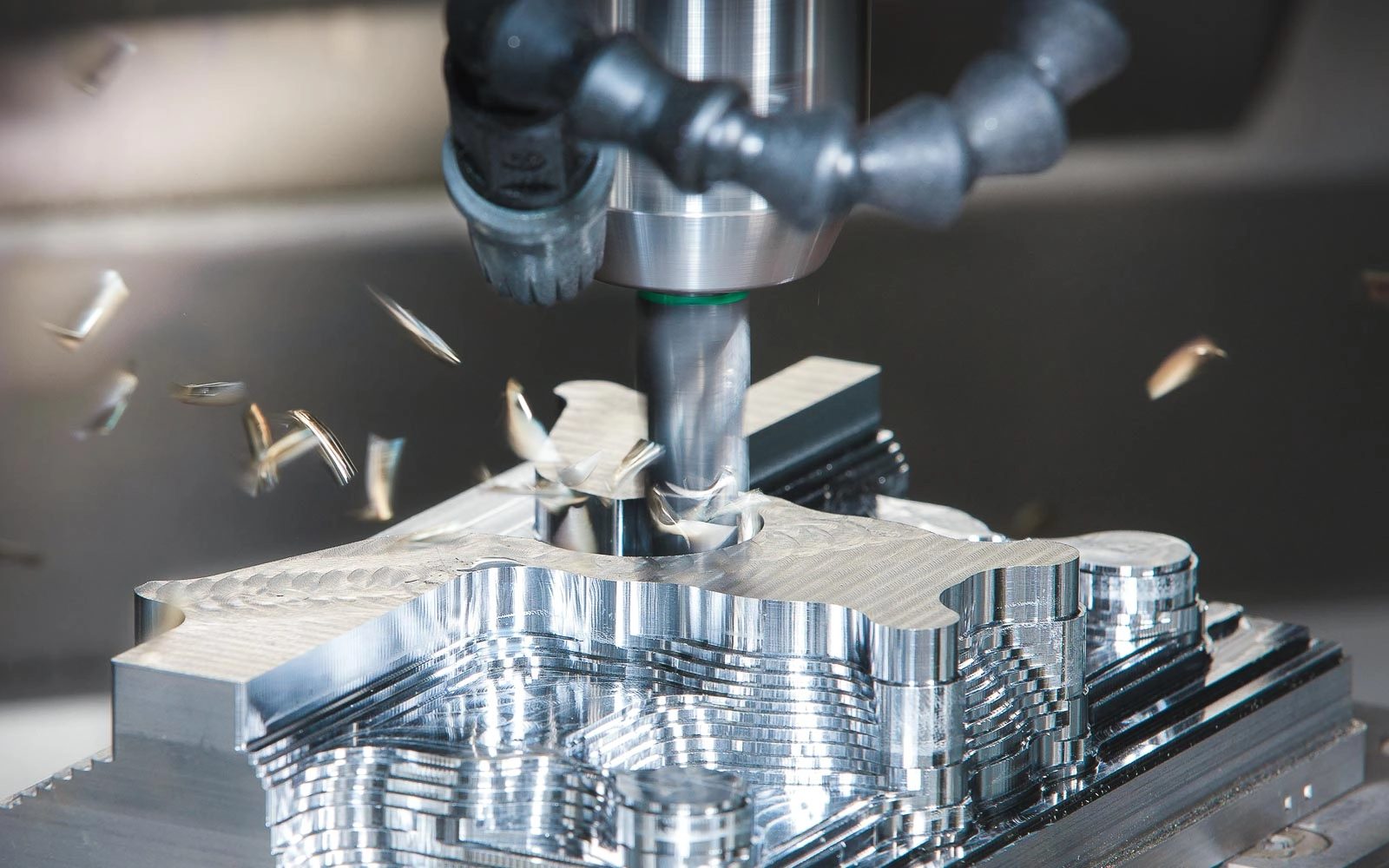

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions centered on high-precision 5-axis CNC machining. Our capabilities bridge complex geometry requirements with stringent quality demands, serving aerospace, medical, and energy sectors where failure is not an option. Unlike additive processes such as FDM 3D printing—which lack the structural integrity and dimensional stability for critical metal components—our subtractive approach ensures superior material properties, surface finishes, and repeatability. We specialize in machining challenging alloys including titanium, Inconel, aluminum 7075, and hardened steels up to Rockwell C 50, transforming raw billets into mission-critical parts with zero compromise on metallurgical integrity.

Our facility operates state-of-the-art 5-axis CNC machines from industry leaders like DMG MORI and Haas, featuring integrated probing systems for in-process verification. This enables single-setup machining of intricate contours, deep cavities, and undercuts, eliminating cumulative errors from multiple fixtures. All equipment maintains thermal stability through climate-controlled environments and regular laser calibration, ensuring micron-level consistency across production runs. Crucially, our process excludes FDM-based metal printing methods, which cannot achieve the tight tolerances, fatigue resistance, or certification standards required for safety-critical metal applications.

Quality control is non-negotiable. Every component undergoes full CMM inspection using Zeiss CONTURA systems, with traceable reports aligned to ISO 10360-2 standards. First-article inspections include GD&T validation, surface roughness analysis (Ra ≤ 0.4 µm achievable), and material certification cross-referencing. We implement real-time SPC monitoring during machining, with corrective actions triggered at 75% of tolerance limits to prevent non-conformances. All inspection data integrates with our digital workflow, providing clients transparent access to quality documentation via secure portals.

Precision tolerance standards are rigorously maintained across all production phases. The following table details achievable specifications for critical features:

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Standard |

|---|---|---|---|

| Linear Dimensions | ±0.02 mm | ±0.005 mm | ISO 2768-mK |

| Hole Diameter | ±0.015 mm | ±0.003 mm | ISO 286-2 (H6) |

| Flatness | 0.02 mm | 0.005 mm | ISO 1101 |

| Positional Accuracy | ±0.015 mm | ±0.005 mm | ISO 5458 |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | ISO 4287 |

This technical foundation—combining 5-axis CNC mastery, certified metrology, and disciplined process control—enables Wuxi Lead to consistently deliver metal components that exceed AS9100 and ISO 13485 requirements. We prioritize what matters in high-stakes manufacturing: dimensional certainty, material reliability, and full traceability from raw stock to finished part. For applications demanding true metal performance, our subtractive precision remains the industry benchmark.

Material & Finish Options

Material selection is a critical factor in achieving optimal performance, durability, and cost-efficiency in custom metal manufacturing, particularly when integrating FDM 3D printing services into hybrid production workflows. At Wuxi Lead Precision Machinery, we specialize in precision metal components and support advanced manufacturing strategies that combine additive techniques with traditional metal processing. Understanding the mechanical properties and finishing options of core materials—aluminum, steel, and titanium—enables engineers and procurement teams to make informed decisions aligned with application demands.

Aluminum stands out for its high strength-to-weight ratio and excellent thermal and electrical conductivity. It is ideal for aerospace, automotive, and consumer electronics components where weight reduction is essential without compromising structural integrity. Our 6061 and 7075 aluminum alloys offer superior machinability and weldability, making them suitable for prototypes and end-use parts alike. When paired with FDM 3D printing for tooling or jigs, aluminum reduces lead times and supports rapid iteration.

Steel, particularly in its stainless and alloy forms, delivers exceptional hardness, wear resistance, and tensile strength. We utilize 304 and 316 stainless steel for applications requiring corrosion resistance in harsh environments, such as medical devices and marine equipment. For industrial tooling and high-stress mechanical parts, 4140 and 4340 alloy steels provide enhanced toughness and fatigue resistance. When combined with FDM-built fixtures or sacrificial molds, steel components benefit from reduced setup costs and increased geometric flexibility.

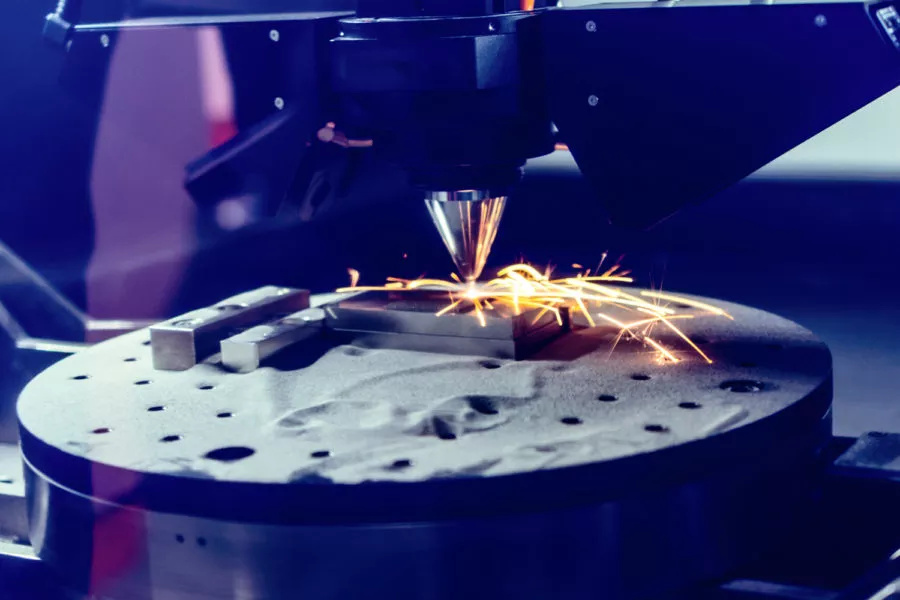

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. Its biocompatibility, outstanding corrosion resistance, and strength at elevated temperatures make it indispensable in aerospace, defense, and medical implant manufacturing. Although more challenging to machine, titanium’s longevity and performance under stress justify its use in mission-critical systems. FDM 3D printing supports titanium production by enabling complex support structures and lightweight lattice designs that would be impossible with traditional methods alone.

For enhanced surface properties and aesthetics, anodizing is a recommended finishing process—especially for aluminum. Anodizing creates a durable, corrosion-resistant oxide layer that can be dyed in various colors for identification or branding. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) delivers superior wear resistance for industrial applications.

Below is a comparison of key material properties:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | FDM Integration Use Case |

|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Aerospace, Automotive | Lightweight fixtures, enclosures |

| Stainless 316 | 570 | 8.0 | Medical, Marine | Corrosion-resistant tooling |

| Steel 4140 | 655 | 7.85 | Industrial Machinery | High-strength molds, dies |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aerospace, Medical Implants | High-temp, lightweight structural parts |

Selecting the right material and finish ensures seamless integration between FDM 3D printing and precision metal manufacturing, optimizing both performance and production efficiency.

Manufacturing Process & QC

Integrated Production Process for Precision Metal Components

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal manufacturing. While FDM 3D printing is valuable for specific prototyping or tooling applications, our core expertise and zero-defect commitment center on precision metal fabrication. We integrate additive insights where strategically beneficial but execute final production through rigorously controlled subtractive and forming processes. Our structured workflow ensures dimensional accountability from concept to volume output.

The process initiates with collaborative Design for Manufacturability (DFM) analysis. Our engineering team scrutinizes CAD models against material properties, geometric complexity, and production constraints specific to metals like aluminum alloys, stainless steel, and titanium. We identify potential stress points, optimize wall thicknesses, and suggest modifications to eliminate costly rework during machining. This phase leverages simulation software to predict thermal behavior and structural integrity, ensuring the design is inherently producible to exacting standards before any material is cut. Client sign-off on the validated design file is mandatory, establishing the definitive blueprint for all subsequent stages.

Prototyping transitions into functional metal validation. For low-volume or complex geometries, we may employ metal additive manufacturing (e.g., DMLS) to produce near-net-shape parts, bypassing traditional tooling costs. These prototypes undergo rigorous functional and dimensional testing against the original specifications. Critical features are verified using coordinate measuring machines (CMM) and optical comparators. This step confirms form, fit, and function under real-world conditions, providing actionable data to refine the production process long before full-scale manufacturing begins. It is not merely a visual check but a critical validation of the metal component’s performance envelope.

Mass production executes under our Zero Defects framework. CNC milling, turning, and multi-axis machining centers operate with automated tool compensation and in-process probing. Every critical dimension is monitored in real-time; deviations trigger immediate machine halts and root-cause analysis. Components progress through defined inspection gates: first-article inspection validates setup accuracy, in-process checks maintain consistency during runs, and final batch certification includes full CMM reports and material traceability documentation. Statistical process control (SPC) data is continuously analyzed to preempt potential drift. This closed-loop system, combined with operator expertise and calibrated metrology, ensures every shipped part meets or exceeds the ±0.005mm tolerance standard demanded by aerospace, medical, and semiconductor clients.

The following table summarizes our core metal production capabilities and quality parameters:

| Process Stage | Key Parameters | Tolerance Capability | Lead Time (Standard) |

|---|---|---|---|

| Design Review | DFM, Material Selection, Simulation | N/A | 3-5 Business Days |

| Metal Prototyping | DMLS, CNC Machining, CMM Validation | ±0.025mm | 7-10 Business Days |

| CNC Production | Multi-Axis Milling/Turning, SPC | ±0.005mm | 15-25 Business Days |

This disciplined progression—grounded in proactive design validation, empirical prototyping, and statistically monitored production—eliminates defects at their source. Wuxi Lead transforms complex metal component requirements into flawless, on-time deliveries, safeguarding your production schedule and end-product integrity through unwavering process control.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced FDM 3D Printing Services in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance FDM (Fused Deposition Modeling) 3D printing services tailored to the rigorous demands of modern industrial applications. As a trusted leader in custom metal manufacturing based in China, we integrate additive manufacturing with precision engineering to provide end-to-end solutions for prototyping, tooling, and low-volume production. Our FDM technology is not just about rapid fabrication—it’s about enabling smarter design, faster iteration, and greater cost efficiency across your product development lifecycle.

Our FDM 3D printing service leverages industrial-grade thermoplastics reinforced with composite materials such as carbon fiber, glass fiber, and Kevlar. These materials deliver exceptional strength-to-weight ratios, high thermal resistance, and excellent dimensional stability—making them ideal for functional prototypes, jigs, fixtures, and end-use components in aerospace, automotive, and heavy machinery sectors. Every part is produced under strict quality control protocols, ensuring repeatability, accuracy, and compliance with international manufacturing standards.

We understand that in high-end manufacturing, specifications matter. Our advanced FDM systems support large build volumes and complex geometries, allowing for the creation of lightweight, integrated components that reduce assembly time and improve performance. Whether you’re validating a new design or producing durable tooling for metal fabrication processes, our engineering team works closely with yours to optimize part orientation, material selection, and support structures for maximum efficiency.

Below are the key technical specifications of our FDM 3D printing capabilities:

| Specification | Detail |

|---|---|

| Build Envelope | Up to 900 x 600 x 900 mm |

| Layer Resolution | 100 – 300 microns |

| Supported Materials | ABS, PC, ULTEM (PEI), PPSF, Nylon, and composites (Carbon Fiber, Glass Fiber) |

| Dimensional Accuracy | ±0.2 mm for first 100 mm, ±0.1 mm per additional 100 mm |

| Infill Options | 10% – 100% (adjustable by application) |

| Lead Time | As fast as 3–5 business days (standard) |

| Post-Processing Available | Sanding, vapor smoothing, painting, tapping, assembly |

By choosing Wuxi Lead Precision Machinery, you gain more than a service provider—you gain a strategic manufacturing partner. Our engineers offer design for additive manufacturing (DfAM) consultations to help you maximize the benefits of FDM technology, reduce material waste, and accelerate time-to-market. With ISO-certified production facilities and a commitment to innovation, we ensure every component meets the highest standards of quality and performance.

To discuss your next project or request a quote for our FDM 3D printing service, contact us today at [email protected]. Let Lead Precision be the foundation of your advanced manufacturing strategy.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.