Technical Contents

Engineering Guide: Cutting Services

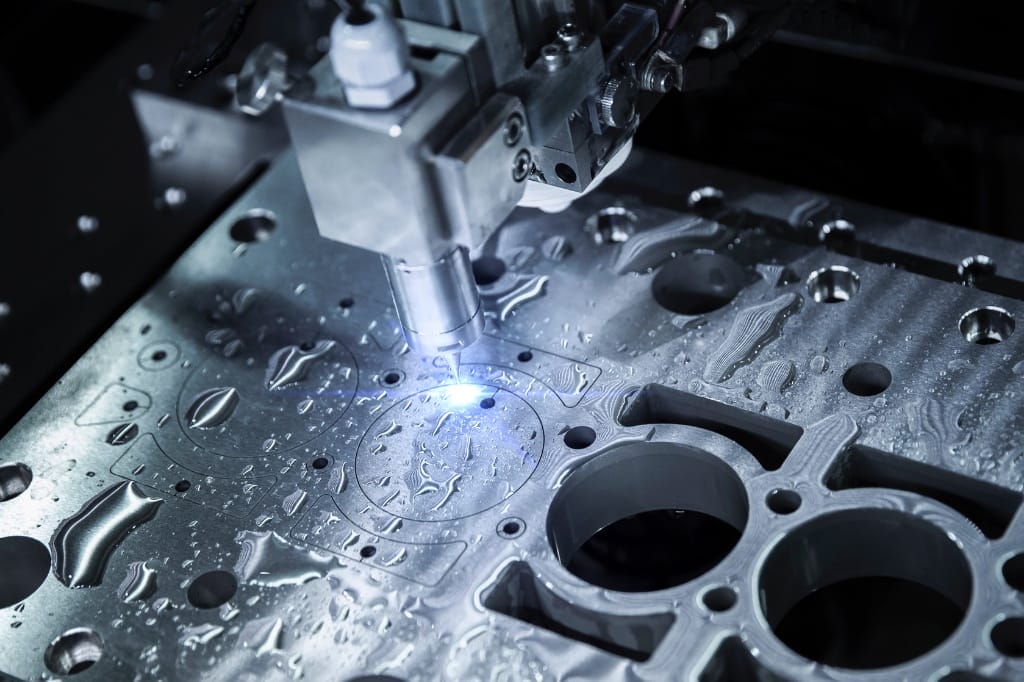

Engineering Insight Precision Cutting Services

Precision in metal cutting services transcends mere dimensional accuracy; it defines the functional integrity and lifecycle performance of engineered components. In high-stakes applications aerospace, defense, and advanced energy systems microscopic deviations compound during assembly causing premature wear, system failure, or catastrophic safety risks. Tolerance stack-up from subpar cutting directly impacts secondary operations like welding or grinding increasing scrap rates and project timelines. True precision demands holistic control over material behavior thermal dynamics and machine stability not just endpoint measurements. At Wuxi Lead Precision Machinery we treat cutting as the foundational engineering process where micron-level consistency is non-negotiable for mission-critical parts.

Our approach integrates advanced CNC multi-axis laser plasma and waterjet systems with proprietary process validation protocols. Material grain orientation thermal distortion compensation and real-time adaptive control are engineered into every cut sequence. This eliminates reliance on post-process corrections saving clients significant time and cost while ensuring first-article compliance. We prioritize understanding the component’s end-use environment whether subjected to cryogenic temperatures supersonic stress or corrosive exposure to tailor cutting parameters that maintain performance under operational extremes.

The following table outlines core capabilities reflecting our engineering commitment to precision cutting:

| Capability | Specification | Application Impact |

|---|---|---|

| Positional Accuracy | ±0.02 mm across all axes | Ensures seamless integration in complex assemblies |

| Material Thickness Range | 0.5 mm to 150 mm stainless steel | Supports ultra-thin sensor housings to armored vehicle components |

| Repeatability | Cpk ≥ 1.67 over 30,000 cycles | Guarantees batch uniformity for serialized production |

| Edge Quality | Burr-free Ra ≤ 0.8 µm (laser) | Eliminates secondary deburring for hydraulic systems |

| Material Versatility | Titanium Inconel 718 300M steel | Meets stringent aerospace and defense specifications |

This precision foundation has been rigorously proven through classified defense programs requiring zero-defect components for critical subsystems. Our processes also contributed to structural elements for the Beijing 2022 Winter Olympic infrastructure where extreme cold weather performance and aesthetic tolerances demanded uncompromising cutting accuracy. These projects underscore our ability to meet specifications where failure is not an option.

For global manufacturers facing complex supply chain challenges Wuxi Lead delivers precision cutting as a strategic advantage. We transform raw material into geometrically perfect starting points for your value chain reducing total production costs while elevating final product reliability. Partner with us to convert engineering intent into physical reality with uncompromised fidelity.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions through state-of-the-art 5-axis CNC machining technology. Our technical capabilities are engineered to meet the stringent demands of aerospace, medical, automotive, and industrial equipment industries, where precision, repeatability, and complex geometry are critical. The integration of 5-axis CNC systems enables us to perform multi-directional cutting in a single setup, significantly reducing cycle times and enhancing dimensional accuracy. This capability supports the production of highly intricate components that would be unattainable with conventional 3-axis machines.

Our 5-axis machining centers utilize simultaneous motion across all five axes, allowing for optimal tool orientation and access to complex contours and undercuts. This results in superior surface finishes, reduced need for secondary operations, and improved part integrity. We work with a broad range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, Inconel, and tool steels, ensuring material performance matches application requirements. Advanced CAD/CAM software drives our machining processes, enabling high-speed machining (HSM) strategies that maximize efficiency while maintaining micron-level precision.

Quality control is embedded throughout every phase of production. All components undergo rigorous inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM systems provide traceable, high-resolution measurement data, supporting first-article inspection reports (FAIR), production part approval processes (PPAP), and full batch validation. This metrology-backed approach ensures that every component meets or exceeds customer specifications and industry standards.

To further guarantee consistency, our manufacturing environment adheres to ISO 9001 quality management protocols. Skilled CNC programmers and machinists oversee each job, applying decades of combined experience in high-precision manufacturing. From prototype development to high-volume production runs, our technical infrastructure supports scalable, reliable output without compromising on accuracy or lead time.

The table below outlines the standard tolerances achievable through our 5-axis CNC machining and inspection processes. These values serve as a baseline; tighter tolerances can be achieved upon request, depending on part geometry, material, and design intent.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 100 mm; ±0.01 mm beyond |

| Positional Tolerance | ±0.01 mm | Per GD&T standards |

| Angular Tolerance | ±0.05° | Measured over full feature length |

| Surface Roughness (Ra) | 0.8 µm (typical) | Down to 0.4 µm with fine finishing |

| Form Tolerance (Flatness, Roundness) | 0.01 mm | Verified via CMM and optical probes |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade inspection to deliver custom metal components of the highest caliber. Our technical capabilities are built for complexity, precision, and consistency—ensuring that every part meets the exacting standards of modern industrial applications.

Material & Finish Options

Material Selection for Precision Cutting Services

Selecting the optimal material is foundational to achieving precision, durability, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we prioritize material properties that align with your functional requirements, environmental exposure, and geometric complexity. Aluminum, steel, and titanium represent the core alloys for high-performance applications, each offering distinct advantages in CNC cutting processes. Understanding their mechanical behavior ensures minimal waste, superior surface integrity, and adherence to tight tolerances during milling, turning, or multi-axis machining.

Aluminum alloys, particularly 6061-T6, dominate aerospace and automotive sectors due to their exceptional strength-to-weight ratio and thermal conductivity. They machine rapidly with reduced tool wear, enabling complex geometries at lower costs. However, aluminum’s softness necessitates precise coolant management to prevent built-up edge and dimensional drift. Steel variants like 304 stainless provide superior hardness and corrosion resistance for medical or marine components, though their abrasiveness demands rigid machine setups and carbide tooling to maintain edge sharpness. Titanium grade 5 (Ti-6Al-4V) excels in extreme environments—such as aerospace or biomedical implants—where fatigue resistance and biocompatibility are critical. Its low thermal conductivity requires aggressive chip evacuation and reduced cutting speeds to avoid heat accumulation, which can compromise material integrity.

Anodizing remains the premier finish for aluminum parts, enhancing surface hardness and corrosion resistance while allowing color customization. Type II (sulfuric acid) anodizing suits general industrial use with moderate wear protection, whereas Type III (hardcoat) delivers 50–100 µm thickness for military or hydraulic applications requiring extreme abrasion resistance. Crucially, anodizing must be specified before precision machining; post-process anodizing risks dimensional shifts in critical features. We integrate finish requirements into our CNC programming to preserve tolerances on anodized surfaces.

Material performance directly impacts machining strategy and final part viability. The table below summarizes key properties to guide your selection:

| Material | Tensile Strength (MPa) | Machinability Rating | Common Grades | Key Applications |

|---|---|---|---|---|

| Aluminum | 310 | Excellent (9/10) | 6061-T6, 7075-T6 | Aircraft frames, heat sinks |

| Stainless Steel | 515 | Moderate (5/10) | 304, 316L | Surgical tools, valve bodies |

| Titanium | 900 | Challenging (3/10) | Ti-6Al-4V | Jet engine components, implants |

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to optimize cutting parameters for each alloy. Our engineers collaborate early in your design phase to recommend materials that balance performance with manufacturability, ensuring your components meet ISO 2768-mK tolerances while minimizing lead times. For titanium or hardened steel projects, we deploy high-pressure coolant systems and adaptive toolpaths to extend tool life by up to 40%. Partner with us to transform material specifications into precision-engineered reality.

Manufacturing Process & QC

From Design to Mass Production: The Zero-Defect Manufacturing Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence into every phase of custom metal manufacturing. Our production process is designed for precision, repeatability, and zero defects—ensuring that each component meets the highest standards of quality and performance. From initial design to full-scale production, our integrated workflow eliminates variability and delivers consistent, high-integrity parts for demanding industrial applications.

The process begins with collaborative design engineering. Our technical team works closely with clients to analyze part geometry, material selection, tolerances, and functional requirements. Using advanced CAD/CAM software and finite element analysis (FEA), we optimize designs for manufacturability, structural integrity, and performance under real-world conditions. This early-stage validation minimizes risks and ensures that every design is not only feasible but optimized for precision cutting and long-term reliability.

Once the design is finalized, we move into prototyping. This critical phase allows us to produce a small batch of parts for functional testing, fit checks, and client approval. Our prototyping leverages the same CNC cutting, laser processing, and forming equipment used in mass production—ensuring that prototypes are true representations of final parts. Dimensional inspections, material verification, and surface quality assessments are conducted using coordinate measuring machines (CMM) and optical comparators. Feedback from this stage is used to fine-tune toolpaths, fixturing, and process parameters, guaranteeing a seamless transition to volume manufacturing.

Mass production is executed under a strict zero-defect framework. Each production run is governed by documented work instructions, statistical process control (SPC), and real-time monitoring. Our CNC cutting systems are calibrated daily, and automated in-process inspections detect deviations before they affect output. Every batch undergoes 100% visual inspection and random sampling for dimensional accuracy, ensuring compliance with ISO 9001 standards. Traceability is maintained through barcode tracking, linking each part to its material certificate, machine log, and inspection report.

Our facility supports a wide range of materials and cutting technologies, enabling flexibility without compromising precision.

| Specification | Capability |

|---|---|

| Cutting Methods | Laser Cutting, CNC Punching, Waterjet, Plasma |

| Materials | Stainless Steel, Aluminum, Carbon Steel, Copper, Brass, Titanium |

| Tolerance Range | ±0.05 mm to ±0.1 mm (depending on process and material) |

| Max Sheet Size | 1500 mm × 3000 mm |

| Thickness Range | 0.5 mm – 25 mm (varies by material and method) |

| Surface Finish | As-cut, Deburred, Passivated, Powder-Coated (optional) |

| Production Capacity | Up to 50,000 parts per month |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP support |

At Wuxi Lead Precision Machinery, the journey from concept to mass production is not just about manufacturing—it’s about delivering confidence. With a relentless focus on precision, consistency, and zero defects, we ensure that every part we produce performs exactly as intended.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Cutting Services Partner

At Wuxi Lead Precision Machinery, we understand that precision metal cutting is not merely a production step—it is the foundation of component integrity, performance, and supply chain resilience. For over 15 years, we have engineered cutting solutions for aerospace, medical device, and energy sector leaders who demand uncompromising accuracy and repeatability. Our ISO 9001 and AS9100-certified facility in Wuxi integrates German-engineered machinery with proprietary process controls, ensuring every cut meets micron-level tolerances while minimizing material waste. When you partner with us, you gain more than a vendor; you secure a technical ally committed to de-risking your manufacturing workflow through transparent communication, real-time production tracking, and engineering collaboration from prototype to volume production.

Our cutting capabilities span advanced technologies tailored to your material and geometric complexities. Below are core specifications defining our operational excellence:

| Technology | Tolerance Range | Max Material Thickness | Material Compatibility | Lead Time Standard |

|---|---|---|---|---|

| Fiber Laser | ±0.05 mm | 30 mm stainless steel | Steel, Aluminum, Titanium, Copper | 5-7 days |

| CO2 Laser | ±0.1 mm | 25 mm acrylic | Plastics, Composites | 4-6 days |

| Precision Waterjet | ±0.13 mm | 150 mm | Exotic Alloys, Glass, Stone | 6-8 days |

| Plasma Cutting | ±0.5 mm | 50 mm | Mild Steel, Corten | 3-5 days |

Unlike commodity suppliers, we prioritize process validation. Every job undergoes rigorous first-article inspection using calibrated CMMs and optical comparators, with full traceability to material certs and machine logs. Our engineers collaborate pre-production to optimize kerf width, heat-affected zones, and nesting efficiency—directly reducing your scrap rates by 18–22% on average. For mission-critical components, we implement in-process SPC monitoring, ensuring dimensional stability across 10,000+ part runs. This systematic approach has earned us zero non-conformances in 12 consecutive customer audits across North America and Europe.

Initiate your technical consultation by emailing [email protected] with your CAD files or engineering drawings. Our applications team will respond within 4 business hours (UTC+8) with a feasibility analysis, including recommended cutting parameters, cost drivers, and a timeline aligned to your project milestones. For urgent requirements, reference “Priority-CTA” in your subject line to trigger our 24-hour rapid-response protocol. We require no NDAs for initial technical reviews—demonstrating confidence in both our IP safeguards and your strategic urgency.

Precision is non-negotiable in high-stakes manufacturing. Partner with an organization where engineering rigor and delivery accountability are inseparable. Contact Lead Precision today to transform your cutting challenges into competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.