Technical Contents

Engineering Guide: Ptfe Machined Parts

Engineering Insight: PTFE Machined Parts – The Critical Role of Precision in High-Performance Applications

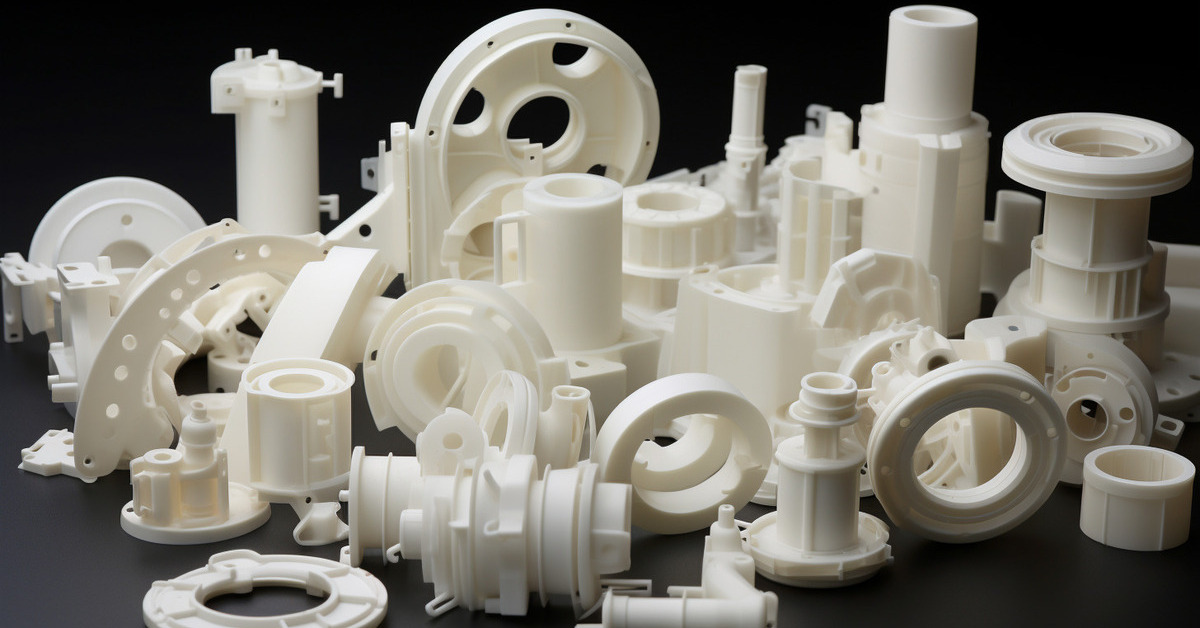

In the realm of advanced engineering materials, polytetrafluoroethylene (PTFE) stands out for its exceptional chemical resistance, low friction coefficient, and thermal stability across extreme temperatures. However, the very properties that make PTFE ideal for demanding environments—such as aerospace, semiconductor manufacturing, and medical devices—also present significant challenges during machining. Achieving tight tolerances and consistent part geometry in PTFE requires not only deep material expertise but also precision-controlled CNC machining processes that few manufacturers can deliver at scale.

At Wuxi Lead Precision Machinery, we understand that PTFE’s inherent creep tendency and low thermal conductivity demand specialized tooling, optimized feed rates, and meticulous process control. Unlike rigid metals, PTFE can deform under pressure or heat, leading to dimensional inaccuracies if not machined with calibrated precision. Even minor deviations—measured in microns—can compromise sealing performance, lead to premature part failure, or contaminate sensitive systems. This is especially critical in applications such as high-vacuum flanges, chemical pump components, or insulating elements in military-grade electronics, where reliability is non-negotiable.

Our experience in producing PTFE machined parts extends to projects with zero tolerance for error, including components used in Olympic-standard analytical instruments and mission-critical defense systems. These high-stakes applications have reinforced our commitment to precision engineering, where every micron is accounted for and every process parameter is documented and controlled. Our CNC machining centers operate under strict environmental controls to minimize thermal fluctuations, and our engineers apply adaptive cutting strategies tailored to PTFE’s viscoelastic behavior. From raw material selection to final inspection, each stage is governed by ISO 9001-certified quality protocols.

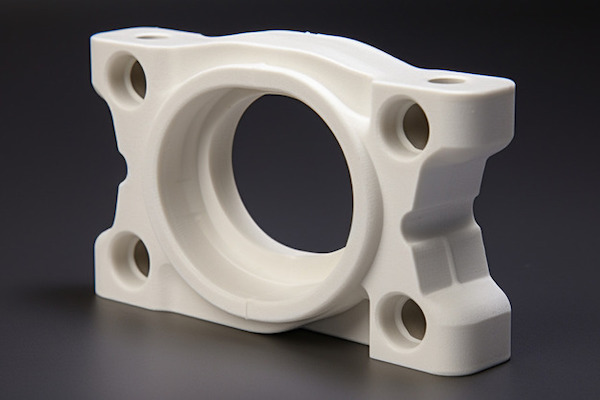

We specialize in complex geometries—custom seals, bushings, insulators, and liners—machined to tolerances as tight as ±0.005 mm. Our in-house metrology lab ensures that every PTFE component meets exacting dimensional and surface finish requirements before shipment. By combining advanced 5-axis CNC technology with decades of polymer machining experience, Wuxi Lead delivers parts that perform reliably in the most aggressive chemical and thermal environments.

| Specification | Detail |

|---|---|

| Material | Virgin PTFE, Filled PTFE (Glass, Carbon, Bronze, etc.) |

| Tolerance | Up to ±0.005 mm |

| Surface Finish | Ra 0.2 μm to Ra 3.2 μm (customizable) |

| Maximum Part Size | Ø1200 mm x 600 mm height |

| Machining Capabilities | CNC Turning, Milling, Drilling, Threading, Grooving |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP available |

| Industries Served | Aerospace, Defense, Semiconductor, Medical, Analytical Instrumentation |

Precision in PTFE machining is not merely a technical requirement—it is a commitment to performance, safety, and longevity. At Wuxi Lead Precision Machinery, we bring proven expertise from the most demanding sectors to every PTFE component we produce.

Precision Specs & Tolerances

Advanced Technical Capabilities for PTFE Machined Components

Wuxi Lead Precision Machinery leverages state-of-the-art 5-axis CNC machining centers to deliver exceptional precision and complexity for PTFE components. Our DMG MORI and Hermle platforms provide simultaneous multi-axis movement, enabling the production of intricate geometries—including undercuts, complex contours, and tight internal features—in a single setup. This minimizes part handling, critical for PTFE’s low stiffness and thermal sensitivity, ensuring dimensional stability and eliminating cumulative errors inherent in multi-operation workflows. Our engineering team employs specialized toolpath strategies and ultra-sharp, polished carbide tooling to manage PTFE’s unique challenges: its tendency to deform under pressure, low thermal conductivity, and high coefficient of thermal expansion. Rigorous process validation ensures optimal spindle speeds, feed rates, and minimal clamping forces to prevent material creep or surface imperfections while achieving superior surface finishes down to Ra 0.4 µm.

Material-specific expertise defines our PTFE machining process. We implement strict environmental controls within our climate-stabilized facility, maintaining consistent temperature and humidity to counteract PTFE’s hygroscopic nature and thermal expansion. Dedicated fixturing solutions using low-pressure vacuum or custom soft-jaw systems secure the workpiece without inducing stress, while continuous coolant mist application manages heat generation during cutting. Each job undergoes thorough pre-machining material verification to confirm grade conformity and homogeneity. Our process protocols include extended stress-relief cycles post-machining, ensuring long-term dimensional integrity for critical applications in semiconductor, aerospace, and chemical processing industries where component failure is not an option.

Quality assurance is non-negotiable. Every PTFE component undergoes comprehensive inspection using Zeiss and Hexagon Coordinate Measuring Machines (CMMs) operating in a certified ISO Class 7 metrology lab. Our CMM routines, developed per ASME Y14.5 standards, capture full 3D geometry data against CAD models, verifying complex profiles and GD&T callouts with micron-level accuracy. Thermal compensation algorithms within the CMM software account for ambient fluctuations, critical for PTFE’s thermal behavior. Full traceability is maintained from raw material lot to final inspection report, with digital records accessible to clients. This integrated approach—combining advanced multi-axis machining, material science understanding, and metrology-grade validation—guarantees components meet the most demanding functional and regulatory requirements.

PTFE Machining Tolerance Specifications

| Feature Category | Typical Capability | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 150 mm; larger dims scale per ISO 2768 |

| Angular Tolerances | ±0.1° | ±0.05° | Verified via CMM vector measurement |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm surface area |

| Concentricity | 0.03 mm | 0.015 mm | Relative to primary datum |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Achieved with optimized tooling/feeds |

| Hole Diameter | +0.03/-0.00 mm | +0.01/-0.00 mm | Reamed or precision bored features |

This technical foundation ensures Wuxi Lead delivers PTFE components that perform reliably under extreme chemical exposure, high purity demands, and critical sealing requirements, backed by quantifiable precision data.

Material & Finish Options

Material Selection for High-Performance PTFE Machined Parts

When engineering precision PTFE machined components for advanced industrial applications, material selection plays a pivotal role in determining performance, longevity, and system compatibility. At Wuxi Lead Precision Machinery, we integrate high-grade substrate materials such as aluminum, steel, and titanium with PTFE (polytetrafluoroethylene) coatings or composite integration to deliver parts with superior chemical resistance, low friction, and thermal stability. The choice of base material directly influences mechanical strength, weight, corrosion resistance, and machinability—critical factors in aerospace, semiconductor, medical, and chemical processing industries.

Aluminum is often the preferred substrate for PTFE-coated components due to its excellent strength-to-weight ratio, thermal conductivity, and ease of CNC machining. It is particularly suitable for applications where weight reduction is essential without sacrificing structural integrity. When anodized, aluminum forms a durable oxide layer that enhances surface hardness and provides an optimal porous structure for PTFE infiltration or bonding, ensuring long-term coating adhesion.

Steel, particularly stainless steel variants such as 304 and 316, offers superior mechanical strength and corrosion resistance in harsh environments. Its high durability makes it ideal for high-load and high-wear applications where PTFE is applied to reduce friction and prevent galling. While more challenging to machine than aluminum, modern CNC techniques ensure tight tolerances and smooth surface finishes, critical for effective PTFE integration.

Titanium stands out in extreme environments due to its exceptional strength-to-density ratio and outstanding resistance to oxidation and corrosion, especially in saline or high-temperature conditions. Though more costly and difficult to machine, titanium substrates with PTFE treatments are indispensable in aerospace and medical implant devices where reliability under stress and biocompatibility are paramount.

Surface finishing, particularly anodizing, is a key step in preparing aluminum for PTFE integration. Anodizing not only increases surface hardness but also creates a micro-porous layer that mechanically locks PTFE into the substrate, significantly improving coating durability. For steel and titanium, alternative surface treatments such as grit blasting or chemical etching are employed to ensure optimal PTFE adhesion.

Below is a comparative overview of the key materials used in PTFE-integrated precision machining:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical PTFE Integration Method | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Moderate (enhanced with anodizing) | Anodizing + PTFE impregnation | Pneumatic components, semiconductor fixtures |

| Stainless Steel 316 | 8.0 | 580 | Excellent | Grit blasting + PTFE coating | Valves, chemical processing equipment |

| Titanium Grade 5 (Ti-6Al-4V) | 4.4 | 900 | Exceptional | Plasma spray + PTFE overlay | Aerospace actuators, medical devices |

Selecting the right material for PTFE machined parts requires a comprehensive understanding of operational demands. At Wuxi Lead, our engineering team supports clients in matching material and finish combinations to application-specific challenges, ensuring optimal performance and lifecycle efficiency.

Manufacturing Process & QC

PTFE Machined Parts: Precision Production Process from Concept to Zero-Defect Delivery

Achieving flawless PTFE components demands a rigorously controlled production sequence, moving seamlessly from initial design through validated prototyping into high-volume manufacturing. At Wuxi Lead Precision Machinery, our process eliminates defects inherent to PTFE’s unique properties—low stiffness, high thermal expansion, and susceptibility to creep—through systematic engineering and advanced CNC protocols. This ensures dimensional stability and surface integrity critical for aerospace seals, semiconductor fluid handling, and medical implants.

The journey begins with Engineering Design & Material Specification. Our engineers collaborate with clients to select the optimal PTFE grade (Virgin, Filled, or Expanded) based on chemical resistance, temperature range, and mechanical load requirements. Finite Element Analysis (FEA) predicts thermal deformation during machining and in-service, enabling precise compensation in the CAD model. Critical tolerances are defined per ISO 2768-mK or client-specific standards, with allowances for PTFE’s 10x higher thermal expansion versus steel. Toolpaths are simulated to minimize cutting forces and heat generation, preventing material smearing or burring.

Prototyping & Process Validation follows immediately. A single prototype is machined using cryogenic cooling or specialized low-friction tooling to suppress thermal distortion. Every dimension undergoes 100% CMM inspection against the compensated CAD model, with surface roughness (Ra) verified via profilometry. Dimensional stability is monitored over 72 hours to confirm minimal post-machining creep. Only when the prototype meets all specifications—including non-destructive testing for internal voids in critical applications—does the process advance. This phase identifies hidden risks like clamp-induced deformation, refining fixturing and speed/feed parameters.

Zero-Defect Mass Production leverages the validated process under strict statistical process control (SPC). Components are machined in controlled-temperature environments (±1°C) using diamond-coated tools and sub-micron precision CNC lathes/mills. Real-time in-process gauging checks key diameters and flatness after each operation, triggering automatic tool compensation if drift exceeds 50% of tolerance. Every batch undergoes 100% visual inspection for surface defects and抽样 CMM verification per ANSI/ASQ Z1.4. Material traceability is maintained from billet lot to finished part, with full inspection reports archived for aerospace and medical clients. Our closed-loop system ensures tolerances remain within ±0.005 mm for critical features, even across 10,000+ unit runs.

This integrated approach transforms PTFE’s machining challenges into consistent, defect-free output. The table below summarizes achievable specifications under our controlled process:

| Parameter | Standard Capability | Critical Tolerance Capability | Verification Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm | CMM (Zeiss CONTURA) |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer (Mitutoyo) |

| Flatness | 0.05 mm | 0.01 mm | Optical Flat + Interferometer |

| Roundness | 0.015 mm | 0.003 mm | Roundness Tester (Taylor Hobson) |

| Material Traceability | Full Lot Tracking | Per-Part Serial Numbering | ERP System (SAP Integrated) |

Wuxi Lead’s end-to-end control—from thermal-compensated design through cryogenic prototyping to SPC-driven mass production—guarantees PTFE parts perform reliably in the most demanding applications, eliminating field failures and supply chain disruptions.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for your most demanding PTFE machined parts requirements. As a leading provider of precision CNC machining services in China, we specialize in delivering high-performance, custom-engineered components from PTFE and other high-grade engineering plastics. Our expertise ensures that every part meets exacting specifications for industries including semiconductor, medical, aerospace, and advanced automation.

At Wuxi Lead, we understand that PTFE presents unique challenges in machining due to its low friction, high thermal expansion, and tendency to deform under pressure. Our engineering team applies decades of cumulative experience to overcome these challenges, using optimized toolpaths, specialized tooling, and tightly controlled environmental conditions to achieve micron-level tolerances and exceptional surface finishes. Whether you require simple seals, complex insulators, or high-purity components for cleanroom environments, our process guarantees repeatability, consistency, and compliance with international quality standards.

Our facility is equipped with state-of-the-art CNC lathes, milling centers, and multi-axis machines, all maintained to the highest operational standards. We implement full process traceability, in-process inspection, and final QA checks using calibrated CMMs and surface profilometers. Every PTFE machined part is documented and certified, ensuring full compliance with your technical and regulatory requirements.

Below are key specifications we routinely achieve for PTFE components:

| Specification | Capability |

|---|---|

| Material Types | Virgin PTFE, Filled PTFE (glass, carbon, bronze, graphite), PTFE composites |

| Tolerance | ±0.005 mm (±0.0002″) typical, down to ±0.002 mm with special process control |

| Surface Finish | As low as Ra 0.2 µm (8 µin), customizable for sealing or wear applications |

| Maximum Part Size | Ø1200 mm diameter, 800 mm height |

| Minimum Feature Size | Ø0.5 mm holes, 1.0 mm wall thickness (geometry dependent) |

| Secondary Operations | Thread cutting, knurling, laser marking, cleaning (ultrasonic, ISO Class 5 compatible) |

| Quality Standards | ISO 9001:2015 certified, full inspection reports, PPAP, APQP support |

We don’t just manufacture parts—we engineer solutions. Our engineering team collaborates closely with clients during prototyping and design for manufacturability (DFM) stages to optimize performance, reduce lead times, and lower total cost of ownership. From prototype to high-volume production, we scale efficiently without compromising quality.

When precision, reliability, and technical partnership matter, Wuxi Lead Precision Machinery is the trusted choice. Contact us today to discuss your next PTFE machining project. Send your drawings, specifications, or inquiries to [email protected] and receive a detailed technical response within 24 hours. Let us become your long-term precision machining partner in China.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.