Technical Contents

Engineering Guide: Injection Mold Service

Engineering Insight: The Critical Role of Precision in Injection Mold Services

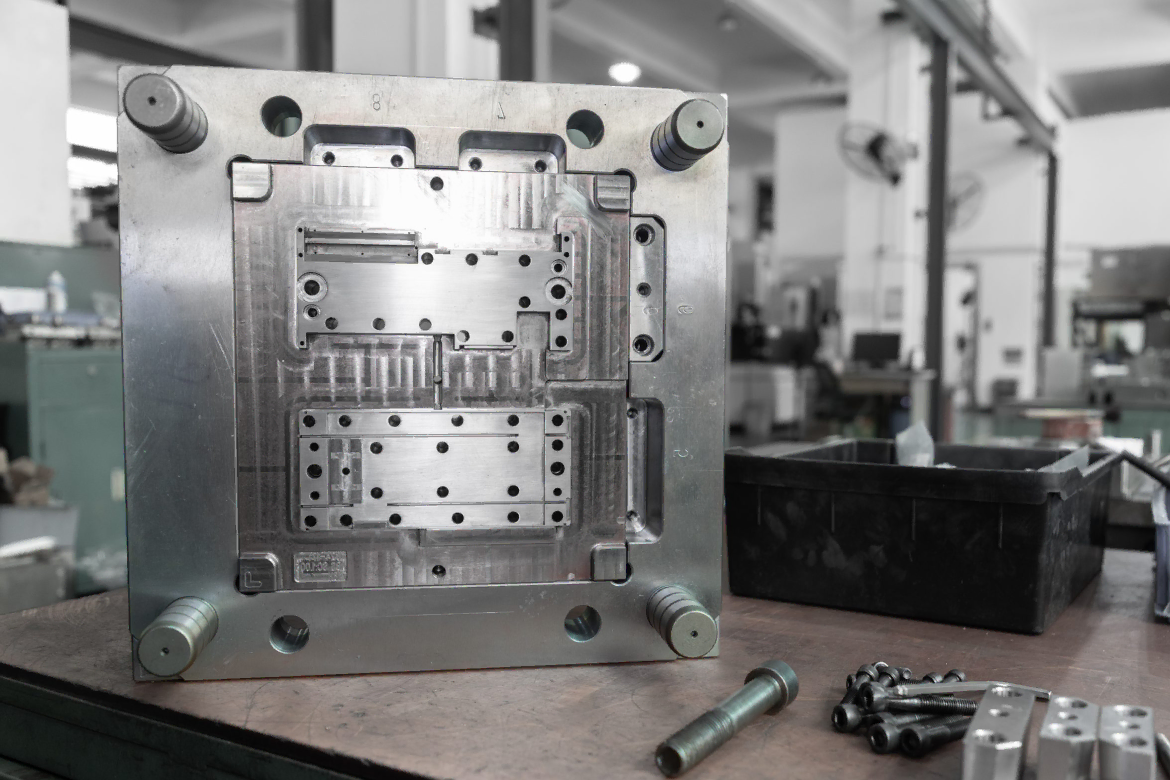

In the realm of custom metal manufacturing, injection mold services represent a cornerstone of modern industrial production. These molds are not merely tools—they are engineered systems that dictate the dimensional accuracy, surface integrity, and repeatability of thousands or even millions of plastic components. At Wuxi Lead Precision Machinery, we treat every injection mold as a high-precision instrument, where tolerances measured in microns directly influence product performance, assembly compatibility, and end-user satisfaction.

Precision in injection molding begins with design integrity and material selection, but it is realized through advanced CNC machining, EDM processing, and meticulous quality control. Even the smallest deviation—such as a 0.01 mm misalignment in cavity and core—can result in flash, parting line mismatch, or ejection failure. In high-volume production environments, such defects translate into costly downtime, scrap, and rework. Our engineering team applies decades of experience in tight-tolerance manufacturing to anticipate and mitigate these risks at the design stage, ensuring robust mold performance over extended cycles.

Wuxi Lead Precision Machinery has leveraged this precision-driven philosophy in mission-critical applications, including components developed for Olympic-grade equipment and military-spec systems. These projects demanded not only flawless dimensional accuracy but also long-term reliability under extreme conditions. Our molds have been deployed in environments requiring resistance to thermal cycling, high injection pressures, and corrosive materials—proof of our capability to meet the most stringent industrial standards.

Our injection mold services integrate a full spectrum of technologies, from 3D mold flow analysis to in-house tooling and validation. Each mold undergoes rigorous testing for gate optimization, cooling efficiency, and wear resistance. We specialize in complex geometries, multi-cavity layouts, and hot runner systems, all executed with a focus on longevity and cycle-time reduction.

The following table outlines key technical specifications that define our injection mold capabilities:

| Specification | Detail |

|---|---|

| Maximum Mold Size | 1200 × 800 × 800 mm |

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Materials Used | P20, 718H, S136, H13, 420 Stainless Steel |

| Surface Finishes | Mirror polish (SPI A1), texture (VDI 3400), matte, bead blast |

| Mold Life Expectancy | 500,000 to 1,000,000+ cycles |

| Standard Lead Time | 25–45 days (depending on complexity) |

| Quality Assurance | CMM inspection, first article reporting, mold trial video |

Precision is not an optional attribute in injection mold services—it is a foundational requirement. At Wuxi Lead Precision Machinery, our engineering discipline, combined with proven experience in elite performance sectors, positions us as a trusted partner for manufacturers demanding reliability, accuracy, and long-term value.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery Technical Capabilities for Injection Mold Services

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing for high-performance injection molds. Our technical foundation integrates advanced multi-axis machining with rigorous metrology, ensuring molds meet the most demanding specifications for complex geometries and extended production lifecycles. We specialize in transforming challenging designs into reality through controlled, repeatable processes that minimize risk for our clients.

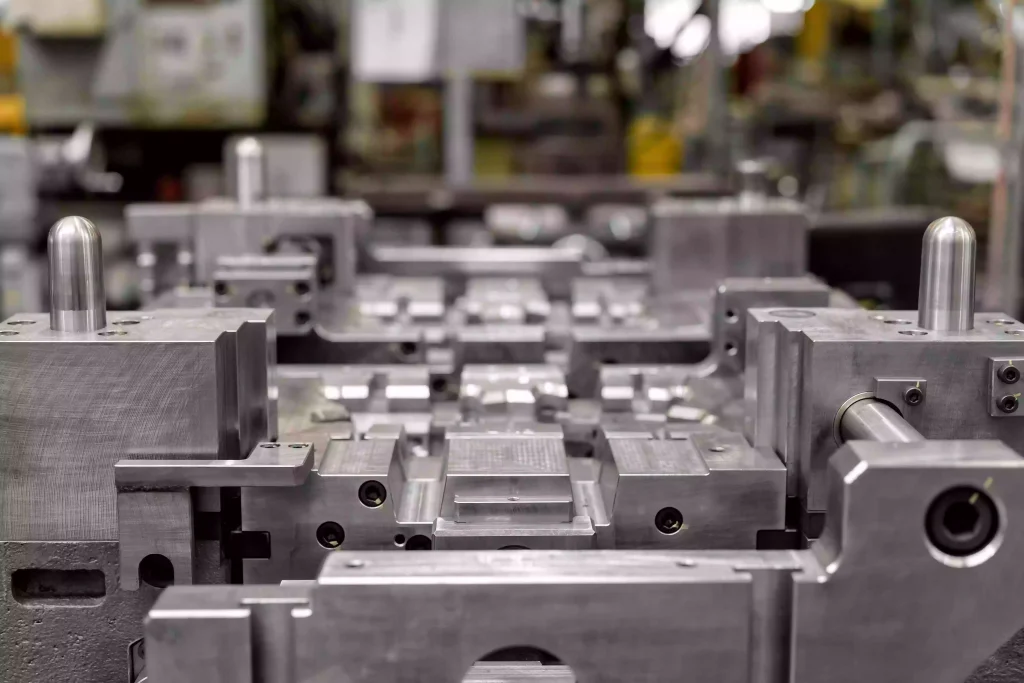

Central to our capability is a modern fleet of high-torque 5-axis CNC machining centers. These systems enable simultaneous multi-directional tool movement, eliminating the need for multiple setups that introduce cumulative errors. Complex core/cavity contours, intricate cooling channels, and undercuts are machined in a single operation, preserving critical datum relationships and surface integrity. This capability is essential for producing molds requiring tight form, fit, and function across aerospace, medical, and automotive applications where part consistency is non-negotiable. Our programming and setup protocols prioritize thermal stability and vibration control, directly impacting the achievable surface finish and dimensional fidelity on hardened tool steels and exotic alloys.

Quality assurance is not a final step but an integrated process. Every critical mold component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using calibrated Zeiss and Hexagon systems. Our inspection routines, developed per ASME Y14.5 and ISO 1101 standards, validate geometric dimensioning and tolerancing (GD&T) across all axes. This includes full 3D surface profile analysis, position tolerances for ejector pins and inserts, and verification of critical draft angles. Real-time data from CMM reports feeds directly into our process control loops, allowing immediate corrective action during machining and ensuring first-article approval success rates exceed 98%. We provide full traceable inspection documentation, including point cloud data for complex surfaces, giving clients complete visibility into component quality.

The following table details our standard achievable tolerances for machined mold components. These values represent typical performance under optimal conditions using appropriate materials, fixturing, and process parameters. Specific project requirements are always validated during the quoting phase.

| Specification Category | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions (up to 500mm) | ±0.005 mm (±0.0002″) | Achieved via 5-axis CNC with thermal compensation |

| Angular Features | ±0.005° | Verified using CMM vector point measurement |

| Surface Roughness (Ra) | 0.4 μm (16 μin) | Typical for core/cavity finishes post-machining |

| Positional Tolerance (Ø) | 0.010 mm (0.0004″) | For critical features like ejector holes |

| Flatness (per 100mm) | 0.003 mm (0.0001″) | Measured on parting surfaces and plates |

These tolerances are consistently maintained through our disciplined approach to machine calibration, tooling management, and environmental control within the production facility. Wuxi Lead Precision Machinery’s technical capabilities ensure your injection molds are manufactured to the highest standards of accuracy and reliability, directly contributing to reduced cycle times, minimized scrap rates, and superior end-part quality in your production environment. We partner with clients to define and achieve the precise specifications required for their unique manufacturing challenges.

Material & Finish Options

Material selection is a critical factor in the performance, longevity, and cost-efficiency of injection molds. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on precision-engineered molds tailored to your production demands. The choice between aluminum, steel, and titanium directly impacts mold durability, cycle time, surface finish, and overall manufacturing economics.

Aluminum is often selected for low- to medium-volume production due to its excellent thermal conductivity and ease of machining. It enables faster cooling cycles, reducing overall production time. While not as wear-resistant as steel, modern high-grade aluminum alloys offer improved hardness and are ideal for prototyping or short-run manufacturing. Aluminum also responds well to anodizing, enhancing surface hardness and corrosion resistance.

Steel remains the standard for high-volume injection molding. Tool steels such as P20, H13, and S136 provide superior hardness, wear resistance, and thermal stability. These properties ensure extended mold life, often exceeding hundreds of thousands of cycles. Hardened steels are particularly suited for complex geometries and abrasive resins. Surface treatments such as nitriding or chrome plating are commonly applied, but anodizing is generally not used on steel due to metallurgical incompatibility.

Titanium is less common but offers exceptional strength-to-density ratio and corrosion resistance. While its high cost and challenging machinability limit its use to specialized applications, titanium molds are ideal for highly corrosive environments or where weight reduction is critical. Titanium can be anodized to achieve decorative finishes and improved surface durability, though this is typically applied in niche aerospace or medical applications.

Anodizing is a key surface treatment for aluminum and titanium molds. It creates a controlled oxide layer that increases surface hardness, improves wear resistance, and enhances corrosion protection. Type II (sulfuric acid) anodizing is standard for aluminum, offering a porous layer suitable for dyeing and sealing. Type III, or hardcoat anodizing, produces a thicker, denser layer for high-wear environments. For titanium, anodizing generates vibrant, durable colors through interference effects, useful in medical and consumer-facing components.

Below is a comparative overview of key material properties and compatibility with anodizing:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Anodizing Compatible | Best Use Case |

|---|---|---|---|---|---|

| Aluminum | 40–45 | 160–200 | 10,000–100,000 | Yes (Type II & III) | Prototyping, low-volume production |

| Steel | 48–54 | 25–35 | 100,000–1M+ | No | High-volume, complex molds |

| Titanium | 35–40 (base) | 6–7 | 50,000–200,000 | Yes (color & hard) | Corrosive environments, aerospace |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production volume, resin type, part geometry, and environmental exposure. Our engineering team ensures optimal material pairing with advanced finishing techniques to deliver molds that meet exact performance criteria.

Manufacturing Process & QC

Precision Injection Mold Service: The Zero-Defect Production Framework

At Wuxi Lead Precision Machinery, our injection mold service transcends conventional manufacturing by embedding zero-defect principles into every phase of production. This rigor ensures your custom metal components meet exacting aerospace, medical, and automotive standards without compromise. Our process begins with collaborative design engineering, where 3D CAD models undergo rigorous simulation using Moldflow and ANSYS. Finite element analysis identifies potential flow imbalances, weld lines, or sink marks before metal is cut. Engineers validate gate locations, cooling channel layouts, and ejection sequences to eliminate in-mold stressors that cause defects. This virtual prototyping reduces physical iterations by 70% while guaranteeing first-article success.

Prototyping transitions digital precision into tangible validation. We machine prototype molds from pre-hardened H13 or S136 stainless steel using 5-axis CNC centers with ±0.002mm positional accuracy. Each prototype undergoes 100+ cycle trials under production-equivalent parameters. Critical dimensions are measured via Zeiss CMMs, while material flow is analyzed using real-time cavity pressure sensors. Any micro-variation triggers immediate design refinement—never mass production. This phase confirms DFM compliance and secures customer sign-off on dimensional, cosmetic, and functional criteria, establishing an unbreakable quality baseline.

Mass production leverages this validated foundation through closed-loop process control. Our dedicated molding cells employ electric and hybrid presses (50–2000T) with IoT-enabled monitoring. Every shot’s pressure, temperature, and cooling time is logged against the approved prototype dataset. Automated vision systems inspect 100% of parts for flash, short shots, or surface defects, rejecting outliers before packaging. Statistical process control (SPC) tracks Cp/Cpk values in real time, with automatic machine adjustments if trends approach tolerance limits. This system achieves <50 PPM defect rates while maintaining ±0.01mm tolerances across runs of 10,000+ units.

Our technical capabilities are engineered for defect prevention, not detection. The table below details the precision infrastructure enabling this standard.

| Parameter | Specification | Impact on Zero-Defect Outcome |

|---|---|---|

| Mold Steel | H13, S136, NAK80 (ESR Grade) | Uniform hardness minimizes wear-induced dimensional drift |

| Machining Tolerance | ±0.002mm (CNC) / ±0.001mm (EDM) | Ensures cavity/core alignment accuracy |

| Cavity Pressure Sensing | 100% shot monitoring | Detects micro-variation in filling phase |

| Cooling Uniformity | ±1°C temperature variance | Prevents warpage and internal stresses |

| SPC Integration | Real-time Cp/Cpk tracking (Min. 1.67) | Proactive correction before defects occur |

This integrated approach—where design foresight, prototyping rigor, and production intelligence converge—delivers injection molds that consistently produce flawless parts. Wuxi Lead transforms quality from a checkpoint into the foundation of manufacturing. Your zero-defect mandate is our operational reality.

Why Choose Wuxi Lead Precision

When it comes to precision-driven custom metal manufacturing, particularly in the field of injection mold services, partnering with a trusted, experienced, and technologically advanced manufacturer is essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance injection molds tailored to the exact specifications of global industries including automotive, medical, consumer electronics, and industrial equipment. Our commitment to engineering excellence, material integrity, and on-time delivery has positioned us as a preferred manufacturing partner for OEMs and tier-one suppliers worldwide.

Our injection mold service is built on a foundation of precision CNC machining, advanced mold design, and rigorous quality assurance protocols. Every mold we produce undergoes comprehensive inspection using coordinate measuring machines (CMM) and 3D scanning technology to ensure micron-level accuracy. We utilize premium-grade tool steels such as P20, 718H, S136, and H13, selected based on your project’s production volume, part complexity, and environmental requirements. With in-house capabilities spanning mold design, cavity/core machining, heat treatment, polishing, texturing, and mold trials, we maintain full control over quality and lead times.

What sets Wuxi Lead Precision Machinery apart is our engineering-first approach. Our team of senior mold designers and process engineers collaborates closely with clients from concept to final validation, offering design for manufacturability (DFM) analysis, mold flow simulation, and rapid prototyping to eliminate risks and optimize cycle times. Whether you require single-cavity molds for low-volume production or high-cavitation molds for mass manufacturing, we deliver robust, long-lasting tooling solutions that ensure consistent part quality and reduced downtime.

We understand that global supply chains demand reliability, transparency, and responsive communication. That’s why every project is managed with real-time updates, detailed documentation, and adherence to international standards including ISO 9001:2015. Our facility in Wuxi, China, is equipped with over 80 CNC machining centers, EDM systems, and automated polishing units, enabling us to support complex projects with tight tolerances and fast turnaround.

Below are key technical specifications that define our injection mold service capabilities:

| Specification | Capability |

|---|---|

| Maximum Mold Size | 1200 × 800 × 900 mm |

| Tolerance | ±0.005 mm |

| Mold Base Materials | LKM, FUTABA, HASCO, DAIDO |

| Steel Types | P20, 718H, S136, H13, NAK80, 2738 |

| Surface Finishes | Mirror polishing, texture (VDI, MT), coating (TiN, CrN) |

| Cavities | Single to 16+ cavities |

| Lead Time | 25–45 days (depending on complexity) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally focused on your long-term success. We are ready to support your next injection mold project with engineering precision, operational excellence, and unwavering commitment to quality.

Contact us today at [email protected] to discuss your requirements and receive a detailed quote. Let Lead Precision be your trusted partner in advanced mold manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.