Technical Contents

Engineering Guide: Local 3D Printing Service

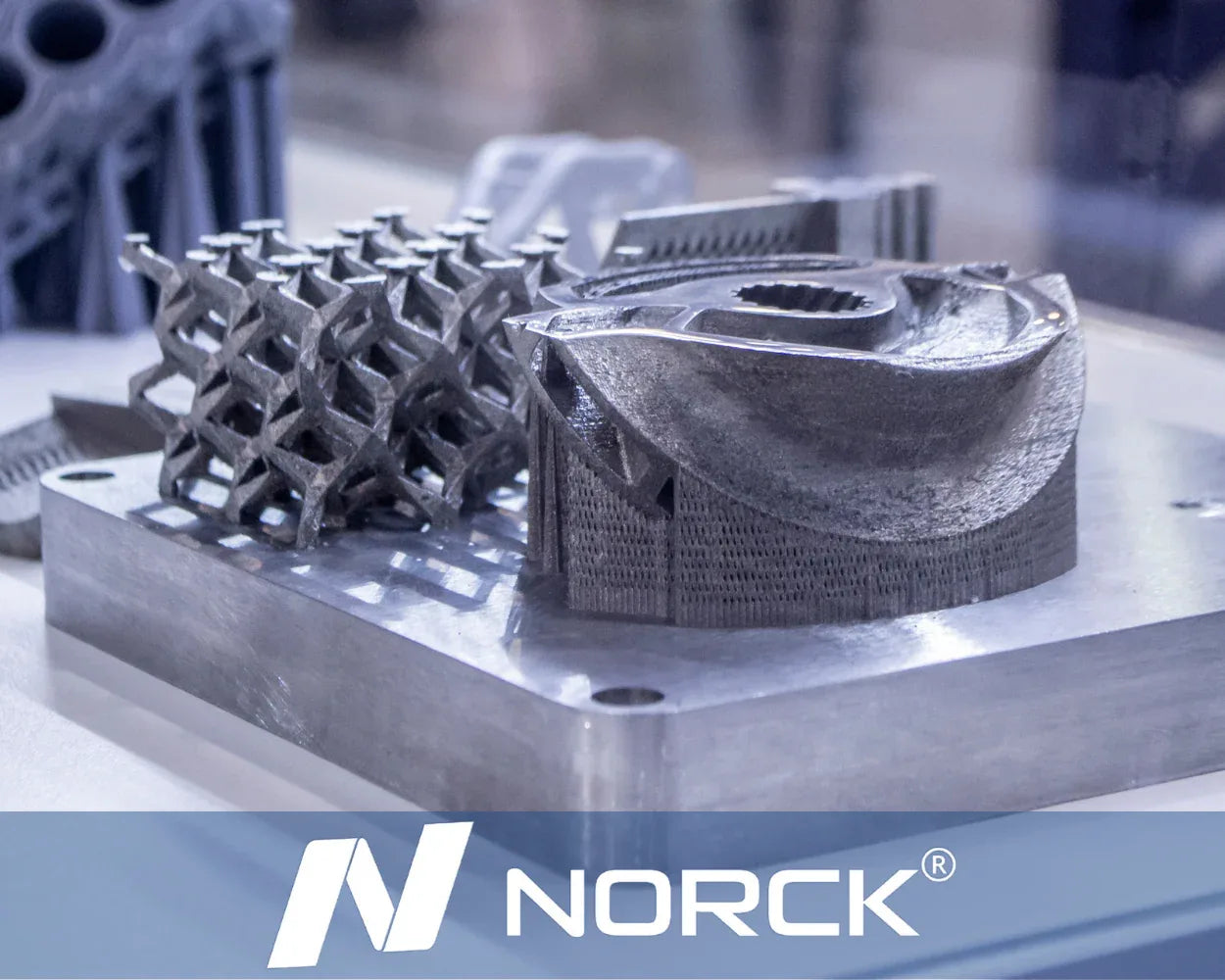

Engineering Insight Precision Defines Local Metal 3D Printing Value

The term “local 3D printing service” often implies speed and convenience for prototyping. However, in high-stakes custom metal manufacturing, proximity alone delivers negligible value if precision engineering is compromised. True local value emerges when advanced additive capabilities are integrated with rigorous metrology and deep process understanding, ensuring components meet exacting functional requirements straight from the build plate. For aerospace actuators, medical implants, or defense subsystems, dimensional accuracy, material integrity, and repeatable microstructure are non-negotiable. A local provider lacking certified processes and engineering oversight merely shifts risk closer to your facility, potentially amplifying cost and delay through failed builds or non-conforming parts.

At Wuxi Lead Precision Machinery, we engineer local metal 3D printing as a precision manufacturing solution, not just a rapid prototyping stopgap. Our facility operates under AS9100 and ISO 13485 quality management systems, with every build informed by decades of precision CNC machining discipline. This foundation ensures our additive processes prioritize geometric accuracy and material performance from the initial design review through final inspection. Our engineers implement validated thermal management protocols and in-situ monitoring on state-of-the-art SLM systems, controlling factors like residual stress and porosity that directly impact fatigue life and dimensional stability. This is why components produced for Olympic-level sporting equipment demanding micron-level tolerances and critical military hardware operating under extreme conditions consistently meet or exceed stringent specifications. Local proximity enables rapid iteration and direct engineering collaboration, but it is our unwavering commitment to precision engineering that transforms proximity into a strategic advantage.

Demanding applications require quantifiable performance. Our metal additive capabilities are structured to deliver certified results:

| Specification Parameter | Capability Value | Industry Relevance |

|---|---|---|

| Layer Thickness Range | 20 μm – 60 μm | Enables fine features & smooth surfaces |

| Build Volume (Max) | 500 x 500 x 500 mm | Supports medium-scale production parts |

| Dimensional Accuracy (Typical) | ± 0.05 mm over 100 mm | Critical for assembly & fit |

| Material Certification | ASTM F75, F138, F1586, F3001, AMS 7000 series | Ensures biocompatibility & aerospace compliance |

| Post-Processing Integration | Full in-house HIP, stress relief, precision machining | Guarantees final part integrity & tolerance |

Local metal 3D printing gains its highest value when engineering excellence eliminates the guesswork. Wuxi Lead Precision Machinery provides the certified processes, metrology-backed validation, and application-specific expertise required for mission-critical metal components. We transform local accessibility into a reliable extension of your precision manufacturing ecosystem, ensuring your most demanding designs achieve functional success on schedule. Partner with an engineering-driven provider where precision is the core metric, not an afterthought.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the demanding requirements of high-performance industries including aerospace, medical, automotive, and energy. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining platform, enabling the production of highly complex geometries with exceptional precision and surface finish. Our multi-axis machining centers eliminate the need for multiple setups, reducing lead times and maintaining superior dimensional accuracy across intricate components. With integrated high-speed spindles and dynamic tool path optimization, we achieve tight tolerances and consistent repeatability on a wide range of metals, including titanium, Inconel, stainless steel, aluminum, and specialty alloys.

Our manufacturing workflow is supported by a comprehensive quality assurance system anchored in CMM (Coordinate Measuring Machine) inspection. Every critical component undergoes full dimensional verification using Zeiss and Hexagon CMM systems, ensuring compliance with ISO 10360 standards. These metrology-grade machines provide micron-level measurement accuracy across 3D datums, geometric tolerances, and surface profiles. Our quality engineers generate detailed inspection reports with full traceability, including first-article inspection (FAI) and production part approval process (PPAP) documentation upon request. This rigorous inspection protocol ensures that every part meets or exceeds customer specifications and industry certifications.

In addition to precision machining and inspection, Wuxi Lead integrates advanced CAM programming and simulation software to optimize tool paths, minimize material waste, and prevent collisions during machining. Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) phase to identify potential improvements in part geometry, material selection, and production efficiency. This proactive approach reduces cost, accelerates time-to-market, and enhances overall product performance.

We maintain strict environmental and operational controls within our ISO 9001:2015-certified facility, ensuring consistent process stability and part quality. Our equipment is regularly calibrated, and operators are trained to adhere to standardized work instructions, supporting high-volume production runs as well as low-volume, high-mix manufacturing.

The following table outlines the standard technical specifications and achievable tolerances across our 5-axis CNC machining services:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.05 mm | ±0.01 mm |

| Geometric Tolerance (GD&T) | ±0.02 mm (per feature) | ±0.008 mm (per feature) |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm (polished finishes available) |

| Feature Size (Minimum) | 0.5 mm (drilled) | 0.3 mm (milled) |

| Maximum Work Envelope | 1200 x 800 x 600 mm | 1200 x 800 x 600 mm |

| Material Compatibility | Steel, Stainless, Aluminum, Titanium, Inconel, Brass, Bronze | Same, with certified material traceability |

Wuxi Lead Precision Machinery combines cutting-edge technology, rigorous quality control, and engineering expertise to deliver mission-critical metal components with unmatched precision and reliability.

Material & Finish Options

Material Selection for High-Performance Metal Additive Manufacturing

Selecting the optimal material is paramount in metal additive manufacturing, directly impacting part performance, longevity, and cost-effectiveness. At Wuxi Lead Precision Machinery, our engineering expertise ensures clients leverage the unique properties of Aluminum, Steel, and Titanium alloys within Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) processes. Understanding the inherent characteristics of each material family is critical for demanding aerospace, medical, and industrial applications where precision and reliability are non-negotiable.

Aluminum alloys, particularly AlSi10Mg and high-strength 7075 variants, dominate applications requiring an exceptional strength-to-weight ratio and thermal conductivity. These materials excel in lightweight structural components, heat exchangers, and complex enclosures where weight reduction is critical without sacrificing rigidity. Aluminum’s inherent machinability also facilitates secondary operations post-printing. Steel alloys, especially corrosion-resistant 316L stainless steel and tool steels like H13, provide superior hardness, wear resistance, and structural integrity under high stress or temperature. They are the standard for tooling inserts, hydraulic components, and parts requiring stringent biocompatibility or chemical resistance in harsh environments. Titanium alloys, primarily Ti6Al4V (Grade 5), offer the highest strength-to-weight ratio among common printable metals, coupled with outstanding biocompatibility and exceptional corrosion resistance, particularly in saline environments. This makes titanium indispensable for critical aerospace structural elements, medical implants, and marine components where failure is not an option.

The following table summarizes key mechanical and application properties for the most utilized alloys in our service:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 540 – 570 | Moderate | Aerospace brackets, high-stress fittings |

| 316L Stainless | 8.00 | 580 – 700 | Excellent | Medical instruments, chemical valves |

| Ti6Al4V (Grade5) | 4.43 | 900 – 950 | Exceptional | Aircraft engine parts, orthopedic implants |

Surface finishing, particularly anodizing for aluminum components, is a vital post-processing step we rigorously control. Anodizing significantly enhances surface hardness, wear resistance, and corrosion protection by creating a controlled oxide layer. It also provides an excellent base for adhesion of paints and primers and allows for precise cosmetic coloring. Our precision anodizing processes are calibrated to meet stringent aerospace (AMS 2469, AMS 2471) and military specifications, ensuring consistent, high-integrity finishes that protect critical surfaces without compromising dimensional tolerances achieved during the additive build.

Material selection must align precisely with the functional requirements, environmental exposure, and regulatory standards of the end-use part. Our engineering team collaborates closely with clients during the design phase to evaluate stress profiles, thermal loads, and lifecycle demands, ensuring the chosen alloy and finishing process deliver optimal performance and value. Choosing the right material foundation is not merely a specification; it is the cornerstone of successful, reliable metal additive manufacturing.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered for precision, consistency, and zero-defect delivery. We specialize in high-end local 3D printing services, integrating advanced additive manufacturing with traditional precision engineering to serve industries where performance and reliability are non-negotiable. Our end-to-end process spans three critical phases: Design, Prototyping, and Mass Production—each governed by strict quality controls and process validation.

The journey begins with Design, where our engineering team collaborates closely with clients to translate concepts into manufacturable solutions. Utilizing advanced CAD and simulation tools, we optimize part geometry, material selection, and structural integrity. Thermal, stress, and flow analyses are conducted to anticipate real-world behavior, ensuring the design is not only functional but also production-ready. This phase includes Design for Additive Manufacturing (DfAM) principles to maximize efficiency, reduce weight, and eliminate unnecessary assembly steps.

Next is Prototyping, a phase critical to de-risking the final product. Using our in-house metal 3D printing systems—including SLM and DMLS technologies—we produce functional prototypes in the actual production-grade materials such as Inconel 718, Titanium Ti6Al4V, Stainless Steel 316L, and Aluminum AlSi10Mg. These prototypes undergo rigorous mechanical testing, dimensional inspection via CMM (Coordinate Measuring Machine), and non-destructive testing (NDT) to validate performance. Feedback from this stage is looped back into the design for refinement, ensuring perfection before scaling.

Once the prototype is approved, we transition seamlessly into Mass Production. Our facility in Wuxi operates a fleet of industrial-grade 3D printers with automated powder management and inert gas controls, ensuring batch-to-batch consistency. Each production run is monitored in real time using in-situ process monitoring systems that track melt pool stability, layer adherence, and thermal gradients. Post-processing—including heat treatment, HIP (Hot Isostatic Pressing), CNC machining, and surface finishing—is performed to meet exact dimensional and metallurgical specifications.

Throughout all stages, our Zero Defects philosophy is enforced through a comprehensive Quality Management System compliant with ISO 9001 and AS9100 standards. Every component is traceable via serialized data logs, and statistical process control (SPC) is used to detect deviations before they impact output.

The following table summarizes key capabilities of our metal 3D printing process:

| Parameter | Specification |

|---|---|

| Build Volume | Up to 500 x 500 x 400 mm |

| Layer Thickness | 20–50 μm |

| Dimensional Accuracy | ±0.05 mm for first 50 mm, ±0.01 mm/mm beyond |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Supported Materials | Ti6Al4V, Inconel 718, 316L, AlSi10Mg, Maraging Steel |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing, anodizing, coating |

With seamless integration from design to full-scale production and an uncompromising commitment to quality, Wuxi Lead Precision Machinery delivers custom metal components that perform under the most demanding conditions.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Additive Excellence

In the rapidly evolving landscape of advanced manufacturing, selecting a metal additive partner demands more than access to printers—it requires engineering mastery, rigorous process control, and unwavering commitment to your application’s success. Wuxi Lead Precision Machinery transcends the role of a standard 3D printing service provider. We integrate industrial-grade metal additive systems with decades of precision CNC expertise, delivering fully qualified, mission-critical components that meet the exacting standards of aerospace, medical, and energy sectors. Our facility operates under AS9100-certified quality management, ensuring traceability, material integrity, and repeatable performance from prototype to serial production. When you partner with Lead Precision, you gain a technical ally invested in solving your most complex engineering challenges, not merely executing print jobs.

Our metal additive capabilities are engineered for real-world industrial application, supported by comprehensive post-processing and metrology resources. The table below outlines core specifications defining our production readiness:

| Specification | Capability Detail |

|---|---|

| Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, CoCr, Maraging Steel |

| Layer Thickness | 20–50 µm (adjustable for resolution/speed balance) |

| Build Volume | Ø250 x 325 mm (EOS M 400-4) / 250 x 250 x 300 mm (Concept Laser M2) |

| Dimensional Accuracy | ±0.05 mm for features < 50 mm; ±0.1% for larger geometries |

| Surface Finish (as-built) | 15–25 µm Ra;可 polished to <0.8 µm Ra with integrated post-processing |

| Certifications | AS9100D, ISO 9001:2015, Material Test Reports (MTRs) per order |

Beyond printing, we own the entire value chain. Our engineers collaborate with your team during design for additive manufacturing (DFAM) analysis, optimizing topology, support structures, and thermal management to eliminate failures and reduce lead times. Every build undergoes in-situ monitoring, followed by precision CNC machining, heat treatment, and 5-axis CMM validation to ensure compliance with GD&T callouts. This integrated approach—where additive and subtractive processes are strategically combined—delivers parts that consistently achieve fatigue life, porosity, and microstructure requirements unattainable through printing alone.

Local 3D printing services often lack the metallurgical expertise or secondary operations to transform raw builds into certified components. Lead Precision bridges this gap with dedicated project management, rapid iteration cycles, and transparent communication from NDA through delivery. We understand that your reputation hinges on component reliability; our process is built to protect it.

Do not settle for vendors who treat metal additive as a standalone process. Elevate your projects with a partner who engineers solutions. Contact us today to discuss your specific application requirements. Email Contact [email protected] to schedule a technical consultation. Our engineering team will respond within 24 hours to review your CAD files, provide actionable DFAM feedback, and establish a clear path to production-ready metal components. Partner with precision. Partner with Lead. Your next breakthrough begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.