Technical Contents

Engineering Guide: Best Metal Print Company

Engineering Insight: The Defining Role of Precision in Advanced Metal Manufacturing

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. For industries ranging from aerospace to defense and high-performance industrial equipment, even micrometer-level deviations can result in catastrophic system failures. This uncompromising demand for accuracy defines the standard by which the best metal print company must operate. At Wuxi Lead Precision Machinery, we recognize that precision is not achieved through advanced machinery alone, but through the integration of engineering expertise, rigorous process control, and a culture of continuous improvement.

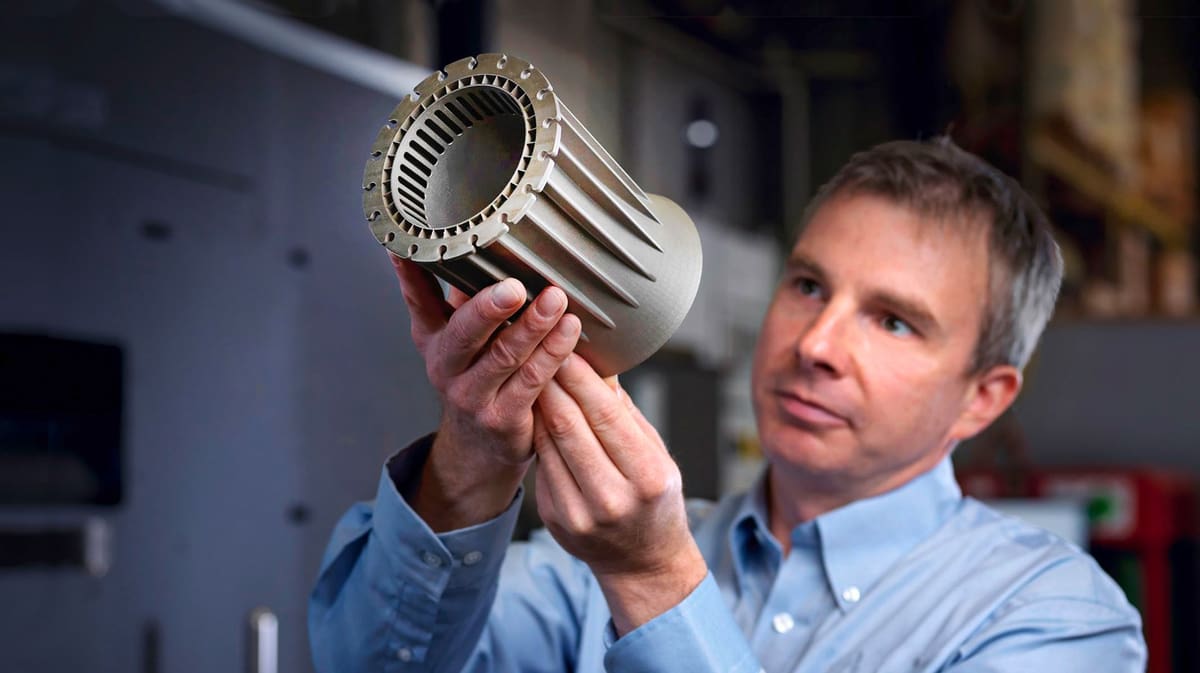

Our commitment to precision is rooted in over a decade of specialization in high-tolerance CNC machining, additive manufacturing, and hybrid metal fabrication techniques. Unlike conventional metal printing services that prioritize speed or cost, we engineer every component with dimensional stability, material integrity, and long-term performance as primary design criteria. This approach has enabled us to deliver mission-critical components for applications where failure is not an option.

Wuxi Lead has proudly contributed to projects of national and international significance, including precision components used in Olympic-grade sporting equipment and subsystems integrated into military-grade defense systems. These high-profile applications demanded not only adherence to ISO and MIL-STD specifications but also the ability to innovate within strict regulatory and performance frameworks. Our role in these projects underscores our technical capability and the trust placed in our engineering processes by leading institutions.

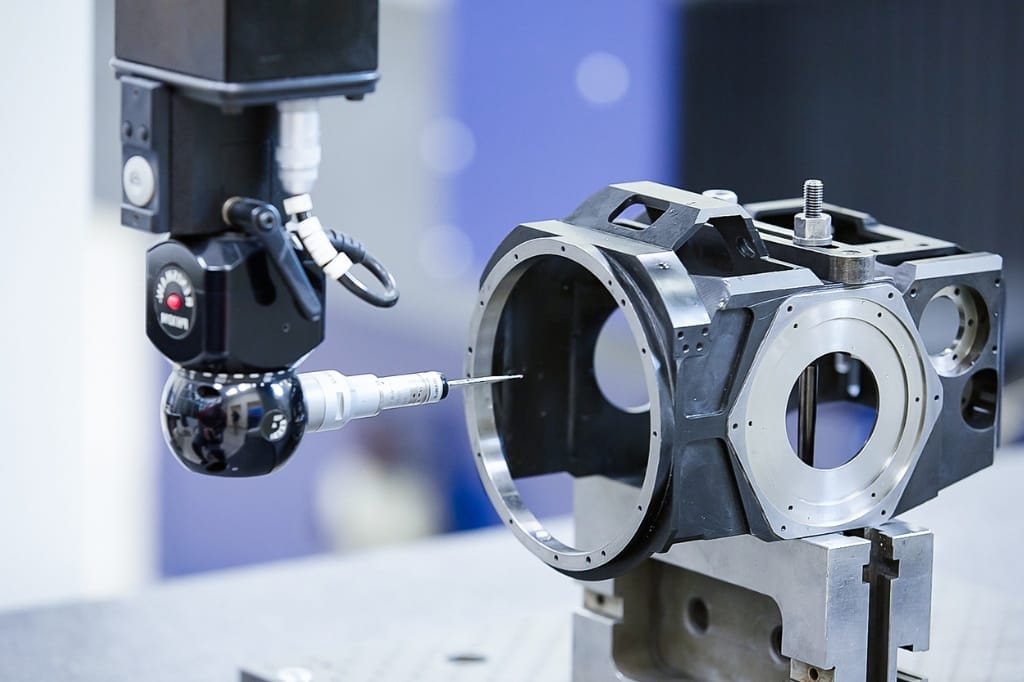

Precision begins at the design phase. Our engineering team collaborates closely with clients to optimize part geometry, material selection, and manufacturing methodology. Finite element analysis (FEA), thermal stress modeling, and tolerance stack-up simulations are standard practices, ensuring that every component performs as intended under real-world conditions. Once in production, our facility employs multi-axis CNC machines, laser powder bed fusion systems, and coordinate measuring machines (CMM) with sub-micron resolution to maintain consistency across production runs.

The table below outlines key performance specifications that define our precision manufacturing capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Feature Resolution | Down to 0.1 mm (additive), 0.01 mm (CNC) |

| Material Compatibility | Titanium, Inconel, Stainless Steel, Aluminum, Tool Steels |

| Maximum Build Volume | 500 x 500 x 400 mm (additive) |

| Quality Standards | ISO 9001:2015, MIL-STD-810, AS9100 (compliant) |

| In-Process Inspection | Real-time laser monitoring, CMM verification |

Precision is not a claim—it is a verifiable outcome. At Wuxi Lead Precision Machinery, our legacy in high-stakes manufacturing environments reflects our ability to meet and exceed the expectations of the most demanding industries. When selecting the best metal print company, clients must look beyond marketing and evaluate engineering depth, proven performance, and documented results. We stand by ours.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision and complexity in custom metal manufacturing, serving industries where failure is not an option. Our core strength lies in advanced multi-axis CNC machining, specifically leveraging state-of-the-art 5-axis milling and turning centers. These systems execute simultaneous five-axis interpolation, enabling the production of intricate geometries—organic contours, deep cavities, undercuts, and complex angled features—in a single setup. This capability eliminates cumulative errors from multiple fixtures, significantly reduces lead times, and ensures superior part integrity critical for aerospace components, medical implants, and high-performance automotive systems. Our Haas, DMG MORI, and Makino platforms utilize high-rigidity structures, thermal compensation systems, and sub-micron resolution feedback, providing the stable foundation required for micron-level accuracy across diverse production volumes.

Rigorous quality assurance is non-negotiable. Every critical dimension undergoes verification using calibrated Coordinate Measuring Machines (CMMs), the industry benchmark for dimensional metrology. Our Zeiss and Hexagon GLOBAL S 07.10.07 CMMs, operating within ISO 17025 accredited environmental controls, perform comprehensive first-article inspections and in-process checks. Utilizing advanced probing systems and PC-DMIS software, we generate detailed inspection reports with GD&T analysis, ensuring absolute conformance to your engineering specifications. This systematic approach, integrated into our ISO 9001:2015 certified processes, guarantees traceability and provides documented proof of quality at every stage.

Material versatility is fundamental to our service. We expertly machine a wide spectrum of engineering alloys including aerospace-grade aluminum (2024, 7075), stainless steels (303, 304, 316, 17-4PH), titanium (Gr 2, Gr 5), tool steels (P20, H13), brass, and copper. Our technical team collaborates closely with clients during the design phase to optimize manufacturability, selecting appropriate materials, tooling strategies, and machining parameters to achieve target tolerances efficiently while minimizing waste. Surface finishes down to Ra 0.4 µm are routinely achievable through specialized finishing protocols.

The following table outlines our standard achievable tolerance capabilities under controlled conditions. Actual tolerances are always determined during engineering review based on specific part geometry, material, and functional requirements.

| Material Category | Feature Type | Standard Tolerance Range |

|---|---|---|

| Aluminum Alloys | General Machining | ±0.010 mm (±0.0004″) |

| Critical Dimensions | ±0.005 mm (±0.0002″) | |

| Hole Location | ±0.008 mm (±0.0003″) | |

| Stainless Steel | General Machining | ±0.012 mm (±0.0005″) |

| Critical Dimensions | ±0.008 mm (±0.0003″) | |

| Hole Location | ±0.010 mm (±0.0004″) | |

| Titanium Alloys | General Machining | ±0.015 mm (±0.0006″) |

| Critical Dimensions | ±0.010 mm (±0.0004″) | |

| Hole Location | ±0.012 mm (±0.0005″) |

This disciplined integration of cutting-edge 5-axis technology, metrology-grade inspection, and deep materials expertise allows Wuxi Lead to consistently meet the stringent demands of high-value metal components. We transform complex designs into reality with the precision, reliability, and documentation required by the world’s most exacting industries. Partner with us for manufacturing where specifications are not targets, but guarantees.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components using high-grade aluminum, steel, and titanium—each offering distinct advantages depending on application requirements. Understanding the mechanical properties and compatibility of these materials ensures optimal part functionality across industries such as aerospace, automotive, medical, and industrial automation.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight structures without sacrificing structural integrity. Common alloys used include 6061-T6 and 7075-T6, with the latter offering higher tensile strength suitable for demanding environments. Aluminum’s natural oxide layer provides inherent corrosion protection, but when enhanced with surface treatments such as anodizing, it achieves superior wear resistance and aesthetic versatility.

Steel remains the standard for high-strength, high-wear applications. We utilize both carbon steel and stainless steel variants depending on the need. Carbon steels like 1045 offer excellent machinability and hardness, making them suitable for shafts, gears, and structural components. In contrast, stainless steels such as 304 and 316 provide outstanding corrosion resistance and are frequently specified in medical devices and food processing equipment due to their hygienic properties. While heavier than aluminum, steel delivers unmatched durability under load and impact.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance demands. Its exceptional strength-to-density ratio, resistance to high temperatures, and immunity to corrosion in harsh environments make it indispensable in aerospace and biomedical applications. Though more challenging to machine and higher in cost, titanium’s long-term reliability in critical systems justifies its use where failure is not an option.

Surface finishing further enhances material performance. Anodizing, primarily applied to aluminum, is an electrochemical process that thickens the natural oxide layer, significantly improving surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing allows for color dyeing, supporting branding or identification needs, while Type III (hardcoat) anodizing delivers extreme wear resistance for industrial components. All anodized finishes are compatible with tight tolerance machining, ensuring dimensional accuracy is maintained.

Below is a comparative overview of key material properties:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | High | Enclosures, brackets, drones | Anodizing, bead blasting |

| Steel 1045 | 600 | 7.85 | Moderate | Shafts, tooling, machinery | Zinc plating, painting |

| Stainless 304 | 515 | 8.0 | Very High | Medical, food equipment | Passivation, polishing |

| Titanium Ti-6Al-4V | 950 | 4.43 | Excellent | Aerospace, implants | Anodizing, grit blasting |

Selecting the right material and finish requires a balance of engineering requirements, environmental exposure, and lifecycle costs. Wuxi Lead Precision Machinery supports clients in making informed decisions through expert consultation and precision manufacturing capabilities.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Zero-Defect Metal Manufacturing Process

At Wuxi Lead Precision Machinery, we transform complex metal component requirements into flawless production realities through a rigorously controlled three-phase workflow. Our process eliminates guesswork and rework, ensuring your custom parts meet exacting specifications from concept to shipment. This systematic approach underpins our Zero Defects commitment, critical for aerospace, medical, and high-performance industrial applications where failure is not an option.

The journey begins with Engineering Design Validation. Our CNC engineering team collaborates with your designers to scrutinize CAD models for manufacturability, material suitability, and geometric feasibility. We perform advanced DFM analysis using Siemens NX software, identifying potential stress points, tool access constraints, and thermal deformation risks. This phase includes material certification verification and fixture simulation, ensuring the design can achieve sub-micron repeatability under production conditions. Only after joint sign-off on the optimized process plan do we proceed, preventing costly errors downstream.

Precision Prototyping follows, executed on the same production-grade DMG MORI and Makino 5-axis CNC centers used for final manufacturing. This eliminates machine-to-machine variation. Prototypes undergo comprehensive metrology: CMM inspection (Zeiss CONTURA), surface roughness testing (per ISO 4287), and first-article reporting per AS9102 standards. Critical dimensions are validated against your blueprint with tolerances held to ±0.002 mm. Feedback loops integrate test results directly into the production program, refining toolpaths and inspection protocols before scaling.

| Critical Production Specification | Wuxi Lead Standard | Industry Typical |

|---|---|---|

| Dimensional Tolerance (mm) | ±0.002 | ±0.010 |

| Surface Roughness (Ra, μm) | 0.2 – 0.8 | 1.6 – 3.2 |

| In-Process Inspection Rate | 100% critical features | 10-30% sampling |

| SPC Control Limits | ±1.5σ | ±3σ |

| Material Traceability | Full heat/lot chain | Batch level |

Zero-Defect Mass Production leverages our closed-loop quality ecosystem. Every component is manufactured under controlled environmental conditions (20±1°C) with real-time tool wear monitoring via Renishaw probes. In-process inspections occur at defined intervals using automated vision systems and calibrated micrometers, with data fed into statistical process control (SPC) charts. Any deviation beyond ±1.5σ triggers immediate machine stoppage and root-cause analysis. Final inspection includes full-spectrum validation: dimensional reports, material certs, and non-destructive testing (NDT) where specified. Parts ship with a complete digital quality dossier, providing auditable proof of conformance.

This integrated methodology ensures defect escape rates below 10 PPM. By embedding quality into every phase—not as a checkpoint but as a continuous parameter—we eliminate scrap costs, accelerate time-to-market, and guarantee your supply chain resilience. Partner with Wuxi Lead for metal components where precision isn’t promised—it’s engineered and proven.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and responsiveness are non-negotiable in high-performance industries such as aerospace, medical devices, automotive, and industrial automation. As a globally trusted name in custom metal manufacturing, we don’t just meet expectations—we redefine them. Our advanced CNC machining capabilities, combined with rigorous quality assurance and a customer-first engineering approach, make us the ideal partner for businesses demanding excellence in every component.

Choosing the right manufacturing partner is a strategic decision. It impacts not only the quality of your end product but also your time-to-market, supply chain stability, and long-term cost efficiency. At Lead Precision, we operate with the understanding that your success is our success. Our team of senior engineers and production specialists works closely with clients from concept through delivery, offering DFM analysis, material selection guidance, and real-time production updates to ensure seamless collaboration.

We specialize in low to medium volume, high-mix production runs, where precision and flexibility are paramount. Our facility in Wuxi, China, is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and multi-tasking machines capable of handling complex geometries with tolerances as tight as ±0.005 mm. Whether your project requires aluminum, stainless steel, titanium, or exotic alloys, we maintain strict ISO 9001:2015-certified processes to guarantee consistency and traceability.

Our commitment to transparency and communication sets us apart. We provide detailed inspection reports, first-article approvals, and full production documentation, ensuring every part meets your exact specifications. With rapid prototyping services and scalable production capacity, we support innovation at every stage.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, Swiss machining |

| Tolerances | ±0.005 mm (0.0002″) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Inconel, PEEK |

| Max Work Envelope | 1200 x 600 x 500 mm (47 x 24 x 20 in) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Bead Blasting |

| Quality Standards | ISO 9001:2015, Full FAI and CMM inspection, Material Certifications |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally. We are committed to delivering not just metal parts, but solutions that drive your innovation forward.

Contact us today at [email protected] to discuss your next project. Let our expertise become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.