Technical Contents

Engineering Guide: Punching Sheet Metal

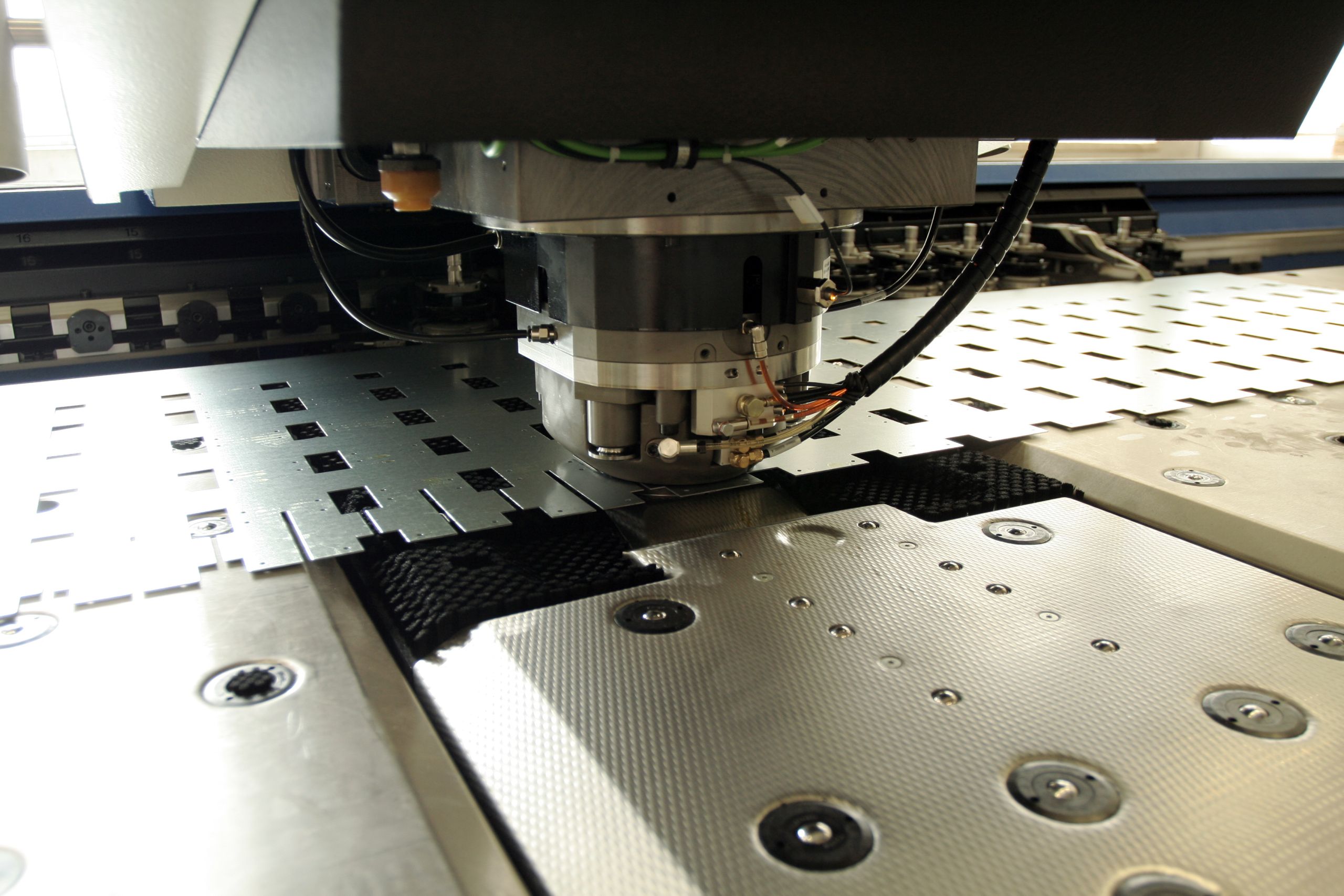

Engineering Insight: Punching Sheet Metal Requires Uncompromising Precision

Punching sheet metal is far more than a simple hole-making operation; it is a critical forming process demanding absolute dimensional accuracy and repeatability. In high-end manufacturing, particularly for aerospace, defense, medical devices, and precision instrumentation, the tolerances achieved during punching directly impact component fit, function, and final assembly integrity. Microscopic deviations in hole position, diameter, or edge quality can cascade into costly assembly failures, performance degradation, or premature part wear. Achieving true precision requires sophisticated CNC turret punch press technology, meticulously maintained tooling, expert process programming, and rigorous in-process quality control. Material behavior under high-speed impact, including springback and burr formation, must be precisely anticipated and compensated for within the machine control system. The difference between acceptable and exceptional punching lies not just in the machine’s capability, but in the deep engineering understanding applied to material science, tool geometry, and machine dynamics for each specific application.

Wuxi Lead Precision Machinery operates at this pinnacle of precision sheet metal fabrication. Our CNC punching centers, calibrated to stringent international standards, consistently deliver results demanded by the world’s most exacting industries. This capability is proven through our direct contribution to landmark projects, including components for Olympic venue infrastructure requiring flawless integration under immense structural loads and critical subsystems for advanced military platforms where reliability is non-negotiable. These engagements demanded not only meeting but exceeding standard industry tolerances, often operating within micron-level specifications under rigorous third-party audit. Our engineering team possesses the deep material science knowledge and process optimization expertise to select optimal punch/die clearances, sequencing strategies, and feed rates for diverse alloys – from ultra-thin stainless steel for medical enclosures to high-strength aluminum alloys for aerospace brackets – ensuring minimal distortion and superior edge quality.

The foundation of this precision is quantifiable in our machine capabilities and process control:

| Key Specification | Performance Metric | Significance |

|---|---|---|

| Positional Accuracy | ±0.02 mm over 1000 mm | Ensures perfect alignment in multi-stage operations and final assemblies |

| Hole Diameter Tolerance | ±0.05 mm (depending on material/thickness) | Critical for press-fit components and precision fastening |

| Maximum Material Thickness | 6.0 mm (Mild Steel) / 4.0 mm (Stainless) | Supports robust structural components |

| Tool Change Speed | < 1.5 seconds per tool | Maximizes uptime and complex part efficiency |

| Material Compatibility | Steel, Stainless, Aluminum, Copper, Brass | Broad application across demanding industries |

Precision punching is not merely a production step; it is an engineering discipline. At Wuxi Lead Precision Machinery, decades of refining this discipline for mission-critical applications inform every project we undertake. We translate complex engineering requirements into flawless punched components, ensuring your sheet metal fabrications meet the uncompromising standards your end products demand. Trust in proven precision, engineered for performance where failure is not an option.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced punching sheet metal solutions tailored for high-precision industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC technology, enabling complex geometries, tight tolerances, and superior repeatability across diverse sheet metal materials. This level of precision ensures that components meet the rigorous demands of industries such as aerospace, medical equipment, telecommunications, and high-end automation.

Our 5-axis CNC punching platforms integrate multi-directional tooling and dynamic workpiece manipulation, allowing for simultaneous punching, forming, and notching operations from multiple angles. This eliminates the need for multiple setups, reduces cumulative error, and significantly improves throughput. The machines are equipped with intelligent tool path optimization software that enhances material utilization and minimizes cycle times, making our processes both efficient and cost-effective for low to medium volume production runs.

Material compatibility spans a broad spectrum, including cold-rolled steel, stainless steel, aluminum, brass, and copper, with thicknesses ranging from 0.5 mm to 6.0 mm. Our systems support both standard and custom tooling configurations, enabling the production of intricate features such as louvers, embossments, counterbores, and multi-stage forms—all within a single processing cycle.

Quality assurance is integral to our manufacturing philosophy. Every punched component undergoes rigorous inspection using coordinate measuring machine (CMM) technology. Our CMM systems provide full 3D verification of critical dimensions, hole positions, and geometric tolerances, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Data from inspections are documented and traceable, supporting full quality reporting for audit and certification purposes.

In addition to dimensional accuracy, surface integrity is carefully maintained through optimized tool clearances, controlled punch penetration, and automated material handling. This results in clean edges, minimal burr formation, and preserved material properties—essential for components requiring subsequent finishing or welding.

The combination of advanced machinery, skilled programming, and systematic quality control allows Wuxi Lead to consistently deliver sheet metal parts that meet exacting engineering specifications. Whether producing prototypes or scaled batches, our punching capabilities ensure precision, reliability, and repeatability across every project.

Technical Specifications and Tolerances

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Punching Centers |

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Maximum Sheet Size | 1250 mm × 2500 mm |

| Positional Tolerance | ±0.05 mm |

| Hole Diameter Tolerance | +0.1 mm / -0.05 mm (depending on material & size) |

| Edge-to-Edge Dimension Tolerance | ±0.1 mm |

| Angular Tolerance | ±0.5° |

| Flatness Tolerance | 0.1 mm per 100 mm² |

| Repeatability | ±0.03 mm |

| Surface Roughness (Ra) | ≤ 3.2 µm (punched edges) |

| Inspection Method | CMM (Coordinate Measuring Machine) |

Material & Finish Options

Material Selection for Precision Sheet Metal Punching

Material choice fundamentally impacts punching performance, tool life, edge quality, and final part functionality. At Wuxi Lead Precision Machinery, we emphasize selecting the optimal material based on your specific application requirements, production volume, and budget constraints. Understanding the behavior of common metals during the punching process is critical for achieving high yields and minimizing secondary operations. Punching generates significant localized force and heat, influencing material deformation, burr formation, and tool wear rates. The selected material must withstand this stress while meeting the end-use environmental and mechanical demands. Incorrect selection often leads to excessive tool maintenance, dimensional inaccuracies, or part failure in service.

Aluminum alloys, particularly 5052 and 6061, are widely favored for their excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. They punch relatively easily with lower force requirements compared to steel, resulting in reduced machine strain and longer tool life. However, aluminum’s softness increases susceptibility to galling and built-up edge on punches, especially with inadequate lubrication or dull tools. Achieving clean edges requires precise tool clearance and sharp tooling. Aluminum is the primary candidate for anodizing, a critical electrochemical finish that significantly enhances surface hardness, wear resistance, and corrosion protection while allowing for decorative coloring. Anodizing must be performed after punching, as the process slightly increases part dimensions and seals surface porosity.

Carbon steel and stainless steel (304, 316) offer superior strength, durability, and cost-effectiveness for structural applications. Mild steel punches predictably with good edge quality when using correct clearances. Stainless steel provides excellent corrosion resistance but demands higher punching forces and generates more heat, accelerating tool wear. Its work-hardening tendency requires sharp tools and precise parameters to prevent cracking or excessive burrs. While steel can receive various protective coatings, anodizing is not applicable; alternatives include powder coating, plating, or passivation for stainless grades. Titanium presents exceptional strength-to-weight ratio and corrosion resistance for aerospace or medical applications but poses significant punching challenges. Its low thermal conductivity causes rapid heat buildup, and high chemical reactivity leads to severe galling and tool adhesion. Punching titanium requires specialized tool coatings, extremely sharp tools, controlled feed rates, and often lower production speeds, significantly impacting cost and throughput.

The following table summarizes key punching characteristics for common materials:

| Material | Typical Thickness Range (mm) | Punching Force (kN/mm) | Tool Wear Rate | Key Punching Considerations |

|---|---|---|---|---|

| Aluminum (5052) | 0.5 – 6.0 | 35 – 45 | Moderate | Prone to galling; requires sharp tools & lubrication; ideal for anodizing |

| Mild Steel (A36) | 0.8 – 12.0 | 80 – 100 | Low | Predictable deformation; standard clearances effective; cost-efficient |

| Stainless (304) | 0.5 – 8.0 | 95 – 115 | High | Work-hardens rapidly; high heat generation; needs sharp tools & slower speeds |

| Titanium (Gr 2) | 0.5 – 3.0 | 110 – 130 | Very High | Severe galling risk; requires coated tools; strict parameter control; low thermal conductivity |

Selecting the right material involves balancing performance needs with manufacturability. Wuxi Lead Precision Machinery leverages decades of punching expertise and advanced CNC turret technology to optimize parameters for each material, ensuring consistent quality and maximizing tool investment. Consult our engineering team early in your design phase to determine the most efficient and cost-effective material and process strategy for your specific punching application.

Manufacturing Process & QC

Design: The Foundation of Precision in Sheet Metal Punching

The journey of high-precision sheet metal punching begins with meticulous design, where engineering intent meets manufacturability. At Wuxi Lead Precision Machinery, our design phase integrates advanced CAD/CAM systems with deep process knowledge to ensure every component is optimized for performance, material efficiency, and production accuracy. Engineers analyze material type, thickness, hole patterns, bend allowances, and tooling compatibility to prevent stress concentrations and deformation during punching. Finite element analysis (FEA) is applied when necessary to simulate load behavior and validate structural integrity. Design for Manufacturing (DFM) reviews are conducted early to eliminate costly revisions, ensuring seamless transition to prototyping. This phase is critical in achieving zero defects—by identifying potential flaws digitally, we prevent physical errors before metal is cut.

Prototyping: Validating Design in Real-World Conditions

Once the design is finalized, we proceed to prototyping using high-torque CNC turret punch presses capable of handling complex geometries with micron-level repeatability. Prototypes are produced under the same conditions as mass production, using the intended material grade and thickness. This allows us to verify form, fit, and function, as well as assess tool wear, edge quality, and dimensional stability. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and optical comparators to confirm compliance with GD&T specifications. Feedback from this stage is looped back into the design if needed, ensuring that only validated, error-free designs advance to full-scale production. Our closed-loop quality system ensures traceability and process consistency from the first part to the last.

Mass Production: Consistency at Scale with Zero Defects

With design and prototype approval, we initiate mass production on automated punching lines synchronized with material handling systems for continuous throughput. Our Amada and Trumpf-compatible CNC punch presses deliver high-speed forming, tapping, and embossing with tool life monitoring and real-time positional feedback. In-process inspections occur at defined intervals, supported by SPC (Statistical Process Control) to detect trends before deviations occur. Every sheet is tracked via barcode, enabling full lot traceability. We employ automated vision systems to detect surface defects, mis-punches, or dimensional drift, ensuring immediate correction. The result is a defect-free output, batch after batch.

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 – 6.0 mm |

| Tolerances | ±0.1 mm (standard), ±0.05 mm (precision) |

| Max Sheet Size | 1500 x 3000 mm |

| Punching Force | Up to 300 kN |

| Tooling Life Monitoring | Real-time sensor feedback |

| Quality Standards | ISO 9001:2015, IATF 16949 |

| Inspection Equipment | CMM, Optical Comparator, Vision System |

At Wuxi Lead Precision Machinery, the integration of intelligent design, verified prototyping, and tightly controlled mass production forms the backbone of our zero-defect philosophy—delivering reliability, precision, and value in every punched component.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Punching Excellence

In high-stakes sheet metal fabrication, precision punching is not merely a process—it is the foundation of structural integrity, cost efficiency, and accelerated time-to-market. Substandard punching leads to material waste, secondary operations, and compromised part performance. At Wuxi Lead Precision Machinery, we engineer solutions that eliminate these risks through advanced CNC technology and deep metallurgical expertise. Our commitment transcends machinery supply; we deliver end-to-end partnership, ensuring your production achieves zero-defect yield and maximum throughput.

Lead Precision operates at the intersection of German engineering rigor and scalable Chinese manufacturing excellence. Our Amada and Trumpf-integrated punching centers feature adaptive force control, real-time tool wear compensation, and AI-driven nest optimization. This translates to consistent ±0.05mm tolerances across complex geometries—even in high-strength alloys up to 6.0mm thickness. We prioritize your operational resilience through hardened tooling systems that extend die life by 40% and reduce unplanned downtime. Every machine undergoes 72-hour stress validation under ISO 9001 protocols before shipment, guaranteeing immediate integration into mission-critical workflows.

Technical Specifications for Lead Precision Punching Systems

| Parameter | Model LP-3015 Pro | Model LP-4020 Ultra |

|---|---|---|

| Max. Punching Force | 30 tons | 40 tons |

| Sheet Size Capacity | 1500 x 3000 mm | 2000 x 4000 mm |

| Material Thickness Range | 0.5–4.0 mm | 0.8–6.0 mm |

| Positioning Accuracy | ±0.03 mm | ±0.02 mm |

| Max. Strokes per Minute | 1200 SPM | 950 SPM |

| Tool Stations | 36 stations | 60 stations |

| Automation Ready | FMS/Robotic integration | Full Industry 4.0 interface |

Beyond machine delivery, we embed value through proactive engineering collaboration. Our team conducts on-site process audits to optimize your material utilization, tooling strategy, and maintenance schedules. Clients gain access to our 24/7 remote diagnostics hub—staffed by CNC specialists who resolve 92% of issues within two hours. For aerospace, medical, and energy sector partners, we provide full traceability documentation compliant with AS9100 and ISO 13485 standards.

The future of sheet metal fabrication demands partners who anticipate complexity. Wuxi Lead Precision Machinery reduces your total cost of ownership through precision that prevents scrap, speed that meets volatile demand, and support that operates as your extended engineering team. Contact us today to schedule a precision audit of your punching operations.

Email Contact [email protected] to connect with our application engineers. Specify your material types, annual volume, and critical tolerances for a customized productivity analysis. Let Lead Precision become the silent force behind your competitive advantage—where every punch meets perfection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.