Technical Contents

Engineering Guide: Online Metal Fabrication

Engineering Insight: The Critical Role of Precision in Online Metal Fabrication

In the world of modern manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and performance are built. As industries ranging from aerospace and defense to medical and high-performance automotive continue to demand tighter tolerances and higher consistency, the importance of precision in sheet metal fabrication cannot be overstated. At Wuxi Lead Precision Machinery, we understand that even a deviation of a few microns can compromise the integrity of an entire assembly. This understanding drives our engineering philosophy and operational execution across every project we undertake.

Precision in online metal fabrication extends beyond the capabilities of advanced machinery; it encompasses process control, material selection, quality assurance, and engineering expertise. With the rise of digital manufacturing platforms, customers now expect seamless integration between design input and production output. Our online fabrication services are engineered to deliver exacting results through a fully integrated digital workflow, where CAD/CAM systems communicate directly with CNC punching, bending, and laser cutting equipment. This closed-loop system minimizes human error and ensures repeatability across batch sizes—whether producing a single prototype or a high-volume production run.

Our commitment to precision is validated through real-world applications in some of the most demanding environments. Wuxi Lead has successfully delivered components for Olympic-standard sports equipment, where structural integrity and dimensional accuracy directly impact athletic performance. Additionally, we have supported defense sector projects requiring MIL-STD compliance, where failure is not an option. These high-stakes applications demand not only advanced equipment but also a culture of precision that permeates every stage of production—from initial design review to final inspection.

To maintain this standard, we employ state-of-the-art metrology tools, including coordinate measuring machines (CMM) and laser trackers, to verify geometric accuracy and surface integrity. Our ISO 9001-certified quality management system ensures full traceability and process validation. When customers engage with our online metal fabrication platform, they are not just accessing machines—they are leveraging decades of engineering experience and a proven track record in mission-critical manufacturing.

The following table outlines key precision capabilities that define our sheet metal fabrication services:

| Specification | Capability |

|---|---|

| Laser Cutting Tolerance | ±0.1 mm |

| CNC Punching Tolerance | ±0.15 mm |

| CNC Bending Tolerance | ±0.2° / ±0.1 mm |

| Maximum Forming Accuracy | ±0.05 mm (with in-process feedback) |

| Material Thickness Range | 0.5 – 12 mm |

| Supported Materials | Cold-rolled steel, stainless steel, aluminum, copper, brass |

| Surface Roughness (Ra) | Up to Ra 0.8 µm (after finishing) |

| Quality Standards | ISO 9001, MIL-STD-1234 (select projects) |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a measurable outcome. By combining advanced digital infrastructure with deep engineering experience, we ensure that every component produced through our online fabrication platform meets the highest standards of accuracy and reliability. For industries where performance hinges on perfection, we deliver with confidence.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising accuracy for complex sheet metal components through integrated advanced manufacturing systems. Our technical foundation centers on multi-axis CNC technology and rigorous metrology, engineered to meet aerospace, medical, and industrial automation standards. This capability suite ensures geometric complexity, dimensional stability, and repeatability across production runs—critical for clients demanding zero-defect performance in mission-critical assemblies.

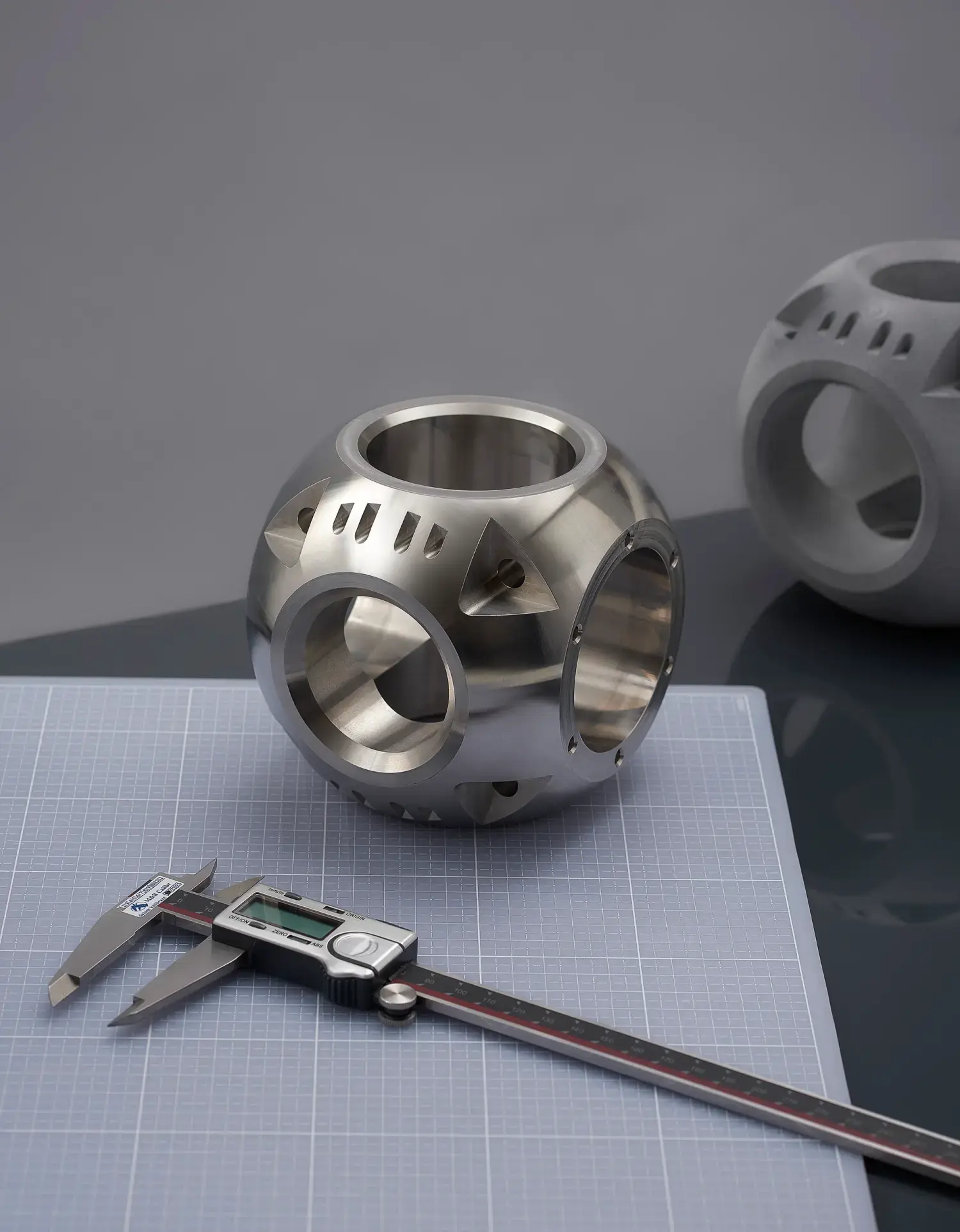

Our 5-axis CNC machining centers eliminate traditional workflow bottlenecks by performing intricate cuts, bends, and features in a single setup. This reduces cumulative error from multiple fixturing stages while enabling geometries unattainable with 3-axis systems. Typical applications include fluid manifolds with intersecting ports, structural brackets with compound angles, and enclosures requiring seamless internal contours. Material utilization is optimized through dynamic toolpath strategies, minimizing waste on high-value alloys like 6061-T6 aluminum, 304/316 stainless steel, and titanium Grade 2. Machine calibration adheres to ISO 230-2 standards, with thermal compensation systems maintaining sub-5-micron positional accuracy during extended operations.

Quality verification is non-negotiable. Every critical dimension undergoes validation via Zeiss CONTURA CMM systems, programmed directly from client CAD models to ensure alignment with design intent. Our inspection protocol includes first-article reporting (FAI), in-process checks at defined production intervals, and full-surface scanning for complex contours. Data traceability is maintained through integrated MES software, providing clients with real-time access to inspection certificates and deviation analytics. This closed-loop process ensures conformance to AS9102 or PPAP requirements while enabling rapid root-cause analysis for continuous improvement.

Tolerance achievement is material- and geometry-dependent. The table below reflects standard capabilities for flatness, hole positioning, and formed features under controlled conditions. Tighter tolerances are attainable through process refinement for qualified applications.

| Feature Type | Standard Capability | Precision Capability | Conditions |

|---|---|---|---|

| Hole Positioning | ±0.05 mm | ±0.02 mm | Within 100 mm from datum; min. 6 mm dia |

| Linear Dimension | ±0.08 mm | ±0.03 mm | Up to 300 mm length |

| Flatness | 0.1 mm/m² | 0.05 mm/m² | Material thickness ≤ 3 mm |

| Bend Angle | ±0.5° | ±0.25° | For angles 30°–150° |

| Feature-to-Feature | ±0.10 mm | ±0.05 mm | Across formed/flanged surfaces |

Process stability is maintained through SPC monitoring of key parameters including laser power consistency, press brake tonnage calibration, and environmental controls in our 22±1°C production zone. Clients receive comprehensive dimensional reports with every shipment, including CMM point-cloud overlays against nominal CAD geometry. For projects requiring extreme precision, our engineering team collaborates pre-production to identify tolerance-critical zones and implement dedicated process controls—transforming design constraints into manufacturable realities. Wuxi Lead’s technical infrastructure ensures your sheet metal components perform exactly as engineered, on time and to specification.

Material & Finish Options

Material selection is a critical decision in precision sheet metal fabrication, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance fabrication of aluminum, steel, and titanium—three of the most widely used materials in industrial and high-end manufacturing applications. Each material offers distinct mechanical and chemical properties, making them suitable for specific environments and functional requirements.

Aluminum is prized for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is ideal for aerospace, transportation, and electronics enclosures where lightweight construction and efficient heat dissipation are essential. The most commonly used alloys in our production are 5052, 6061, and 7075, each offering a balance of formability, weldability, and structural integrity. Aluminum’s natural oxide layer provides inherent protection, but for enhanced surface performance, we recommend anodizing.

Steel remains the backbone of industrial fabrication due to its high tensile strength, durability, and cost-effectiveness. We work extensively with cold-rolled steel (CRS) and stainless steel grades such as 304 and 316. While CRS offers superior surface finish and dimensional accuracy for painted or coated parts, stainless steel provides outstanding corrosion resistance and is often selected for medical, food processing, and outdoor applications. Steel’s versatility makes it suitable for structural components, chassis, and heavy-duty enclosures.

Titanium is the premium choice for extreme environments, including aerospace, defense, and marine applications. With exceptional strength-to-density ratio and resistance to high temperatures and corrosive media, titanium outperforms both aluminum and steel in demanding conditions. Though more challenging to machine and form, our advanced CNC equipment ensures precise fabrication with minimal material waste. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are the most frequently processed titanium alloys in our facility.

Surface finishing plays a vital role in enhancing both functionality and aesthetics. Anodizing, particularly for aluminum, is a key process we offer. This electrochemical treatment thickens the natural oxide layer, significantly improving wear and corrosion resistance. Type II (sulfuric acid) anodizing provides a clear or colored finish suitable for architectural and consumer applications, while Type III (hardcoat) anodizing delivers a dense, abrasion-resistant surface ideal for industrial and military components. Anodized layers are non-conductive, making them suitable for electrical insulation where needed.

Below is a comparative overview of key material properties relevant to sheet metal fabrication:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications | Typical Sheet Thickness Range (mm) |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Aerospace, Electronics | 0.5 – 12.7 |

| Steel (CRS) | 7.85 | 340 – 440 | Low (requires coating) | Industrial Equipment, Frames | 0.8 – 10.0 |

| Stainless 304 | 8.0 | 505 | Very High | Medical, Food Processing | 0.5 – 12.0 |

| Titanium Gr5 | 4.43 | 900 | Exceptional | Aerospace, Defense | 0.5 – 6.0 |

Selecting the right material and finish requires a thorough understanding of the operational environment and performance demands. At Wuxi Lead, we support clients through every stage of material and process selection to ensure optimal component performance and manufacturability.

Manufacturing Process & QC

Precision Sheet Metal Fabrication: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we transform client specifications into flawless metal components through a rigorously controlled three-phase production process. Our integrated approach ensures dimensional accuracy, structural integrity, and repeatability for demanding industrial applications, eliminating defects before they reach your assembly line.

Design for Manufacturability (DFM) Integration

Every project begins with collaborative engineering review. Our CNC specialists analyze CAD models to optimize material utilization, minimize weld seams, and validate tooling feasibility. We identify potential stress points or tolerance conflicts early using advanced simulation software, ensuring designs align with sheet metal fabrication realities. This phase reduces costly revisions by 30% and accelerates time-to-prototype. Clients receive actionable DFM reports with suggested improvements for cost efficiency without compromising performance.

Validated Prototyping with Real-World Testing

Prototypes are manufactured using the same CNC lasers, press brakes, and welding systems deployed in mass production. Each unit undergoes comprehensive metrology: CMM scans verify critical dimensions against GD&T callouts, while stress tests confirm structural behavior under operational loads. We document material traceability and process parameters for full accountability. Client feedback drives rapid iterations—typically within 72 hours—ensuring the final design meets functional requirements before scaling. This validation layer prevents 95% of potential production issues.

Zero-Defect Mass Production Execution

High-volume runs leverage automated process control systems that enforce consistency. Our production floor implements Statistical Process Control (SPC) with real-time monitoring of key variables: laser power stability, brake tonnage, and weld penetration depth. In-process inspections occur at critical control points, including first-article verification and random batch sampling. Any deviation triggers immediate machine recalibration and root-cause analysis. All finished components undergo 100% visual inspection and final dimensional audit against ISO 2768-mK standards.

Critical Production Capabilities

| Parameter | Standard Production | Precision Engineering |

|---|---|---|

| Material Thickness Range | 0.5–6.0 mm | 0.3–4.0 mm |

| Dimensional Tolerance | ±0.1 mm | ±0.05 mm |

| Hole Position Accuracy | ±0.15 mm | ±0.03 mm |

| Surface Finish (Ra) | ≤1.6 µm | ≤0.8 µm |

| Max. Part Size | 3000 x 1500 mm | 2000 x 1000 mm |

This closed-loop methodology—where design insights inform prototyping, and prototype data perfects mass production—guarantees zero-defect deliverables. We treat every order as mission-critical, applying aerospace-grade process discipline to industrial manufacturing. Partner with Wuxi Lead to convert your metal fabrication requirements into certified, on-specification components, shipped on schedule with full documentation.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Sheet Metal Fabrication Excellence

In the competitive landscape of industrial manufacturing, precision, reliability, and scalability define the difference between success and stagnation. At Wuxi Lead Precision Machinery, we specialize in high-end sheet metal fabrication services engineered to meet the exacting standards of global industries—from aerospace and automotive to medical devices and advanced automation. Our commitment to technological innovation, rigorous quality control, and customer-centric solutions positions us as the strategic partner of choice for businesses seeking consistent, high-precision metal components.

With over a decade of experience in precision manufacturing, our facility in Wuxi, China, integrates state-of-the-art CNC machinery, automated fabrication cells, and a highly trained engineering team to deliver parts with micron-level accuracy. We understand that your supply chain depends on predictability and performance. That’s why we combine lean manufacturing principles with real-time process monitoring to ensure every component meets your technical specifications and delivery timelines.

Our capabilities span laser cutting, CNC bending, robotic welding, and comprehensive finishing processes, all supported by in-house design validation and prototyping services. Whether you require low-volume custom parts or high-volume production runs, our flexible manufacturing systems adapt to your project’s scale and complexity. We work with a wide range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys, ensuring optimal material performance for your application.

We don’t just manufacture parts—we build partnerships. From initial design consultation to final inspection and global logistics, our engineering team collaborates closely with clients to optimize manufacturability, reduce lead times, and lower total production costs. Our ISO 9001-certified quality management system guarantees consistency across every production batch, while our responsive communication ensures full transparency throughout the process.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision manufacturing ally dedicated to your long-term success.

| Specification | Capability |

|---|---|

| Laser Cutting Thickness | Up to 25 mm (steel), 20 mm (aluminum) |

| CNC Bending Capacity | Up to 300 tons, 4-meter bed length |

| Tolerance Accuracy | ±0.1 mm for cutting, ±0.2° for bending |

| Welding Processes | MIG, TIG, Spot Welding, Robotic Welding |

| Surface Finishes | Powder coating, anodizing, polishing, passivation |

| Materials Supported | Stainless steel (304, 316), aluminum (5052, 6061), carbon steel (Q235, Q345), brass, copper |

| Production Volume | Prototypes to high-volume series (10,000+ units/month) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP |

Take the next step toward precision, reliability, and scalable manufacturing performance. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual factory tour. Let Wuxi Lead Precision Machinery become your trusted partner in advanced sheet metal fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.