Technical Contents

Engineering Guide: 3D Printed Parts For Sale

Engineering Insight Precision in Metal Additive Manufacturing for Critical Applications

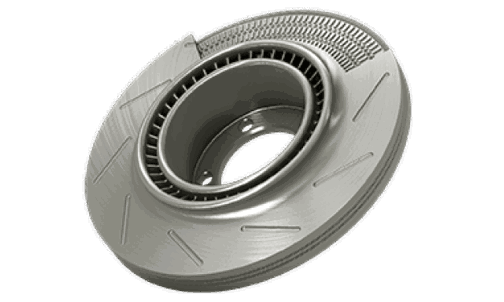

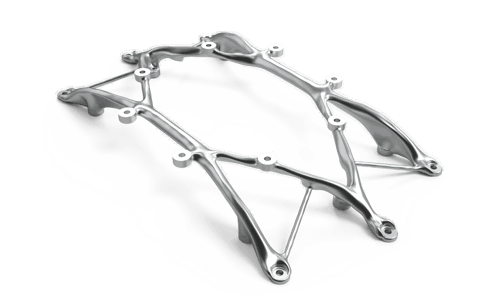

In the realm of industrial metal additive manufacturing AM transcends prototyping to deliver end-use components where precision dictates performance and safety. For high-stakes sectors like aerospace defense and elite sports equipment the tolerance stack-up inherent in traditional multi-part assemblies becomes a liability. Metal 3D printing offers consolidation but raw deposition capability alone is insufficient. True value emerges only when micron-level dimensional control surface integrity and material properties are consistently achieved across production runs. A 0.1mm deviation in a turbine blade cooling channel or hydraulic manifold can cascade into catastrophic system failure. Precision here is non-negotiable it is the foundation of reliability.

Wuxi Lead Precision Machinery operates at this critical intersection of AM capability and uncompromising quality. Our engineering team possesses deep expertise in qualifying metal AM processes for mission-critical components. This is validated through stringent production for Olympic-caliber equipment where marginal performance gains are measured in milliseconds and structural integrity is paramount. Similarly our military-grade part manufacturing adheres to aerospace standards AS9100 and NADCAP requiring full traceability destructive testing and zero-defect delivery. We do not merely print metal parts; we engineer certified solutions where every micron is accounted for from CAD model through post-processing to final inspection.

The distinction lies in mastering the entire production ecosystem beyond the printer. Material handling atmospheric control in the build chamber thermal management during deposition precision machining of support structures and stress-relief cycles all contribute to final part fidelity. Our integrated facility combines state-of-the-art metal AM systems with 5-axis CNC finishing and CMM validation ensuring parts meet geometric dimensioning and tolerancing GD&T requirements essential for fit function and longevity. This holistic approach transforms AM from a novelty into a reliable production pillar.

Key production parameters we rigorously control include

| Parameter | Capability | Industry Standard Context |

|---|---|---|

| Material Options | Ti-6Al-4V Inconel 718 17-4PH | Aerospace/Medical Grade |

| Dimensional Accuracy | ±0.02mm per 100mm | Exceeds typical AM tolerances |

| Surface Finish Ra | As-built 12.5μm Post-processed 1.6μm | Critical for fatigue life |

| Max Build Volume | 250 x 250 x 300 mm | Suitable for complex assemblies |

| Certification | ISO 9001 AS9100 NADCAP | Mandatory for defense/aerospace |

OEMs seeking to integrate metal AM into their supply chain must prioritize partners with demonstrable precision engineering discipline not just printing capacity. At Lead Precision every build undergoes rigorous first-article inspection with full material certification. Our experience delivering components where human performance and safety depend on absolute part integrity informs every process decision. When evaluating 3D printed parts for sale scrutinize the supplier’s quality infrastructure and real-world validation in demanding applications. Precision is not an add-on feature it is the core requirement for industrial metal AM adoption. Partner with an engineering-led manufacturer who treats tolerances as inviolable specifications not suggestions.

Precision Specs & Tolerances

At Wuxi Lead Precision Machinery, our technical capabilities in custom metal manufacturing are engineered to meet the most demanding specifications of high-performance industries such as aerospace, medical, energy, and advanced automation. Central to our precision manufacturing infrastructure is our fleet of advanced 5-axis CNC machining centers. These systems allow for complex geometries to be machined in a single setup, minimizing human intervention and reducing cumulative tolerances associated with multi-stage processes. The simultaneous movement across five axes enables us to produce intricate contours, deep cavities, and organic forms with exceptional surface finish and dimensional accuracy.

Our machining centers are operated by certified CNC engineers with over a decade of experience in high-mix, low-volume production environments. Each machine is maintained to OEM standards and monitored through real-time performance tracking systems to ensure consistent output. Materials we routinely process include titanium alloys, Inconel, stainless and tool steels, aluminum alloys, and specialty refractory metals. Our programming workflow integrates Mastercam, Siemens NX, and native CAD/CAM environments to generate optimized toolpaths that maximize efficiency and part fidelity.

Quality assurance is embedded at every stage of production. All critical dimensions are verified using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), equipped with a VAST XT sensor for high-accuracy tactile probing. The CMM operates in a temperature-controlled metrology lab maintained at 20°C ±0.5°C, ensuring measurement repeatability down to ±0.001 mm. Full first-article inspection (FAI) reports and PPAP documentation are available upon request, and in-process inspections are conducted at defined control points for batch consistency.

We adhere to ISO 1302, ISO 2768, and ASME Y14.5 standards for geometric dimensioning and tolerancing (GD&T). Our default machining tolerances are designed to exceed industry norms, and we are fully capable of holding tighter tolerances when mission-critical applications demand it. Surface finishes are controllable down to Ra 0.4 µm through optimized tool selection and finishing strategies.

The following table outlines our standard achievable tolerances based on material and feature type under controlled production conditions.

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Surface Finish (Ra) | Notes |

|---|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | 0.8 – 3.2 µm | Up to 500 mm |

| Hole Diameter | ±0.01 mm | ±0.005 mm | 0.8 – 1.6 µm | Reamed/precision bored |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | — | GD&T controlled |

| Angular Features | ±0.05° | ±0.02° | 1.6 – 3.2 µm | 5-axis simultaneous |

| Surface Flatness | 0.02 mm | 0.01 mm | 0.4 – 1.6 µm | Per 100 mm² |

All tolerances are achievable across aluminum, steel, titanium, and high-temperature alloys, subject to part geometry and structural rigidity. We welcome DFM reviews to optimize manufacturability and cost-efficiency without compromising performance.

Material & Finish Options

Material Selection Guide for Precision 3D Printed Metal Parts

Selecting the optimal material and finish is critical for achieving performance, durability, and cost efficiency in additive manufacturing. At Wuxi Lead Precision Machinery, we specialize in post-processing 3D printed metal components to aerospace and medical tolerances, ensuring raw builds meet stringent industrial specifications. Our engineering team evaluates material properties against application demands, prioritizing fatigue resistance, thermal stability, and corrosion performance. Below we detail key alloys and surface treatments for high-integrity parts.

Aluminum alloys dominate lightweight applications requiring thermal conductivity and moderate strength. Aluminum 7075 offers exceptional strength-to-weight ratios post-heat treatment, ideal for aerospace brackets and drone components. For complex geometries with inherent porosity from printing, AlSi10Mg provides superior castability and weldability while maintaining machinability. Stainless steel 316L remains the benchmark for medical implants and marine hardware due to its molybdenum-enhanced corrosion resistance and biocompatibility. When extreme wear resistance is paramount, tool steels like H13 deliver hardness up to 52 HRC after specialized heat treatment. Titanium Ti6Al4V excels in high-stress, high-temperature environments such as jet engine components, combining 40% weight savings versus steel with outstanding fatigue strength. All materials undergo rigorous ASTM-certified testing to validate mechanical properties.

Critical material specifications are summarized below for rapid comparison.

| Material | Key Properties | Common Applications | ASTM Standard |

|---|---|---|---|

| Aluminum 7075 | UTS: 570 MPa, Yield: 505 MPa, Density: 2.81 g/cm³ | Aerospace structural parts | B221/B247 |

| Stainless 316L | Corrosion resistance, UTS: 580 MPa, Ductility: 40% | Surgical instruments, valves | F318L |

| Titanium Ti6Al4V | UTS: 900 MPa, Fatigue limit: 550 MPa, Temp resistance: 600°C | Turbine blades, implants | F2924 |

Surface finishing transforms functional prototypes into production-ready components. Anodizing is essential for aluminum parts requiring enhanced wear resistance and electrical insulation. Type II (sulfuric acid) anodizing produces decorative, corrosion-resistant layers at 18–25 μm thickness, suitable for enclosures and consumer hardware. For mission-critical aerospace or defense applications, we implement Type III (hardcoat) anodizing at 50–75 μm thickness, achieving 600+ HV hardness while maintaining tight dimensional control through precision masking. All anodizing baths are monitored to MIL-A-8625 specifications, with dye sealing eliminating micro-porosity. Note that titanium and steel require alternative treatments like passivation or HVOF coating due to oxide layer incompatibility with standard anodizing.

Material and finish selection directly impacts part longevity and total cost of ownership. We recommend initiating engineering reviews early in the design phase to optimize alloy choice, minimize post-processing, and avoid costly rework. Wuxi Lead’s integrated additive-to-machining workflow ensures your 3D printed components meet ISO 2768-mK tolerances with certified material traceability. Contact our engineering team to discuss application-specific validation testing and material certification protocols.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for custom 3D printed metal parts is engineered for precision, repeatability, and zero defects. We integrate advanced additive manufacturing technologies with rigorous quality assurance protocols across every phase—Design, Prototyping, and Mass Production—to deliver components that meet the exacting standards of aerospace, medical, and high-performance industrial sectors.

The process begins with Design, where our engineering team collaborates closely with clients to translate functional requirements into manufacturable digital models. Using topology optimization and finite element analysis (FEA), we refine geometries to maximize strength-to-weight ratios while minimizing material waste. All designs are validated through simulation software to predict thermal behavior, stress distribution, and dimensional stability before any physical production begins. This digital-first approach ensures that only optimized, error-free designs advance to the next stage.

Prototyping follows, serving as both a functional and dimensional verification step. Utilizing selective laser melting (SLM) with high-precision fiber lasers, we produce initial units in the client’s specified alloy—typically Inconel 718, Ti-6Al-4V, or 316L stainless steel. Each prototype undergoes comprehensive metrology inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify conformance to tolerances as tight as ±0.02 mm. Surface roughness, porosity, and microstructure are analyzed metallurgically to confirm material integrity. Feedback from this stage is incorporated iteratively, ensuring design fidelity and performance under real-world conditions.

Once design validation is complete, we transition seamlessly into Mass Production. Our automated SLM systems operate in a controlled argon environment, ensuring consistent part quality across large batches. Every build is monitored in real time using in-situ melt pool monitoring and layer-wise imaging to detect anomalies at the micron level. Any deviation triggers immediate alerts, enabling corrective action without compromising batch integrity. Post-processing—including stress relieving, hot isostatic pressing (HIP), CNC machining, and surface finishing—is performed in-house under strict process controls to maintain dimensional accuracy and mechanical properties.

Throughout the entire production cycle, our zero-defect philosophy is enforced through full traceability. Each part is assigned a unique identifier linked to its build log, material certification, and inspection data. This closed-loop quality system ensures complete accountability and compliance with ISO 9001 and AS9100 standards.

The result is a seamless, scalable manufacturing workflow that delivers high-performance metal 3D printed components with unparalleled consistency and reliability.

| Parameter | Specification |

|---|---|

| Build Volume (Max) | 250 x 250 x 325 mm |

| Layer Thickness | 20–50 µm |

| Dimensional Tolerance | ±0.02 mm |

| Surface Roughness (As-Built) | Ra 8–12 µm |

| Supported Alloys | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, CoCrMo |

| Post-Processing Options | HIP, CNC Machining, Polishing, Anodizing, Passivation |

| Quality Standards | ISO 9001, AS9100, Full Material & Process Traceability |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Additive Manufacturing

In the demanding landscape of high-performance engineering, your choice of additive manufacturing partner directly impacts product integrity, time-to-market, and operational resilience. Wuxi Lead Precision Machinery transcends conventional 3D printing service bureaus by integrating aerospace-grade metal additive systems with decades of precision CNC heritage. We engineer solutions where failure is not an option—delivering fully validated, end-use metal components that meet stringent AS9100 and ISO 9001 standards. Our facility in Wuxi operates under controlled cleanroom environments with real-time process monitoring, ensuring every part adheres to the exacting tolerances required by defense, energy, and medical device innovators.

Unlike generic providers, Lead Precision implements a closed-loop engineering workflow. Your CAD file undergoes rigorous design-for-additive (DfAM) analysis by our in-house metallurgists, followed by build simulation to eliminate thermal distortion risks. Post-processing leverages proprietary stress-relief cycles and 5-axis CNC contouring to achieve surface finishes down to Ra 0.8 µm—critical for hydraulic manifolds or turbine blades. This integrated approach reduces lead times by 40% compared to fragmented supplier chains while guaranteeing dimensional stability across production runs.

Our technical capabilities are engineered for your most complex challenges. The table below details our certified production parameters for mission-critical applications:

| Parameter | Capability | Industry Standard Compliance |

|---|---|---|

| Materials | Ti-6Al-4V, Inconel 718, 17-4PH SS, AlSi10Mg, Custom Alloys | AMS, ASTM F3301, ISO/ASTM 52900 |

| Build Volume | 250 x 250 x 300 mm (LPW A250) | NIST-traceable calibration |

| Layer Thickness | 20–50 µm | In-process melt pool monitoring |

| Dimensional Tolerance | ±0.02 mm/mm (with post-machining) | AS9100 Rev D First-Article Inspection |

| Surface Finish | As-built: Ra 12–25 µm; Machined: Ra 0.8 µm | ISO 21920-2:2021 |

| Certification | Full material traceability, Metallurgical reports, 3D scan validation | PPAP Level 3, FAI per AS9102 |

The true differentiator lies in our engineering accountability. We do not merely print parts—we validate performance. Every shipment includes comprehensive test coupons, microstructure analysis, and dimensional reports aligned to your critical-to-quality (CTQ) specifications. Our quality management system integrates seamlessly with global supply chain partners, providing auditable data for regulatory submissions.

Initiate your project with a partner who treats your requirements as engineering imperatives. Submit your CAD files and technical specifications to [email protected] for a confidential feasibility assessment within 24 business hours. Our application engineers will respond with a detailed manufacturability report, including build orientation optimization, cost drivers, and a traceable project timeline. For urgent prototyping or bridge production needs, reference code LP-AM2024 to prioritize your request. Trust Wuxi Lead Precision Machinery to transform additive potential into certified, field-ready reality—where precision is non-negotiable and partnership is performance-driven.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.