Technical Contents

Engineering Guide: Plastic Injection Moulding Uk

Engineering Insight: The Critical Role of Precision in Plastic Injection Moulding UK

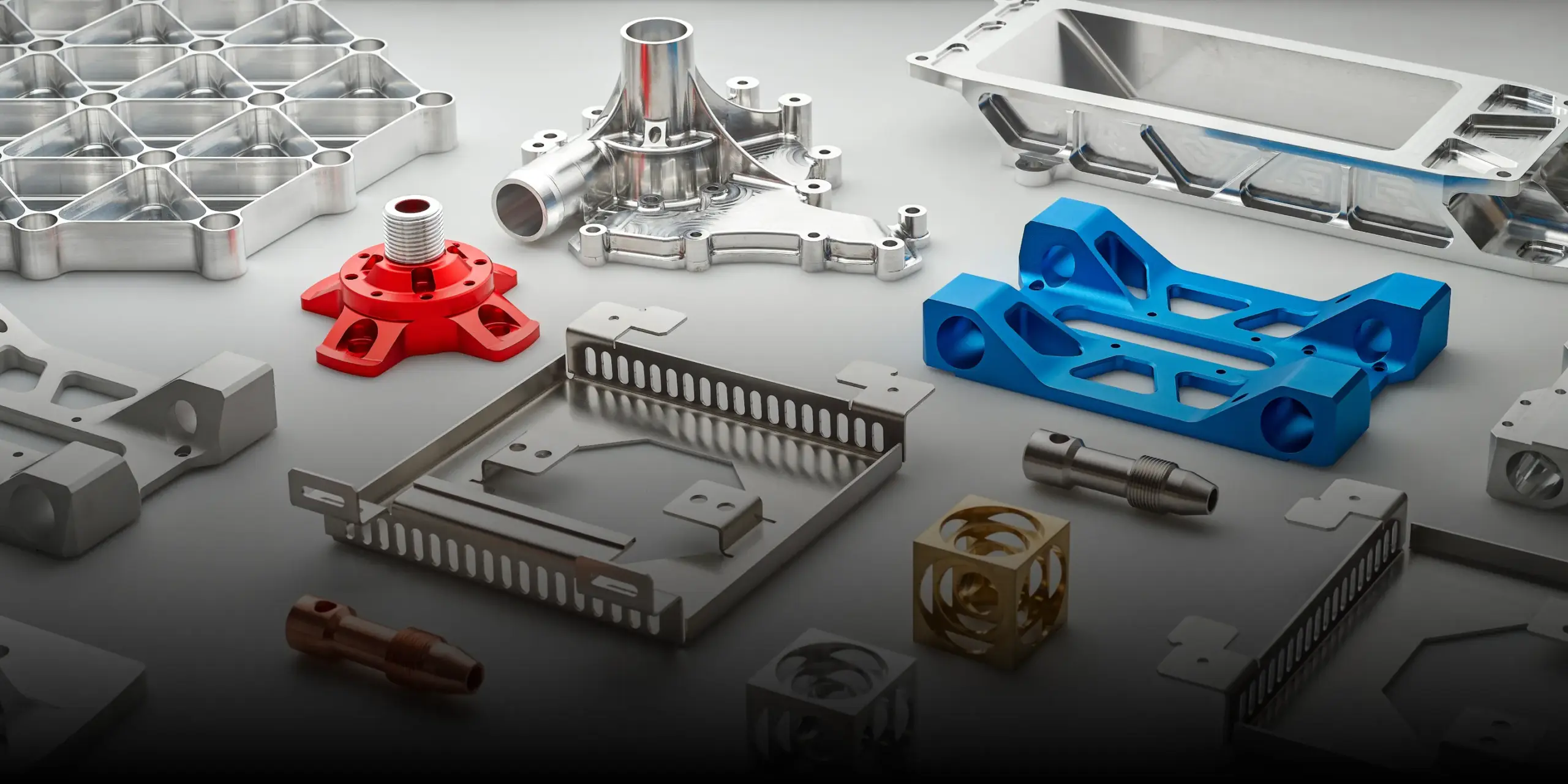

In the highly competitive landscape of UK manufacturing, plastic injection moulding stands as a cornerstone process for producing high-volume, complex components with repeatability and efficiency. However, the success of any injection moulding operation hinges not just on the machinery or materials used, but on the precision of the tooling and supporting metal components that form the foundation of the process. At Wuxi Lead Precision Machinery, we understand that micron-level accuracy in mould fabrication directly translates to part consistency, reduced waste, and long-term cost savings—factors that are non-negotiable in aerospace, medical, automotive, and industrial applications.

Precision in plastic injection moulding begins long before the first pellet is melted. It starts with the design and manufacture of custom mould bases, inserts, ejector systems, and guide components—all of which must meet exacting tolerances to ensure seamless operation under high pressure and thermal cycling. Even minor deviations in parallelism, flatness, or alignment can lead to flash, part warpage, or premature tool failure. This is where advanced CNC machining, rigorous quality control, and deep engineering expertise become decisive advantages.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in delivering mission-critical metal components for high-performance injection moulding systems. Our work has supported precision tooling for applications demanding the highest reliability, including components used in Olympic-grade equipment and military-specification hardware. These projects required not only adherence to international standards such as ISO 2768 and GB/T 1804, but also a culture of zero-defect manufacturing, in-process inspections, and full traceability.

Our facility in Wuxi, China, leverages state-of-the-art 5-axis CNC centres, wire EDM, and surface grinding technologies to produce mould components with tolerances as tight as ±0.002 mm. We specialize in hardened steels, pre-hardened tool steels, and corrosion-resistant alloys, all machined to meet the thermal and mechanical demands of modern injection moulding cycles. Every component is validated through CMM inspection and surface roughness testing, ensuring compatibility with high-cavitation, hot-runner, and multi-material mould designs commonly used in the UK’s advanced manufacturing sector.

Below are key specifications reflecting our standard capabilities for custom mould components:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05–0.8 µm |

| Maximum Workpiece Size | 1200 × 800 × 600 mm |

| Materials Supported | P20, 718H, H13, S136, 420SS, Aluminum 7075 |

| Machining Processes | 5-axis milling, Wire EDM, Surface grinding, Boring |

| Quality Standards | ISO 9001:2015, ISO 2768, GB/T 1804 |

| Inspection Tools | CMM, Height Gauge, Surface Profiler, Optical Comparator |

For UK manufacturers seeking to enhance the performance and longevity of their injection moulding operations, partnering with a precision metal specialist like Wuxi Lead ensures that every component is engineered for reliability, repeatability, and real-world performance. Precision isn’t just a metric—it’s the foundation of excellence.

Precision Specs & Tolerances

Technical Capabilities for Precision Injection Mould Components

Wuxi Lead Precision Machinery delivers mission-critical metal components for the UK plastic injection moulding sector, where dimensional stability and surface integrity directly impact mould longevity and part quality. Our capabilities are engineered to meet the stringent demands of high-cavitation, tight-tolerance moulds operating under extreme thermal cycling. We specialize in complex cores, cavities, inserts, and precision-guided ejection systems requiring micron-level accuracy to prevent flash, sink, and premature wear.

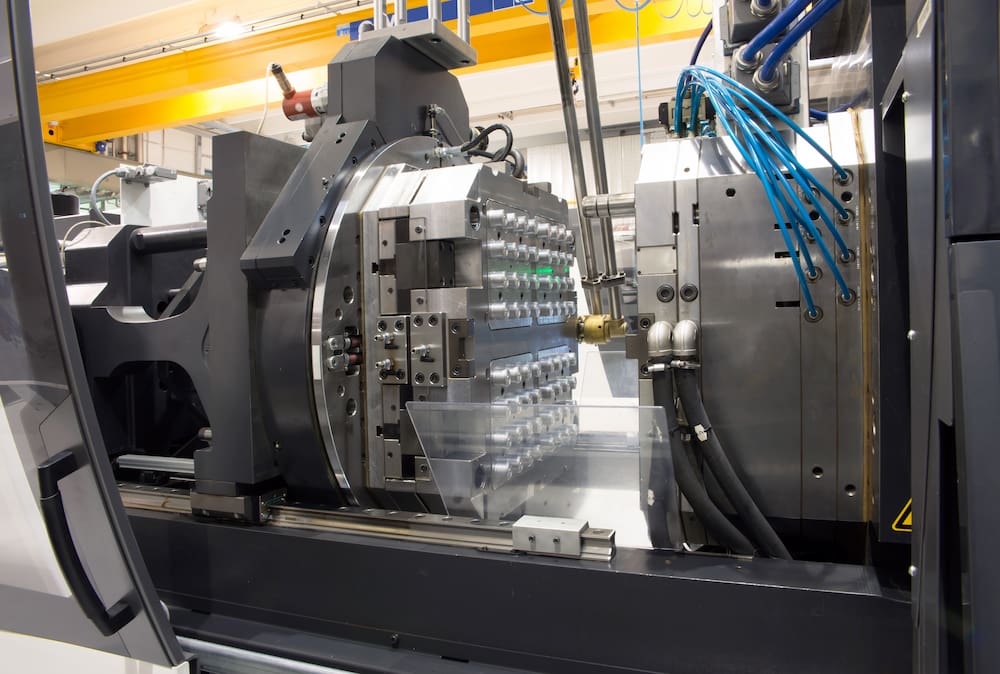

Our foundation is a dedicated fleet of DMG MORI and Hermle 5-axis CNC machining centres. These systems execute simultaneous multi-axis contouring, eliminating secondary setups and ensuring geometric coherence across intricate 3D surfaces. This capability is essential for non-rotational features like cooling channels, textured surfaces, and undercuts common in automotive and medical mould tools. Advanced high-speed machining protocols maintain thermal stability during extended cuts, preserving material integrity in hardened tool steels (up to 60 HRC) and exotic alloys like maraging steel. All programmes undergo rigorous virtual simulation to prevent collisions and optimize toolpaths for surface finish consistency.

Quality verification is non-negotiable. Every critical dimension undergoes validation via Zeiss METROTOM 800 industrial CT scanners and Hexagon GLOBAL S CLASS Coordinate Measuring Machines (CMMs). Our CMM cells operate in ISO 17025-accredited environmental chambers (20°C ±0.5°C), utilizing calibrated Renishaw probes for traceable measurements down to ±0.5μm. Full first-article inspection reports (FAIRs) include GD&T analysis, surface roughness mapping (Ra, Rz), and 3D deviation colour maps against CAD nominal data. This closed-loop process ensures conformity to ISO 2768-mK and customer-specific aerospace or medical standards.

The following table details our standard achievable tolerances for mould-critical features:

| Feature Category | Tolerance Range | Measurement Method |

|---|---|---|

| Linear Dimensions | ±0.005 mm | CMM with calibrated probe |

| Angular Features | ±0.001° | Optical comparator/CMM |

| Positional Accuracy | Ø0.008 mm | CMM with iterative best fit |

| Surface Roughness (Ra) | 0.2 μm – 0.8 μm | Profilometer (ISO 4287) |

| Flatness | 0.003 mm per 100 mm | CMM with high-density scan |

Component reliability in UK production environments hinges on our adherence to these tolerances. Reduced variation in core-cavity alignment minimizes parting line flash, while precise cooling channel geometry ensures uniform thermal dissipation—directly extending mould life and reducing scrap rates. Our technical team collaborates with UK mould makers during DFM stages to identify critical-to-quality features, applying our machining and inspection expertise to preempt manufacturing risks. This proactive approach transforms precision metal fabrication into a strategic asset for your injection moulding operations, guaranteeing consistent performance under high-volume production demands.

Material & Finish Options

Material Selection in Precision Injection Moulding: Aluminum, Steel, and Titanium

Selecting the appropriate material for injection moulding tooling is critical to ensuring production efficiency, part quality, and long-term cost-effectiveness. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance tooling used in plastic injection applications. Our expertise enables clients to make informed decisions when choosing between aluminum, steel, and titanium based on production volume, part complexity, and environmental conditions.

Aluminum is widely used for prototype and low-to-medium volume production runs due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle times during injection moulding. While not as durable as steel, modern high-grade aluminum alloys offer sufficient strength for many industrial applications. Its lightweight nature also reduces handling and shipping costs, making it ideal for rapid tooling solutions.

Steel remains the standard for high-volume production moulds. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and longevity. These properties make steel particularly suitable for complex geometries and abrasive materials. Although steel moulds require longer machining times and higher initial costs, their extended service life delivers a lower cost per part over large production runs. Hardened steel also supports tighter tolerances and finer surface finishes, critical in precision manufacturing.

Titanium is less common in standard injection moulding but offers unique advantages in specialized applications. With an exceptional strength-to-density ratio and outstanding corrosion resistance, titanium is ideal for moulds exposed to aggressive chemicals or high-stress environments. While its high cost and challenging machinability limit widespread use, titanium is increasingly considered for aerospace, medical, and defense applications where performance outweighs cost.

Surface treatment plays a vital role in enhancing mould performance and lifespan. Anodizing, particularly for aluminum moulds, significantly improves surface hardness and wear resistance while providing excellent corrosion protection. The anodized layer is integral to the base material, ensuring it does not flake or peel under thermal cycling. Different types of anodizing—such as Type II (sulfuric acid) and Type III (hard coat)—offer varying levels of thickness and durability, allowing customization based on operational demands.

Below is a comparative overview of key material properties relevant to injection moulding applications.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Use Case | Surface Treatment Compatibility |

|---|---|---|---|---|---|

| Aluminum (7075-T6) | 15–20 | 570 | 130 | Prototyping, low-volume runs | Anodizing (Type II & III) |

| Steel (P20) | 28–32 | 900 | 30 | Medium-to-high volume | Nitriding, polishing, coating |

| Steel (H13) | 46–52 | 1,300 | 28 | High-stress, high-temp | PVD, HVOF, anodizing (limited) |

| Titanium (Ti-6Al-4V) | 35–40 | 900–950 | 7 | Corrosive environments | Anodizing, thermal spray |

Material selection directly impacts tool performance, maintenance frequency, and overall production economics. At Wuxi Lead Precision Machinery, we work closely with clients to match material and finish options to specific application requirements, ensuring optimal results in every injection moulding project.

Manufacturing Process & QC

Precision Injection Moulding: From Concept to Zero-Defect Production

Achieving flawless plastic injection moulded components for demanding UK industrial applications requires an uncompromising, integrated process. At Wuxi Lead Precision Machinery, our methodology rigorously bridges Design, Prototyping, and Mass Production, engineered specifically to eliminate defects before they reach your assembly line. This systematic approach ensures dimensional accuracy, material integrity, and functional reliability critical for aerospace, medical, and automotive sectors.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineers collaborate closely with UK clients during the initial CAD phase, scrutinizing part geometry, wall thickness transitions, gate locations, and ejection strategies. We simulate thermoplastic polymer flow, cooling dynamics, and potential warpage using advanced Moldflow software. This proactive analysis identifies stress concentrations, sink marks, or knit lines before tooling begins, optimizing the design for manufacturability and inherent quality. Material selection is validated against stringent UK and EU regulatory requirements, ensuring compatibility with end-use environments and processing parameters.

Prototyping transitions validated designs into tangible validation. Utilizing our high-precision CNC-machined aluminium or pre-hardened steel prototype tools, we produce functional parts mirroring final production conditions. These prototypes undergo rigorous dimensional inspection via CMM, material property testing, and assembly fit checks within your actual application context. This phase is not merely about form; it validates the entire process window – injection speed, pressure, temperature profiles, and cooling times – confirming the design’s robustness and identifying any micro-adjustments needed for zero-defect scalability. Feedback loops are immediate, minimizing downstream risk.

Mass Production executes the perfected process with military precision. Our state-of-the-art all-electric and hybrid hydraulic presses, operating within tightly controlled cleanroom environments, replicate the validated parameters with micron-level consistency. Real-time process monitoring tracks critical variables like cavity pressure, melt temperature, and clamp force, triggering automatic corrections to maintain stability. Every component undergoes 100% automated vision inspection for surface defects and critical dimensions, supplemented by statistical process control (SPC) on key features. This multi-layered quality gate, combined with our ISO 9001-certified procedures and traceable material lots, guarantees batch-to-batch uniformity and absolute adherence to your zero-defect mandate. The result is UK-bound components meeting BS, ISO, and bespoke OEM specifications without compromise.

Key Production Process Specifications

| Parameter | Capability Range | Control Tolerance | Verification Method |

|---|---|---|---|

| Dimensional Accuracy | 0.005mm – 0.05mm (depending on size) | ±0.002mm critical dims | CMM, Optical Comparator |

| Material Compatibility | Engineering Thermoplastics (PPS, PEEK, PSU, ABS, PC, POM) | Material Certificates | Spectroscopy, MFR Testing |

| Cavity Count | 1 – 64 cavities | Balanced Runner Design | Flow Simulation, Pressure Sensors |

| Injection Pressure | Up to 2500 bar | ±10 bar real-time | Closed-Loop Hydraulic Control |

| Cycle Time Optimization | Client-specific | ±0.5 seconds stability | Process Monitoring Software |

| Surface Finish | SPI A1 (Mirror) to Texture VT-03 | Ra 0.01µm – 3.2µm | Surface Roughness Tester |

| Quality Assurance | 100% Automated Vision + SPC Sampling | Zero-Defect Target | AI Vision Systems, Cpk >1.67 |

Why Choose Wuxi Lead Precision

When it comes to precision-driven custom metal manufacturing for the plastic injection moulding industry in the UK, global standards demand more than just capability — they require consistency, innovation, and a partner committed to engineering excellence. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance components and integrated systems tailored to the exacting needs of modern injection moulding operations. Our expertise bridges the gap between advanced Chinese manufacturing efficiency and European precision requirements, offering UK-based clients a strategic advantage in cost, quality, and delivery speed.

We understand that plastic injection moulding relies heavily on the integrity and precision of metal components — from mould bases and cores to ejector systems and cooling channels. Any deviation in tolerance can lead to defects, downtime, or increased cycle times. That’s why every product we manufacture is engineered using state-of-the-art CNC machining, wire EDM, and surface grinding technologies, all governed by strict ISO-compliant quality control protocols. Our facility in Wuxi is equipped to handle both prototype development and high-volume production runs, ensuring scalability without compromise.

Our clients across the UK and Europe benefit from a direct partnership model that eliminates intermediaries, reduces lead times, and enhances communication. Whether you require standard mould components or fully customized tooling solutions, our engineering team collaborates closely with your designers to optimize manufacturability, material selection, and longevity. We work with a wide range of tool steels, stainless alloys, and specialty metals, applying surface treatments such as nitriding, PVD coating, and hard chrome plating to extend service life in demanding environments.

To support seamless integration into your existing workflows, we provide comprehensive documentation, including GD&T drawings, material certifications, and inspection reports. Our quality assurance process includes CMM verification, roughness testing, and 100% dimensional checks on critical features.

Below are key specifications that define our manufacturing capabilities:

| Feature | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.05 μm |

| Maximum Workpiece Size | 1200 × 800 × 600 mm |

| Materials Processed | P20, 718, H13, S136, 420SS, Aluminum 7075, and custom alloys |

| Processing Methods | CNC Milling, Turning, Wire EDM, Surface & Cylindrical Grinding |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting, First Article Inspection (FAI) |

| Lead Time (Typical) | 15–25 days, depending on complexity |

Partnering with Wuxi Lead Precision Machinery means gaining access to a reliable, technically advanced manufacturing partner who understands the unique challenges of the plastic injection moulding sector. We are committed to supporting UK industries with scalable, high-precision solutions that enhance productivity and reduce total cost of ownership.

For technical inquiries, project consultations, or to request a quote, contact us today at [email protected]. Let us help you achieve the precision your moulding applications demand.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.