Technical Contents

Engineering Guide: Plastic Injection Mold Global Sourcing

Engineering Insight: Precision as the Non-Negotiable Foundation in Plastic Injection Mold Global Sourcing

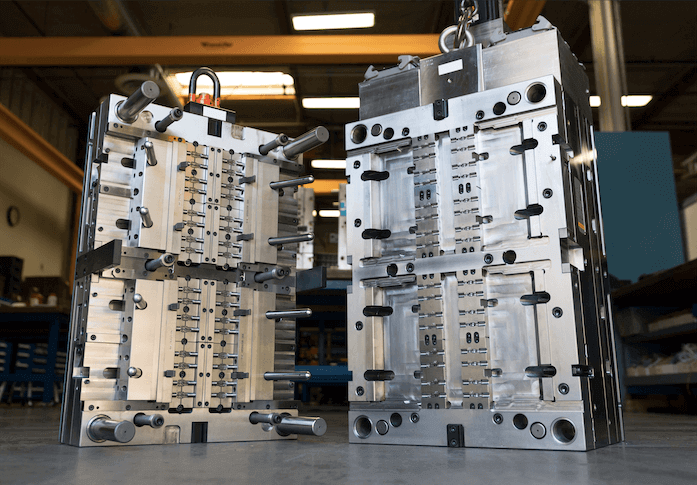

Global sourcing for plastic injection molds presents significant cost advantages but introduces critical engineering risks where precision cannot be compromised. The relentless pursuit of micron-level accuracy defines mold performance, part consistency, and ultimately, the viability of the entire production line. Sub-micron deviations in cavity geometry, core alignment, or cooling channel placement cascade into part warpage, flash, dimensional instability, and catastrophic mold failure under high-cycle production. For industries demanding zero-defect output—medical devices, aerospace components, or automotive safety systems—tolerances below 0.002mm are not optional; they are the baseline requirement for functional parts and regulatory compliance. Sourcing teams must prioritize engineering rigor over initial cost quotes, recognizing that a mold failing to maintain tight tolerances after 50,000 cycles incurs exponentially higher costs through scrap, downtime, and rework than a precision-engineered solution from the outset.

Wuxi Lead Precision Machinery operates at this extreme precision frontier, leveraging 18 years of specialized CNC manufacturing expertise honed through mission-critical applications. Our engineering protocols were rigorously validated producing molds for Olympic-grade sporting equipment components requiring flawless aerodynamic surfaces and repeatability under extreme stress. Similarly, we supply molds for sensitive military subsystems where environmental durability and absolute dimensional integrity under vibration and thermal cycling are non-negotiable. This experience instills a systemic approach: from multi-axis machining of hardened P20 and H13 tool steels to stress-relieved invar inserts for optical applications, every process step is calibrated to eliminate cumulative error. We implement real-time thermal compensation during machining and enforce post-heat-treatment metrology using calibrated CMMs traceable to NIST standards, ensuring cavity conformity persists through thousands of cycles.

The difference lies in engineered stability, not just initial accuracy. Below are key specifications demonstrating the precision foundation we deliver for global clients demanding reliability:

| Critical Parameter | Industry Standard Range | Wuxi Lead Precision Standard | Impact on Production |

|---|---|---|---|

| Cavity Plate Hardness | HRC 48-50 | HRC 52-54 (uniform) | 40% longer mold life, reduced wear |

| Core/Cavity Alignment | ±0.01mm | ±0.003mm | Eliminates flash, ensures part sealing |

| Cooling Channel Position | ±0.05mm | ±0.015mm | Uniform part cooling, prevents warpage |

| Thermal Stability (ΔL/L) | 12 ppm/°C | ≤ 8 ppm/°C | Consistent part dimensions across shifts |

| Surface Finish (Cavity) | Ra 0.2µm | Ra 0.05µm (optical grade) | Critical for lenses, medical components |

True value in global mold sourcing emerges from partnerships where engineering excellence is embedded in the supply chain. Wuxi Lead Precision Machinery delivers this through disciplined process control, advanced metrology, and a proven track record in the world’s most demanding applications. We transform the inherent risks of global procurement into a strategic advantage by guaranteeing the precision that keeps your production line running. Contact our engineering team to discuss how our military and Olympic-proven standards can secure your next mold project.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of global plastic injection mold sourcing. Our facility integrates precision engineering with state-of-the-art production technologies, ensuring consistent quality and performance for complex mold components. At the core of our machining capacity is a full suite of 5-axis CNC machining centers, enabling us to produce highly intricate geometries with superior surface finishes and dimensional accuracy. This technology allows for simultaneous multi-axis movement, reducing setup time and part handling while maintaining tight tolerances across complex contours—critical for mold cores, cavities, and inserts used in high-cycle injection molding applications.

Our 5-axis CNC systems are operated by experienced machinists and supported by integrated CAD/CAM software, ensuring seamless translation from design to finished component. This digital workflow enhances repeatability and reduces lead times, especially for multi-cavity molds or family molds requiring precise alignment and uniformity. Materials are carefully selected based on application requirements, including hardened tool steels (such as P20, 718, H13, S136), aluminum for prototyping, and specialty alloys where corrosion resistance or thermal performance is critical. Each material is processed using optimized cutting strategies to preserve structural integrity and minimize residual stress.

Quality assurance is central to our manufacturing philosophy. Every component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing metrology-grade verification of geometric dimensions and surface characteristics. The CMM system ensures full compliance with ISO 10360 standards and supports first-article inspection reports (FAIR), production part approval protocols (PPAP), and full traceability documentation. In addition to CMM inspection, we employ surface roughness testers, hardness testers, and optical comparators to validate critical features.

The following table outlines our standard machining tolerances, reflecting our commitment to precision and consistency in injection mold manufacturing:

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.005 mm (reamed/ground) |

| Positional Tolerance | ±0.015 mm | ±0.01 mm (GD&T controlled) |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm (polished/finished) |

| Angular Tolerance | ±0.05° | ±0.02° |

| Repeatability (5-axis) | ±0.008 mm | ±0.003 mm |

These capabilities are maintained under ISO 9001-certified processes, with environmental controls to ensure measurement stability. Wuxi Lead Precision Machinery is equipped to support global OEMs and mold makers with technically demanding projects, combining high-end equipment, rigorous quality control, and deep domain expertise in injection mold fabrication.

Material & Finish Options

Material Selection for High-Performance Injection Molds: Global Sourcing Insights

Selecting the optimal mold material is a critical strategic decision impacting part quality, production efficiency, tool longevity, and total cost of ownership in global plastic injection molding. Wuxi Lead Precision Machinery emphasizes that material choice must align precisely with production volume, part complexity, resin type, and surface finish requirements. Sourcing from international suppliers demands rigorous material verification protocols to ensure specifications match contractual agreements and avoid costly field failures. Aluminum, steel, and titanium represent the primary structural choices, each with distinct performance profiles suited to specific applications.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping and low-to-medium volume production. Their superior thermal conductivity enables up to 50% faster cooling cycles compared to steel, directly boosting productivity for suitable applications. Aluminum’s machinability reduces lead times and tooling costs. However, lower hardness limits its use with abrasive resins or high-cavity-count molds requiring extreme wear resistance. Steel remains the dominant choice for high-volume manufacturing. Pre-hardened steels like P20 offer good balance for medium runs, while hardened tool steels (H13, S136, 420SS) provide exceptional wear resistance, polishability, and longevity for millions of cycles, especially with corrosive or glass-filled polymers. Titanium alloys, though exceptionally strong and corrosion-resistant, see limited mold application due to high cost, challenging machinability, and thermal properties less ideal than aluminum for rapid cycling. Its use is typically confined to highly specialized, corrosive environments where other materials fail.

Surface finishing, particularly anodizing for aluminum molds, is integral to performance. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness (up to 60-70 HRC equivalent), corrosion resistance, and release properties. This is crucial for molds processing abrasive materials or requiring minimal ejection force. Anodizing thickness must be precisely controlled (typically 25-50 μm for hard coat) to maintain critical tolerances; inconsistent application by unreliable suppliers is a common global sourcing pitfall. Steel molds utilize alternative finishes like nitriding, PVD coatings, or electroless nickel plating for similar wear and corrosion mitigation goals.

Verify all material certifications (mill test reports) and finish specifications rigorously during global procurement. The table below summarizes key comparative properties:

| Material | Typical Hardness (HRC) | Thermal Conductivity (W/m·K) | Primary Use Case | Key Limitation |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 (Base) | 130 | Prototypes, Low/Med Volume | Wear Resistance |

| P20 Steel | 28-32 | 28-36 | Medium Volume Production | Limited Cycle Life vs Hardened |

| H13 Steel | 48-52 (Hardened) | 25-30 | High Volume, Hot Runner Systems | Machining Cost/Time |

| S136 Stainless | 48-52 (Hardened) | 20-25 | Corrosive Resins, Optical Clarity | Highest Cost |

Material selection transcends simple cost per kilogram. Partner with suppliers possessing deep metallurgical expertise and stringent quality control, like Wuxi Lead Precision Machinery, to navigate global sourcing complexities. We implement full material traceability and validate all properties against international standards (ASTM, ISO), ensuring your mold investment delivers maximum ROI through predictable performance and extended service life. The right material, correctly processed and finished, is foundational to competitive manufacturing.

Manufacturing Process & QC

Design: Precision Engineering from Concept to Digital Model

At Wuxi Lead Precision Machinery, the foundation of every successful plastic injection mold begins with advanced design engineering. Our team of experienced mold designers utilizes industry-leading CAD/CAM software—such as Siemens NX, SolidWorks, and AutoCAD—to transform client specifications into highly accurate 3D digital models. Every design phase incorporates mold flow analysis, thermal simulation, and structural stress testing to anticipate potential defects before physical production begins. This proactive approach ensures optimal gate placement, cooling channel layout, and ejection mechanisms, minimizing warpage, sink marks, and cycle time inefficiencies. Design for manufacturability (DFM) reviews are conducted collaboratively with clients to refine part geometry, material selection, and tolerances, ensuring alignment with both functional requirements and production scalability.

Prototyping: Validating Performance Before Scale

Once the digital model is approved, we proceed to prototype development using high-precision CNC machining, wire EDM, and surface grinding technologies. Prototypes are manufactured from the same tool steel grades—such as P20, 718H, or H13—as the final mold, enabling true-to-production validation. These pilot molds undergo rigorous testing on our in-house injection molding machines, allowing us to produce initial sample parts for dimensional inspection, material behavior analysis, and assembly compatibility checks. Any deviations detected during this stage are systematically corrected through iterative refinement, ensuring that all geometric, thermal, and mechanical parameters meet the zero-defect standard. This phase not only confirms mold functionality but also accelerates time-to-market by identifying and resolving risks early.

Mass Production: Consistency, Control, and Quality Assurance

With prototype approval, we transition seamlessly into full-scale production under a fully documented quality control protocol. Each mold is manufactured using ISO 9001-certified processes, with real-time monitoring at every stage—from rough machining to fine polishing and final assembly. Our production floor integrates automated inspection systems, including CMM (Coordinate Measuring Machines) and optical comparators, to verify tolerances down to ±0.002 mm. Every mold undergoes a comprehensive pre-shipment trial run, generating detailed reports on cycle time, part weight consistency, and surface finish quality.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Mold Base Materials | P20, 718H, H13, S136 |

| Surface Finish Options | Mirror Polish (SPI A1), Textured, EDM Finish |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–55 days |

| Injection Machine Range | 50–1,600 tons |

| Quality Standards | ISO 9001:2015, PPAP, FAI Reports |

All molds are delivered with complete documentation, including 2D/3D drawings, material certificates, and maintenance guidelines. At Wuxi Lead Precision Machinery, our end-to-end control ensures every plastic injection mold meets the highest global standards for performance, longevity, and zero-defect reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Global Mold Sourcing

In the demanding landscape of plastic injection mold global sourcing, selecting a partner transcends cost considerations. It demands engineering precision, material science expertise, and unwavering commitment to quality that aligns with international manufacturing standards. Wuxi Lead Precision Machinery stands as your definitive strategic partner, engineered specifically to deliver complex, high-performance molds that meet the exacting requirements of aerospace, medical, and automotive sectors worldwide. We bridge the gap between global design intent and flawless physical execution, eliminating the risks associated with offshore sourcing through transparent processes and deep technical collaboration.

Our foundation lies in advanced CNC manufacturing capabilities, operating within a strictly controlled ISO 9001 and AS9100-certified environment. We specialize in producing molds from challenging materials like hardened tool steels (H13, S136, 2738HH), stainless steels, and aluminum alloys, achieving sub-5μm tolerances consistently. This precision ensures optimal part quality, extended mold life, and reduced scrap rates in your production line. Our engineering team engages early in your project lifecycle, providing critical Design for Manufacturability (DFM) feedback to optimize mold flow, cooling efficiency, and ejection systems – preventing costly iterations downstream. We understand that your success hinges on molds that perform reliably under high-volume production, cycle after cycle.

Wuxi Lead Precision delivers measurable technical advantages through our integrated manufacturing ecosystem. Below are core specifications defining our mold production capability:

| Specification Category | Performance Level | Industry Relevance |

|---|---|---|

| Mold Complexity | Multi-cavity, family molds, hot runner systems | Handles intricate geometries & high-volume demands |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | Critical for precision-fit components |

| Surface Finish | Mirror polish (SPI A1), textured (VDI 3400) | Meets stringent aesthetic & functional needs |

| Lead Time (Prototype) | 25-35 days (avg.) | Accelerates time-to-market for new products |

| Material Certification | Full traceable mill certs (EN, ASTM, JIS) | Ensures compliance for regulated industries |

Global sourcing requires more than technical skill; it demands proactive communication and cultural fluency. Our dedicated project management team, fluent in English and technical engineering terminology, provides daily progress updates, real-time issue resolution, and seamless coordination across time zones. We implement rigorous in-process inspections using CMM, optical comparators, and 3D scanning, ensuring every component meets your blueprint before final assembly. This systematic approach minimizes supply chain disruptions and guarantees mold readiness upon delivery. Partnering with us means gaining an extension of your engineering department, focused solely on your project’s success from initial concept to sustained production.

Elevate your plastic injection molding outcomes with a partner built for global excellence. Contact our engineering sales team directly at [email protected] to initiate a technical consultation. Provide your project specifications, and we will deliver a detailed capability assessment and timeline within 24 business hours. Let Wuxi Lead Precision Machinery become the cornerstone of your reliable, high-precision global mold supply chain. Your next-generation product deserves the foundation of engineered perfection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.