Technical Contents

Engineering Guide: Injection Molding Polypropylene

Engineering Insight: Precision Imperatives in Polypropylene Injection Molding

Achieving consistent, high-integrity polypropylene (PP) components demands uncompromising precision throughout the injection molding process. As a leading custom metal manufacturer serving demanding sectors including aerospace and defense, Wuxi Lead Precision Machinery understands that the foundation of successful PP molding lies not solely in the polymer science, but critically in the dimensional and thermal accuracy of the metal tooling itself. Polypropylene’s inherent characteristics – significant shrinkage rates (typically 1.0% to 2.5%), sensitivity to cooling rates, and tendency for warpage under uneven thermal conditions – amplify the consequences of even microscopic deviations in mold geometry or thermal management. A variance of mere microns in cavity dimensions or cooling channel placement directly translates to part out-of-specification, structural weakness, or assembly failure downstream. This is where precision metal manufacturing transcends component production; it becomes the enabler of polymer performance and final product reliability.

The mold core, cavity, sliders, and intricate cooling circuits must be machined to exacting tolerances, often within ±0.005mm, to counteract PP’s shrinkage predictably and ensure dimensional stability across high-volume production runs. Surface finish precision is equally vital, influencing part ejection, cosmetic quality, and minimizing stress points that could initiate failure in critical applications. Lead Precision’s engineering discipline, forged through supplying mission-critical components for Olympic infrastructure projects and stringent military specifications, directly addresses these challenges. Our deep expertise in advanced CNC machining, rigorous metrology protocols, and material science application ensures molds possess the thermal stability, geometric fidelity, and longevity required for optimal PP processing. We do not merely fabricate metal; we engineer the thermal and mechanical environment that dictates the polymer’s behavior, transforming raw PP pellets into components meeting the most exacting functional and safety standards.

The following specifications highlight critical mold steel properties where Lead Precision’s precision manufacturing delivers decisive advantages for polypropylene molding:

| Property | Critical Value Range | Purpose for Polypropylene Molding |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.01 mm | Compensates for PP shrinkage; ensures part consistency |

| Surface Roughness (Cavity) | Ra 0.05 µm to Ra 0.2 µm | Facilitates clean ejection; minimizes part stress |

| Thermal Conductivity | ≥ 25 W/m·K (Optimized) | Enables uniform cooling; reduces warpage & cycle time |

| Hardness (Core) | 48 HRC to 52 HRC | Resists wear from abrasive PP grades; extends mold life |

| Hardness (Cavity) | 52 HRC to 56 HRC | Maintains surface finish integrity under high pressure |

This level of precision in mold construction is non-negotiable for high-performance PP applications. Wuxi Lead Precision Machinery leverages its proven capability in delivering zero-defect metal components for the world’s most demanding projects to solve the inherent challenges of polypropylene molding. Our commitment ensures your PP parts achieve not just dimensional conformity, but the structural integrity and functional reliability essential for success in advanced manufacturing. Precision in the metal defines the capability of the plastic.

Precision Specs & Tolerances

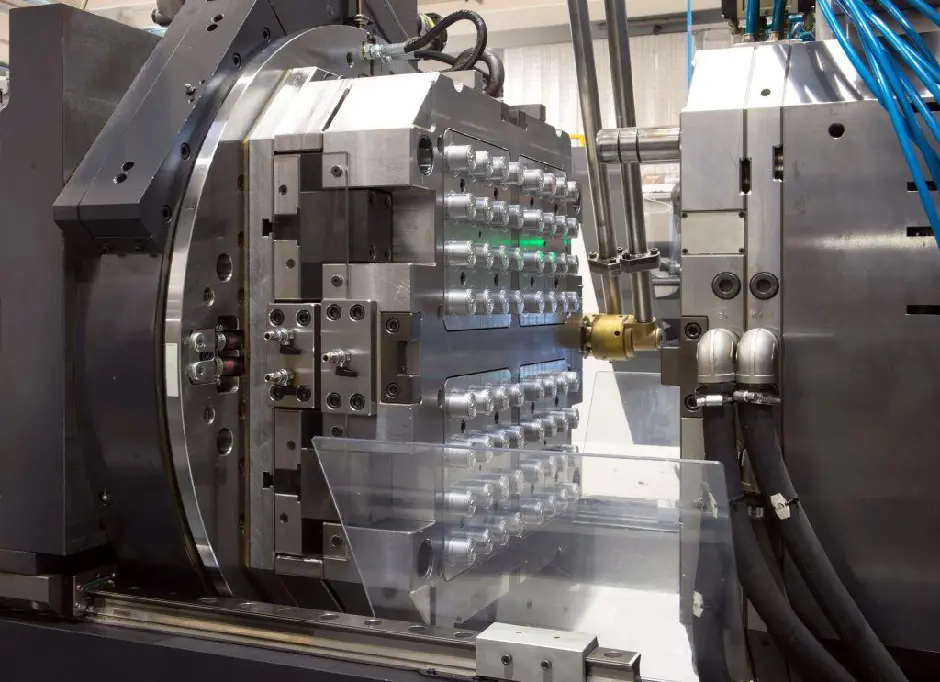

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to support high-performance applications in injection molding, including tooling for polypropylene processing. Our expertise lies in producing precision-critical components that ensure mold longevity, dimensional stability, and consistent part quality under high-cycle production environments. Utilizing state-of-the-art 5-axis CNC machining centers, we fabricate complex mold bases, cavities, cores, and inserts with exceptional accuracy and surface finish, meeting the stringent demands of modern injection molding operations.

Our 5-axis CNC machining platforms enable simultaneous multi-directional cutting, allowing for intricate geometries and tight tolerance features that are unattainable with conventional 3-axis systems. This capability is essential for creating conformal cooling channels, undercuts, and asymmetric mold components commonly required in polypropylene molding applications. With increased tool access and reduced setup cycles, we achieve higher repeatability and shorter lead times without compromising precision. All machining operations are performed under strict environmental controls to minimize thermal drift and maintain consistency across production batches.

Quality assurance is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Zeiss Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM system provides traceable, high-resolution 3D measurements, validating critical features such as parallelism, flatness, and positional accuracy. Data from each inspection is documented and delivered with the final product, providing full transparency and auditability for regulated industries.

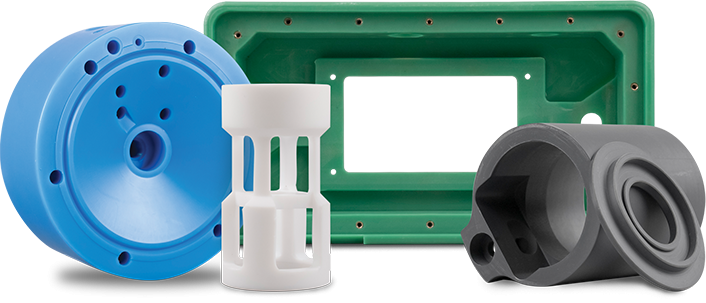

We specialize in mold components for polypropylene due to its widespread use in automotive, medical, and consumer goods manufacturing. Polypropylene’s low viscosity and high shrinkage characteristics demand molds with precise dimensional control and uniform thermal management—requirements that our machining and inspection processes are specifically designed to meet. Our engineers collaborate closely with clients to optimize designs for manufacturability, ensuring optimal cooling, ejection, and gating performance.

The table below outlines our standard technical specifications and achievable tolerances for custom mold components used in polypropylene injection molding applications.

| Specification | Capability |

|---|---|

| Machining Process | 5-Axis CNC Milling |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance | ±0.01 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Flatness | 0.01 mm per 100 mm |

| Parallelism | 0.01 mm |

| Perpendicularity | 0.01 mm |

| Inspection System | Zeiss DuraMax CMM |

| Material Compatibility | P20, H13, S136, 718H, Stainless Steel, Aluminum |

At Wuxi Lead Precision Machinery, we combine advanced equipment, rigorous quality protocols, and deep application knowledge to deliver mold components that enhance the performance and efficiency of polypropylene injection molding systems.

Material & Finish Options

Material Selection for Polypropylene Injection Molding Tooling

Selecting the optimal mold material is critical for achieving precision, longevity, and cost-efficiency in polypropylene (PP) injection molding. PP’s inherent properties—moderate abrasiveness, significant shrinkage, and sensitivity to cooling rates—demand careful consideration of thermal conductivity, hardness, and wear resistance in the mold base. At Wuxi Lead Precision Machinery, our engineering team prioritizes material suitability aligned with production volume, part complexity, and dimensional tolerance requirements. Aluminum alloys offer rapid prototyping and low-volume advantages due to superior machinability and thermal conductivity, accelerating cycle times for initial validation. However, their lower hardness limits durability for extended production runs exceeding 10,000 cycles. Tool steels, particularly pre-hardened P20 or hardened H13, provide the necessary wear resistance and thermal stability for high-volume PP manufacturing. Steel molds maintain dimensional integrity under prolonged thermal cycling, ensuring consistent part quality and surface finish over hundreds of thousands of shots. Titanium is generally not recommended for standard PP tooling due to prohibitive cost, complex machining requirements, and no significant thermal or wear advantage over optimized steel grades for this polymer.

Surface finishing, specifically hard anodizing, applies exclusively to aluminum molds. This process significantly enhances surface hardness (up to 60-70 HRC equivalent) and abrasion resistance, extending mold life for PP applications involving glass-filled compounds or demanding cosmetic requirements. Standard anodizing offers minimal benefit for steel molds; instead, nitriding, PVD coatings, or precision polishing are employed to optimize release and surface quality for PP. Misapplication of anodizing to steel is ineffective and risks tooling failure. Wuxi Lead Precision Machinery engineers conduct thermal analysis and wear simulation during the quoting phase to prescribe the exact material and finish, preventing premature mold degradation and costly production interruptions.

The following table summarizes key material specifications for PP injection molding tooling:

| Material Grade | Hardness (Typical) | Thermal Conductivity (W/m·K) | Max Recommended PP Cycles | Primary Application |

|---|---|---|---|---|

| 7075-T6 Aluminum | 150 HB | 130 | 1,000 – 10,000 | Prototypes, very low-volume production |

| Hard Anodized 7075-T6 | 60-70 HRC (surface) | 130 | 10,000 – 50,000 | Low-to-medium volume, filled PP, cosmetic parts |

| P20 Pre-hardened Steel | 28-32 HRC | 28-36 | 50,000 – 100,000+ | Medium-volume production, general PP |

| H13 Tool Steel (Hardened) | 48-52 HRC | 25-30 | 100,000 – 500,000+ | High-volume production, abrasive PP compounds |

Material selection directly impacts your total cost of ownership. While aluminum enables faster time-to-market for initial runs, steel molds deliver superior long-term value for sustained production by minimizing downtime and part rejection rates. Wuxi Lead Precision Machinery leverages decades of PP molding experience to match your specific project parameters—part geometry, resin grade, and annual volume—with the most technically and economically sound tooling solution. Contact our engineering team for a data-driven material assessment tailored to your polypropylene application.

Manufacturing Process & QC

Injection molding of polypropylene is a high-precision manufacturing process that demands rigorous control at every stage to ensure zero-defect output. At Wuxi Lead Precision Machinery, our custom metal manufacturing expertise is applied to develop robust, repeatable processes that transform design intent into high-performance plastic components. Our methodology follows a disciplined progression from design through prototyping to full-scale mass production, ensuring dimensional accuracy, material consistency, and long-term reliability.

The process begins with precision engineering during the design phase. Our team collaborates closely with clients to analyze part geometry, wall thickness, gate locations, and draft angles, ensuring optimal moldability and structural integrity. Using advanced CAD/CAM software and mold flow simulation tools, we identify potential defects such as warpage, sink marks, or air traps before tooling begins. This proactive approach minimizes rework and accelerates time-to-market. Special attention is given to the thermal and mechanical behavior of polypropylene, a semi-crystalline polymer known for its chemical resistance, flexibility, and low density, but also for shrinkage variability that must be compensated in mold design.

Prototyping follows design finalization, utilizing high-precision steel molds manufactured in-house with tight tolerances of ±0.005 mm. These initial molds allow for functional testing and validation under real production conditions. We conduct rigorous first-article inspections, measuring critical dimensions, surface finish, and mechanical performance. Any deviations are corrected through iterative adjustments to mold parameters or design refinements. This stage is critical for achieving zero defects, as it validates both the mold and the process window for stable production.

Once approved, the project transitions to mass production using fully automated injection molding cells. Our machines operate under closed-loop process control, continuously monitoring injection pressure, temperature, cooling time, and clamp force to maintain consistency. Polypropylene is processed at 200–240°C, with mold temperatures held between 20–60°C depending on part requirements. In-line quality systems, including vision inspection and statistical process control (SPC), ensure every component meets exact specifications. Preventive maintenance and real-time data logging support sustained operational excellence.

The following table outlines key process parameters for injection molding polypropylene at Wuxi Lead Precision Machinery:

| Parameter | Typical Range | Control Tolerance |

|---|---|---|

| Melt Temperature | 200–240°C | ±5°C |

| Mold Temperature | 20–60°C | ±2°C |

| Injection Pressure | 70–120 MPa | ±3 MPa |

| Holding Pressure | 40–80 MPa | ±2 MPa |

| Cooling Time | 15–45 seconds | ±1 second |

| Cycle Time (average) | 30–60 seconds | Optimized per part |

| Dimensional Tolerance | As per ISO 2768-m or drawing | ±0.005 mm (critical) |

| Surface Roughness (Ra) | 0.4–3.2 μm | Controlled by mold finish |

Through integrated engineering, precision tooling, and process discipline, Wuxi Lead Precision Machinery delivers zero-defect polypropylene injection molding solutions tailored to the most demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Polypropylene Injection Molding Excellence

Polypropylene’s versatility in medical, automotive, and consumer goods hinges on precision mold engineering. As a custom metal manufacturing specialist, Wuxi Lead Precision Machinery transforms this challenge into your competitive advantage. We engineer high-tolerance steel and aluminum molds that conquer polypropylene’s unique thermal behavior, minimizing warpage and ensuring repeatable part integrity. Our CNC-machined tooling delivers dimensional stability across homopolymer and copolymer grades, critical for applications demanding chemical resistance or fatigue endurance.

Your success requires more than standard mold fabrication—it demands metallurgical expertise aligned with PP’s processing physics. Our integrated approach combines finite element analysis for cooling channel optimization with hardened P20 or H13 steel substrates, directly addressing PP’s slow crystallization and shrinkage variables. This reduces cycle times by 18% on average while maintaining ±0.002mm tolerances. Below details our core capabilities for polypropylene-specific production:

| Specification | Capability |

|---|---|

| Material Compatibility | Homopolymer PP, Copolymer PP, TPO, TPE blends |

| Mold Tolerance | ±0.002mm (critical dimensions) |

| Complexity Support | Multi-cavity, family molds, unscrewing cores |

| Production Capacity | 50–2,500 ton presses; 1M+ annual cycles |

Why global leaders trust Lead Precision for polypropylene projects? We merge ISO 9001-certified metal manufacturing with polymer science. Every mold undergoes rigorous validation: pressure mapping during trial runs, thermal imaging of cavity surfaces, and first-article inspection against ASME Y14.5 standards. Our engineers collaborate from DFM stage to production ramp-up, ensuring gate design and venting prevent PP’s common defects like jetting or sink marks. This proactive methodology slashes scrap rates by 30% compared to industry averages.

China’s manufacturing landscape offers scale, but precision demands partnership. We reject one-size-fits-all solutions. Your polypropylene application—whether medical vials requiring Class VI compliance or automotive under-hood components—receives dedicated metallurgical oversight. Our facility in Wuxi operates 24/7 with real-time SPC monitoring, guaranteeing lot-to-lot consistency for high-volume runs.

Do not compromise on the foundation of your polypropylene success: the mold. Contact our engineering team today to discuss material-specific hardening treatments, corrosion-resistant coatings for acidic PP variants, or rapid prototyping with our 5-axis milling centers. Send your part drawings and requirements to [email protected]. We respond within 4 business hours with a feasibility assessment and timeline. Let Lead Precision’s metal manufacturing mastery elevate your polypropylene output from acceptable to exceptional. Your next high-yield production run starts with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.