Technical Contents

Engineering Guide: Plastic For Milling

Engineering Insight: Plastic for Milling – The Role of Precision in High-Performance Applications

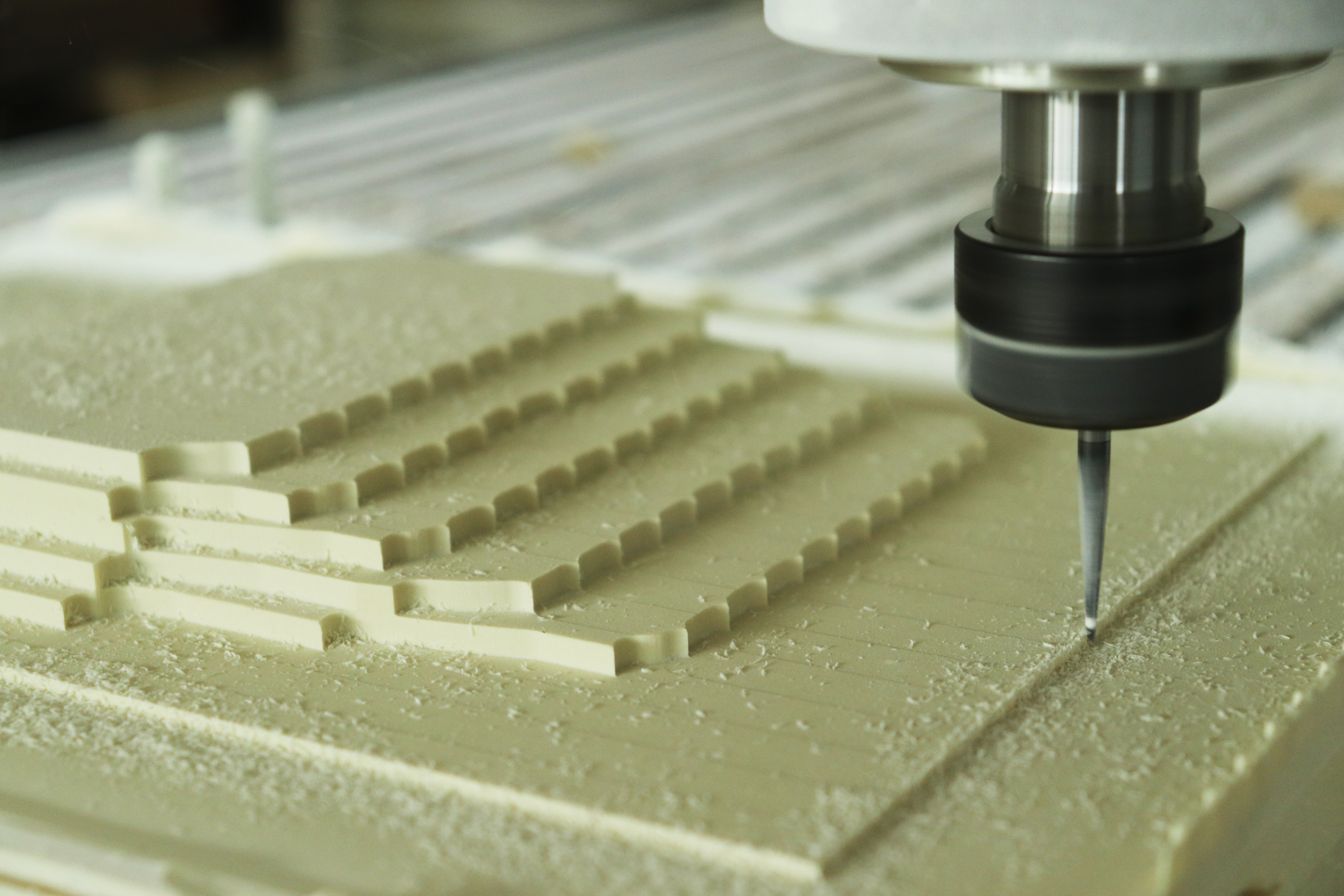

In the realm of precision CNC machining, the selection and handling of plastic materials demand a level of expertise that transcends conventional metalworking practices. Plastics such as PEEK, Delrin, PTFE, and Ultem exhibit unique thermal expansion characteristics, lower rigidity, and variable chip formation behaviors, all of which require meticulous control during the milling process. At Wuxi Lead Precision Machinery, we understand that success in plastic milling is not merely about toolpath optimization—it is about mastering material response under dynamic cutting conditions to achieve micron-level tolerances consistently.

Precision in plastic milling is non-negotiable, especially when serving industries such as aerospace, medical devices, and defense. These sectors rely on components that must perform under extreme environments—whether it’s sustained high temperature, chemical exposure, or structural loading. A deviation of even 0.02 mm can compromise part functionality or lead to system failure. Our experience in delivering mission-critical components for Olympic-grade equipment and military-grade systems has reinforced our commitment to dimensional stability, surface integrity, and repeatability.

Unlike metals, plastics are prone to deformation due to heat buildup and clamping pressure. Traditional machining strategies often result in warping, burring, or poor surface finish. At Lead Precision, we employ advanced fixturing techniques, cryogenic cooling, and high-speed spindle optimization to minimize thermal impact. Our engineers conduct pre-machining material stress-relief cycles and utilize real-time in-process monitoring to ensure each component meets exacting specifications.

Our CNC machining centers are calibrated daily, and we maintain a climate-controlled environment to counteract the hygroscopic and thermally sensitive nature of engineering-grade plastics. This level of environmental and procedural control is what enables us to consistently deliver parts with tolerances down to ±0.005 mm and surface finishes as fine as Ra 0.4 µm.

Below is a comparison of commonly milled engineering plastics and their machinability characteristics under our precision protocols:

| Material | Tensile Strength (MPa) | Thermal Expansion (µm/m·°C) | Typical Tolerance (± mm) | Common Applications |

|---|---|---|---|---|

| PEEK | 90–100 | 45 | 0.005 | Aerospace seals, medical implants |

| Delrin (POM) | 65–75 | 110 | 0.01 | Gears, bushings, connectors |

| PTFE | 20–30 | 120 | 0.02 | Chemical linings, insulators |

| Ultem (PEI) | 100–110 | 54 | 0.008 | Electrical housings, sterilizable parts |

| Nylon 6 | 70–85 | 80 | 0.015 | Structural components, rollers |

With over a decade of specialization in polymer machining, Wuxi Lead Precision Machinery has developed proprietary cutting strategies tailored to each material’s behavior. Our work on precision components for Olympic timing systems and military communication housings underscores our ability to meet the highest standards of performance and reliability. When engineering plastics are involved, precision isn’t just a target—it’s a discipline.

Precision Specs & Tolerances

Technical Capabilities: Precision Plastic Milling

Wuxi Lead Precision Machinery delivers uncompromising accuracy in plastic CNC milling through integrated advanced engineering and rigorous process control. Our specialization in thermally sensitive polymers—such as PEEK, Ultem, PTFE, acrylic, and engineering-grade nylons—demands tailored methodologies distinct from metal machining. We address inherent plastic challenges including thermal expansion, chip adhesion, and dimensional stability through optimized toolpaths, specialized tooling, and environmental conditioning.

Our 5-axis CNC machining centers (DMG MORI and Hermle platforms) feature high-speed spindles (42,000 RPM) with adaptive feed control to minimize heat generation and prevent material deformation. Precision vacuum workholding ensures zero distortion on thin-walled or large-format plastic components, while automated coolant systems utilize non-reactive, low-pressure mist for effective swarf management without part deflection. All equipment operates within a climate-controlled facility (20±1°C, 45% RH) to mitigate ambient thermal effects on both machine and material.

Material science drives our programming strategy. We adjust cutting parameters per polymer group: slower feeds for crystalline resins (e.g., POM) to avoid stress cracking, and aggressive chip evacuation protocols for amorphous materials (e.g., PC) to prevent melting. In-process probing validates part alignment after each setup phase, correcting for minor thermal drift before critical features are machined. This proactive approach ensures geometric integrity across complex contours and tight-tolerance bores.

Quality assurance is anchored in ISO 17025-accredited CMM inspection (Zeiss CONTURA). Every batch undergoes full-spectrum validation: dimensional checks per ASME Y14.5, surface roughness analysis (Ra 0.4μm achievable), and first-article reporting with GD&T callouts. For mission-critical components, we implement statistical process control (SPC) tracking cavity-to-cavity variation in multi-cavity fixtures. All inspection data is traceable to NIST standards and delivered digitally within 24 hours of part completion.

Plastic Milling Tolerance Specifications

| Material Category | Standard Tolerance (mm) | Tight Tolerance (mm) | Critical Feature Validation Method |

|---|---|---|---|

| Amorphous (PC, PMMA) | ±0.05 | ±0.015 | CMM + Optical Comparator |

| Semi-Crystalline (PEEK, POM) | ±0.03 | ±0.01 | CMM + Laser Micrometer |

| Elastomers (Silicone) | ±0.10 | ±0.05 | CMM (Post-Stabilization) |

| Foams & Composites | ±0.08 | ±0.03 | CMM + Coordinate Measuring Arm |

All tolerances assume stable ambient conditions post-machining. Tight tolerances require material pre-drying and 72-hour stress-relief conditioning. We collaborate with clients during DFM to identify tolerance-critical zones, eliminating over-engineering costs while guaranteeing functional performance. Our process achieves sub-10-micron repeatability on geometric features for aerospace and medical applications where plastic component failure is not an option. Partner with Wuxi Lead to transform complex plastic designs into dimensionally flawless production realities.

Material & Finish Options

Material Selection for Precision CNC Milling at Wuxi Lead Precision Machinery

Selecting the appropriate material is critical in achieving optimal performance, durability, and cost-efficiency in precision CNC milling applications. At Wuxi Lead Precision Machinery, we specialize in machining high-performance materials tailored to meet the rigorous demands of aerospace, medical, automotive, and industrial equipment sectors. Among the most widely used materials in our operations are aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages.

Aluminum stands out for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly favored in industries where weight reduction is essential without compromising structural integrity. The 6061 and 7075 aluminum alloys are commonly used, with 7075 offering higher strength for demanding environments. Aluminum’s natural corrosion resistance can be further enhanced through surface treatments such as anodizing, which also improves wear resistance and allows for color coding in assembly processes.

Steel, particularly in its alloy and stainless forms, provides superior strength, hardness, and resistance to wear and deformation. Materials like 4140 alloy steel and 304/316 stainless steel are frequently selected for high-stress mechanical components, tooling, and parts exposed to harsh environments. While steel is denser and more challenging to machine than aluminum, our advanced CNC platforms are optimized to maintain tight tolerances and surface quality even with these tougher materials.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. Its exceptional strength-to-density ratio, corrosion resistance, and ability to perform under high temperatures make it ideal for aerospace and medical implant manufacturing. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and precise machining parameters—expertise that Wuxi Lead has refined over years of high-precision production.

Surface finishing plays a pivotal role in the functional lifespan of milled components. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that resists wear and environmental degradation. We offer both Type II (sulfuric acid) and Type III (hardcoat) anodizing, with the latter providing enhanced thickness and hardness for industrial applications.

Below is a comparative overview of key material properties relevant to CNC milling:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Typical Applications | Common Finishes |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Enclosures, brackets, heat sinks | Anodizing, bead blasting |

| Aluminum 7075 | 2.8 | 572 | Aerospace components, fittings | Hard anodizing, passivation |

| Steel 4140 | 7.85 | 655 | Shafts, gears, tooling | Zinc plating, painting |

| Stainless 316 | 8.0 | 580 | Medical devices, marine hardware | Electropolishing, passivation |

| Titanium Ti-6Al-4V | 4.42 | 950 | Aircraft structures, implants | Anodizing, thermal oxidation |

At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to match material and finish selection with functional requirements, ensuring every component meets exacting standards for performance and reliability.

Manufacturing Process & QC

Precision Plastic Milling: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, mastering plastic CNC milling demands a rigorously controlled process chain, distinct from metal machining due to material sensitivity. Our methodology ensures dimensional stability, surface integrity, and absolute compliance from initial design through high-volume output. Success hinges on material-specific protocols at every stage, eliminating defects before they occur.

The process begins with collaborative engineering during the Design phase. We analyze part geometry, material properties, and functional requirements to identify potential stress points, warpage risks, and optimal toolpaths. Critical considerations include thermal expansion coefficients, chip evacuation strategies for non-conductive materials, and fixture design to prevent deformation under clamping forces. This phase integrates DFMA principles specifically for engineering plastics like PEEK, PTFE, or Ultem, ensuring manufacturability without compromising performance. Material datasheets and finite element analysis guide critical decisions, preventing costly revisions later.

Prototyping is not merely a validation step but a critical process refinement opportunity. Using the same CNC machines, tooling, and skilled operators designated for production, we manufacture functional prototypes under controlled environmental conditions. This phase rigorously tests the optimized machining strategy: spindle speeds, feed rates, coolant/lubrication methods (often air or minimal mist for plastics), and specialized tool geometries to prevent melting or burring. Dimensional inspection against CAD models and functional testing occur iteratively with the client. Any micro-defect—surface imperfection, slight dimensional drift, or internal stress—triggers immediate process recalibration. This tight feedback loop guarantees the production protocol is flawless.

Mass Production executes the perfected process under stringent statistical process control. Every machine undergoes real-time thermal compensation and vibration monitoring. Automated in-process gauging verifies critical dimensions after key operations, feeding data directly into our SPC system. First-article inspection is mandatory for each production run, followed by rigorous lot sampling against AQL 0.65 standards. Material traceability from certified suppliers is maintained throughout. Our closed-loop system detects minute process drifts—such as tool wear affecting edge finish on acetal—before they impact parts, ensuring every component meets the zero-defect commitment demanded by aerospace, medical, and semiconductor clients.

Material selection and machining parameters are inseparable. The following table details critical plastic-specific parameters we enforce:

| Parameter | PEEK 450G | Acetal (POM-C) | Polycarbonate | Critical Control Method |

|---|---|---|---|---|

| Max Spindle Speed | 8,000 RPM | 12,000 RPM | 10,000 RPM | Material-specific CAM presets |

| Optimal Feed Rate | 0.05 mm/tooth | 0.08 mm/tooth | 0.06 mm/tooth | Real-time chip load monitoring |

| Coolant Requirement | Minimal Mist | Dry/Air Blast | Minimal Mist | Dedicated mist systems per cell |

| Thermal Compensation | 12 µm/mm/°C | 8 µm/mm/°C | 6.5 µm/mm/°C | Integrated machine thermal sensors |

| Critical Defect Risk | Micro-cracking | Burrs at edges | Stress whitening | In-process vision inspection |

This disciplined integration of material science, precision engineering, and real-time quality control transforms complex plastic designs into flawless, high-performance components at scale. Wuxi Lead’s process is your assurance of zero-defect delivery.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Plastic Milling and Precision CNC Machining

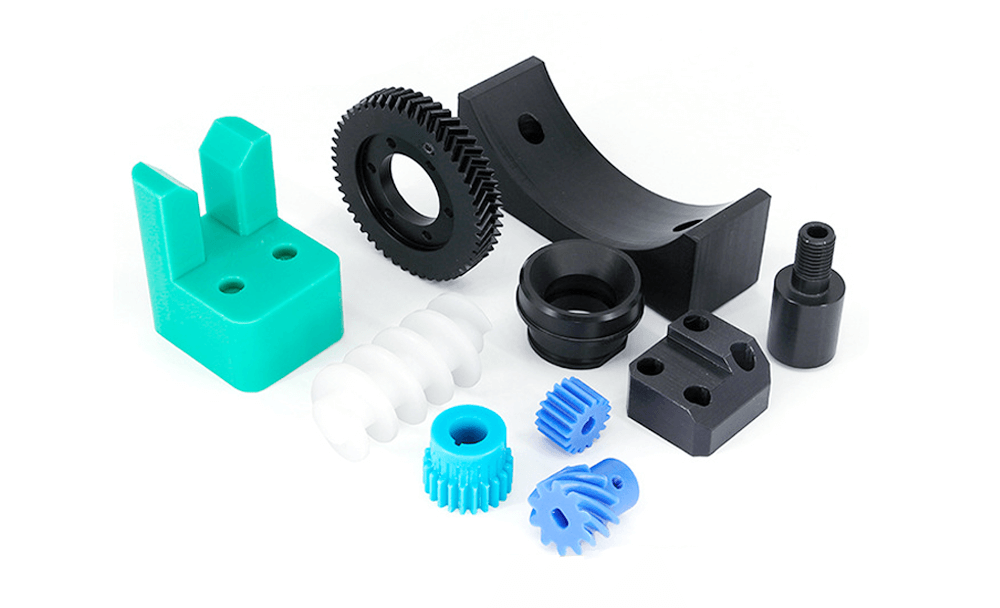

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision CNC machining solutions tailored to the complex demands of modern industrial applications. Our expertise in plastic milling sets us apart as a trusted partner for global manufacturers seeking reliability, repeatability, and superior surface finishes in engineered polymer components. Whether you’re developing prototypes or scaling up to high-volume production, our advanced machining capabilities ensure your plastic parts meet exacting specifications every time.

Plastics present unique challenges in milling due to their thermal sensitivity, varying hardness, and dimensional stability requirements. At Lead Precision, we address these challenges with optimized cutting strategies, specialized tooling, and real-time process monitoring. Our CNC machining centers are equipped with high-speed spindles and precision cooling systems, enabling clean cuts and minimal deformation across a broad range of engineering plastics such as PEEK, Delrin, Nylon, PTFE, and PMMA.

Our team of experienced engineers works closely with clients to select the ideal material, design for manufacturability, and implement strict quality control protocols. From initial design review to final inspection, we ensure every component adheres to ISO 9001 standards and your unique technical requirements. With in-house 3D metrology, CMM inspection, and first-article reporting, we provide full traceability and documentation for regulated industries including medical devices, aerospace, and semiconductor manufacturing.

We understand that precision is not just about tolerances—it’s about consistency, material integrity, and long-term performance. That’s why we invest in continuous process improvement and staff training to maintain the highest standards in plastic CNC machining.

Below are the key technical specifications of our plastic milling capabilities:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 × 600 × 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Spindle Speed Range | 8,000 – 24,000 rpm |

| Typical Surface Finish | Ra 0.8 – 3.2 µm (adjustable) |

| Materials Processed | PEEK, Delrin, Nylon, PTFE, PC, PMMA, PEI, PPS |

| Tolerances Achieved | ±0.025 mm (standard), down to ±0.005 mm (tight-tolerance) |

| Quality Standards | ISO 9001:2015, RoHS compliant, full FAI reporting |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to technical excellence and responsive service. We support global clients with fast turnaround times, DFM feedback within 24 hours, and seamless communication in English and Chinese.

For precision plastic milling that meets the demands of high-performance industries, contact us today. Send your drawings and project requirements to [email protected] and let our engineering team provide a detailed quote and technical consultation. Trust Lead Precision to transform your designs into high-accuracy plastic components—on time, every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.