Technical Contents

Engineering Guide: Cnc Machining Georgia

Engineering Insight Precision Imperatives in Georgia Manufacturing

Georgia’s advanced manufacturing ecosystem demands uncompromising precision across aerospace, energy, and medical sectors. For facilities in Marietta aerospace hubs or Savannah’s industrial corridors, tolerances measured in thousandths of an inch directly impact product safety, performance, and regulatory compliance. A turbine blade operating at 30,000 feet or a surgical implant requires dimensional stability beyond standard machining capabilities. Sub-micron repeatability isn’t merely desirable; it is a non-negotiable engineering requirement dictating yield rates, lifecycle costs, and ultimately, market viability. Georgia manufacturers face intense pressure to deliver components that perform flawlessly under extreme conditions, making the selection of a machining partner with demonstrable precision mastery a strategic imperative.

Wuxi Lead Precision Machinery operates at this critical precision frontier. Our engineering protocols are forged through direct collaboration on Olympic timing systems requiring microsecond synchronization and military-grade components where failure is not an option. These projects demanded and validated our ability to consistently achieve tolerances down to ±0.0002 inches across complex geometries in exotic alloys like Inconel 718 and titanium Grade 5. This experience translates directly to Georgia’s high-stakes manufacturing environment. We implement AS9100-certified workflows with real-time in-process metrology, thermal compensation systems, and multi-axis machining centers calibrated to ISO 230-2 standards. Our process control extends beyond the machine shop; material traceability, environmental monitoring, and rigorous first-article inspection are embedded in every production run, ensuring the dimensional integrity required by Georgia’s Tier 1 aerospace suppliers and medical device innovators.

The following specifications represent our baseline capabilities for critical Georgia applications:

| Parameter | Capability | Application Example |

|---|---|---|

| Positional Accuracy | ±0.0001 inch (2.5 µm) | Aircraft structural fittings |

| Repeatability | ±0.00004 inch (1 µm) | Fuel system metering components |

| Surface Finish (Ra) | 2 µin (0.05 µm) | Hydraulic valve spools |

| Max Work Envelope | 2000 x 1000 x 800 mm | Satellite bus structural elements |

| Material Complexity | Titanium, Inconel, CFRP, PEEK | Jet engine housings, medical implants |

| Critical Tolerance | ±0.0002 inch (5 µm) sustained | Guidance system interfaces |

Geographic proximity alone cannot guarantee the precision outcomes Georgia’s advanced industries require. What matters is verifiable engineering rigor, process maturity, and a documented history of delivering mission-critical components under stringent specifications. Wuxi Lead Precision Machinery provides this assurance through our Olympic-proven methodologies and military-grade quality systems. We partner with Georgia manufacturers not just as a supplier, but as an extension of their engineering team, ensuring every machined part meets the exacting standards demanded by global markets and regulatory bodies. Precision is the foundation; our commitment is to make it your competitive advantage.

Precision Specs & Tolerances

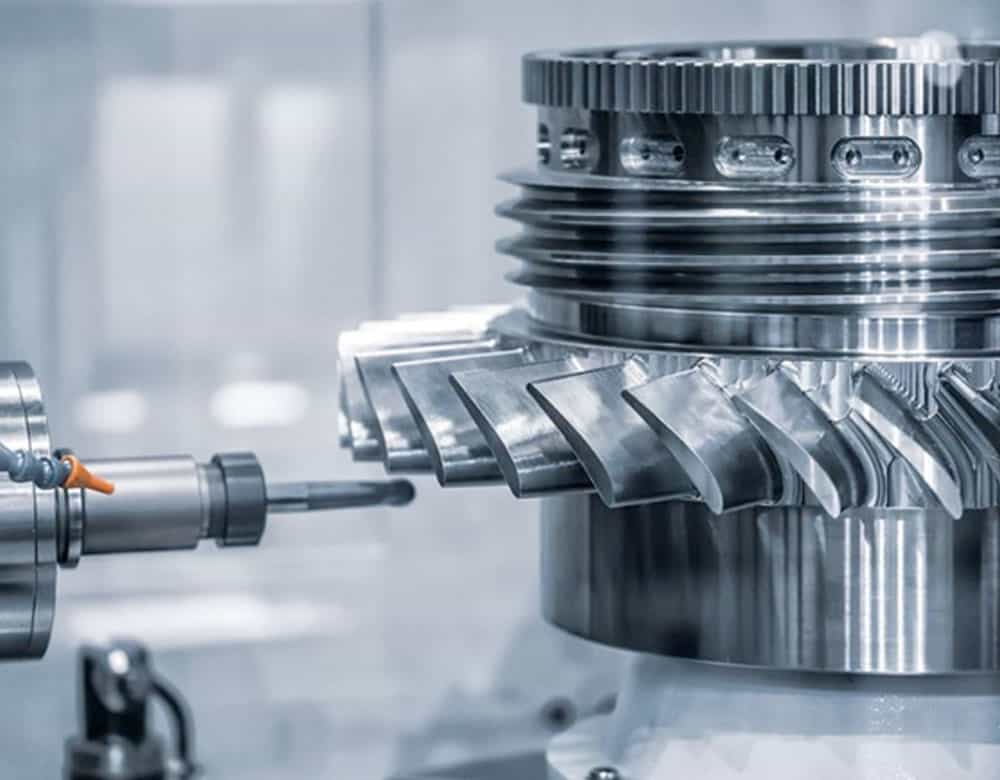

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services engineered to meet the rigorous demands of high-performance industries including aerospace, medical, energy, and industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five axes, significantly enhancing machining flexibility, reducing setup times, and ensuring tight tolerances on intricate components.

Our 5-axis CNC machining centers are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software, ensuring consistent part quality and process stability. This capability supports the production of monolithic structures, organic contours, and deep cavities that are unattainable with conventional 3-axis methods. By leveraging 5-axis technology, we minimize the need for multiple fixtures and secondary operations, resulting in faster lead times and reduced potential for human error.

Quality control is integrated at every stage of production. All machined components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring dimensional conformity to design specifications. Our CMM systems provide micron-level measurement accuracy and generate detailed inspection reports traceable to international standards. These reports include geometric dimensioning and tolerancing (GD&T) analysis, surface profile verification, and critical feature validation, offering full transparency and compliance for regulated industries.

In addition to CMM inspection, our quality assurance protocol includes in-process checks, first-article inspection, and final batch verification. All equipment is regularly calibrated, and our technicians are trained in precision measurement techniques and statistical process control. This systematic approach ensures repeatability, reliability, and adherence to ISO 9001 standards.

The table below outlines the standard tolerances we consistently achieve across various dimensional and geometric characteristics:

| Feature Type | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Flatness | 0.02 mm | 0.005 mm |

| Roundness | 0.01 mm | 0.003 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Angular Dimensions | ±0.1° | ±0.05° |

These capabilities are supported by robust CAD/CAM integration, allowing seamless translation from digital design to physical part with full toolpath simulation and collision detection. Our engineering team collaborates closely with clients to optimize designs for manufacturability, ensuring performance, cost-efficiency, and compliance with technical requirements. Whether producing low-volume prototypes or high-volume production runs, Wuxi Lead Precision Machinery maintains the technical excellence required by the most demanding applications in precision manufacturing.

Material & Finish Options

Material Selection Guide for Precision CNC Machining in Georgia

Selecting optimal materials is critical for Georgia manufacturers seeking performance, cost efficiency, and regulatory compliance in precision CNC components. At Wuxi Lead Precision Machinery, we leverage 15+ years of aerospace and medical-grade machining expertise to guide clients through material and finish decisions. Below we detail key considerations for aluminum, steel, and titanium, alongside essential anodizing specifications.

Aluminum remains the top choice for weight-sensitive applications like aerospace brackets or heat sinks due to its high strength-to-weight ratio and excellent machinability. Grade 6061-T6 offers balanced mechanical properties and weldability, while 7075-T6 provides superior strength for high-stress components. Its natural corrosion resistance suits Georgia’s humid climate, though anodizing is recommended for extended outdoor exposure.

Carbon and alloy steels dominate structural and high-wear applications. 4140 steel delivers exceptional toughness for oil and gas tooling, while 17-4 PH stainless steel combines corrosion resistance with high strength for medical implants. Steel’s durability requires precise toolpath strategies to manage heat generation during machining—a capability our HAAS and DMG MORI centers excel at with coolant-through spindles and rigid tapping.

Titanium Grade 5 (Ti-6Al-4V) is indispensable for extreme environments, including marine hardware and aerospace landing gear. Its exceptional strength, corrosion resistance, and biocompatibility justify higher costs in mission-critical parts. However, titanium’s low thermal conductivity demands reduced cutting speeds and specialized tooling to prevent work hardening—a process our engineers optimize using high-pressure coolant systems and carbide inserts with polished flutes.

Anodizing transforms aluminum surfaces for functional and aesthetic requirements. Type II (sulfuric acid) anodizing provides standard corrosion resistance and dye compatibility for consumer products. Type III (hardcoat) anodizing delivers 50–100μm thickness with Rockwell C60+ hardness, essential for hydraulic pistons or military hardware exposed to abrasion. Both processes require precise voltage control and sealing—executed to AMS 2469 and MIL-A-8625 standards in our ISO 13485-certified facility.

Material Comparison for Georgia Applications

| Material | Key Properties | Common Grades | Best Applications in Georgia |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, 100% recyclable | 6061-T6, 7075-T6 | Aerospace brackets, heat sinks, marine fittings |

| Steel | High strength, wear resistance, magnetic | 4140, 17-4 PH SS | Oil/gas tooling, medical implants, structural frames |

| Titanium | Extreme strength-to-weight, biocompatible, non-magnetic | Ti-6Al-4V (Gr5) | Aircraft landing gear, surgical instruments, naval components |

Wuxi Lead Precision Machinery ensures material integrity through certified supply chains and in-process metallurgical testing. Our Georgia clients reduce prototyping costs by 30% when leveraging our material selection consultancy—aligning substrate properties with environmental demands and finishing requirements. Partner with us for CNC machining where material science meets precision execution.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every successful CNC machining project begins with a rigorously engineered design phase. We collaborate closely with clients to translate conceptual requirements into manufacturable, high-tolerance 3D models. Using advanced CAD/CAM software such as SolidWorks, AutoCAD, and Mastercam, our engineering team ensures that every dimension, surface finish, and geometric tolerance aligns with both functional intent and machining feasibility. Design for Manufacturability (DFM) analysis is conducted in-house to identify potential production challenges early, reducing lead time and eliminating costly revisions. This stage is critical for achieving zero defects—by simulating tool paths, material behavior, and stress points digitally, we preemptively resolve issues before any material is cut.

Prototyping: Validating Precision at Scale

Once the design is finalized, we move to the prototyping phase, where precision meets practicality. Utilizing 5-axis CNC milling, turning centers, and wire EDM, we produce functional prototypes that mirror final production quality. These prototypes serve as physical validations of design integrity, fit, form, and function. Clients receive detailed inspection reports, including First Article Inspection (FAI) documentation and GD&T analysis, ensuring all features meet ISO 2768 or customer-specific standards. Any necessary adjustments are implemented with rapid iteration cycles, typically within 7 to 10 days. This phase not only confirms design accuracy but also verifies the stability of the manufacturing process, forming the basis for defect-free mass production.

Mass Production: Engineered for Zero Defects

With prototype approval, we transition seamlessly into high-volume CNC machining. Our facility in Wuxi operates over 120 CNC machines, including multi-spindle lathes and automated pallet systems, enabling continuous production with minimal human intervention. Each component undergoes real-time in-process inspection using coordinate measuring machines (CMM), laser probes, and optical comparators. Statistical Process Control (SPC) monitors key dimensions across production runs, ensuring consistency and traceability. Our quality management system is ISO 9001:2015 certified, and we enforce a zero-defect mindset through operator training, preventive maintenance, and full documentation per batch.

The result is a scalable, repeatable process that delivers precision-machined parts with tolerances as tight as ±0.002 mm, surface finishes down to Ra 0.4 µm, and 100% compliance with international standards.

Production Specifications

| Parameter | Capability |

|---|---|

| Maximum Workpiece Size | 1200 × 800 × 600 mm |

| Tolerance Accuracy | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.4 µm |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| CNC Equipment | 3-axis, 4-axis, 5-axis, CNC Turning, EDM |

| Quality Standards | ISO 9001:2015, ISO 2768, GD&T, FAI Reports |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (varies by volume) |

This integrated workflow—design, prototyping, and mass production—ensures that every part shipped from Wuxi Lead meets the highest benchmarks in precision, reliability, and quality, making us a trusted partner for advanced manufacturing needs worldwide.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Global CNC Machining Advantage for Georgia Operations

For Georgia manufacturers demanding uncompromising precision and scalability, Wuxi Lead Precision Machinery delivers engineered solutions that transcend geographical boundaries. We understand Georgia’s growing aerospace, medical device, and industrial equipment sectors require partners capable of executing complex components with zero defects and on-time delivery. Our ISO 9001:2015-certified facility in Wuxi, China, operates as a seamless extension of your production ecosystem—not merely a vendor. We eliminate the perceived risks of offshore manufacturing through transparent communication, rigorous quality gates, and a proven logistics network ensuring seamless integration with your Atlanta, Savannah, or Augusta supply chain.

Our technical capabilities are engineered for Georgia’s high-stakes applications. Below are core specifications defining our precision machining capacity:

| Specification | Capability Detail |

|---|---|

| Material Range | Aluminum 6061-T6, 7075-T6; Stainless Steel 303, 304, 316; Titanium Gr5; Inconel 718; Plastics (PEEK, Delrin) |

| Tolerance Capability | ±0.0002″ (5µm) for critical features; ±0.0005″ (13µm) standard |

| Equipment Portfolio | 42 CNC centers: DMG MORI 5-axis milling; Mazak turning centers; Swiss-type lathes; CMM verification (Zeiss CONTURA) |

| Max Work Envelope | 2000 x 1000 x 800 mm (milling); Ø400 x 1000 mm (turning) |

| Lead Time Efficiency | Prototype: 10–15 days; Production: 25–35 days (including shipping to GA ports) |

Georgia’s manufacturers face unique pressures: stringent AS9100 compliance for aerospace, FDA validation for medical components, and rapid iteration cycles for industrial OEMs. Lead Precision addresses these through dedicated project management teams fluent in English and engineering protocols. Every component undergoes in-process inspection with real-time data sharing via secure client portals. Our facility’s strategic location near Shanghai Port ensures consolidated shipping to Savannah—reducing transit time to 18–22 days with full customs brokerage support. This operational synergy means your Georgia facility gains capacity without capital expenditure, while maintaining full traceability from raw material to finished part.

Do not let geographical distance compromise your precision ambitions. Partner with an engineering team that treats your specifications as non-negotiable imperatives. Contact us today to discuss how Lead Precision can resolve your bottleneck challenges with certified quality, competitive costing, and unwavering reliability. Our engineers are ready to analyze your CAD files, validate manufacturability, and deliver a seamless transition plan—within 48 hours of engagement.

Initiate your precision partnership: Contact [email protected]. Specify “Georgia Manufacturing Guide” in your subject line for expedited technical consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.